Composite piezoelectric film and preparation method and application thereof

A piezoelectric film, piezoelectric technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, material selection for piezoelectric devices or electrostrictive devices Etc., can solve problems such as poor impact resistance, and achieve high yield, good environmental benefits, and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The present embodiment carries out the preparation of PVDF nanofiber membrane, comprises the following steps:

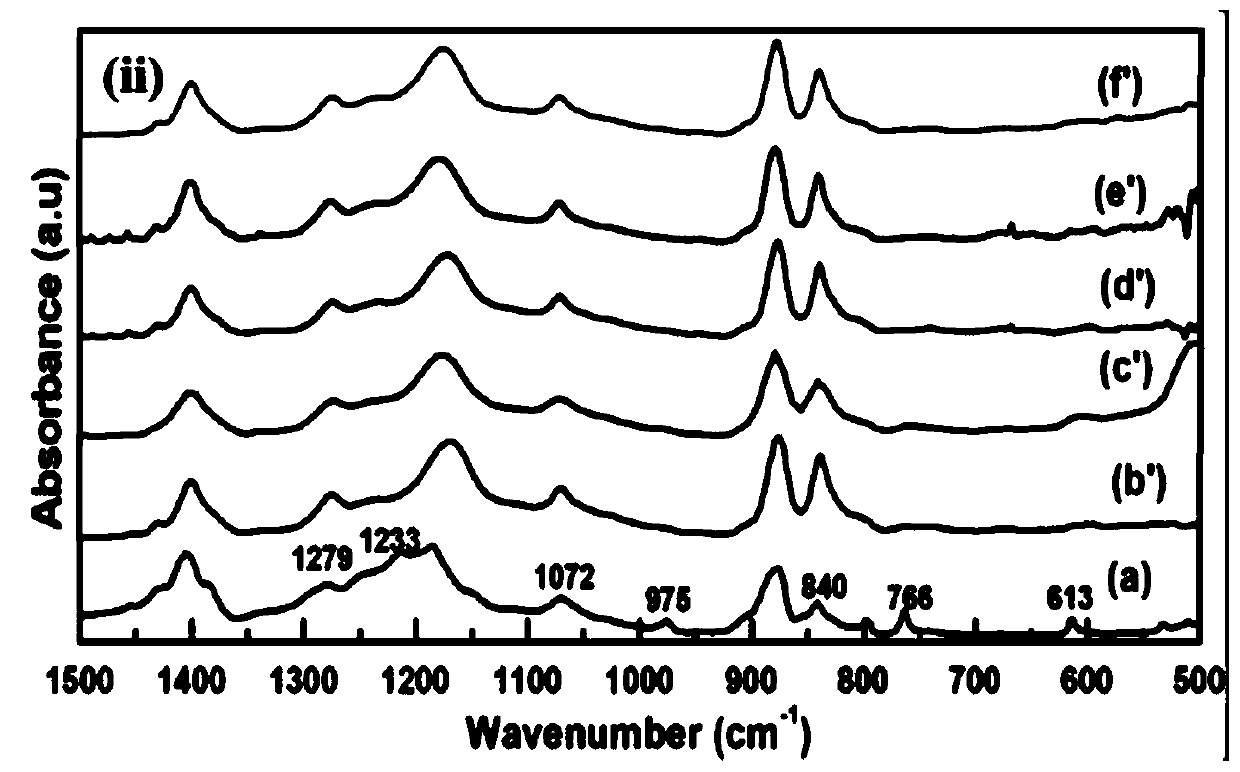

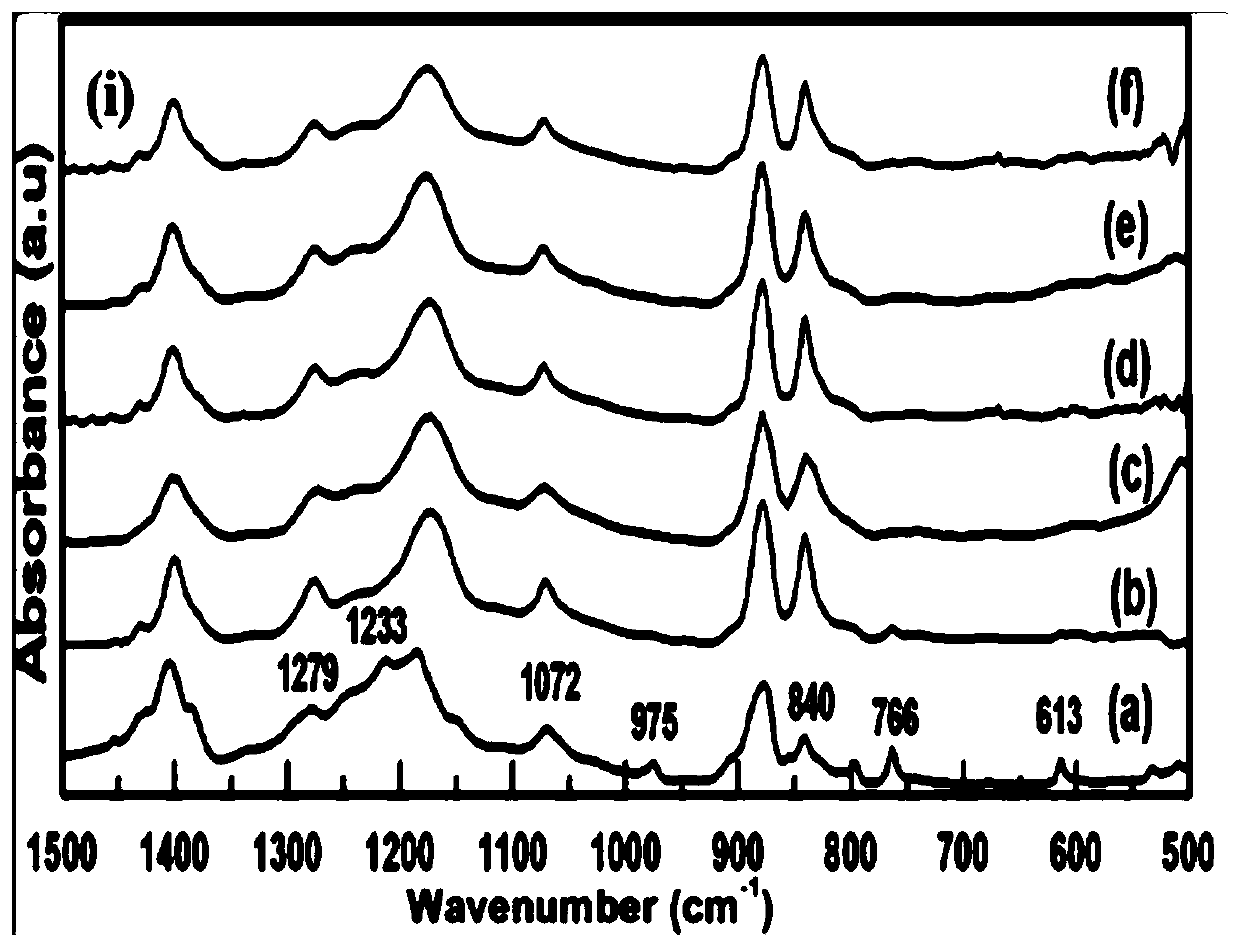

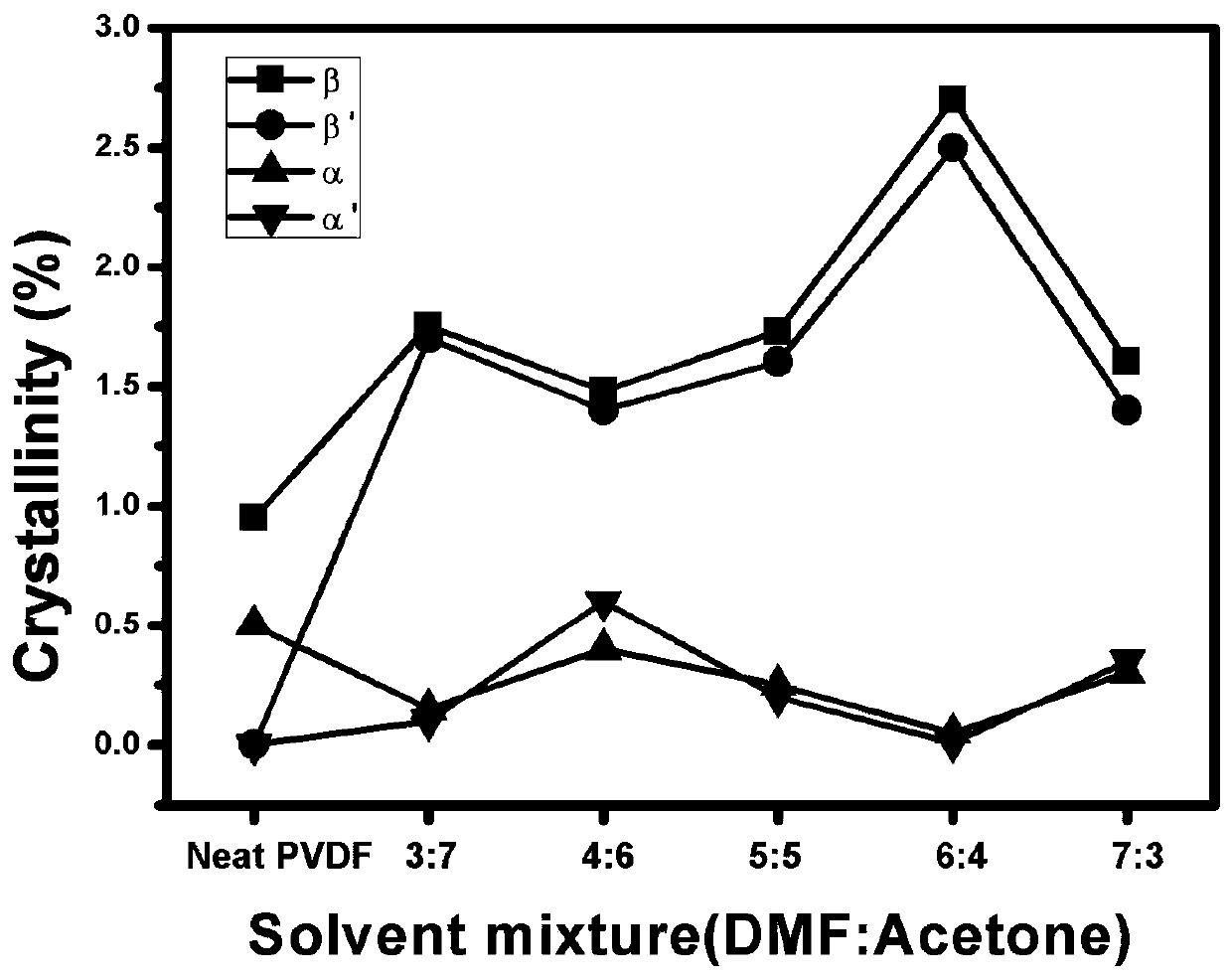

[0059] 1) Put the PVDF powder in a 50°C drying oven and bake it at a constant temperature for 3 hours; mix acetone and DMF solution, and then add PVDF powder to the DMF / acetone solvent under stirring at 40°C until a 16wt% transparent and homogeneous PVDF solution is obtained . Wherein, the volume ratio of DMF and acetone in the solvent is 3:7, 4:6, 5:5, 6:4 and 7:3 in sequence.

