Method for recovering potassium nitrate from anthraquinone dye alkali wastewater

A recovery method and anthraquinone technology are applied in the field of recycling and reuse of printing and dyeing wastewater, which can solve the problems of immature technology, high equipment requirements, and unsatisfactory effects, and achieve the effects of saving treatment costs, high removal rates, and improved effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

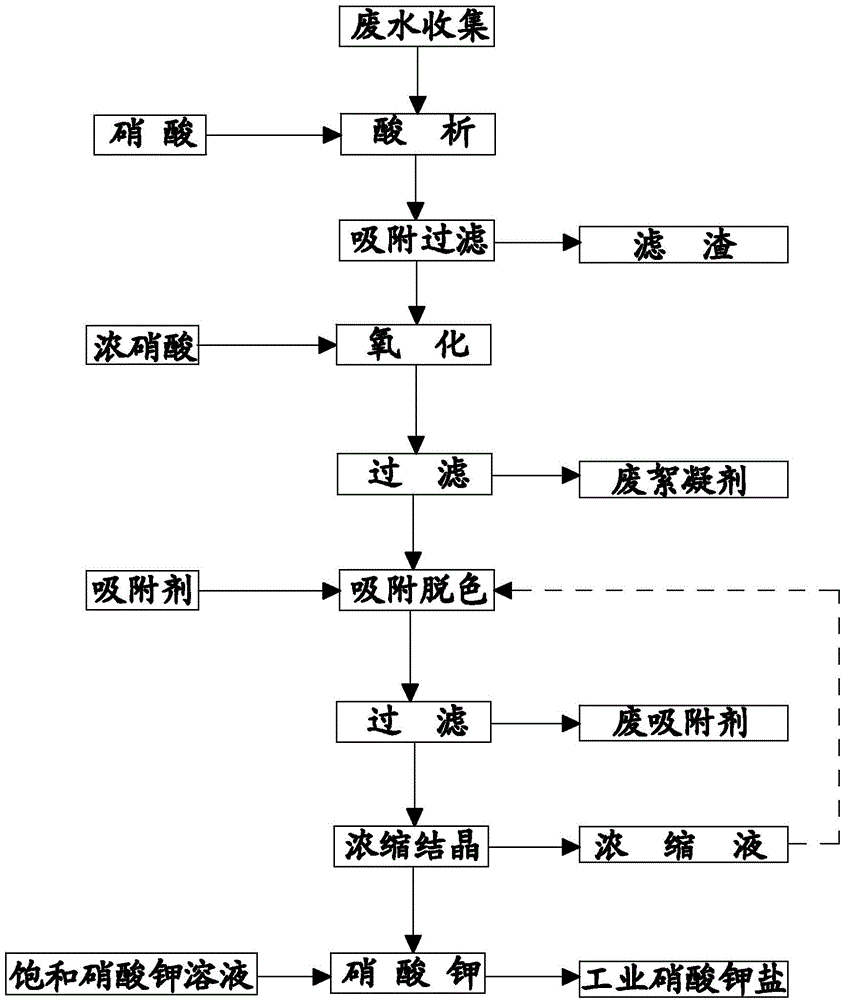

Method used

Image

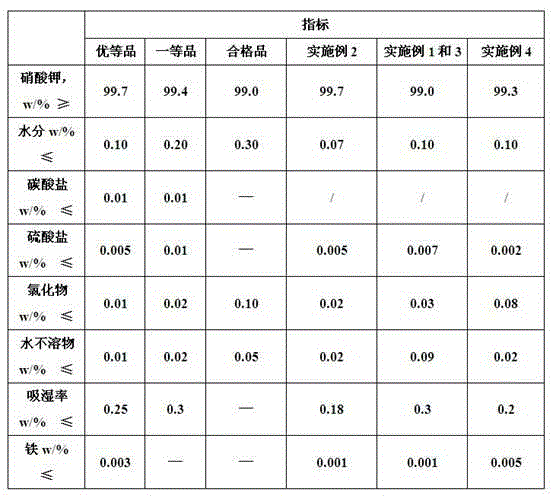

Examples

Embodiment 1

[0026] In this example, alkaline wastewater (pH = 13, COD = 211000mg / L) is subjected to acid analysis first, acid analysis is only performed once, and concentrated nitric acid (concentration: 65%), which accounts for 25% of the wastewater mass, is added to stir and react for 1.5 Add activated carbon accounting for 0.4% of the waste water mass after one hour, continue to stir and react for 1 hour, and filter; the COD of the filtrate is about 121000mg / L. Slowly add concentrated nitric acid accounting for 4% of the waste water mass to this filtrate, keep warm at 85-95°C, stir for 4 hours, cool down to 40-50°C, and filter. After the filtrate is concentrated, the color of the obtained salt is reddish brown. After adding 15% washing water, the salt is still slightly yellow, and the COD of the condensed water is greater than 1000mg / L.

Embodiment 2

[0028] Add concentrated nitric acid with a mass fraction of 65% to alkaline wastewater (pH=13, COD=211000mg / L), keep the wastewater pH=4, stir and react for 1 hour, consume 20% of the acid, and then add 0.3% of the total mass of the wastewater to be treated The activated carbon was stirred and reacted for 0.5 hours and then filtered, the filtrate COD=104100mg / L, the COD removal rate was about 51%, but the chroma was still relatively large; 5% concentrated nitric acid was added to the filtrate, and 0.1% was added after stirring for 0.5 hours The activated carbon was stirred and reacted for 0.5 hour, and filtered to obtain about 80000 mg / L of wastewater COD. Raise the temperature of the waste water to 85-95°C, while slowly adding concentrated nitric acid, while bubbling with the air, and stirring constantly, keep warm for 4 hours, add 4% nitric acid in total, cool down to 40-50°C and then filter, the filtrate is wine red, COD=10000mg / L, then add 0.1% activated carbon to stir and...

Embodiment 3

[0031] The setting and working principle of this example are the same as those of Example 2, the difference is that after the nitric acid is oxidized and filtered directly without adding activated carbon, the obtained salt is wine red, and after washing with 25% washing water, it is still slightly yellow, and the condensed water is orange-red , COD about 700mg / L.

[0032] Can find out by embodiment 3: directly filter after nitric acid oxidation, the salt color that obtains is darker, and the washing water consumption increases, and condensed water COD and chromaticity all rise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com