Device and method for continuously preparing biodiesel

A technology of biodiesel and oil, applied in the direction of chemical methods for reacting liquids, biofuels, chemical instruments and methods, etc., can solve problems such as low reaction efficiency, enlarged contact interface, complex system, etc., and achieve simple process, Ease of mass production and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

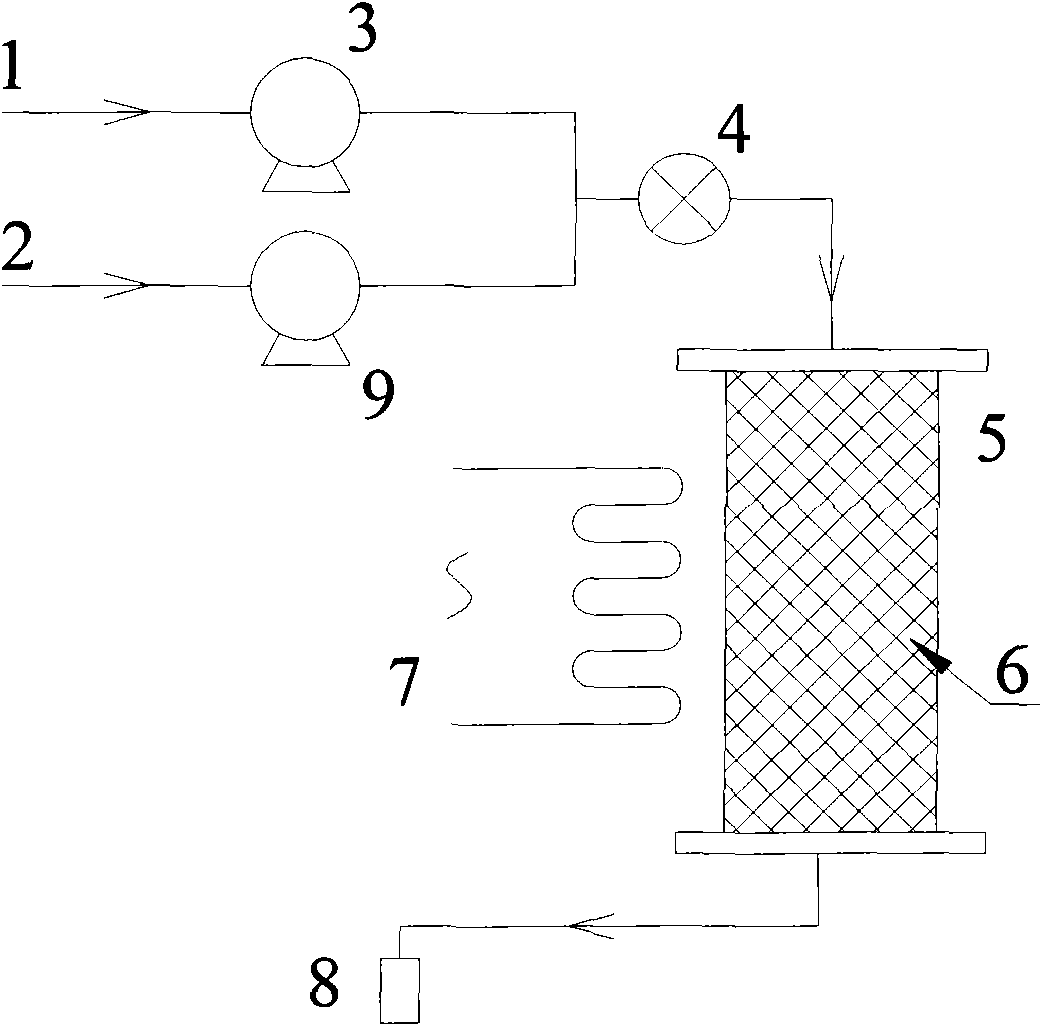

Embodiment 1

[0033] 13g NaOH was dissolved in 287.5g methanol to form a homogeneous mixture. The mixed solution and soybean oil were mixed in 20ml·min -1 and 80ml·min -1 The flow rate is continuously injected into the small passive mixer through the metering pump. The mixer has a Y-shaped inlet, a Zigzag-shaped flow channel, an equivalent diameter of 1.2mm, and a length of 0.5m. At this time, the molar ratio of methanol to soybean oil was 6:1, and the concentration of NaOH was 1% (calculated by the mass of soybean oil). The premixed mixed solution enters a metal foam filled reactor with an inner diameter of 20mm and a length of 0.5m. The metal foam is cylindrical, made of stainless steel, with an outer diameter of 20 mm, a length of 20 mm, a PPI (pores per inch of wire length) of 20, and a porosity of 95%. The electric heating and control device installed on the outer surface of the metal foam reactor maintained and stabilized the reaction temperature at 60°C, and the residence time of ...

