Preparation method of flexible piezoelectric film

A flexible piezoelectric and thin-film technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc. Inhomogeneity, low piezoelectric constant, etc., to avoid processing difficulties, improve film quality, and improve the effect of piezoelectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

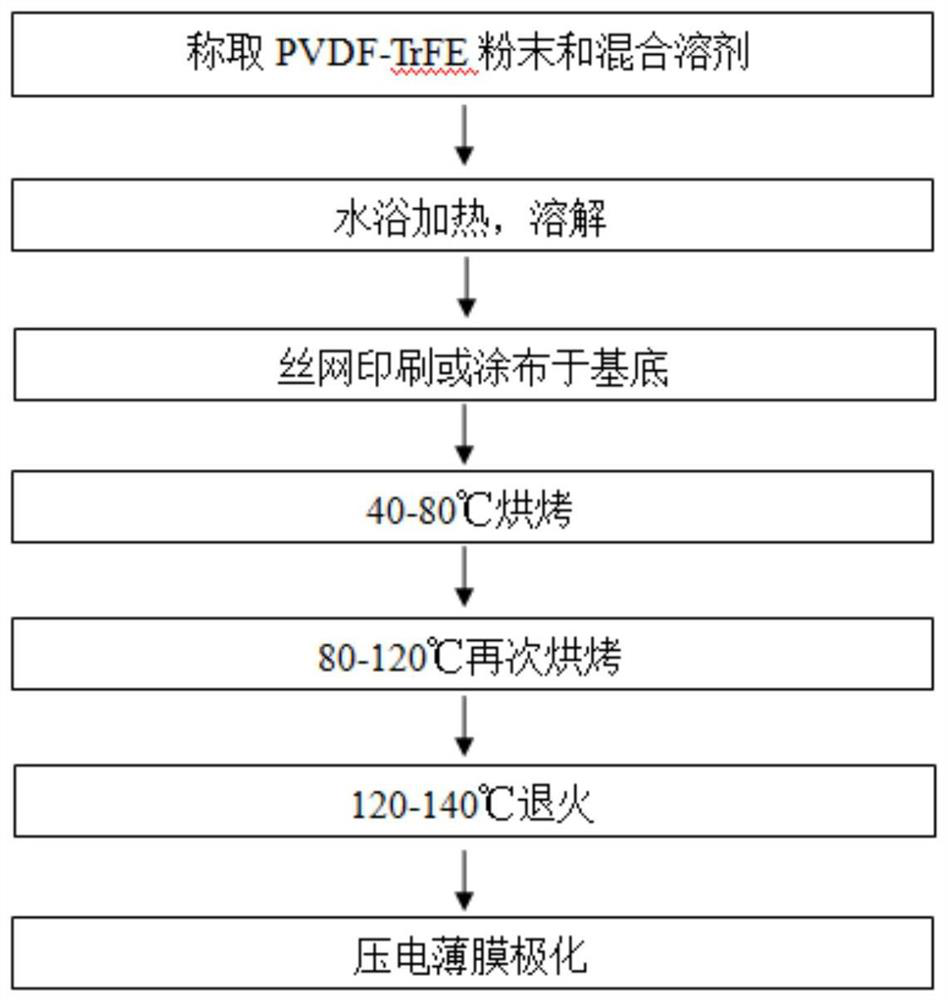

[0024] A method for preparing a flexible piezoelectric film, such as figure 2 shown, including the following steps:

[0025] S1. Weigh polyvinylidene fluoride-trifluoroethylene powder with a content of 10-25%wt;

[0026] S2. Weighing a high boiling point solvent and a low boiling point solvent and mixing them to obtain a mixed solvent, wherein the mass ratio of the high boiling point solvent to the low boiling point solvent is: (1:4)~(4:1);

[0027] S3. Dissolving the polyvinylidene fluoride-trifluoroethylene powder in the above mixed solvent, stirring in a water bath for 1-8 hours, the temperature of the water bath is 50-80°C, and the stirring speed is 200-2000 rpm to prepare a mixed solution;

[0028] S4. Apply the mixed solution above to a flexible substrate by screen printing, spin coating or coating process to form a film, first bake at 40-80°C for 20-60min, and then bake at 80-120°C for 20-60min , and finally annealed at 120-140°C for 0.5-8 hours to obtain a semi-fini...

Embodiment 1

[0032] A method for preparing a flexible piezoelectric film, comprising the steps of:

[0033] S1. Weigh polyvinylidene fluoride-trifluoroethylene (PVDF-TrFE) powder with a content of 18%wt;

