Reactor for producing tetrachloroethylene

A technology of tetrachlorethylene and reactors, which is applied in the field of reactors, can solve problems such as troublesome installation and maintenance, poor mixing effect, and easy falling off of refractory bricks, and achieve the effects of low maintenance frequency, simple and quick heating, and long residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the embodiments of the accompanying drawings.

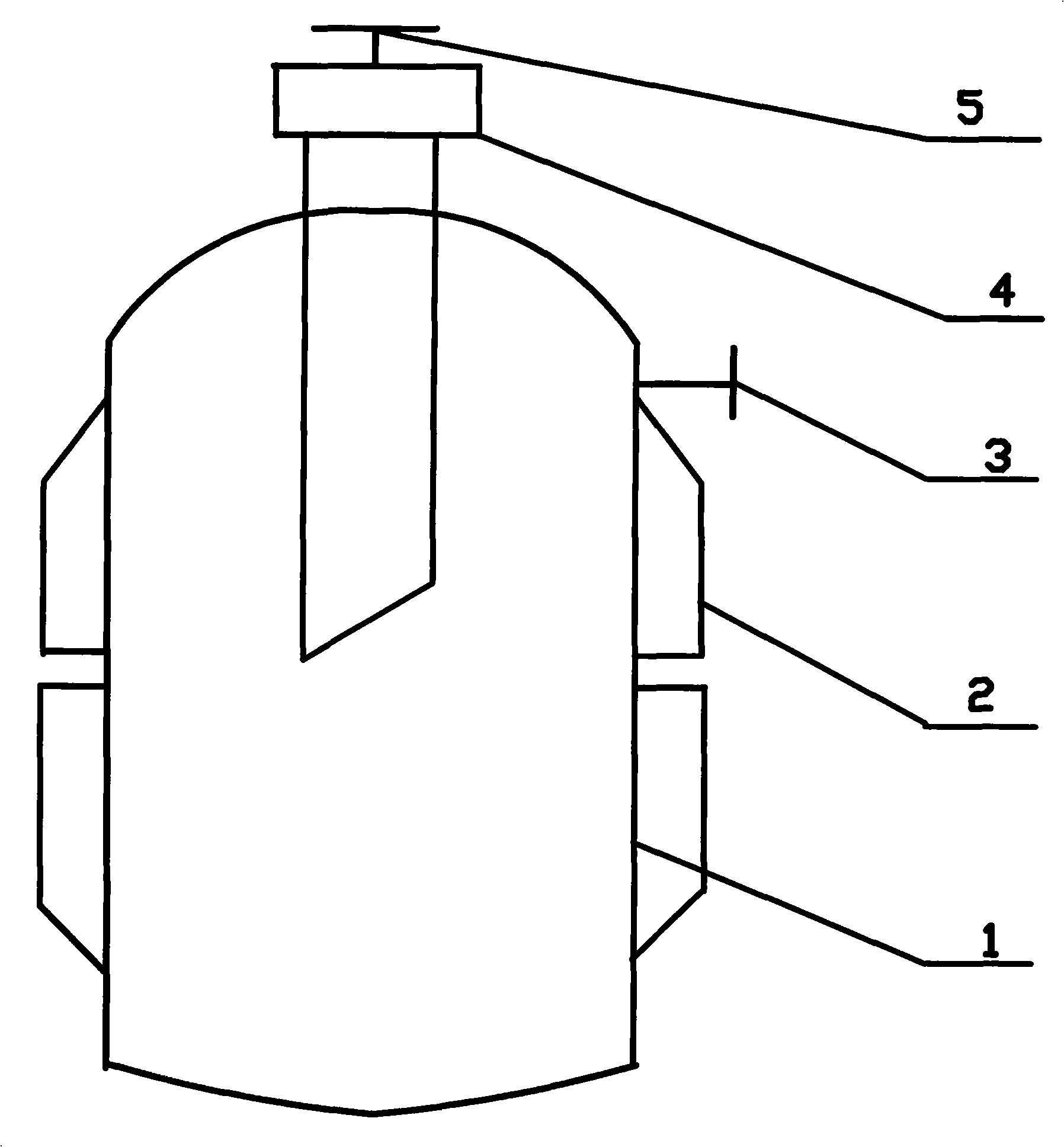

[0026] A reactor for the production of tetrachlorethylene as shown in the figure includes 1. a reactor body, 2. an electric heater, 3. a discharge port, 4. a mixer, and 5. a feed port.

[0027] After the temperature of the reactor is raised to the temperature required by the reaction through the electric heater 2, the raw materials are mixed through the feed port 5 to the mixer 4, and then enter the reactor 1 for reaction, and the reacted material is discharged from the feed port 3 for reaction. device.

[0028] Two examples of using this device to produce tetrachlorethylene:

[0029] example 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com