Abnormal piezoelectric anisotropy lead-free piezoelectric ceramic and texturing preparation method thereof

An anisotropic, lead-free piezoelectric technology, applied in the field of piezoelectric ceramic materials, can solve the problems of long cycle, high cost, unfavorable industrialization and application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Preparation composition is: (Bi 1 / 2 Na 1 / 2 )TiO 3 +0.5%Nb 2 o 5 +0.1%CeO 2

[0019] The preparation method is:

[0020] To analyze pure Bi 2 o 3 、Na 2 CO 3 , Nb 2 o 5 , CeO 2 and TiO 2 As a raw material, according to the chemical formula:

[0021] (Bi 1 / 2 Na 1 / 2 )TiO 3 +0.5%Nb 2 o 5 +0.1%CeO 2

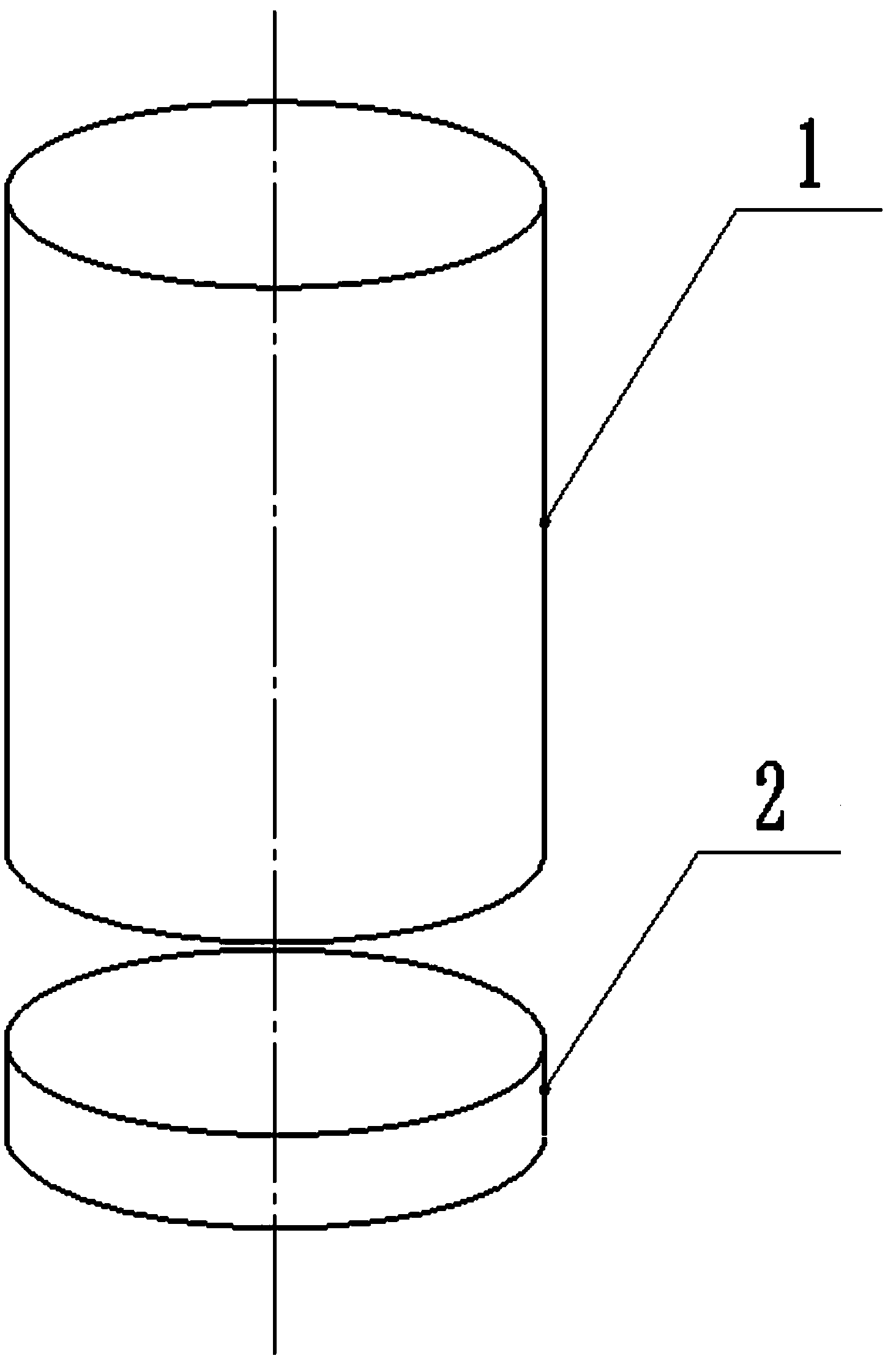

[0022] Proceed to the ingredients. Use absolute ethanol as the medium, ball mill for 24 hours, and after drying, keep warm at 850°C for 2 hours in a zirconium crucible to synthesize the main crystal phase. The synthesized powder was pulverized, and 8% PVA was added and ball-milled for 12 hours for a second time with absolute ethanol as the medium. After drying, it is pressed under a pressure of 500 MPa to form a cylinder 1 with a diameter of 12 mm and a height of 15 mm.

[0023] The cylinder 1 is kept at 700° C. for 2 hours, and then kept at 1150° C. for 2 hours to sinter the cylinder ceramics. The sintered cylindrical ceramics are cut into thin discs ...

Embodiment 2

[0025] Preparation composition is: (Bi 1 / 2 Na 1 / 2 )TiO 3 +0.8%Nb 2 o 5 +0.5%CeO 2

[0026] The preparation process is the same as in Example 1, except that the molding pressure is 400 MPa, the diameter of the cylinder 1 is 10 mm, and the height is 15 mm.

Embodiment 3

[0028] Preparation composition is: (Bi 1 / 2 Na 1 / 2 )TiO 3 +0.2%Nb 2 o 5 +0.8%CeO 2

[0029] The preparation process is the same as in Example 1, except that the molding pressure is 450 MPa, the diameter of the cylinder 1 is 10 mm, and the height is 18 mm.

[0030] The performance measurement results are shown in Table 1. For comparison, the performance of the non-textured thin wafer samples prepared by the traditional method is also listed in the table.

[0031] Table 1 Properties of textured samples cut by high-pressure cylinder and non-textured samples prepared by traditional preparation methods

[0032] Preparation d 33 (pC / N) k t k p k t / k p High-pressure cylinder cut sample (Example 1) 125 0.65 0.08 8.1 High-pressure cylinder cut sample (Example 2) 112 0.58 0.09 6.4 High-pressure cylinder cut sample (Example 3) 120 0.63 0.08 7.9 Non-textured samples 76 0.46 0.12 3.8

[0033] Through the exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com