Integrated aftertreatment equipment

A post-processing and integrated technology, applied in the direction of exhaust gas treatment, mechanical equipment, electronic control of exhaust gas treatment devices, etc., can solve the problems of pollutant treatment without diesel engines, so as to improve SCR conversion efficiency, reduce costs, reduce risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

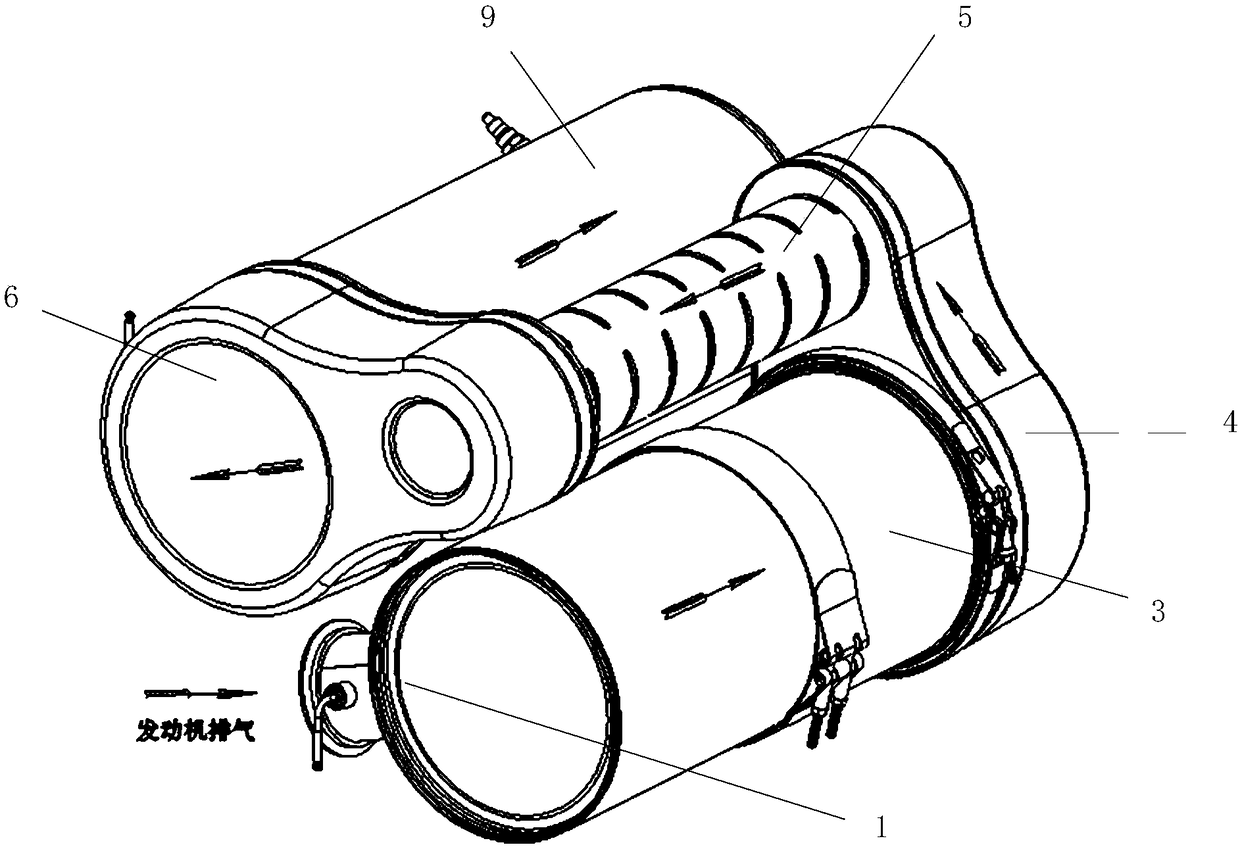