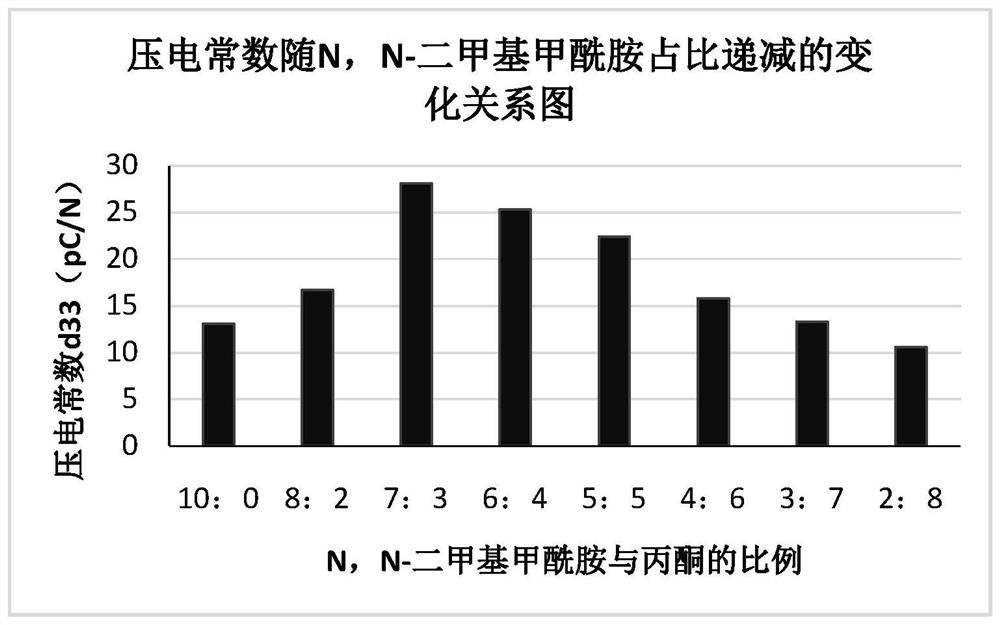

[0034] S2. Take N, N-dimethylformamide solvent and acetone solvent according to the ratio in Table 1 and mix them to prepare a mixed solvent;

[0035] S3. Dissolving polyvinylidene fluoride-trifluoroethylene (PVDF-TrFE) powder in a mixed solvent, stirring continuously, and heating in a water bath for 2 hours, the temperature of the water bath is 60° C.;

[0036] S4, bonded to the substrate by coating, first baked at 60°C for 30 minutes, then baked at 100°C for 50 minutes, and finally annealed at 130°C for 4 hours to obtain a semi-finished flexible piezoelectric film;

[0037] S5. Polarizing the annealed semi-finished flexible piezoelectric film in air at room temperature with a polarization voltage of 15 MV / cm for 20 minutes to obtain a finished flexible piezoelectric film.

[0038] Th...

Embodiment 2

[0043] A method for preparing a flexible piezoelectric film, comprising the steps of:

[0044] S1. Weigh polyvinylidene fluoride-trifluoroethylene (PVDF-TrFE) powder with a content of 15%wt;

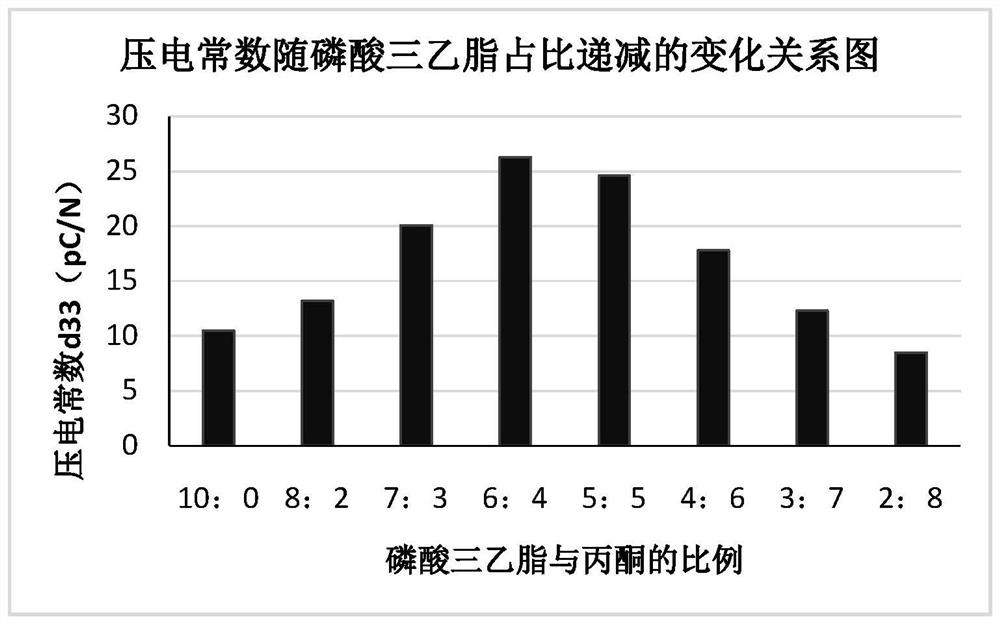

[0045] S2, take triethyl phosphate solvent and acetone solvent and mix according to the ratio in table 2, make mixed solvent;

[0046] S3. Dissolving polyvinylidene fluoride-trifluoroethylene (PVDF-TrFE) powder in the mixed solvent, stirring continuously, and heating in a water bath for 1 hour, the temperature of the water bath is 70° C.;

[0047] S4, bonded to the substrate by coating, first baked at 80°C for 60 minutes, then baked at 110°C for 60 minutes, and finally annealed at 140°C for 4 hours to obtain a semi-finished flexible piezoelectric film;

[0048] S5. Polarizing the annealed semi-finished flexible piezoelectric film in air at room temperature with a polarization voltage of 35 MV / cm for 10 minutes to obtain a finished flexible piezoelectric film.

[0049] The piezoelectric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com