High-alumina glass frosting liquid and preparation method thereof

A high-alumina glass and frosting liquid technology, which is applied in the field of glass surface processing, can solve the problems of unguaranteed production yield, poor stability of etching liquid, and poor etching stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] High alumina glass frosting liquid, including the following components by weight: 10kg ammonium bifluoride, 2.5kg citric acid, 1.5kg barium sulfate, 1.4kg starch, 1.6kg bentonite, 4.2kg ferric chloride, 2.9kg potassium fluoride kg, potassium nitrate 2.2kg, hydrofluoric acid 1.8kg and water 4.2kg.

[0022] Its concrete preparation method is:

[0023] Weigh each raw material according to the proportion, mix water, ammonium hydrogen fluoride, citric acid, ferric chloride, potassium fluoride, potassium nitrate, hydrofluoric acid, barium sulfate, and stir evenly, add starch and bentonite, and age after stirring evenly. The curing temperature is 35-45° C., and the aging time is more than 48 hours to obtain a high-alumina glass frosting solution.

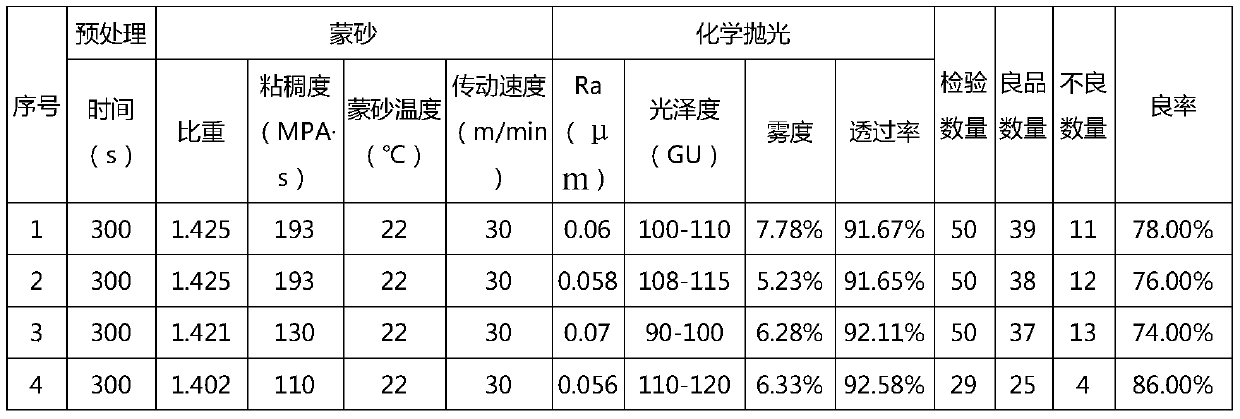

[0024] The prepared high-alumina glass frosting solution is used for anti-glare etching of high-alumina glass. The same set of frosting solution is used for anti-glare etching of high-alumina glass several times. The specific param...

Embodiment 2

[0028] High alumina glass frosting liquid, including the following components by weight: 9.5kg ammonium bifluoride, 1.6kg citric acid, 0.7kg barium sulfate, 1.3kg starch, 0.8kg bentonite, 3.2kg ferric chloride, potassium fluoride 1.6kg, potassium nitrate 2.0kg, hydrofluoric acid 0.8kg and water 3.5kg.

[0029] The preparation method is the same as in Example 1.

[0030] Weigh each raw material according to the proportion, mix water, ammonium hydrogen fluoride, citric acid, ferric chloride, potassium fluoride, potassium nitrate, hydrofluoric acid, barium sulfate, and stir evenly, add starch and bentonite, and age after stirring evenly. The curing temperature is 35-45° C., and the aging time is more than 48 hours to obtain a high-alumina glass frosting solution.

