Method for recovering dimethyl formamide

A dimethylformamide, evaporator technology, applied in chemical instruments and methods, carboxylic acid amide separation/purification, water/sludge/sewage treatment, etc. Insufficient rate and other problems, to achieve the effect of reducing the operating temperature of rectification, reducing the rate of re-steaming, and reducing the displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

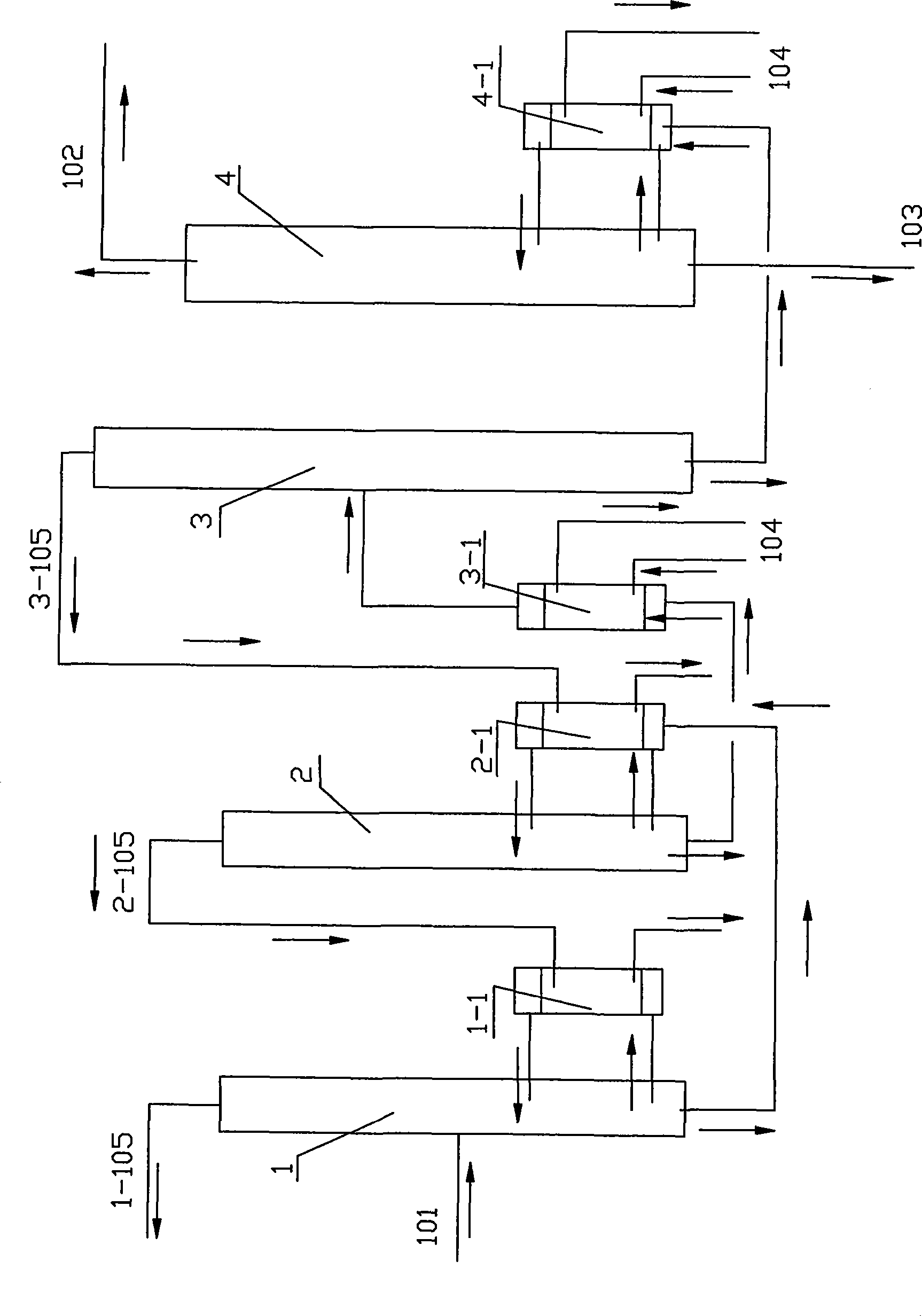

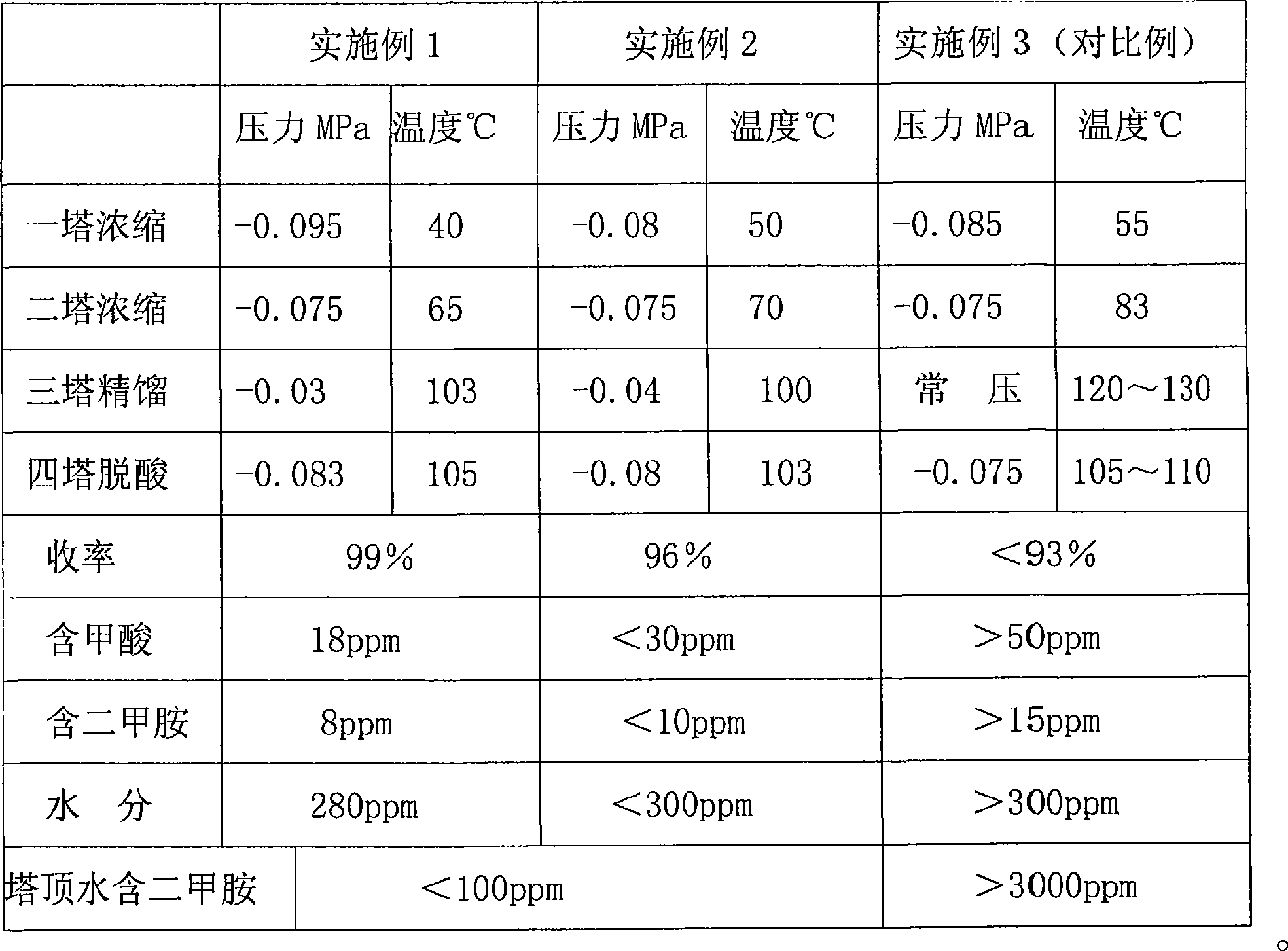

[0020] Example 1 As shown in the attached figure, a method for recovering dimethylformamide is carried out in four columns with evaporators operated under negative pressure.

[0021] Wastewater 101 containing about 20% DMF is introduced into a tower 1 with evaporator 1-2 for negative pressure concentration, the operating pressure is -0.095Mpa, the operating temperature is 40°C, and the concentration of DMF can be concentrated to about 40%; At the same time, the steam 2-105 leaving the top of the second tower is introduced into the evaporator 1-1 of the first tower as a heat source to heat the waste water in the first tower 1; the steam 1-105 leaving the top of the first tower is discharged to the outside.

[0022] The waste water containing about 40% DMF drawn from the bottom of the first tower 1 is sent into the evaporator 2-1 of the second tower 2 and heated together with the waste water in the second tower 2, and then enters the second tower 2 for negative pressure concentra...

Embodiment 2

[0026] Example 2 As shown in the attached figure, a method for recovering dimethylformamide is carried out in four columns with evaporators operated under negative pressure. The flow of the entire material is the same as that of Example 1, the difference lies in the operating conditions and the use of low-pressure steam instead of heat transfer oil 104 as a heat source.

