Water-soluble tea tree oil and method for preparing same

A tea tree oil and water-soluble technology, which is applied in the field of preparation of water-soluble tea tree oil, can solve the problems of limiting the range of use of tea tree oil, tea tree oil is highly irritating, and evaporates quickly, and achieves the goals of saving raw materials, good fluidity, and reducing prices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

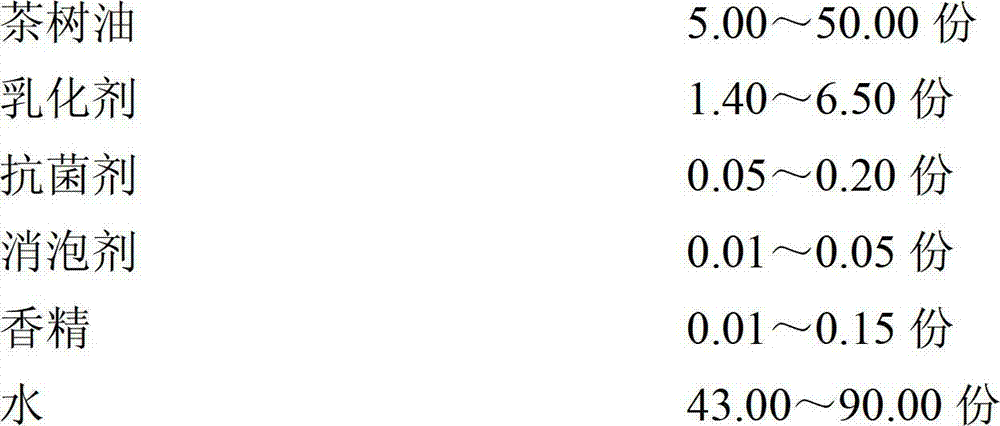

Method used

Image

Examples

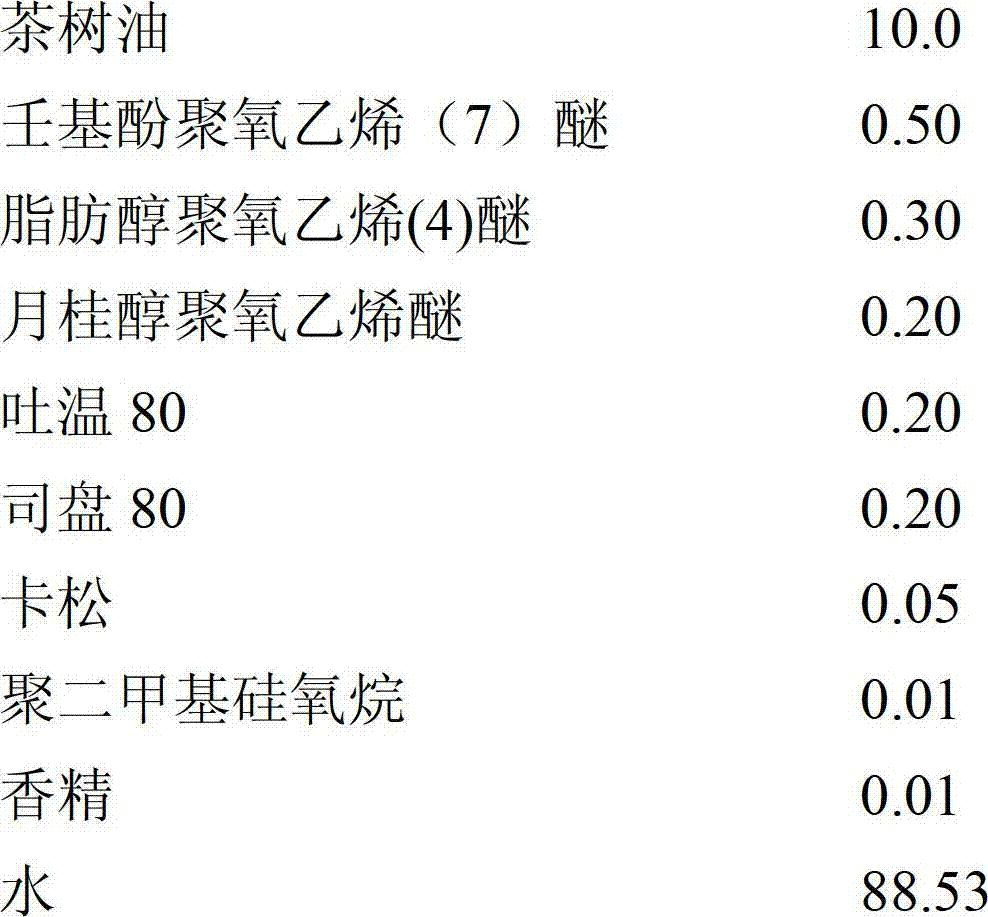

Embodiment 1

[0027] (1) Add tea tree oil into the reaction kettle;

[0028] (2) Add the emulsifier, antibacterial agent, and defoamer to the tea tree oil respectively, heat to 30°C, and under the action of an emulsifier, the emulsification temperature is 30°C, the stirring time is 10min, and the stirring speed is 2000rpm;

[0029] (3) Dissolve the essence in water, heat it to 30°C, and slowly add it to the above mixture. Under the action of an emulsifier, the emulsification temperature is 30°C, the stirring time is 10 minutes, and the stirring speed is 2000rpm to obtain water-soluble tea tree oil.

