Mixer integrated type spraying unit

An integrated, mixer technology, applied in injection devices, liquid injection devices, engine components, etc., can solve the problems of compact structure, easy urea crystallization, low integration, etc., to reduce the risk of crystallization, compact structure, Excellent blending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

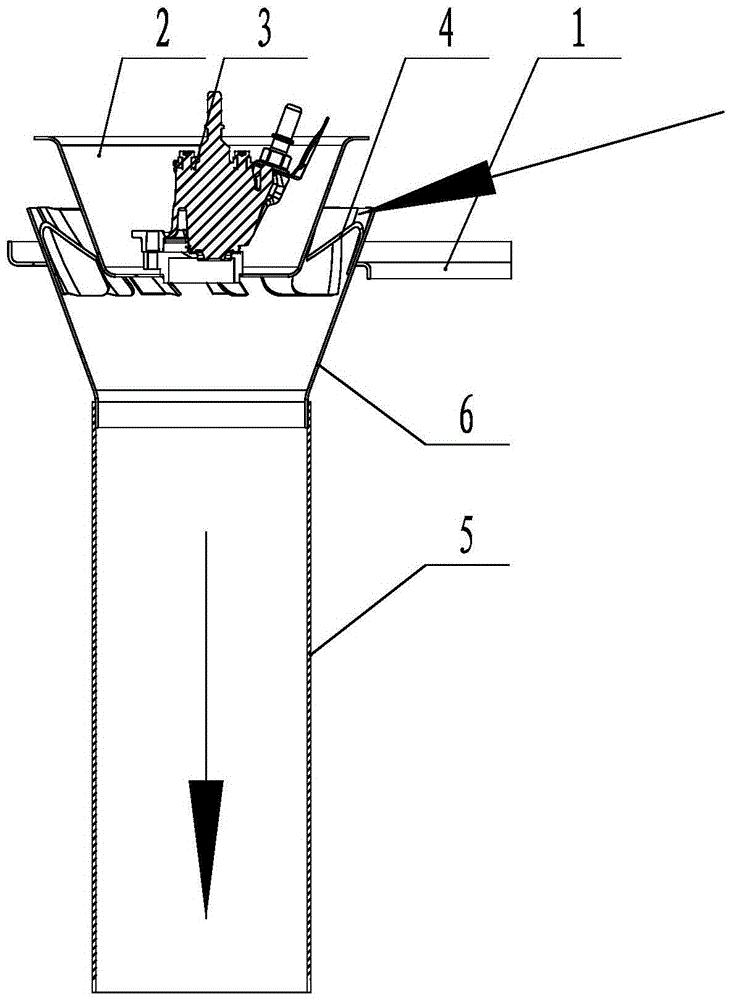

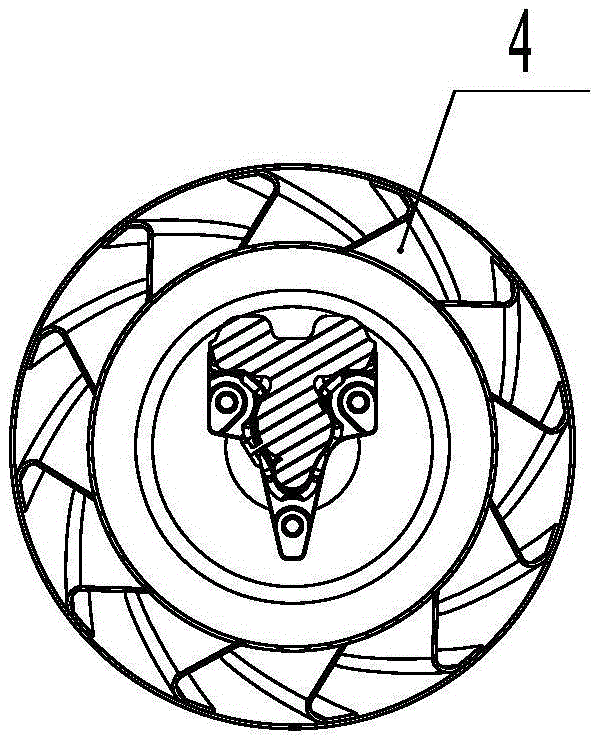

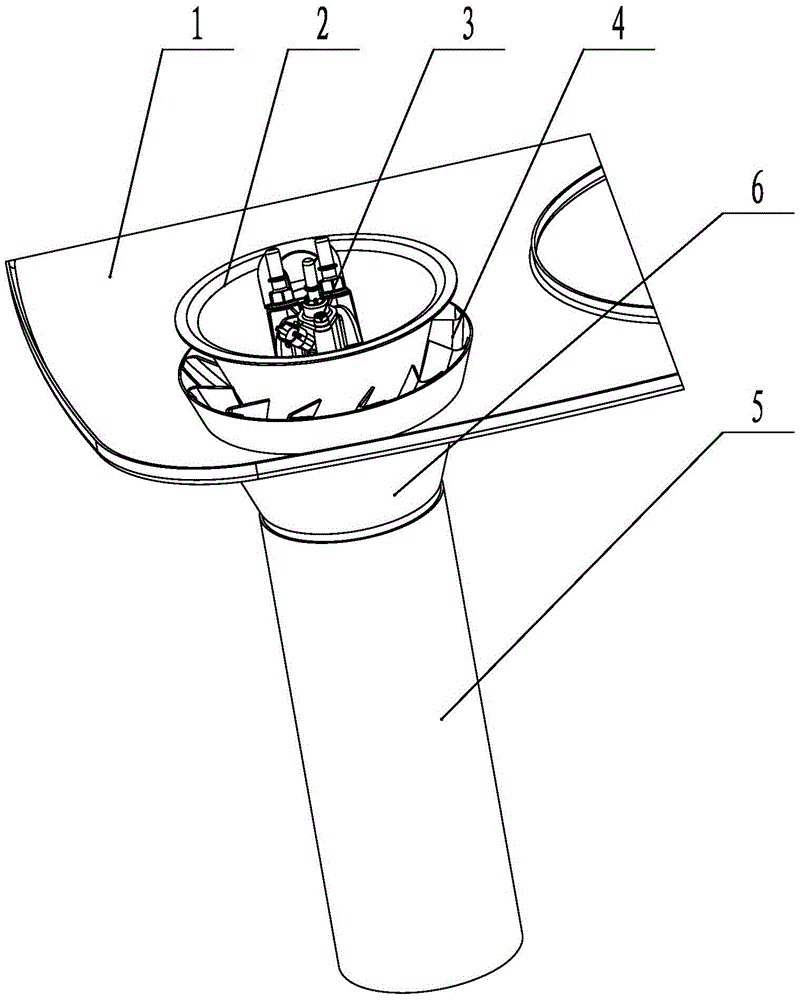

[0014] Figure 1~3 Among them, including partition 1, sinking bowl 2, urea nozzle 3, blade 4, pipe 5, cone 6 and so on.

[0015] Such as Figure 1~3 As shown, the present invention is a mixer-integrated injection unit, including a conical member 6, the lower nozzle of the conical member 6 is fixedly connected to the hollow pipe member 5, and the inner wall surface of the conical member 6 is circumferentially evenly arranged with several blades 4. The sinking bowl 2 is embedded inside the blade 4, the urea nozzle 3 is fixed on the bottom of the sinking bowl 2 through the urea injection base, the urea nozzle 3 faces the direction of the pipe 5, and the surface of the cone 6 is fixed with a partition 1.

[0016] The distance between the upper surface of the separator 1 and the top surface of the cone 6 is 30 mm to 50 mm.

[0017] The middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com