[0027] In this embodiment, a tower 1 carries out negative pressure concentration, operating conditions: the pressure is -0-08Mpa, the temperature is 50°C, and the waste water 101 containing about 20% DMF can be concentrated to a concentration of about 45% DMF.

[0028] The second tower 2 carries out negative pressure concentration, operating conditions: the pressure is -0.075Mpa, the temperature is 70°C, the waste water containing about 45% DMF can be concentrated to a concentration of about 65% DMF.

[0029] The three towers 3 carry out negative pressure rectification, operating conditions: the pressure is -...

Embodiment 3

[0032] Example 3 (Comparative Example) The four-tower recovery method of the prior art is used to treat wastewater containing DMF. That is, one tower and two towers are concentrated under negative pressure; three towers are rectified at normal pressure; four towers are deacidified under negative pressure; the flow of materials is basically the same as the above-mentioned examples, the only difference is that the DMF containing high formic acid obtained at the bottom of the four towers needs to pass through alkali After neutralization in water, it goes to three towers for rectification.

[0033] In this embodiment, one tower is concentrated under negative pressure, operating conditions: the pressure is -0.08 ~ -0.085Mpa, the temperature is 50 ~ 60 ° C, the waste water 101 containing about 20% DMF is concentrated to a concentration of about 40% DMF .

[0034] The second tower is concentrated under negative pressure, operating conditions: the pressure is -0.065 ~ -0.07Mpa, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com