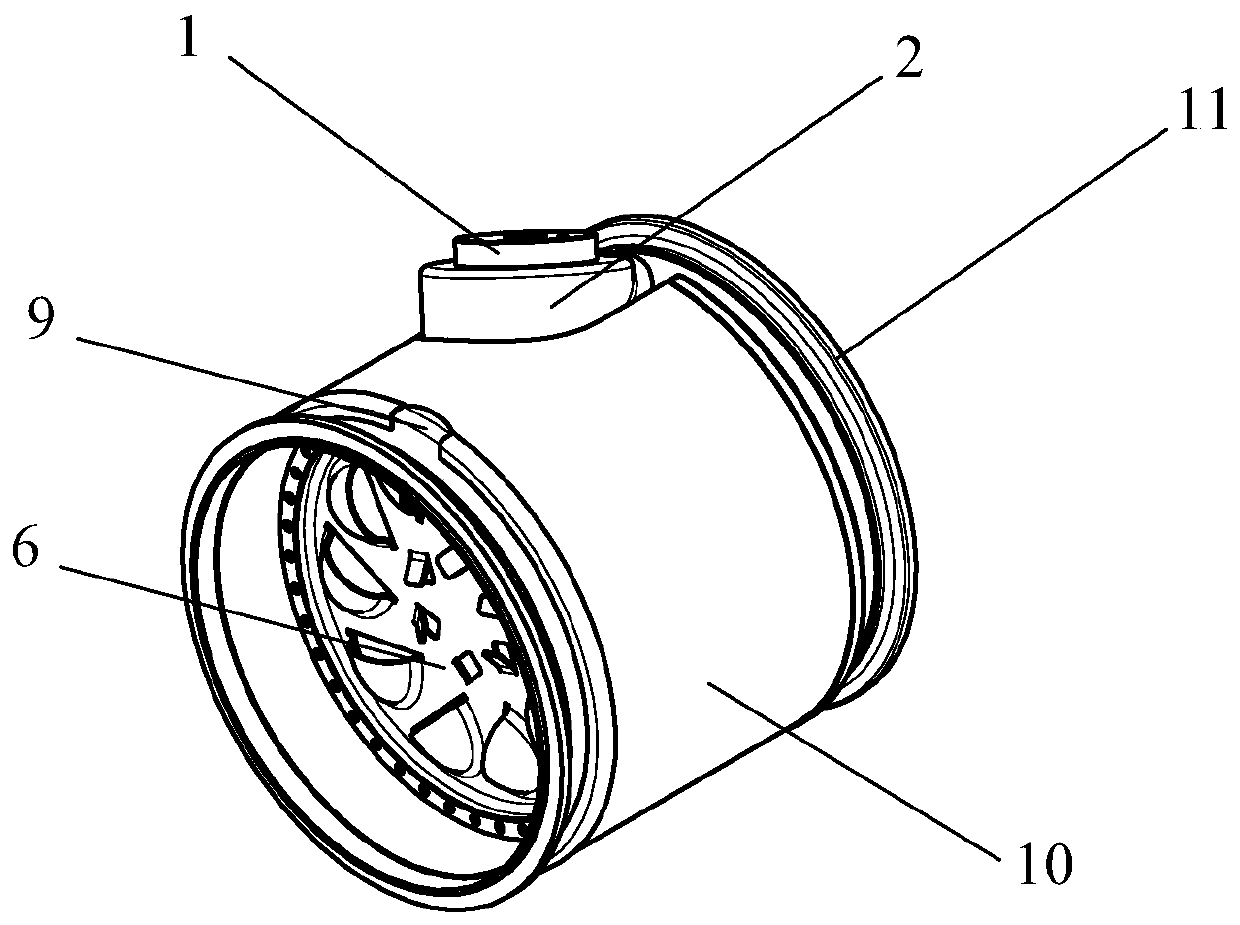

Two-way rotational flow cylinder type urea mixing device

The technology of a mixing device and a swirl cylinder, which is applied in the muffler device, exhaust device, exhaust gas treatment and other directions, can solve the problems of low crystallization and urea decomposition efficiency, and achieve the effect of reducing the risk of crystallization, reducing the risk and ensuring the efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

