Self-cleaning polymerization reactor

A polymerization reactor and self-cleaning technology, applied in chemical/physical/physical-chemical stationary reactors, etc., can solve the problems of poor fluidity, affecting product quality, thickening of the retention layer, etc., to weaken the retention layer and ensure Blending effects, effects of removing lingering layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

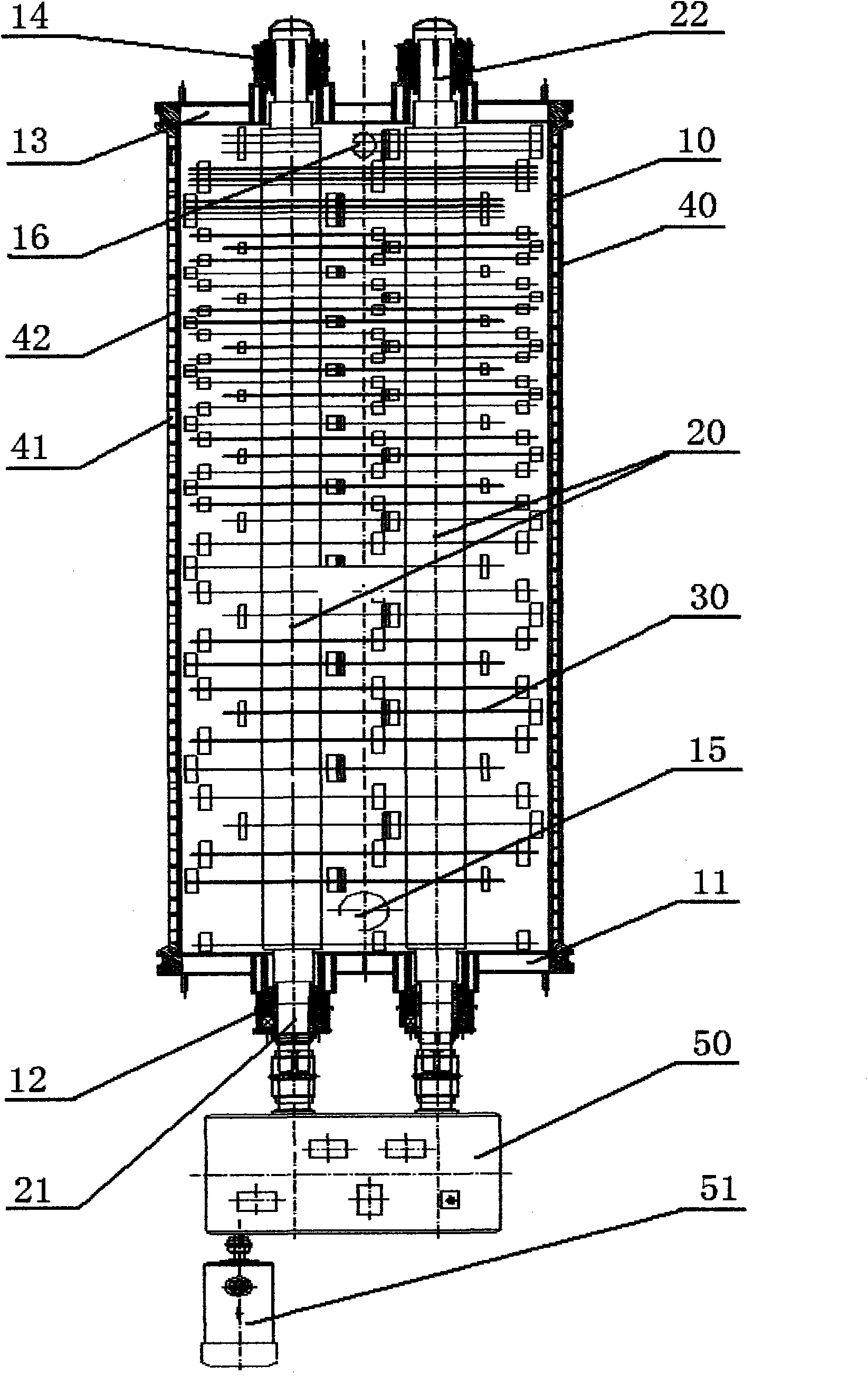

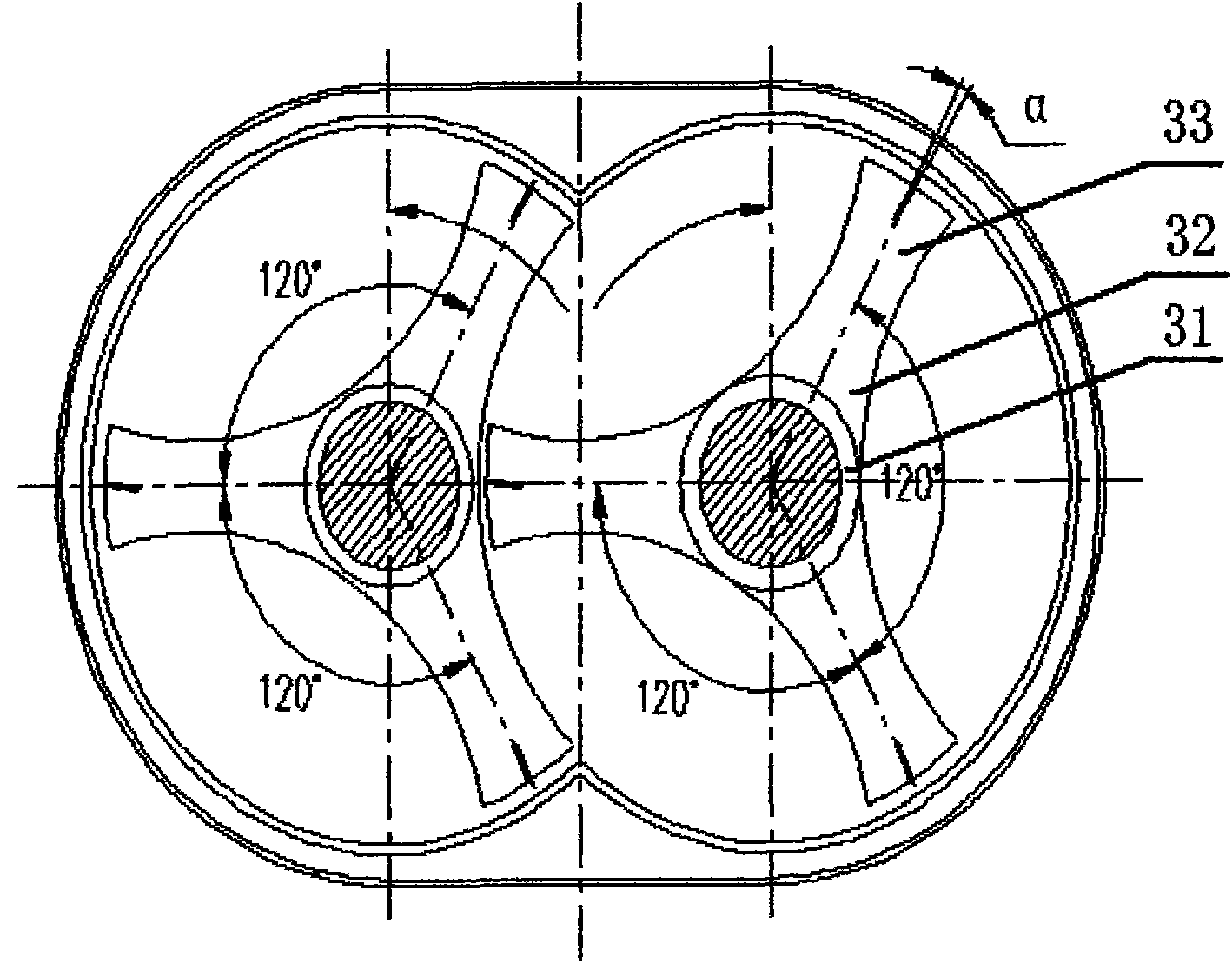

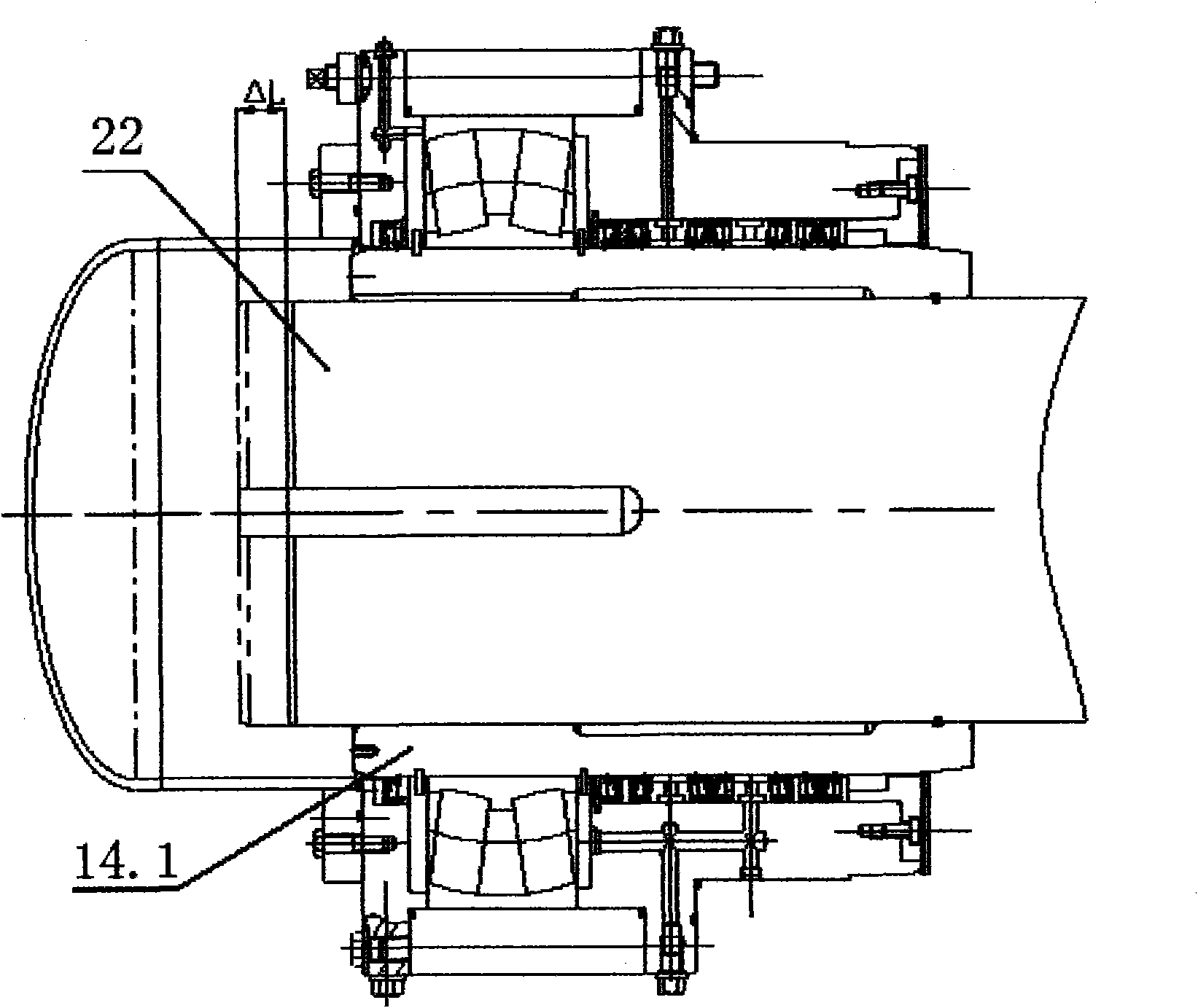

[0013] see figure 1 , the present invention provides a self-cleaning polymerization reactor, including a sealed horizontal cylinder 10, the cross-sectional shape of the horizontal cylinder is double circular, and two main shafts 20 are arranged in the cylinder, and the two main shafts Respectively located at the two centers of the double circles, the main shaft is provided with several star rotors 30, the star rotors are composed of a disc body 332 and a hub 31 arranged in the center of the disc body, the disc body is set There are a plurality of spokes 33, the hub is sleeved on the main shaft, the power input ends 21 of the two main shafts extend outside the horizontal cylinder, and are respectively connected to drive the two main shafts to rotate synchronously and in reverse The driving device 50. The so-called double circle in the present invention refers to the closed figure formed by the exposed arcs of the two circles after two circles cross each other (partial area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com