Reduced-pressure drying apparatus

一种减压干燥装置、减压腔的技术,应用在干燥固体物料、不加热来干燥固体材料、烘干等方向,能够解决膜厚均匀性下降、蒸气浓度差异、分布不同等问题

Inactive Publication Date: 2007-02-07

SEIKO EPSON CORP

View PDF1 Cites 25 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

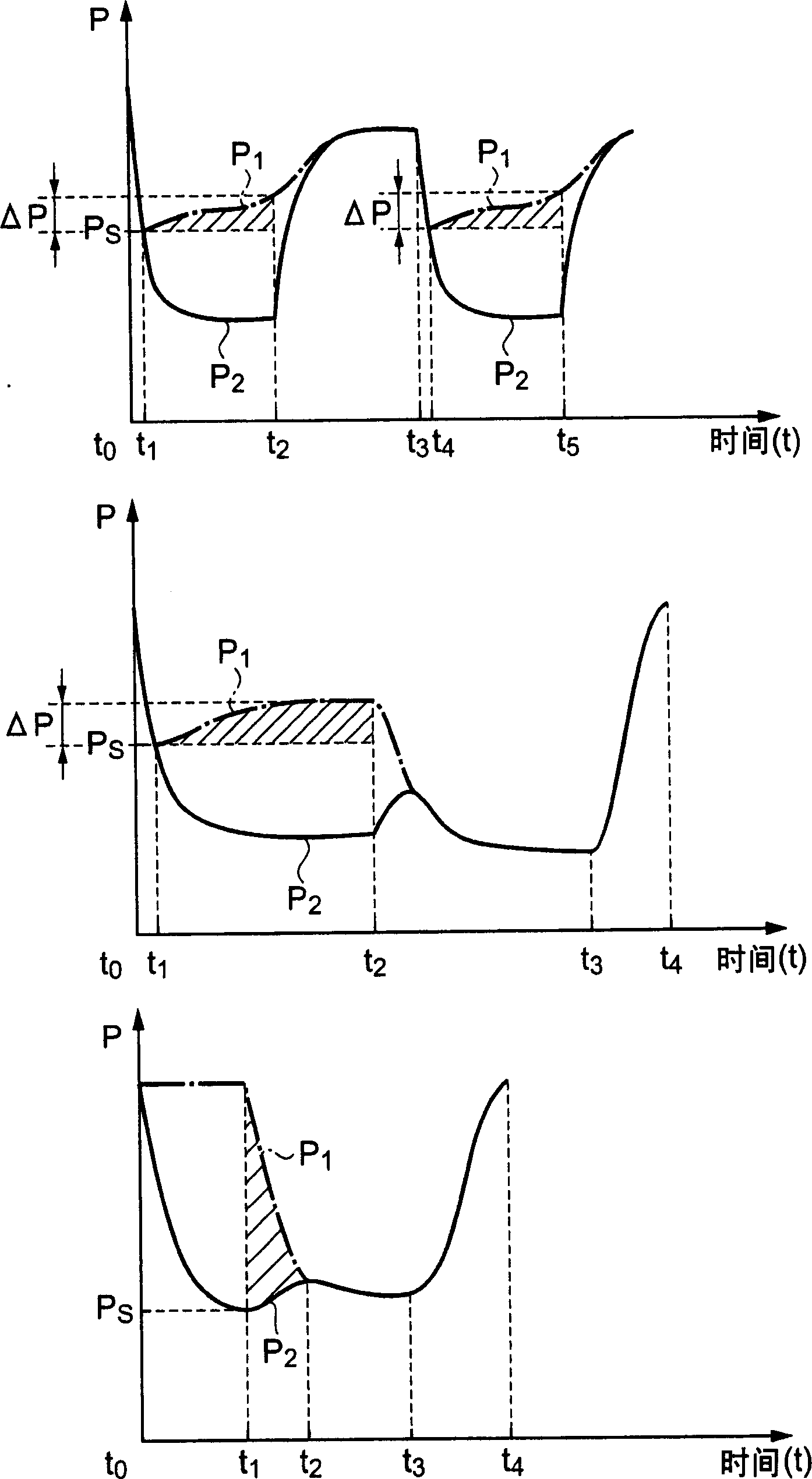

Therefore, using the above-mentioned prior art decompression drying device, even after setting the rectifying plate, the air flow of the solvent evaporated from the liquid under reduced pressure is controlled with a certain speed in a certain direction, and there is a problem in drying. The flow of liquid (convection) occurs during the process, and under the action of surface tension, the uniformity of film thickness decreases.

In addition, there is a problem that the distribution of vapor concentration (or pressure) differs between the central part and the peripheral part of the workpiece, and as a result, the in-plane distribution of the film thickness is different due to the difference in drying speed.

