Preparation method of preferred orientation BaTiO3/SrTiO3 nano composite ceramic

A nano-composite and oriented technology, applied in chemical instruments and methods, titanium compounds, inorganic chemistry, etc., can solve the problems of low cost, long cycle, low degree of ceramic anisotropy, etc., and achieve significant economic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Preparation of HT crystals

[0036] Use an electronic balance to accurately weigh 6.9 g of nanometer titanium dioxide, 5.1 g of potassium hydroxide, and 0.6 g of lithium hydroxide, measure 25 mL of distilled water in a 50 mL reactor, and react in a homogeneous reactor at 250° C. for 24 hours. After the hydrothermal treatment, the sample was washed with distilled water, filtered, and dried to obtain K 0.80 Ti 1.73 Li 0.27 O 4 ·XH 2 O (KTLO) crystal. This KTLO crystal uses 500mL HNO with a concentration of 0.2mol / L 3 Stir for 24h, use H + Exchange K + And Li + . Then the sample was washed with distilled water and acidified twice to obtain the layered protonated titanate H 1.07 T 1.73 □ 0.27 O 4 ·H 2 O crystals. The obtained crystals were washed with distilled water and ethanol and dried in a drying oven at 60°C for 12 hours to obtain HT crystals.

Embodiment 2

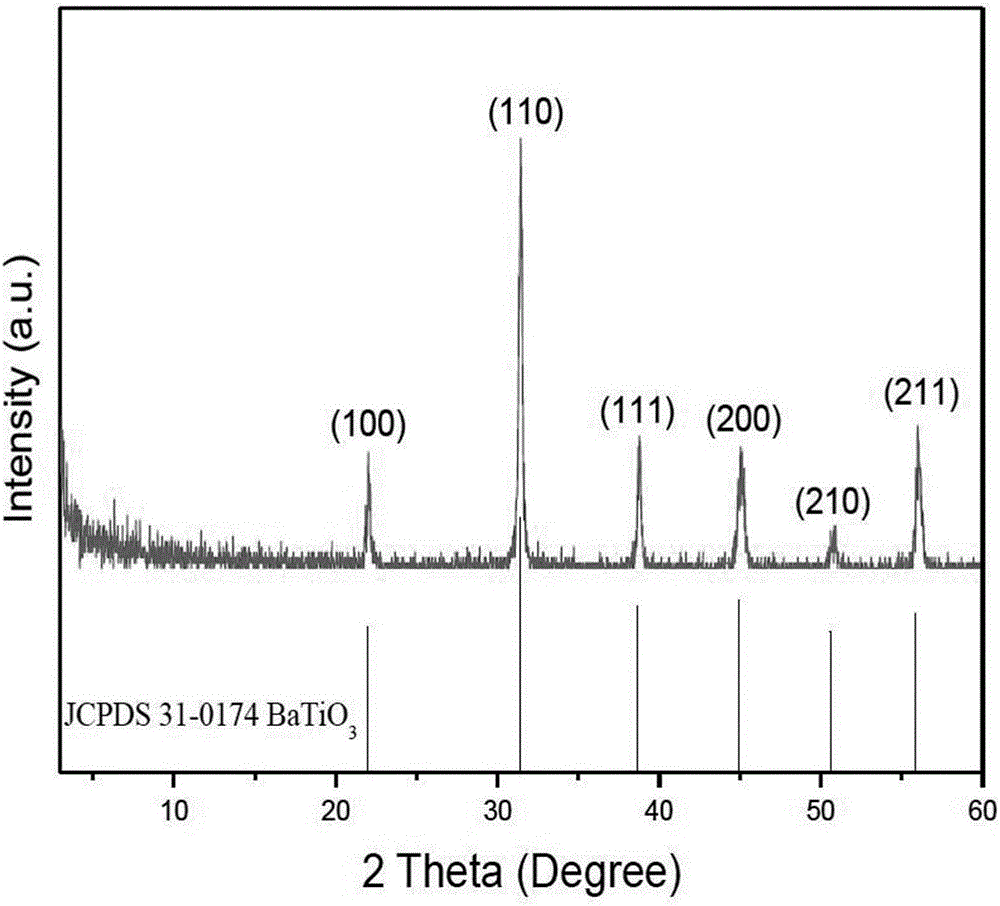

[0037] Example 2: Preparation of barium titanate powder

[0038] Accurately weigh 0.1 g of titanic acid and 0.4927 g of barium hydroxide (50% excess), measure 30 mL of distilled water and place in a 50 mL reactor, stir well, and react in a homogeneous reactor at 200° C. for 12 hours. After cooling, it is suction filtered, washed with 10 mL of a 0.1 mol / L HAc solution to remove excess barium hydroxide, washed with distilled water and absolute ethanol in turn, and dried for later use.

