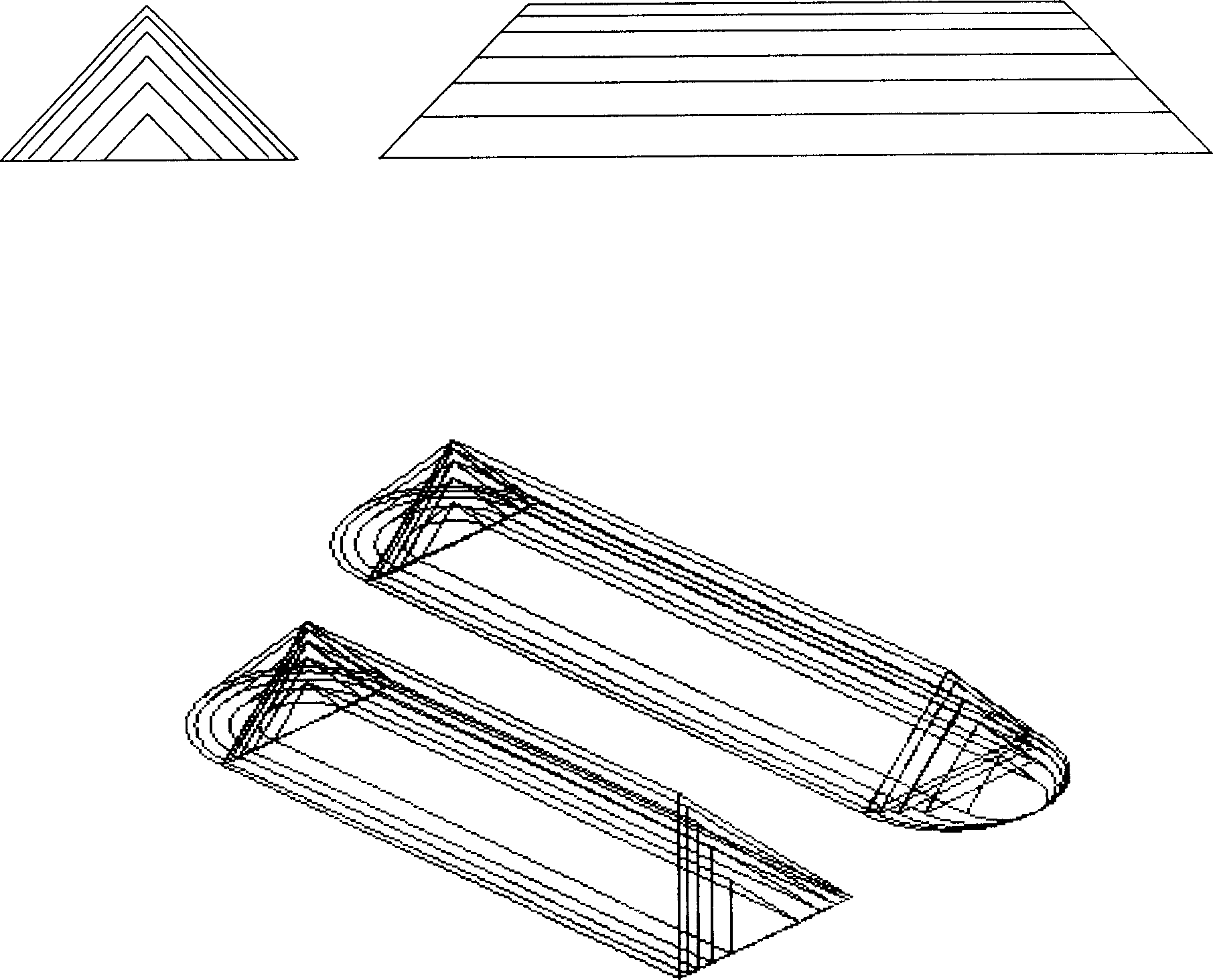

Materials piling method at end of rectangular pre-equalizing materials field

A pre-homogenization and rectangular technology, applied in loading/unloading, program control in sequence/logic controller, electrical program control, etc., can solve problems affecting cement quality and poor mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] PLC control design can be adopted.

