PZT-based piezoelectric ceramic and preparation method thereof

A technology of electric ceramics and base pressure, which is applied in the field of PZT-based piezoelectric ceramics and its preparation, can solve the problems of long heating and cooling time, difficult industrial production, expensive mold cost, etc., so as to reduce the sintering temperature, reduce volatilization, reduce human body and Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

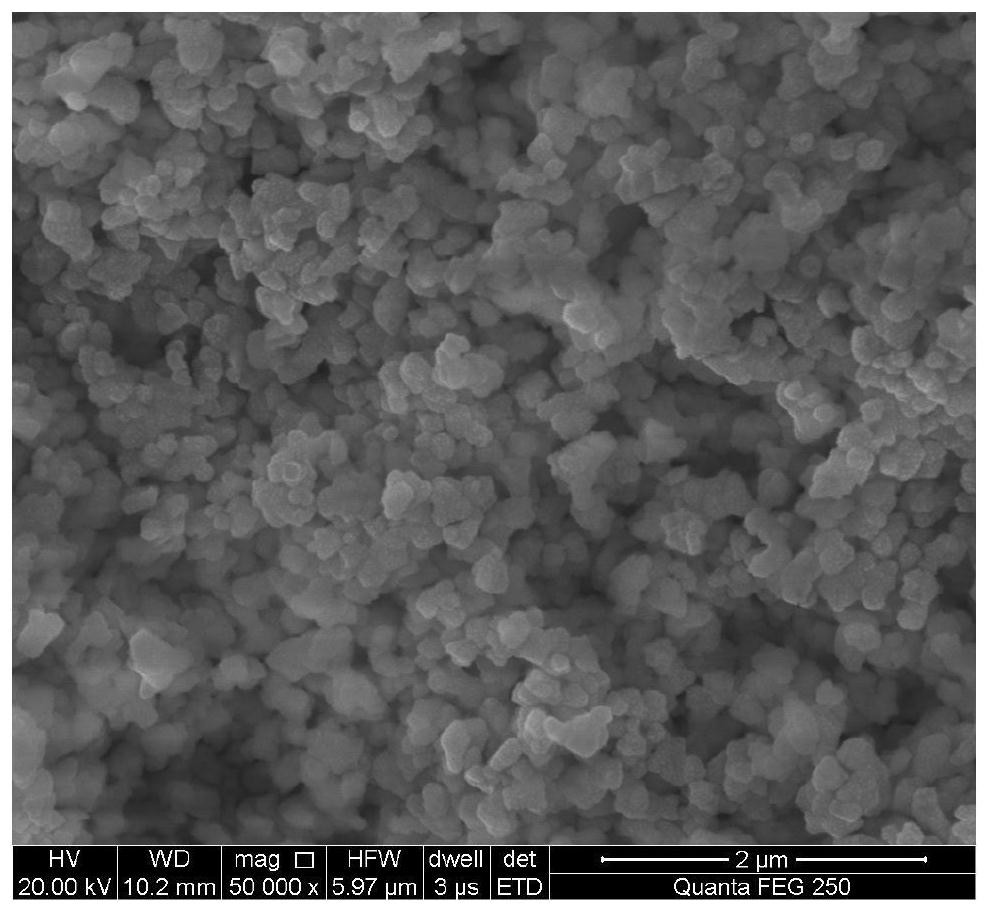

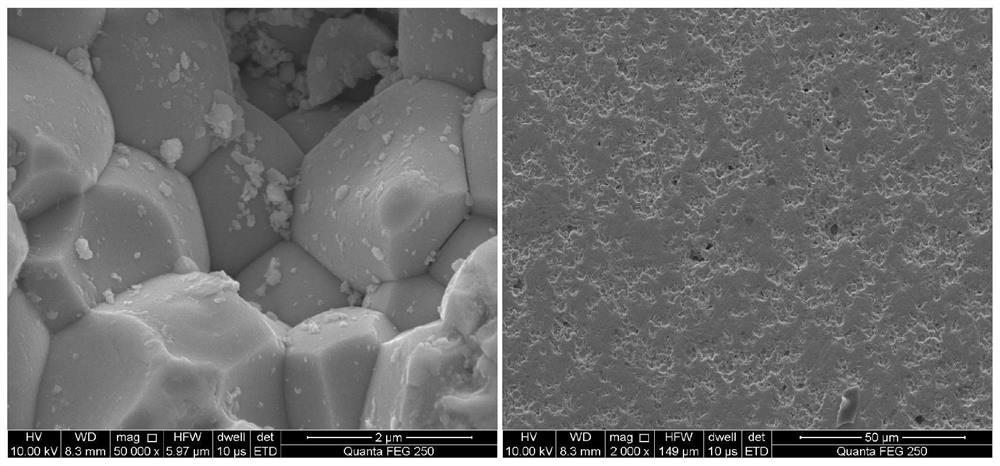

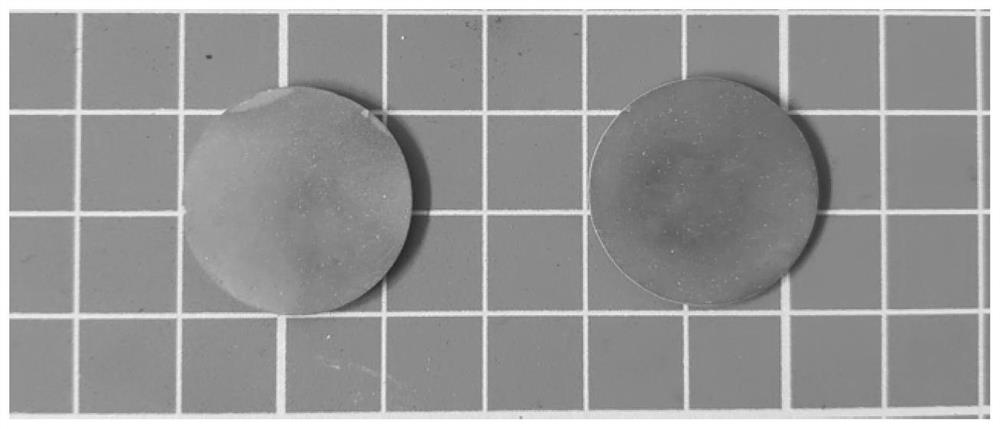

[0047] A preparation method of lead zirconate titanate (PZT) based piezoelectric ceramics, the process is as follows:

[0048] A. Formulation design: 99%Pb(Zr 0.52 Ti 0.48 )O 3 +1%CaO (wt%), weigh the corresponding raw materials according to the formula according to the stoichiometric ratio;

[0049] B. Primary ball milling: Put the weighed chemical raw materials in a ball milling jar, use zirconia balls as the ball milling body, and ethanol as the ball milling medium, and use a ball mill to perform primary grinding. Among them, the mass ratio of balls, materials and ethanol is 2:1:1, the speed of ball milling is 600r / min, and the ball milling time is 12h;

[0050] C. Drying & sieving: put the ball-milled powder in a drying oven at 80°C for 12 hours, and then pass through an 80-mesh sieve;

[0051] D. Microwave synthesis: put the sieved powder into a corundum crucible, and radiate and synthesize it into a pre-fired powder in a microwave oven. The frequency is 500MHz, the s...

Embodiment 2

[0059] A preparation method of lead zirconate titanate (PZT) based piezoelectric ceramics, the process is as follows:

[0060] A. Formulation design: 99%Pb(Zr 0.52 Ti 0.48 )O 3 +1%BaO (wt%), weigh the corresponding raw materials according to the formula according to the stoichiometric ratio;