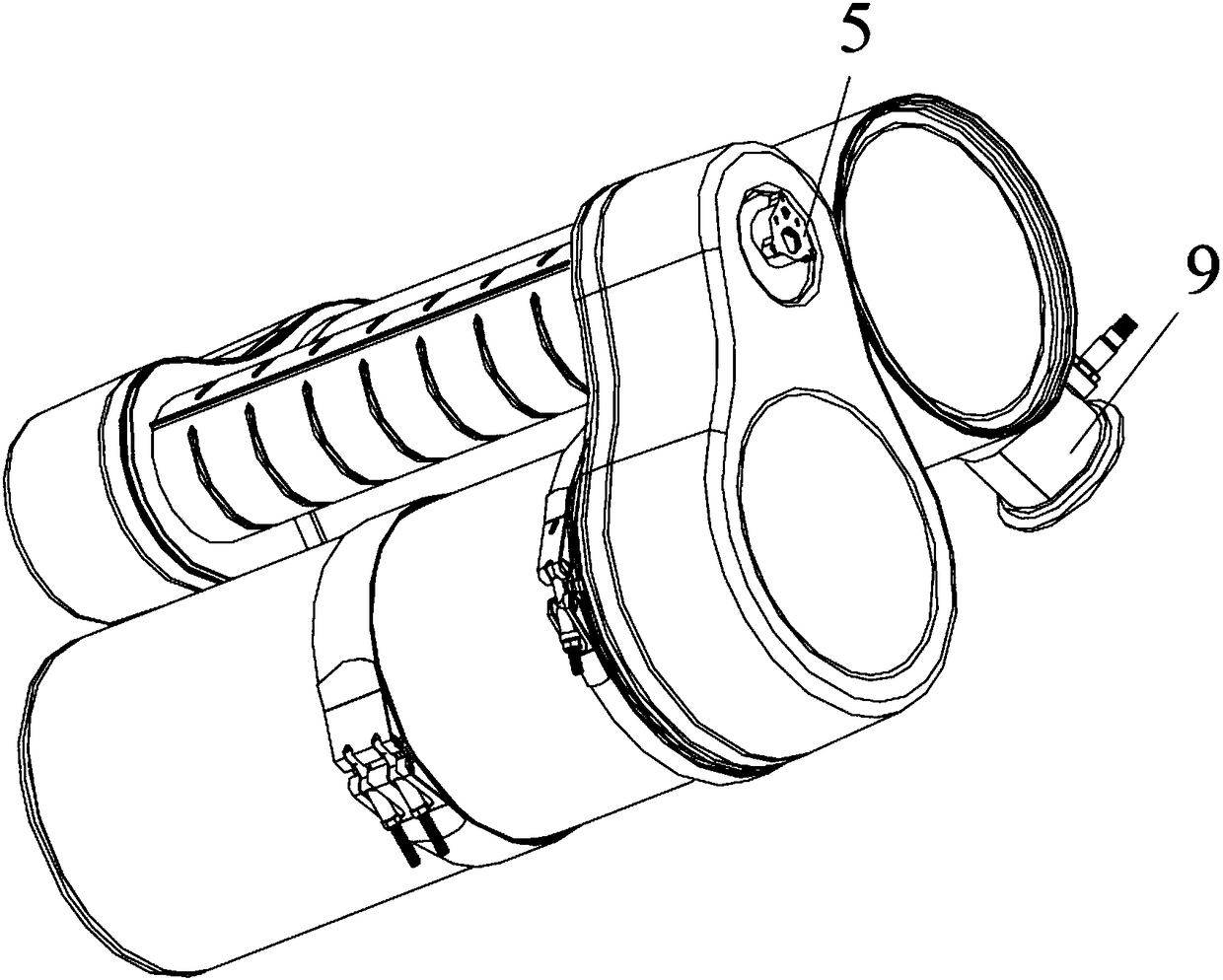

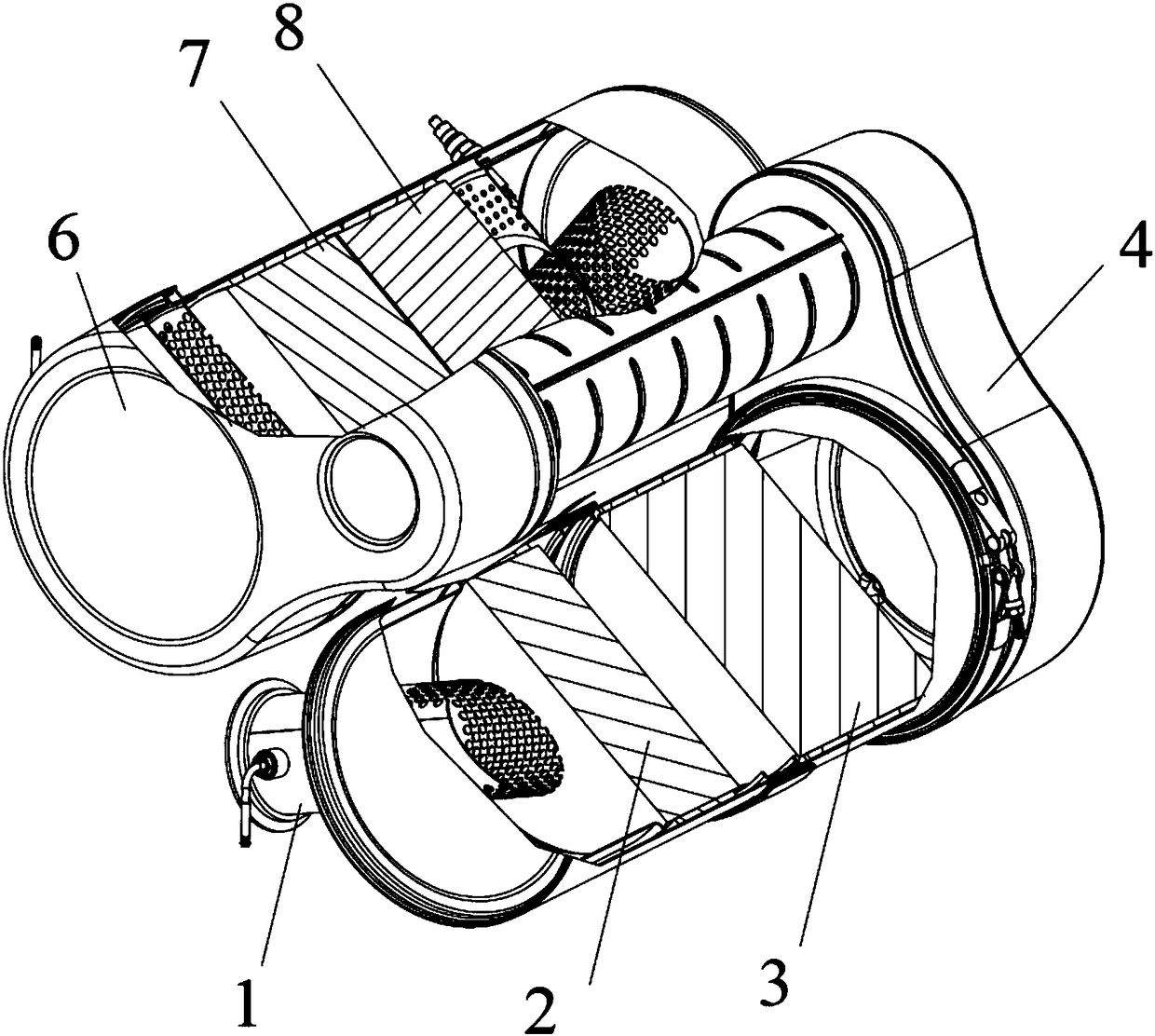

[0022] Fig. 1(a) and Fig. 1(b) are the overall assembly schematic diagrams of the integrated post-processing equipment provided by the embodiment of the present invention respectively; figure 2 An internal cross-sectional view of the integrated post-processing equipment provided by the embodiment of the present invention; image 3 Explosion schematic diagram of the integrated post-processing equipment provided by the embodiment of the present invention; Figure 4 The detailed exploded schematic diagram of the integrated post-processing equipment provided by the embodiment of the present invention.

[0023] like Figure 1(a) to Figure 3 As shown, the integrated post-processing equipment provided by the embodiment of the present invention includes a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com