Hydrophilic polyester fiber and preparation method thereof

A cotton polyester fiber, hydrophilic technology, applied in the field of polyester fiber and its preparation, can solve the problems of adverse effects of polyester melt spinning processing, unreasonable product structure, fierce homogeneity competition, etc., to improve moisture conductivity performance, good antistatic properties, the effect of improving the effect of cotton imitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The invention provides a kind of preparation method of hydrophilic cotton imitation polyester fiber, comprises the steps:

[0046] (1) The preparation process of modified polyvinyl alcohol: dissolving polyvinyl alcohol in calcium chloride aqueous solution, then precipitating with alcohol, drying the separated precipitate, and preparing the chelated polyvinyl alcohol and calcium chloride matter; preferably, the chelate formed by the polyvinyl alcohol and calcium chloride has high temperature resistance; the degree of polymerization of the polyvinyl alcohol is 1000-4000;

[0047] In the process of preparing modified polyvinyl alcohol, other alcohols can be used for precipitation, such as methanol and ethylene glycol, and the precipitation efficiency of methanol is higher than that of other alcohol precipitants.

[0048] The mass fraction of the polyvinyl alcohol added in the calcium chloride aqueous solution is 5wt%-20wt%, and the added mass fraction is controlled within ...

Embodiment 1

[0086] A kind of preparation method of highly comfortable hydrophilic cotton-like polyester fiber, its specific steps are:

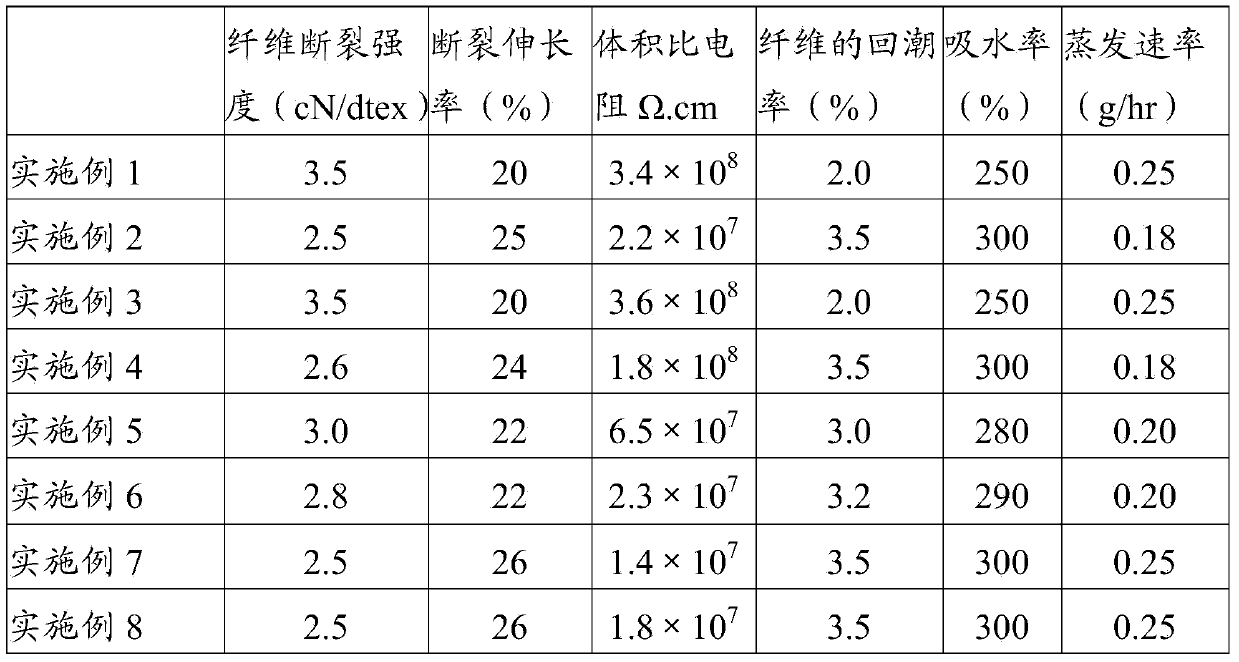

[0087] Mix polyester chips, high-temperature-resistant modified polyvinyl alcohol and polyester cooling masterbatch to obtain 1kg of the mixture, dry the mixture at 105°C for 20h, and melt-spin through a hollow special-shaped spinneret at 240°C to prepare raw polyester Silk, after winding, doffing, balanced clustering, moisture conduction, pre-stretching and oiling, stretching once or twice, and finally tension heat setting, crimping, relaxation heat setting, cutting, packaging, and finally prepared Cotton-like polyester staple fiber, which is a short fiber with a specification of 1.5D×38mm, is used to measure the fiber breaking strength, elongation at break, volume specific resistance, moisture regain, water absorption, and evaporation rate of the fiber sample. The results are shown in Table 1;

[0088] Its raw material mass percentage is:

[0089] Hi...

Embodiment 2

[0098] Preparation

[0099] A kind of preparation method of highly comfortable hydrophilic cotton-like polyester fiber, its specific steps are:

[0100] Mix polyester chips, high-temperature-resistant modified polyvinyl alcohol and cooling masterbatch to obtain 1kg of the mixture, dry it at 125°C for 10h, and prepare POY and FDY fiber, then compound the prepared POY fiber with FDY, and use the shrinkage difference of the two fibers to prepare the mixed fiber to obtain the mixed fiber formed by POY and FDY. The prepared mixed fiber has more characteristics of cotton. The sample was tested for fiber breaking strength, elongation at break, volume specific resistance, moisture regain, water absorption, and evaporation rate of the fiber. The results of the measurement are shown in Table 1.

[0101] Its raw material mass percentage is:

[0102] High temperature resistant modified polyvinyl alcohol: 5%

[0103] Polyester cooling masterbatch: 10%

[0104] Polyester chips: 85%

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Evaporation rate | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com