[0060] Pour the homogeneous PVDF solution into a 20mL syringe, and perform electrospinning on the electrospinning instrument, the DC voltage of the electrospinning is 15kV, the distance between the needle of the electrospinning and the collector is 10cm, The temperature is 25°C, the humidity of electrospinning is 30%, the flow rate of polymer solution for electrospinning is 1.0mL / h, and 20mm deep deionized water is placed or not placed in the receiving container, so that the electros...

Embodiment 2

[0063] This embodiment carries out the preparation of composite piezoelectric film, comprises the following steps:

[0064] 1) Pretreatment of inorganic piezoelectric powder

[0065] The barium titanate powder with a particle size of 500nm was immersed in 95wt% ethanol solution, stirred ultrasonically for 30min, and then dried at 300°C. Repeat the above steps 5 times to ensure the depolarization of the barium titanate powder (BT) and effectively remove the impurities in the barium titanate powder. The scanning electron microscope image of the obtained inorganic piezoelectric powder barium titanate is as follows Figure 4 shown.

[0066] 2) Configuration of precursor solution

[0067] Dissolve polyvinylidene fluoride (PVDF) powder in a mixed solvent of N,N-dimethylformamide (DMF) and acetone (the volume ratio of DMF / acetone is 6:4, and stir at a temperature of 60°C for 6h , and subjected to 30min ultrasonic treatment to obtain a 16wt% transparent and homogeneous PVDF solutio...

Embodiment 3

[0071] In this embodiment, a composite piezoelectric film is prepared, and the steps are the same as those in Embodiment 1, except that the mass of barium titanate powder is 1% of that of the PVDF solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com