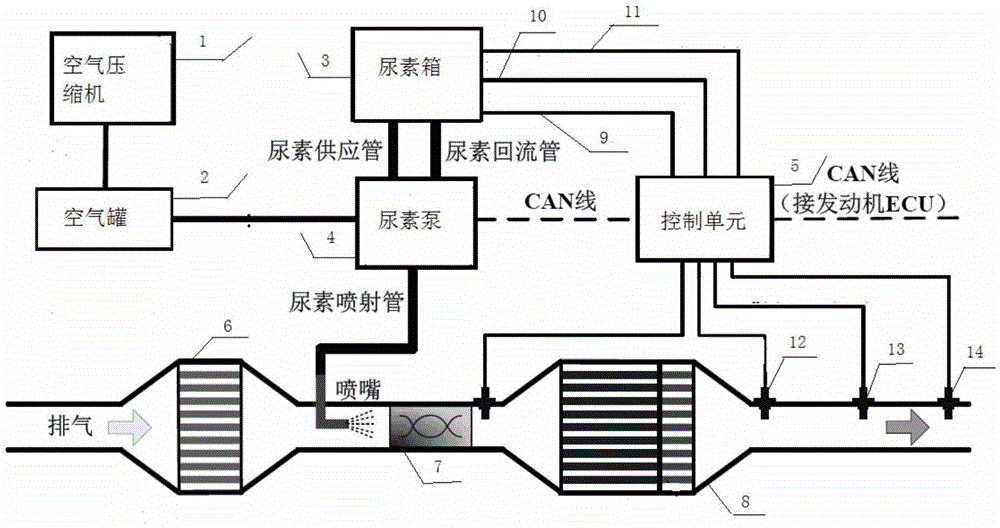

Mixer used for exhaust facility and SCR system

A mixer and facility technology, applied in the field of tail gas treatment, can solve the problems of easy crystallization, uneven distribution of reducing agent, low efficiency of selective catalytic reduction reaction, etc. The effect of reducing the risk of crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

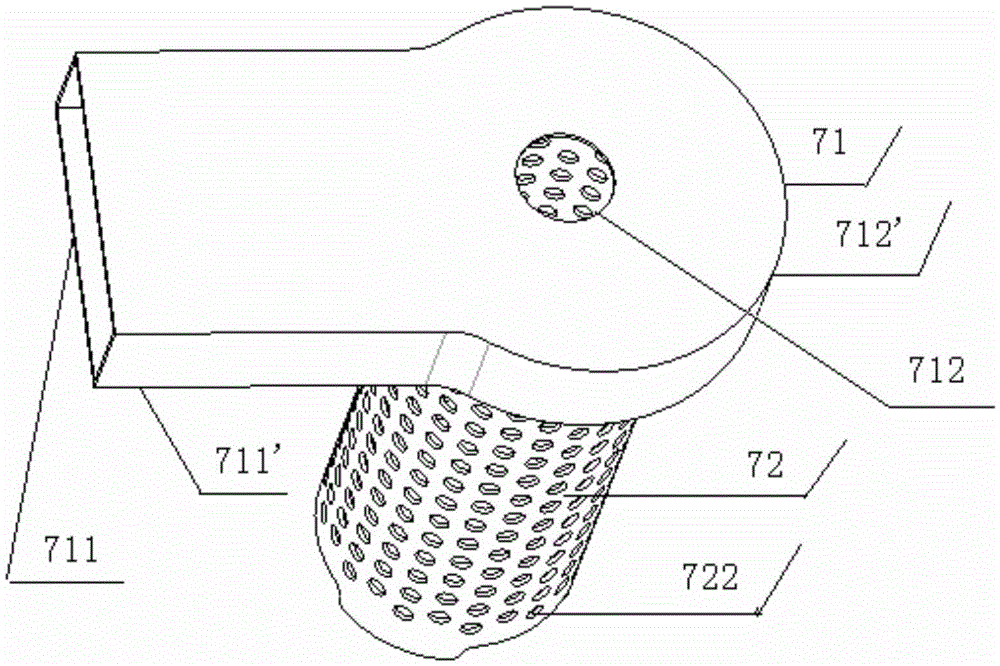

[0047] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0048] Figure 2-Figure 6 A schematic structural view of a mixer used for an exhaust facility according to an embodiment of the present invention is shown. Such as Figure 2-Figure 6 As shown, the mixer for the exhaust facility includes:

[0049] Gas cyclone 71 and liquid disperser 72;

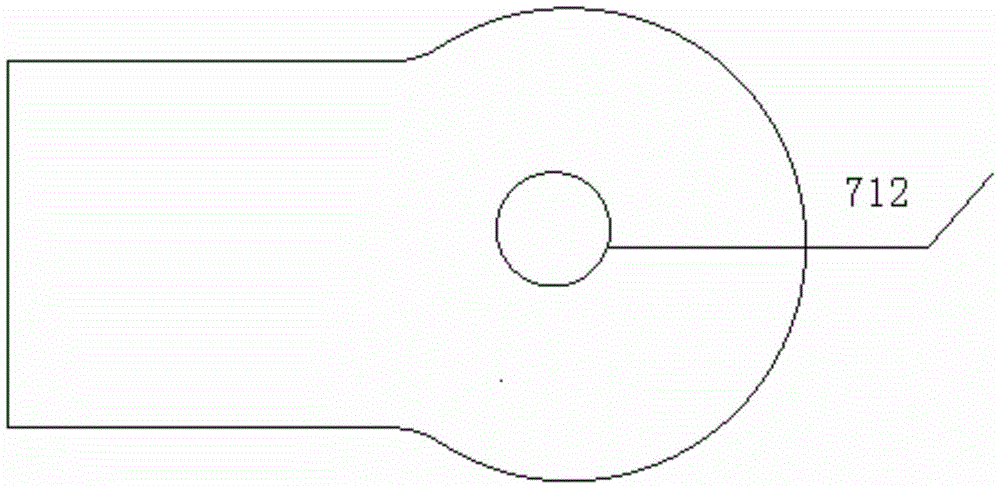

[0050] The shape of the gas swirler 71 is a shell, the gas swirler 71 includes an air inlet 711, and the gas swirler 71 is provided with a first hole 712 and a second hole 713 opposite to the direction perpendicular to the gas inlet direction;

[0051] One end of the liquid disperser 72 is vertically connected with the gas cyclone 71 through the second hole 713;

[0052] The first hole 712 of the gas cyclone 71 is used to introduce the reducing agent ejected from the nozzle;

[0053] The end of the liquid disperser 72 close to the gas swirler 71 is provided with at le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com