Double-ended tuning fork scanning probe probe system and its measurement method

A double-ended tuning fork and measurement method technology, applied in the field of micro-nano probes, can solve problems such as being unsuitable for measurement, and achieve the effects of avoiding energy leakage, large piezoelectric constant, and small energy coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

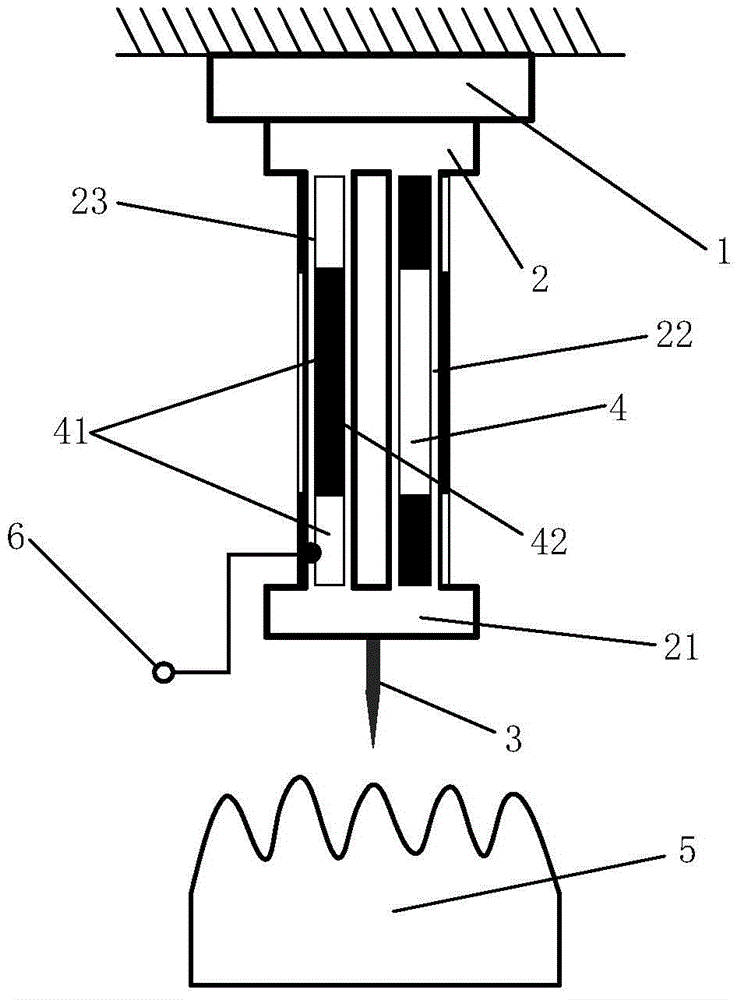

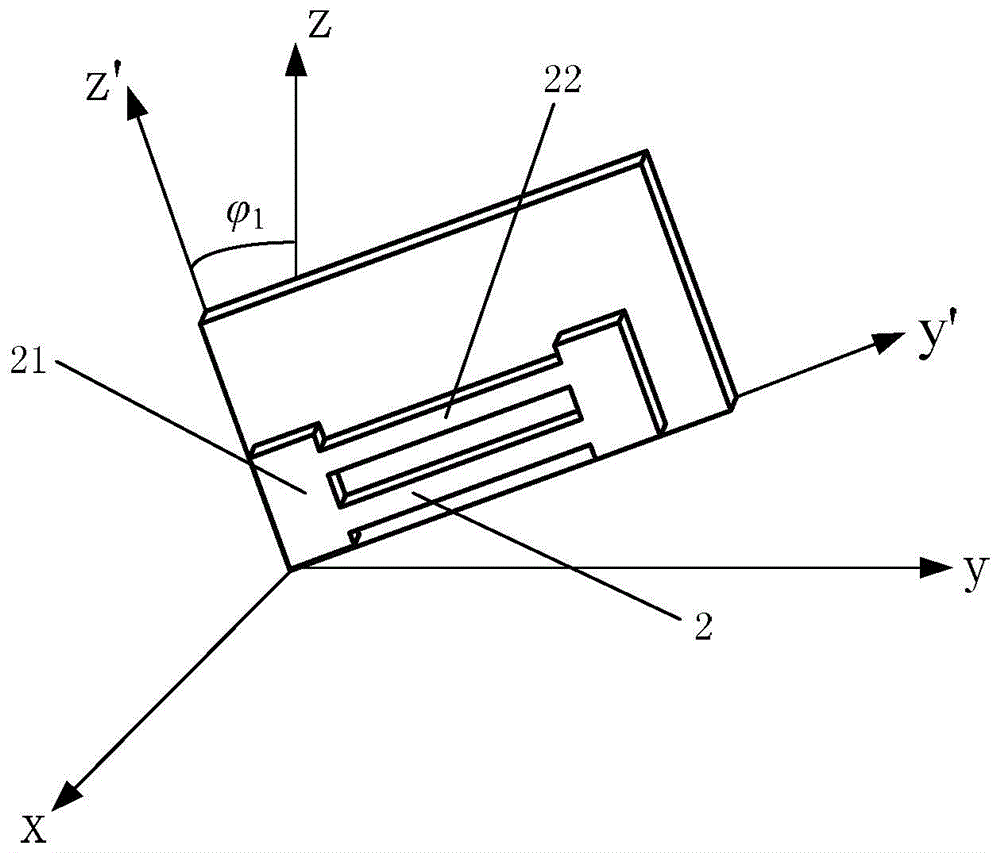

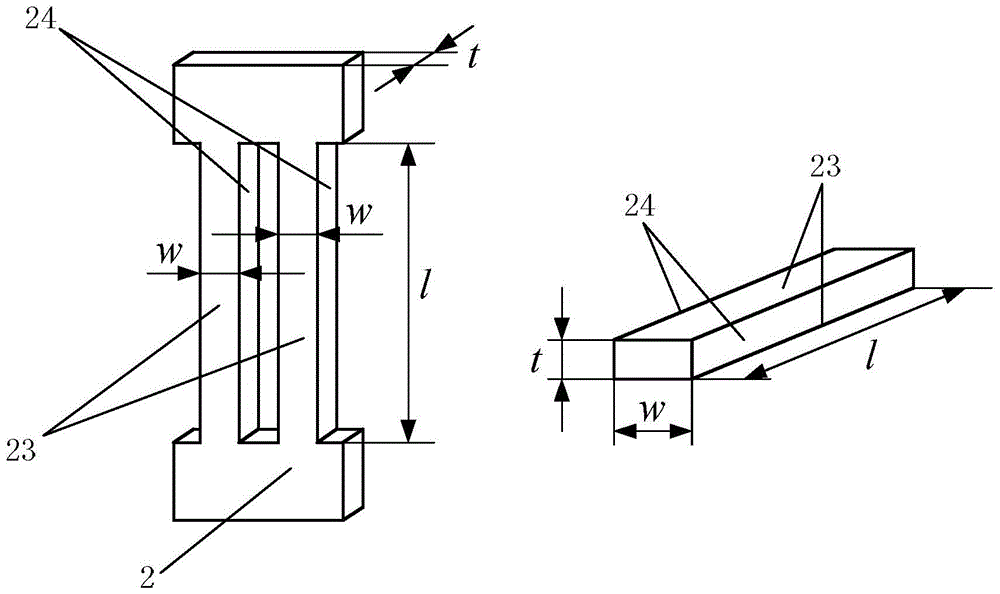

[0032] Such as figure 1 As shown, the double-ended tuning fork scanning probe probe system includes a rigid support 1 and a double-ended tuning fork 2. The double-ended tuning fork 2 is composed of two fork ends 21 and a pair of fork arms connecting the two fork ends. The double-ended tuning fork 2 One fork end 21 is connected to the bottom surface of the rigid support 1, and the other fork end 21 is a free end; the two fork arms 22 in the center of the fork arm are respectively perpendicular to the bottom surface of the rigid support 1 and arranged in parallel vertically; the free end of the double-ended tuning fork 1 is below the A tungsten probe 3 is fixed in the middle of the bottom surface.

[0033] Electrodes 4 are arranged around the pair of fork arms of the double-ended tuning fork 2 , and the double-ended tuning fork 1 is excited to resonate through the electrodes 4 .

[0034] The vibration mode of the double-ended tuning fork 2 is that under the excitation of the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com