Embodiment 2

[0035] 13g NaOH was dissolved in 287.5g methanol to form a homogeneous mixture. The mixed liquid and soybean oil are continuously injected into a small passive mixer through a metering pump at a flow rate of 20ml / min and 80ml / min respectively. The mixer has a Y-shaped inlet, a Zigzag-shaped flow channel, an equivalent diameter of 1.2mm, and a length of 0.5 m. At this time, the molar ratio of methanol to soybean oil was 6:1, and the concentration of NaOH was 1% (calculated by the mass of soybean oil). The premixed mixed solution enters a metal foam filled reactor with an inner diameter of 20mm and a length of 0.5m. The metal foam is cylindrical, made of stainless steel, with an outer diameter of 20 mm, a length of 20 mm, a PPI (pores per linear inch) of 30, and a porosity of 95.3%. The electric heating and control device installed on the outer surface of the metal foam reactor maintained and stabilized the reaction temperature at 60°C, and the residence time of the materials ...

Embodiment 3

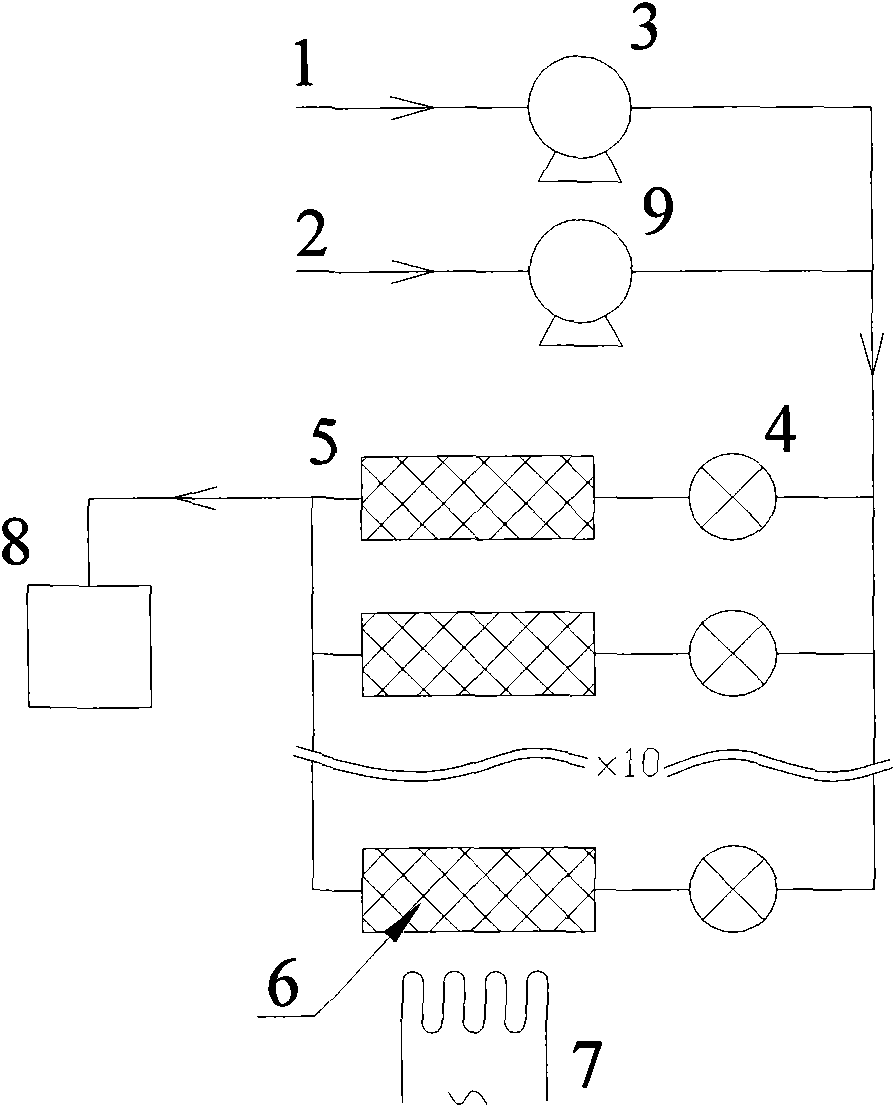

[0037] Dissolve 850g NaOH in 14375g methanol to form a homogeneous mixture. Such as figure 2 shown. Transported by the pump, the mixed liquid and soybean oil are mixed at 200ml·min -1 and 800ml·min -1 The flow of the flow is entered into 10 small passive mixers by the three-way joint for premixing. The mixer has a Y-shaped inlet, a Zigzag-shaped flow channel, an equivalent diameter of 3mm, and a length of 0.5m. At this time, the molar ratio of methanol to soybean oil was 6:1, and the concentration of NaOH was 1% (calculated by the mass of soybean oil). Then, the premixed mixed solution enters 10 metal foam-filled reactors with an inner diameter of 50 mm and a length of 1 m respectively. The metal foam is cylindrical, made of stainless steel, with an outer diameter of 20 mm, a length of 20 mm, a PPI (pores per inch of wire length) of 20, and a porosity of 95.1%. The electric heating and control device installed on the outer surface of the metal foam filled reactor maintai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com