Piezoelectric thin-film sensor with vinylidene difluoride and production thereof

A polyvinylidene fluoride piezoelectric and thin-film sensor technology, which is applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric devices/electrostrictive devices, etc., can solve the problem that the stretching ratio cannot achieve high crystal transformation Problems such as orderly orientation, piezoelectric film sensor preparation and production are not good, and polymer piezoelectric film cannot be processed continuously, so as to achieve the effects of easy operation and control, increased capacitance, and increased piezoelectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

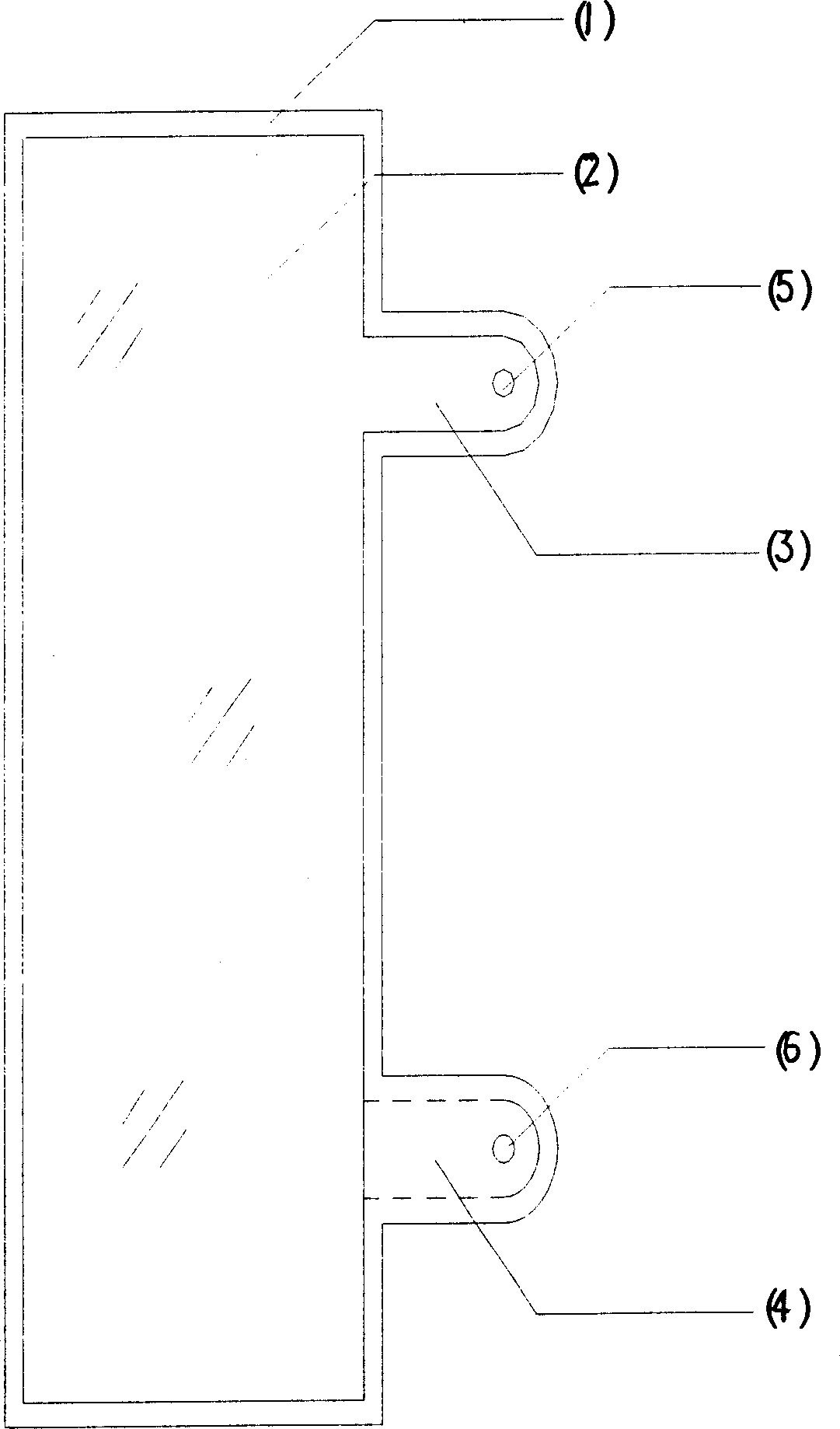

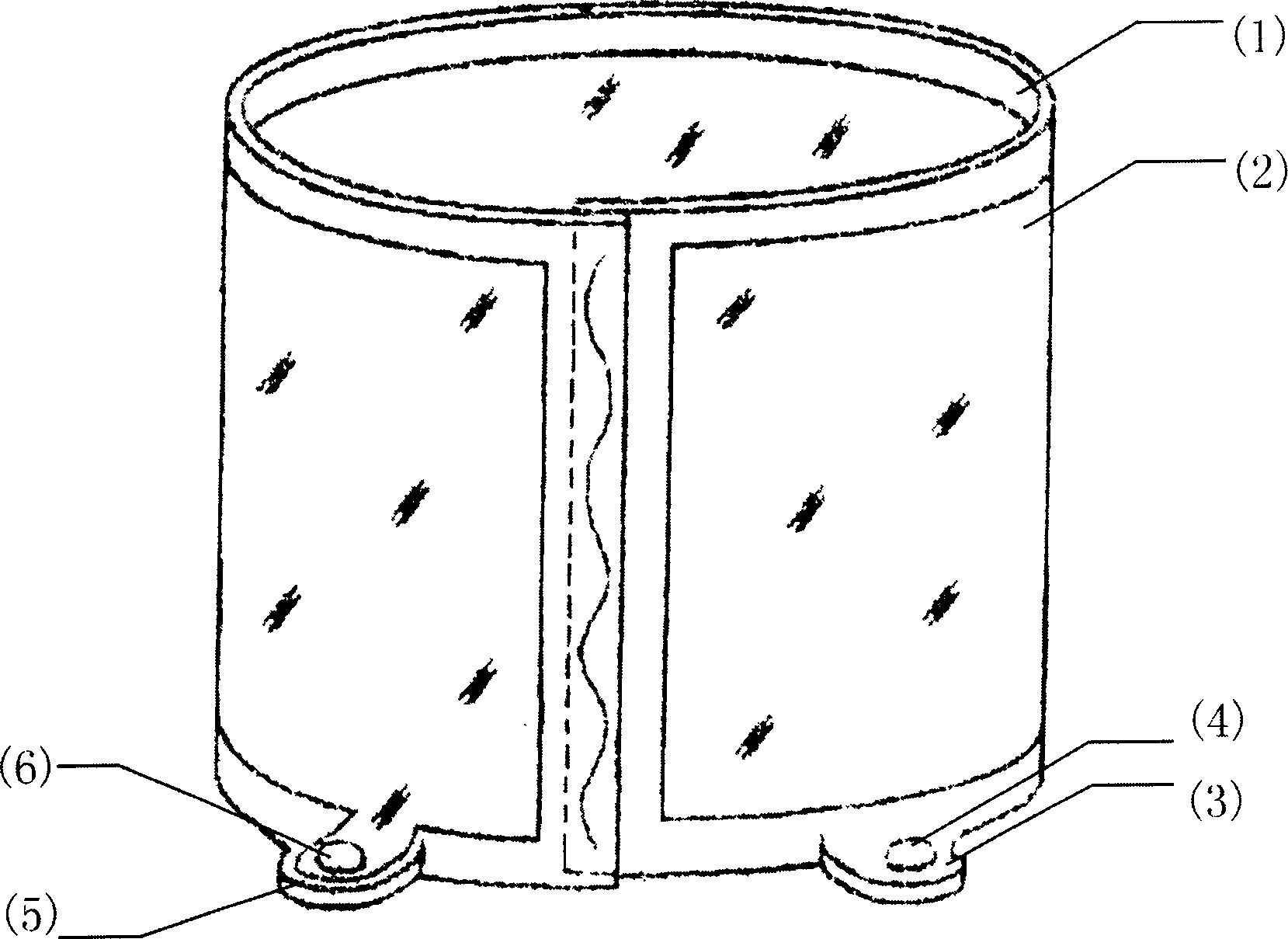

[0010] Example 1: The granular resin was extruded into a film at a die temperature of 240°C, stretched 4.5 times at 70°C and a field of 40MV / m, and then stretched at 1×10 -3 Aluminium and silver are plated by molds under Pa vacuum, first the aluminum electrode is 55nm, then the silver electrode is 16nm, and finally the electrode is drawn. The shape of the resulting sensor is 38.8 mm in circumference. A cylindrical shape with a height of 12.0mm, the distance between the two electrodes is 21.6mm, the thickness of the sensor is 49.5μm, the capacitance is 1080pF, and the piezoelectric constant d 33 It is 11pC / N. The performance of applying this sensor to the electronic whiteboard is stable and good.

Embodiment 2