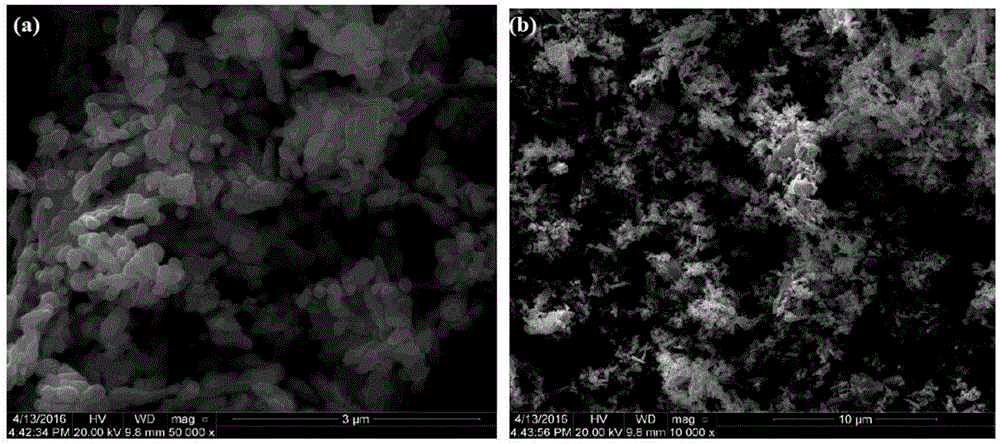

[0039] XRD and SEM were used to characterize the composition, particle size, and microstructure of barium titanate powder. Among them, Ultima IV model XRD was used for structure and crystal phase analysis, Cu Kα target, λ=0.15418nm, scanning tube voltage The tube current is 40kV, 40mA, the scanning range is 3°~60°, the scanning speed is 5° / min, the resolution of the SEM for measuring the sample morphology is 3.5nm, the maximum magnification is 300,000, and the maximum acceleration voltage is 30kV , T...

Embodiment 3

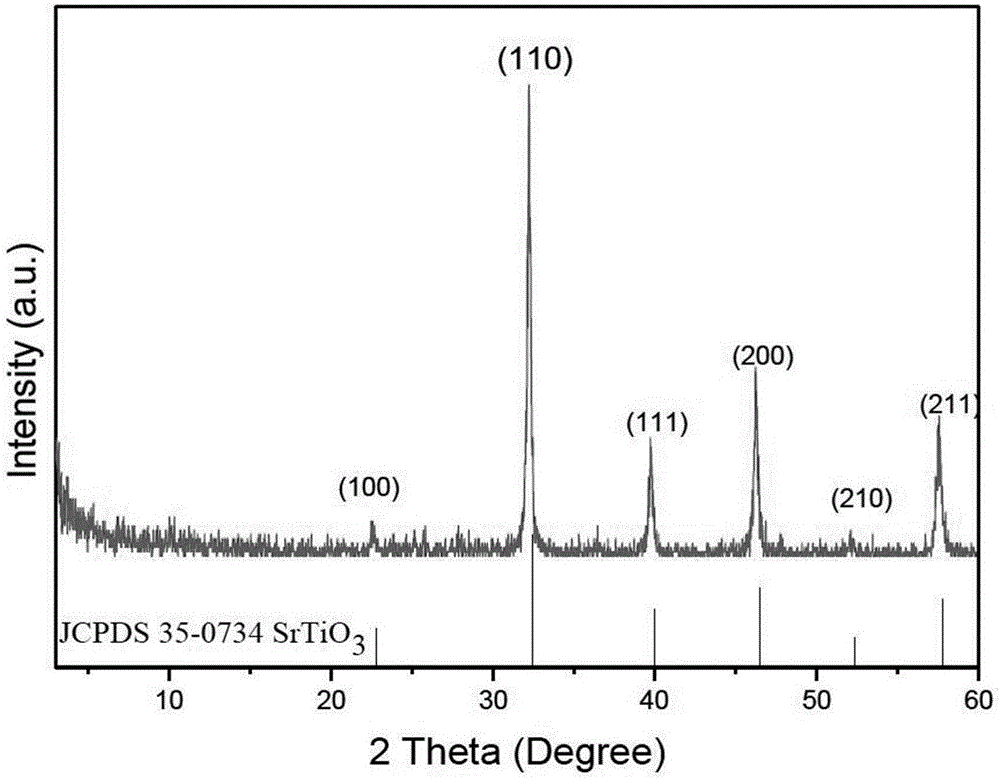

[0041] Example 3: Preparation of strontium titanate powder

[0042] When preparing strontium titanate, weigh out 0.1g titanic acid and 0.5534g strontium hydroxide (100% excess), measure 30mL distilled water and place in a 50mL reactor, stir well, and react in a homogeneous reactor at 200℃ 12h, after cooling, suction filtration, washing with 10mL of 0.1mol / L HAc solution to remove excess strontium hydroxide, washing with distilled water and absolute ethanol in turn, and drying for later use.

[0043] XRD and SEM were used to characterize the composition, particle size and microstructure of strontium titanate powder (the method is the same as in Example 2), and the results are as follows image 3 , Figure 4 Shown. image 3 What is shown is at 200℃, HT and Sr(OH) 2 ·8H 2 The XRD pattern of the ST sample obtained after 12 hours of O reaction, all diffraction peaks of the sample are consistent with the standard diffraction card of cubic phase ST. The samples are all composed of ST crys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com