Multistage air deep dehumidification device for ultra-low dew point environments

An ultra-low dew point, air technology, applied in air treatment details, air conditioning systems, space heating and ventilation, etc., can solve the problems of reduced economy, large energy consumption of dehumidification rotor regeneration, high supply air temperature and ambient temperature, etc. , to achieve the effect of reducing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

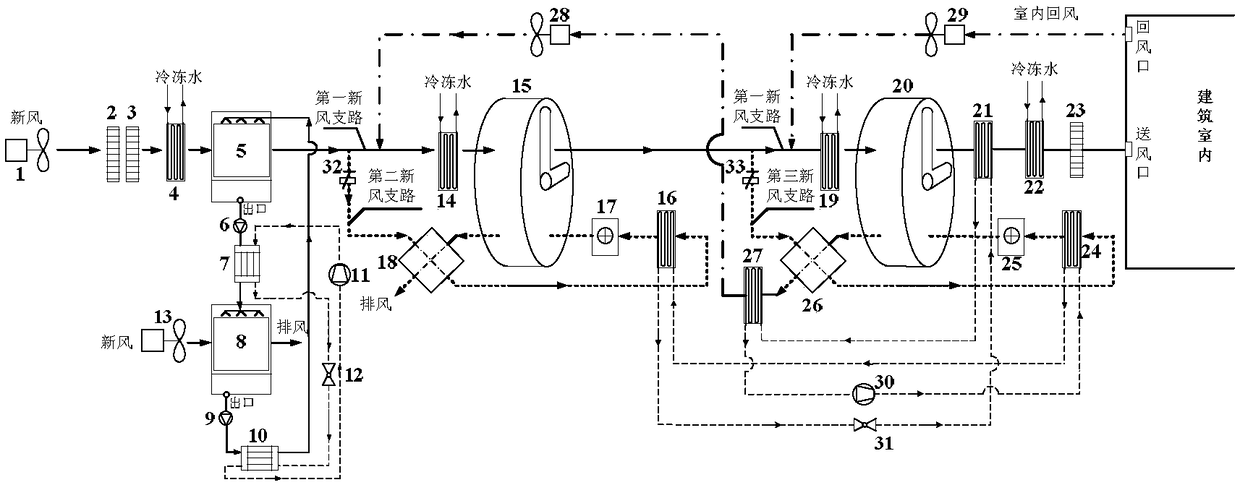

[0033] combined with figure 1 , taking the air supply volume as 3000m 3 / h, unit air volume 1200m 3 / h, fresh air temperature 35°C, relative humidity 56%, moisture content 20g / kg, air supply temperature 18°C, moisture content 0.01g / kg typical preset working conditions in summer as an example, specific implementation of the present invention way to describe in detail,

[0034] In the multi-stage deep air dehumidification device of the ultra-low dew point environment of the present invention, firstly, the first fan 1 is turned on to input 1200m into the unit. 3 / h fresh air. The fresh air entering the unit is purified by the primary filter 2 and the intermediate filter 3 in turn, and then sent into the first surface cooler 4 for cooling and dehumidification. The chilled water at 7°C is used in the first surface cooler 4, and after being treated by the first surface cooler 4, the state of the fresh air becomes 25°C and 8g / kg. The solution dehumidifier 5 is arranged directly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com