[0011] Example 2: The granular resin is extruded into a film at a die temperature of 240°C, stretched 4.5 times at 75°C and a voltage of 50MV / m, and then stretched at 2.5×10 -3 Under Pa vacuum degree, use mold to plate aluminum and silver. First, the aluminum-plated electrode is 40nm, then the silver-plated electrode is 25nm, and finally the electrode is drawn. The shape of the resulting sensor is 38.8 mm in circumference. A cylinder with a height of 12.0mm, the distance between the two electrodes is 21.6mm, the thickness of the sensor is 45μm, the capacitance is 1120pF, and the piezoelectric constant d 33 It is 15pC / N. The performance of applying this sensor to the electronic whiteboard is stable and good.

Embodiment 3

[0012] Example 3: The granular resin is extruded into a film at a die temperature of 240°C, stretched 4.5 times at 82°C and an electric field of 58MV / m, and then at 3.8×10 -3 Under Pa vacuum degree, use mold to plate aluminum and silver, first silver-plated electrode is 30nm, then aluminum-plated electrode is 40nm, and finally lead electrode. The shape of the resulting sensor is 38.8 mm in circumference. A cylinder with a height of 12.0mm, the distance between the two electrodes is 21.6mm, the thickness of the sensor is 40μm, the capacitance is 1180pF, and the piezoelectric constant d 33 It is 18pC / N. The performance of applying this sensor to the electronic whiteboard is stable and good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com