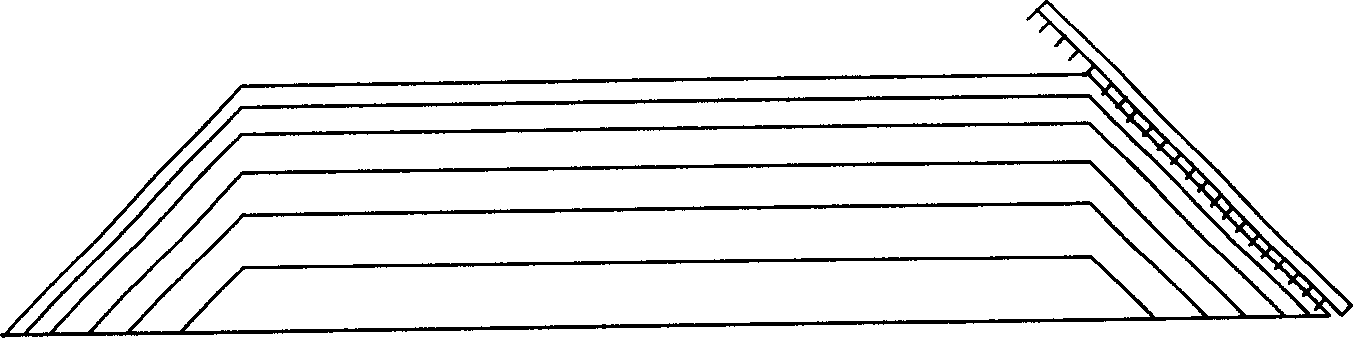

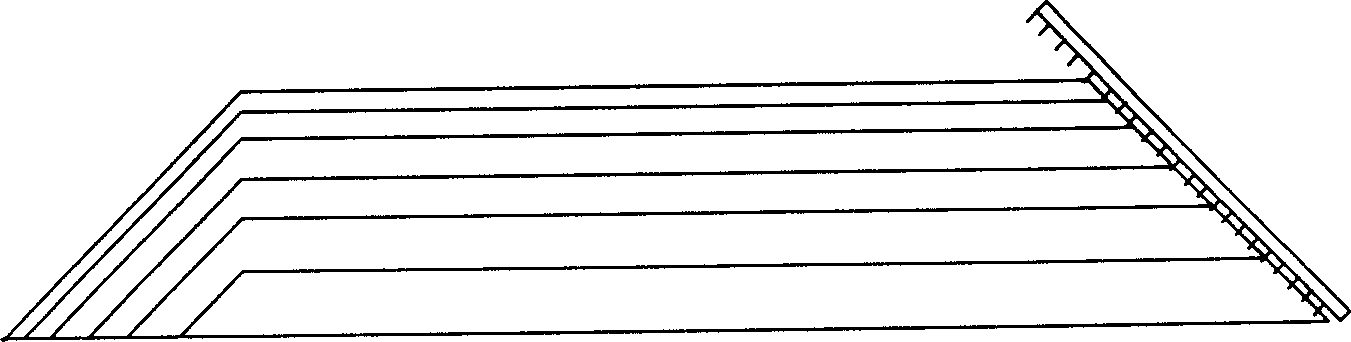

[0057] According to the above theoretical analysis and calculation, PLC mainly calculates the offset ΔL m and end stack residence time T m To control the walking mechanism. In order to meet the control requirements, first set up sensing elements at both ends of the pile, and program parameters such as standard pile height, material bulk density, standard half-bottom width of the pile, and stacker walking speed into the PLC program, and use the number of stacked layers as a variable , the number of layers is input to the PLC by the sensing element set at the end stack, and then programmed in the PLC by the formula

[0058] ΔL=B m -B m-2 ,

[0059] Δ T m = [ π 6 ( B m 2 H m - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com