Urea injection system and control method thereof, controller and storage medium

A technology of urea injection system and control method, which is applied in the field of urea injection system and its control, and can solve the problems of poor urea atomization effect, high risk of urea crystallization, low exhaust gas temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

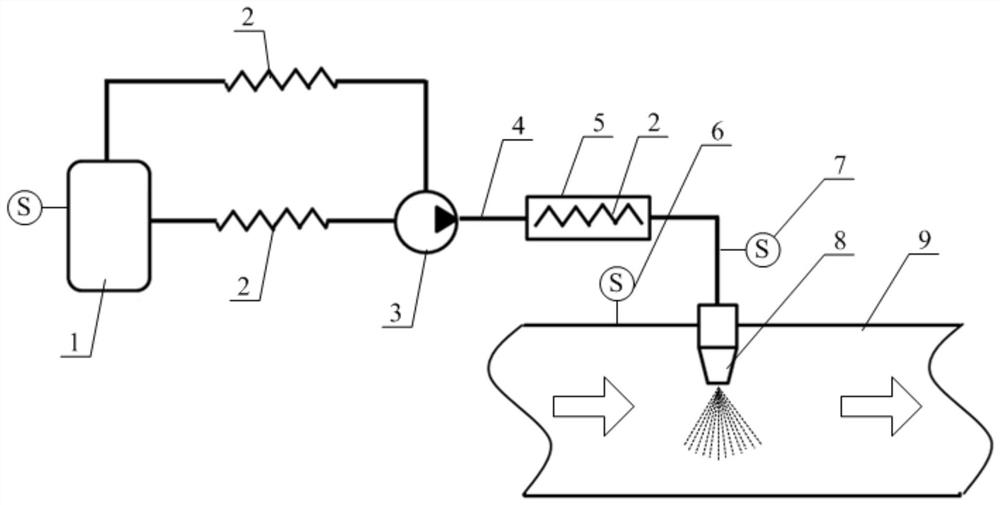

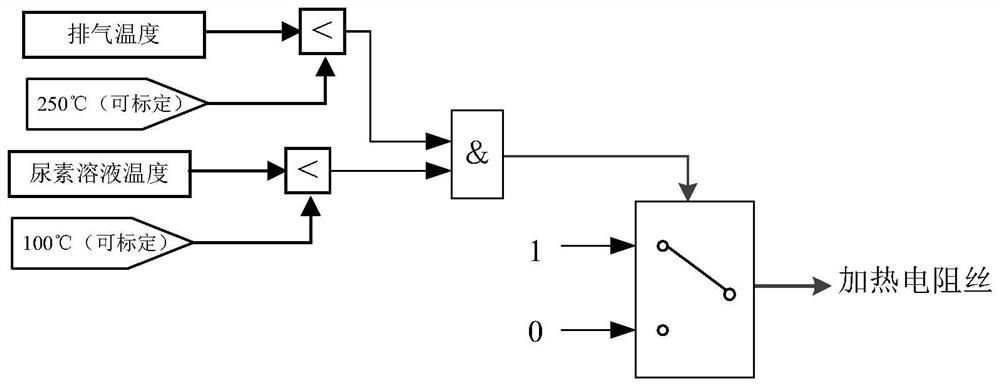

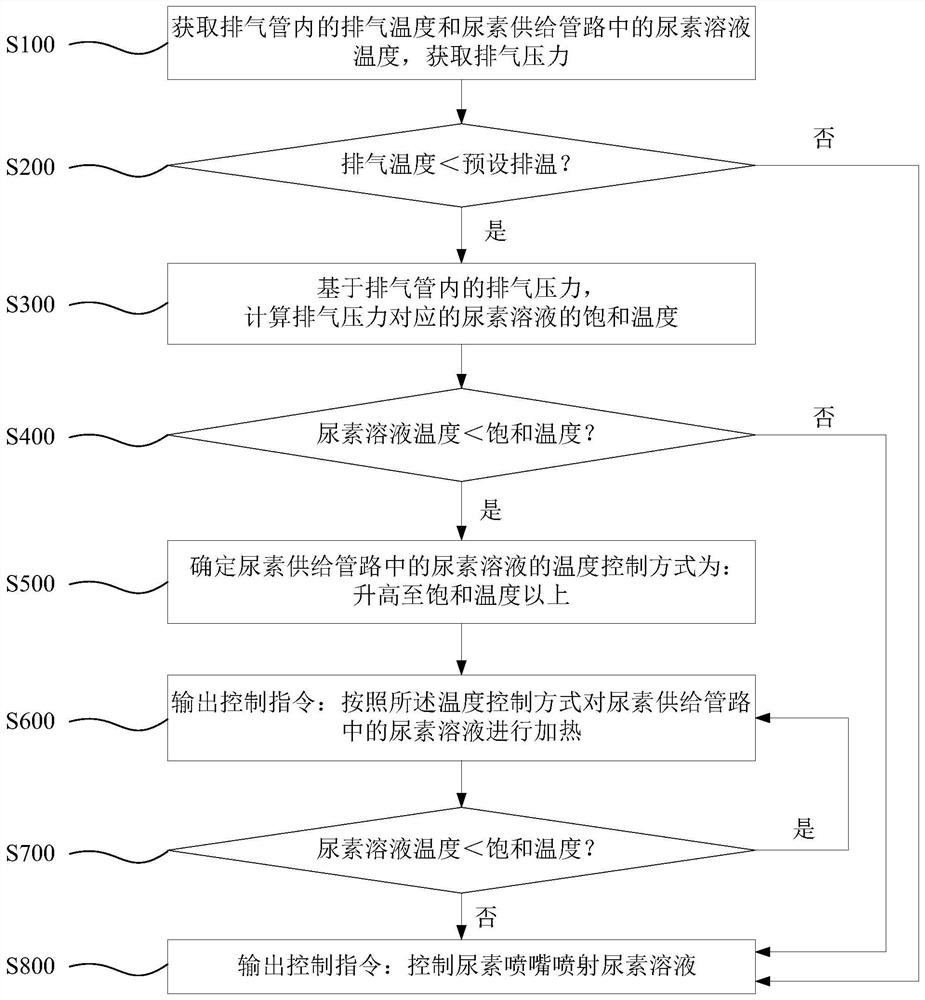

[0033]Please refer toFigure 1 to 3The present invention provides a method of controlling an urea injection system, which includes the following steps:

[0034]S100: Get the exhaust gas temperature in the exhaust pipe 9 and the temperature of the urea supply line 4 in the urea supply line 4. In step S100, the exhaust gas temperature in the exhaust pipe 9 can be specifically detected by the first temperature sensor 6, and the urea solution temperature in the urea supply line 4 is detected by the second temperature sensor 7. Preferably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com