Micro-droplet jetting printing device and method for preparing graphene metamaterial microstructure through device

A technology of droplet ejection and printing device, which is applied in the direction of manufacturing tools, additive processing, ceramic molding machines, etc., and can solve problems such as complex methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

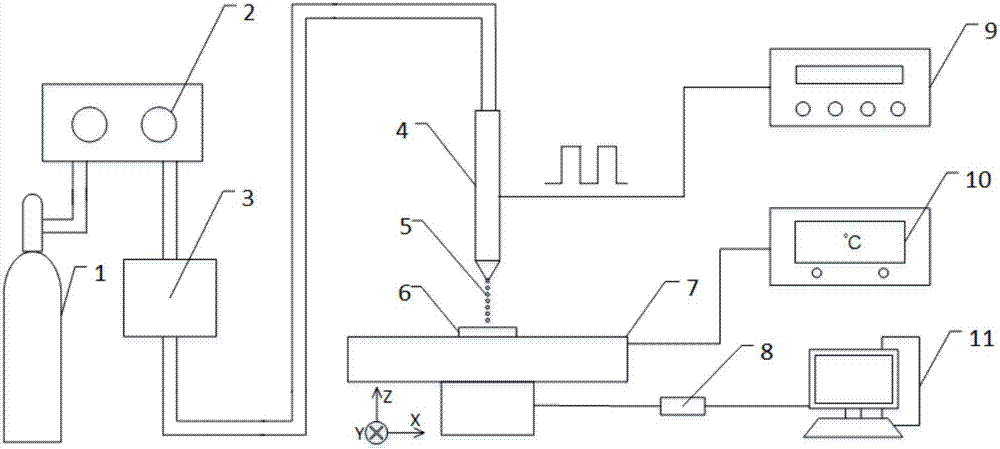

[0019] The following examples refer to figure 1 .

[0020] The droplet jet printing device of the present invention includes a nitrogen bottle 1, a pressure controller 2, a liquid reservoir 3, a piezoelectric micro-spray head 4, a microstructure substrate 6, a three-dimensional combined motion substrate 7, a three-dimensional combined motion substrate controller 8, and a piezoelectric ceramic Driver 9, temperature controller 10 and computer 11. The nitrogen cylinder 1 is connected to the liquid reservoir 3 through the pressure controller 2, and the liquid reservoir 3 is connected to the piezoelectric micro-spray head 4 through the pipeline, and the pressure controller 2 is applied to the liquid reservoir 3 by the gas provided by the nitrogen cylinder 1. Pressure, so that the solution at the piezoelectric micro-spray head 4 forms a back pressure with an adjustable pressure value. The three-dimensional joint motion substrate 7 is located directly below the piezoelectric micro-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com