[0061] B. Primary ball milling: Place the weighed chemical raw materials in a ball milling jar, use zirconia balls as the ball milling body, and ethanol as the ball milling medium, and use a ball mill to perform primary grinding. Among them, the mass ratio of balls, materials and ethanol is 2:1:1, the speed of ball milling is 600r / min, and the ball milling time is 16h;

[0062] C. Drying & sieving: put the ball-milled powder in a drying oven at 90°C for 8 hours, and then pass it through a 80-mesh sieve;

[0063] D. Microwave synthesis: put the sieved powder into a corundum crucible, and radiate and synthesize it into a pre-fired powder in a microwave oven. The frequency is 500MHz, th...

Embodiment 3

[0071]A preparation method of lead zirconate titanate (PZT) based piezoelectric ceramics, the process is as follows:

[0072] A. Formulation design: 98.5% Pb(Zr 0.52 Ti 0.48 )O 3 +1%SrO+0.5%BaO (wt%), weigh the corresponding raw materials according to the formula according to the stoichiometric ratio;

[0073] B. Primary ball milling: Place the weighed chemical raw materials in a ball milling jar, use zirconia balls as the ball milling body, and ethanol as the ball milling medium, and use a ball mill to perform primary grinding. Among them, the mass ratio of balls, materials, and ethanol is 2:1:1, the speed of ball milling is 600r / min, and the ball milling time is 16h;

[0074] C. Drying & sieving: put the ball-milled powder in a drying oven at 90°C for 8 hours, and then pass it through a 80-mesh sieve;

[0075] D. Microwave synthesis: put the sieved powder into a corundum crucible, and radiate and synthesize it into a pre-fired powder in a microwave oven. The frequency is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Piezoelectric constant | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com