A precision measuring device for flatness of tiny parts

A technology for precision measurement and tiny parts, which is applied in the field of precision measurement, can solve problems such as the inability to meet the precision measurement of the flatness of tiny parts, and achieve the effects of simple structure, improved measurement accuracy, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below through specific examples.

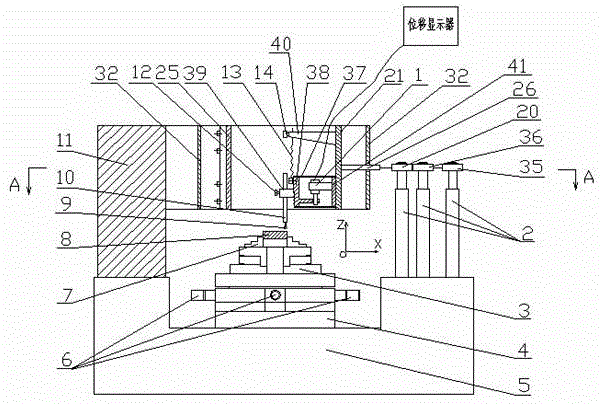

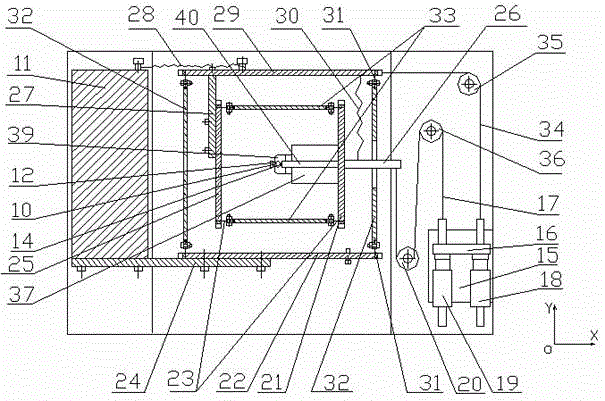

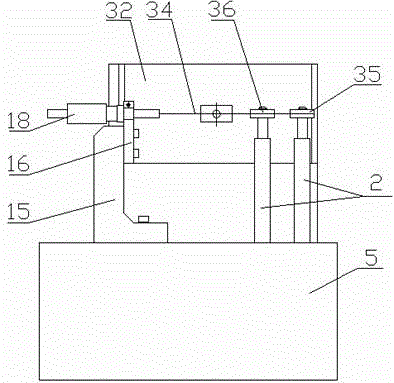

[0027] see Figure 1 to Figure 6 , it can be seen from the figure that the part to be tested is the base 5 of the device, and a four-degree-of-freedom adjustment platform 4 and a chuck 3 are installed on the base 5, and the workpiece 8 to be tested can be clamped by the jaws 7 of the chuck The position adjustment of the measured workpiece 8 can be accurately realized by adjusting the screw 6. The column 11 is placed on the base 5, and the guide mechanism is installed on the column 11. The guide mechanism is composed of two groups of flexible mechanisms, and the measuring needle is realized through the flexible mechanism. 9 Measuring action on the workpiece 8 to be measured, the measured displacement variation of the stylus 9 is measured by the displacement sensor 1 and displayed by the displacement display, and the measuring force of the stylus 9 on the workpiece 8 to be measured can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com