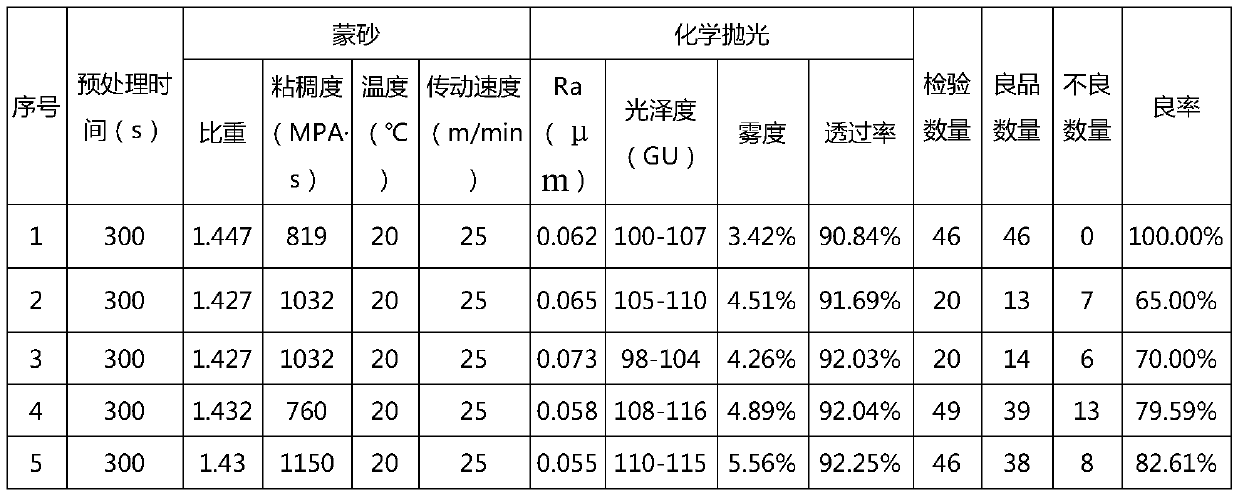

[0031] The prepared high-alumina glass frosting solution is used for anti-glare etching of high-alumina glass. The same set of frosting solution is used for anti-glare etching of high-alumina glass several times. The ...

Embodiment 3

[0035] High alumina glass frosting liquid, including the following components by weight: 13kg ammonium bifluoride, 4.2kg citric acid, 1.55kg barium sulfate, 2.8kg starch, 1.8kg bentonite, 5kg ferric chloride, 4kg potassium fluoride, Potassium nitrate 3.6kg, hydrofluoric acid 1.8kg and water 7kg.

[0036] The preparation method is the same as in Example 1.

[0037] Weigh each raw material according to the proportion, mix water, ammonium hydrogen fluoride, citric acid, ferric chloride, potassium fluoride, potassium nitrate, hydrofluoric acid, barium sulfate, and stir evenly, add starch and bentonite, and age after stirring evenly. The curing temperature is 35-45° C., and the aging time is more than 48 hours to obtain a high-alumina glass frosting solution.

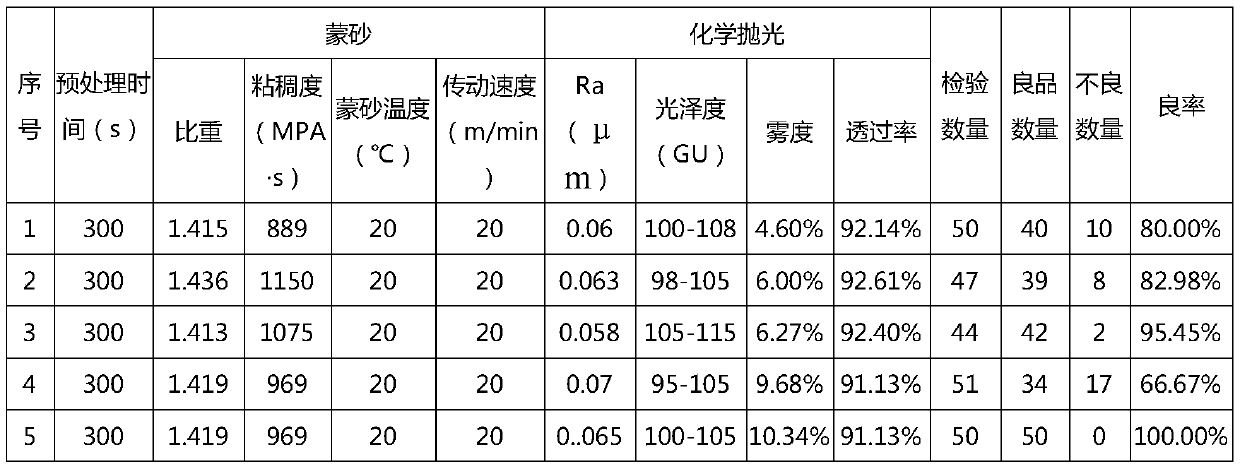

[0038] The prepared high-alumina glass frosting solution is used for anti-glare etching of high-alumina glass. The same set of frosting solution is used for anti-glare etching of high-alumina glass several times. The specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com