[0030] The ratio is as follows: (unit: kg)

[0031]

Embodiment 2

[0033] The difference between this example and Example 1 is: step (2) (3) emulsification temperature 40°C, stirring time 20min, stirring speed 8000rpm, others are as follows: (unit: kg)

[0034]

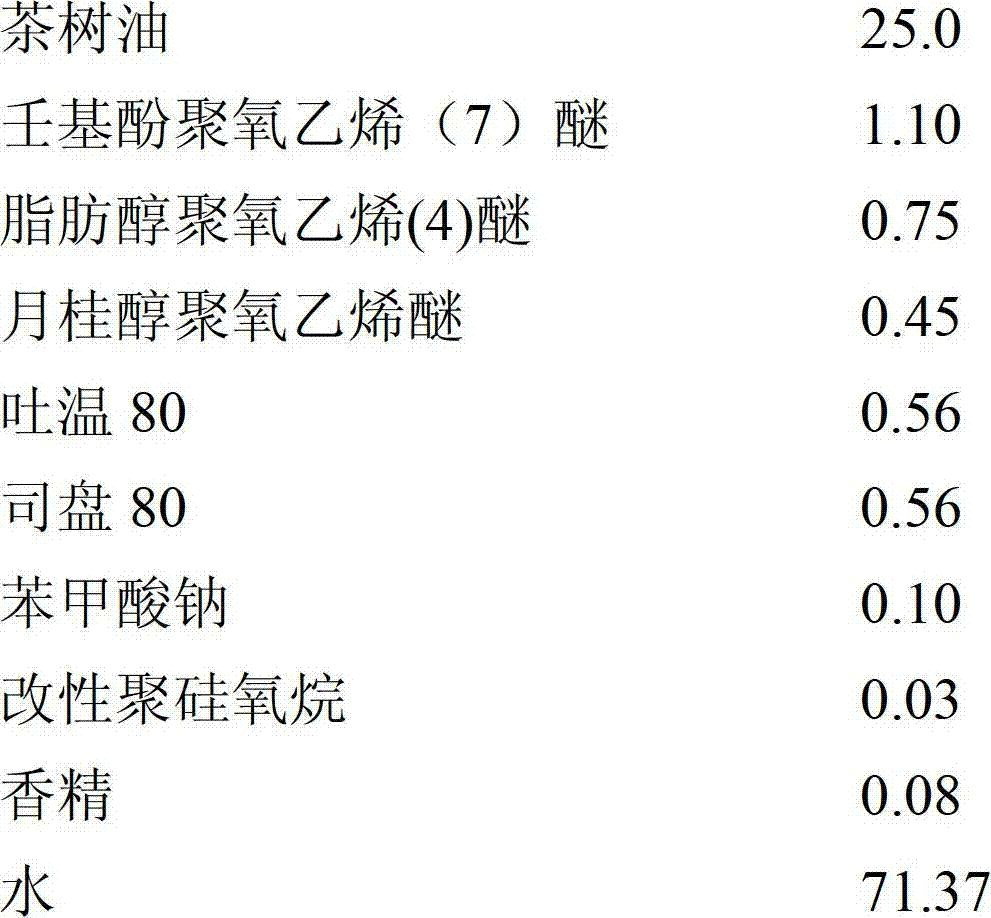

Embodiment 3

[0036] The difference between this example and Example 1 is: step (2) (3) emulsification temperature 60°C, stirring time 30min, stirring speed 15000rpm, others are as follows: (unit: kg)

[0037]

[0038] Three kinds of water-soluble tea tree oil performance effects in the embodiment

[0039]

[0040] Described floating layer height experiment is, respectively get experimental sample 5mL, centrifuge 10min under the rotating speed of 1000r / min, compare the pros and cons of stability according to the number of the top floating layer that comes out, the less top floating layer is more stable. it is good.

[0041] The sample deterioration test is to take 100 mL of each experimental sample, expose it to the air for 15 days, and then judge whether it has deteriorated.

[0042] Described diffusivity experiment is to get experimental sample 10mL respectively, will pour into 200ml water, observe whether to become uniform emulsion rapidly, can rapidly become homogeneous emulsion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com