Furthermore, after adopting the structural design of the optimal drying device corresponding to the shape of various liquid materials and coated workpieces, there is also the problem of decreased versatility.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0031]

Embodiments of the present invention will be described taking, as an example, a reduced-pressure drying device used in the step of forming an alignment film covering pixel electrodes of a pair of substrates constituting a liquid crystal panel of a liquid crystal display device.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

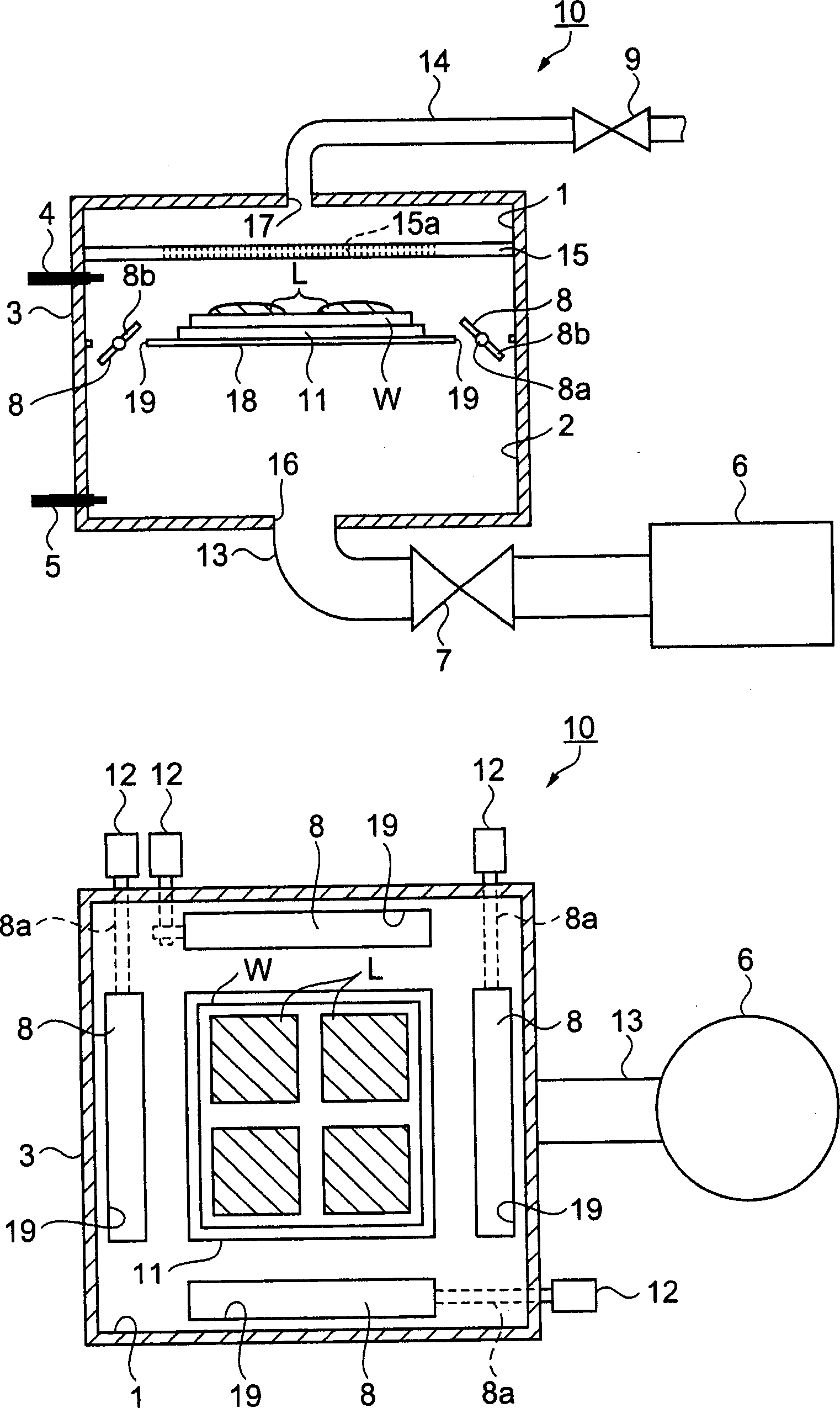

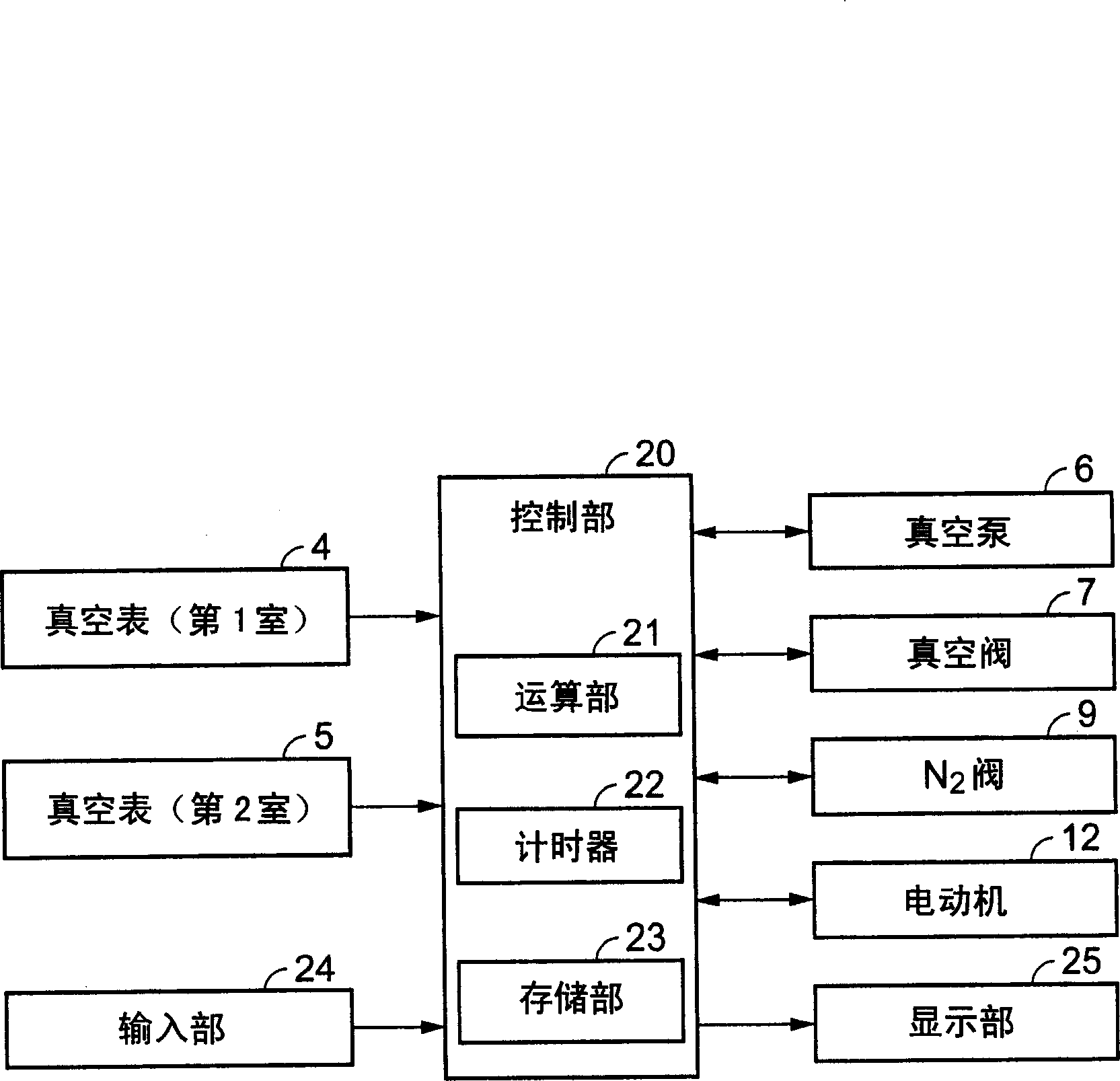

A decompression drier (10) is provided with a chamber (3) housing a substrate W applied with the liquid (L) and placed on a mounting block (11), and having a first chamber (1) and a second chamber (2), and a vacuum pump (6) used as a decompressing means provided in a state capable of decompressing the second chamber (2). It is provided with a communication port (19) used as a communication part provided in a bulkhead part (18) separating the first chamber (1) and the second chamber (2), and a communication valve (8) capable of opening and closing the communication port (19); a control part provided for controlling driving of the vacuum pump (6), and opening and closing of the communication valve (8), and vacuum gauges (4, 5) provided for detecting respective pressures of the first chamber (1) and the second chamber 2. The volume of the second chamber 2 is set such that it is larger than the volume of the first chamber 1. The decompression drier capable of optimizing an evaporation rate of an applied liquid solvent in response to the type of the liquid in a drying process, and capable of carrying out drying under reduced pressure with distribution of vapor pressure of the solvent held in a substantially even state.

Description

technical field [0001] The present invention relates to a reduced-pressure drying device used when a workpiece coated with a liquid is dried under reduced pressure to form a film on the surface of the workpiece. Background technique [0002] When coating a liquid containing a film-forming material on the surface of a wafer-like substrate such as a semiconductor to form a film, a vacuum drying device is used that evaporates a solvent component contained in the liquid under reduced pressure and then dries it. As this decompression drying device, there is a proposal that a rectifying plate is arranged to face the substrate in a chamber where the substrate coated with photoresist is placed and the pressure is reduced, and a vent hole is provided on the outer edge of the rectifying plate. (Patent Document 1). [0003] In the above-mentioned decompression drying device, exhaust is exhausted from the upper part of the decompression chamber, thereby forming an air flow in a c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F26B5/04F26B25/00

CPCF26B5/04

Inventor 五味一博

Owner SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com