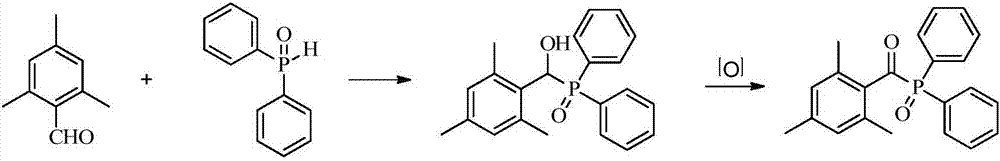

Method for efficiently and recyclably synthesizing 2,4,6-trimethylbenzoyldiphenyl phosphine oxide

A technology of trimethylbenzoyl and diphenylphosphine oxide, which is applied in chemical instruments and methods, chemical recovery, organic chemistry, etc., can solve the problems of shortening the preparation process, catalysts that cannot be reused, and complicated post-treatment methods. Achieve the effect of simple process, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

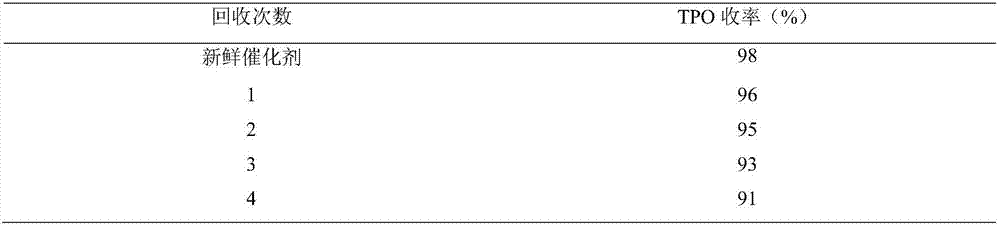

Embodiment 1

[0027] Will 3.24g V 2 o 5 Solid-phase grinding with 43.55g MCM-41 molecular sieve for 0.5h and roasting to obtain vanadium molecular sieve (V-MCM-41). Add 37.61g of 2,4,6-trimethylbenzaldehyde and 56.17g of diphenylphosphine oxide into a three-necked flask containing 450mL of dichloromethane, stir and react at room temperature for 6 hours, and then put the three-necked flask into a low-temperature water bath Cool to 8-10°C, add 3.23g vanadium molecular sieves (4% vanadium load) and 37mL tert-butanol peroxide in sequence, react at low temperature for 0.5 hours, then place at room temperature for stirring, and react for 5 hours.

[0028] After the reaction is finished, vanadium molecular sieves are recovered by filtration. Add 5% Na to the filtrate 2 S 2 o 3 The aqueous solution neutralized the unreacted tert-butanol peroxide, extracted, collected the organic layer, washed three times with saturated brine, then added anhydrous sodium sulfate to remove water, then recrystall...

Embodiment 2

[0031] 4.17g NH 4 VO 3 Solid phase grinding with 43.55g ZSM-5 molecular sieve for 0.5h and then roasting to obtain vanadium molecular sieve (V-ZSM-5-N). Add 37.61g of 2,4,6-trimethylbenzaldehyde and 56.17g of diphenylphosphine oxide into a three-necked flask containing 450mL of dichloromethane, stir and react at room temperature for 6 hours, and then put the three-necked flask into a low-temperature water bath Cool to 8-10°C, add 3.23g of vanadium molecular sieves (4% vanadium load), 37mL of tert-butanol peroxide, react at low temperature for 0.5 hours, then place at room temperature for stirring, and react for 4 hours.

[0032] After the reaction is finished, vanadium molecular sieves are recovered by filtration. Add 5% Na to the filtrate 2 S 2 o 3 The aqueous solution neutralized the unreacted tert-butanol peroxide, extracted, collected the organic layer, washed three times with saturated brine, then added anhydrous sodium sulfate to remove water, then recrystallized, s...

Embodiment 3

[0035] vanadyl sulfate (VOSO 4 ) to make a 1mol / L solution, mix 35.63mL of the solution with 43.55g of ZSM-5 molecular sieve, stir for 4 hours, and roast to obtain vanadium molecular sieve. Add 37.61g of 2,4,6-trimethylbenzaldehyde and 56.17g of diphenylphosphine oxide into a three-necked flask containing 450mL of dichloromethane and stir, react at room temperature for 6 hours, and then put the three-necked flask into a low-temperature water bath Cool in medium to 8-10°C, add 3.23g vanadium molecular sieve (4% vanadium load) and 37mL tert-butanol peroxide in sequence, react at low temperature for 0.5 hours, then place at room temperature for stirring, and react for 5 hours.

[0036] After the reaction is finished, vanadium molecular sieves are recovered by filtration. Add 5% Na to the filtrate 2 S 2 o 3 The aqueous solution neutralized the unreacted tert-butanol peroxide, extracted, collected the organic layer, washed three times with saturated brine, then added anhydrous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com