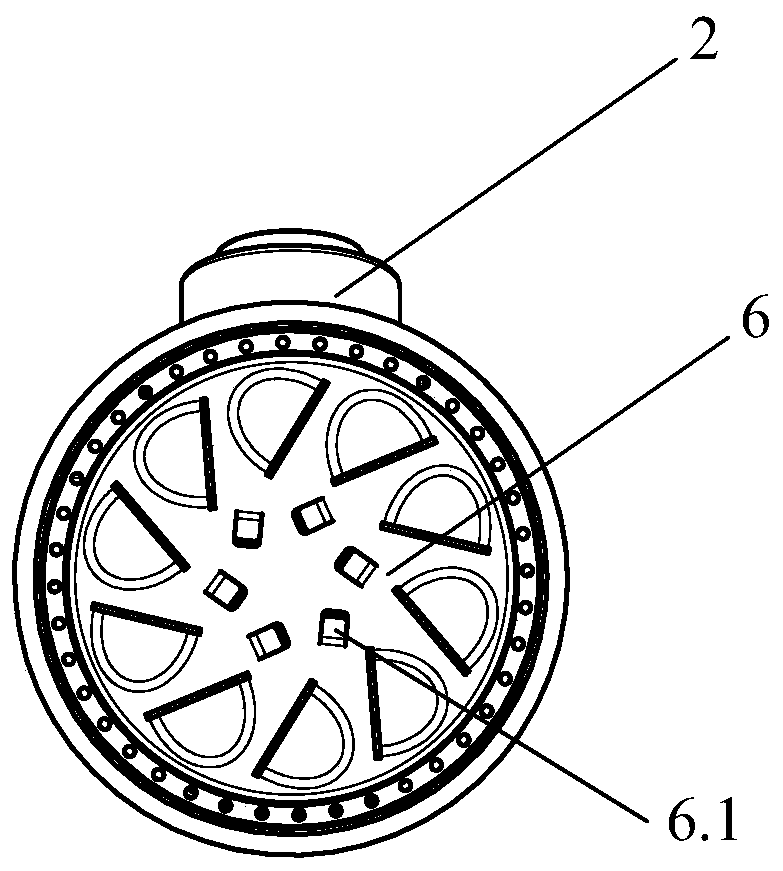

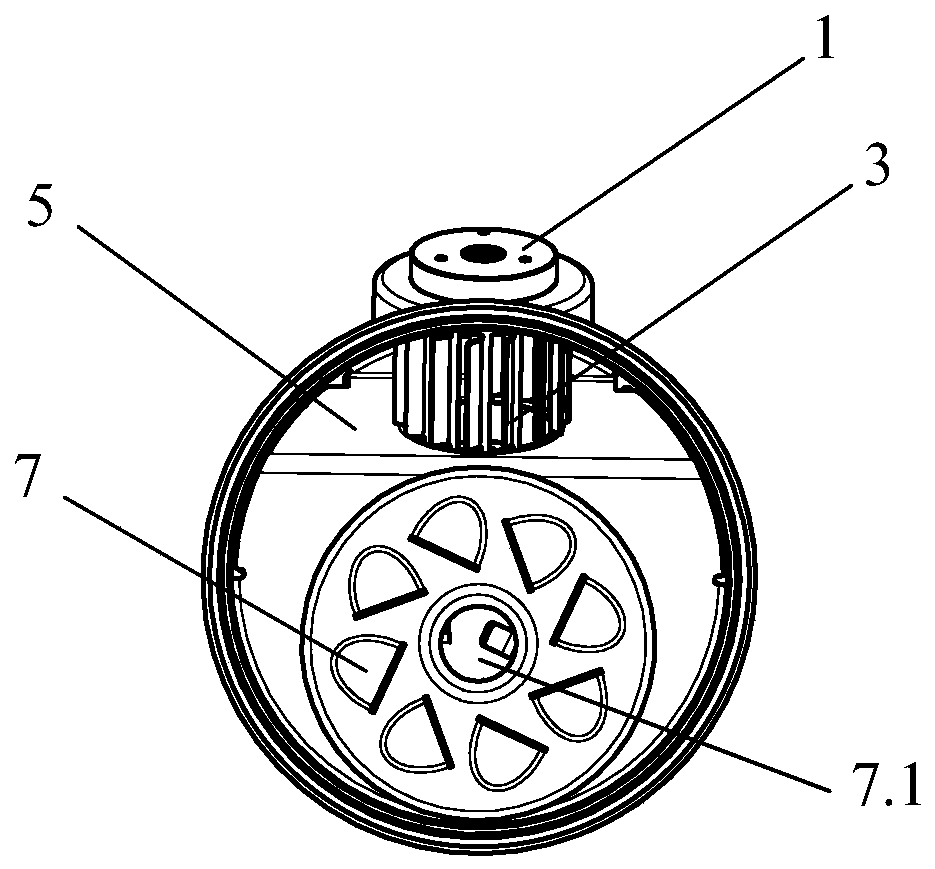

[0032] The present invention will be further described below in conjunction with specific drawings.

[0033] The application of the two-way cyclone cylinder type urea mixing device of the present invention on the exhaust aftertreatment device is as follows: Figure 7 shown. The exhaust post-treatment device consists of an intake pipe assembly 1', a DOC assembly 2', a DPF assembly 3', a two-way swirling cylindrical urea mixing device 4' (that is, a two-way swirling cylindrical urea mixing device described in the present invention), The SCR assembly 5' and the air outlet pipe assembly 6' are composed. The exhaust gas from the engine enters the exhaust after-treatment device from the intake pipe assembly 1', passes through the DOC assembly 2', the DPF assembly 3', and then enters the two-way swirl drum urea mixing device 4', and is mixed in the two-way swirl drum urea mixing device. The mixing, secondary crushing and decomposition of urea are completed inside the device 4'. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com