Automobile AC (Alternating Current) generator, wire embedding system and wire embedding method thereof

A technology for alternators and automobiles, applied in the field of wire embedding system and wire embedding, which can solve the problems of waste of empty circles, waste, and high investment costs, and achieve the effects of high reliability mechanized production, low cost, and convenient wire embedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Refer below Figures 1 to 8 The gist of the present invention will be described in detail.

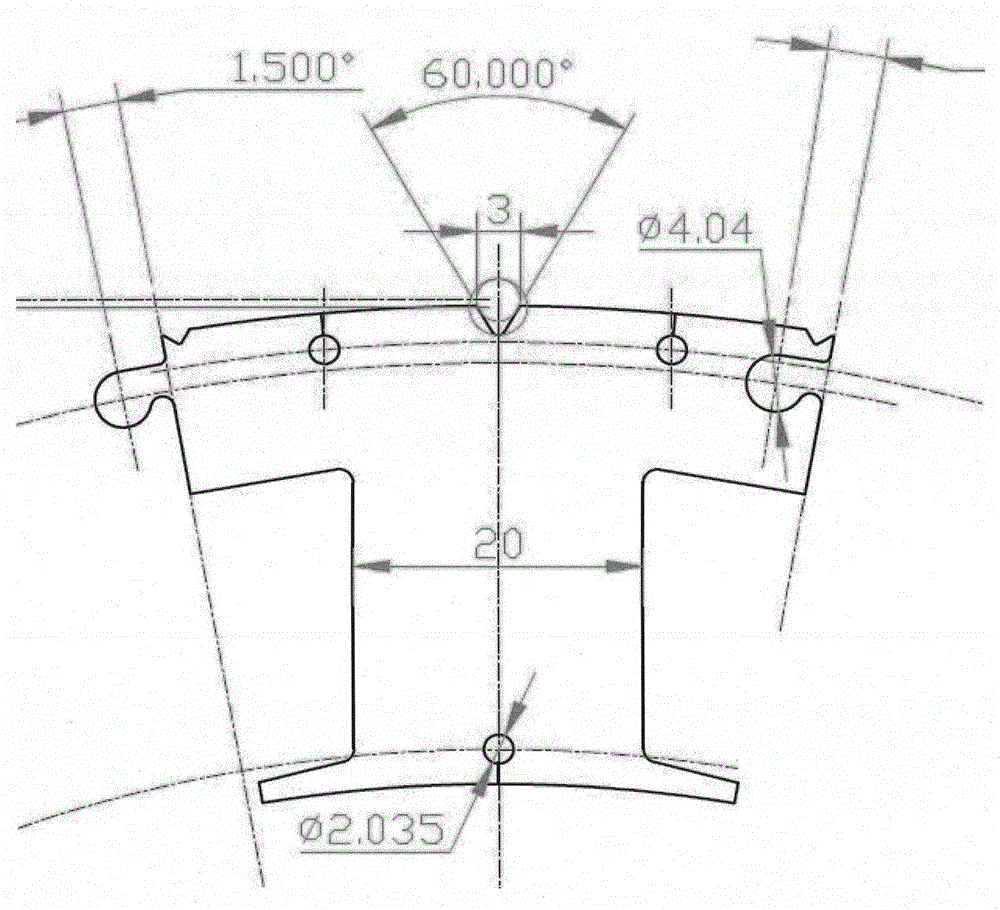

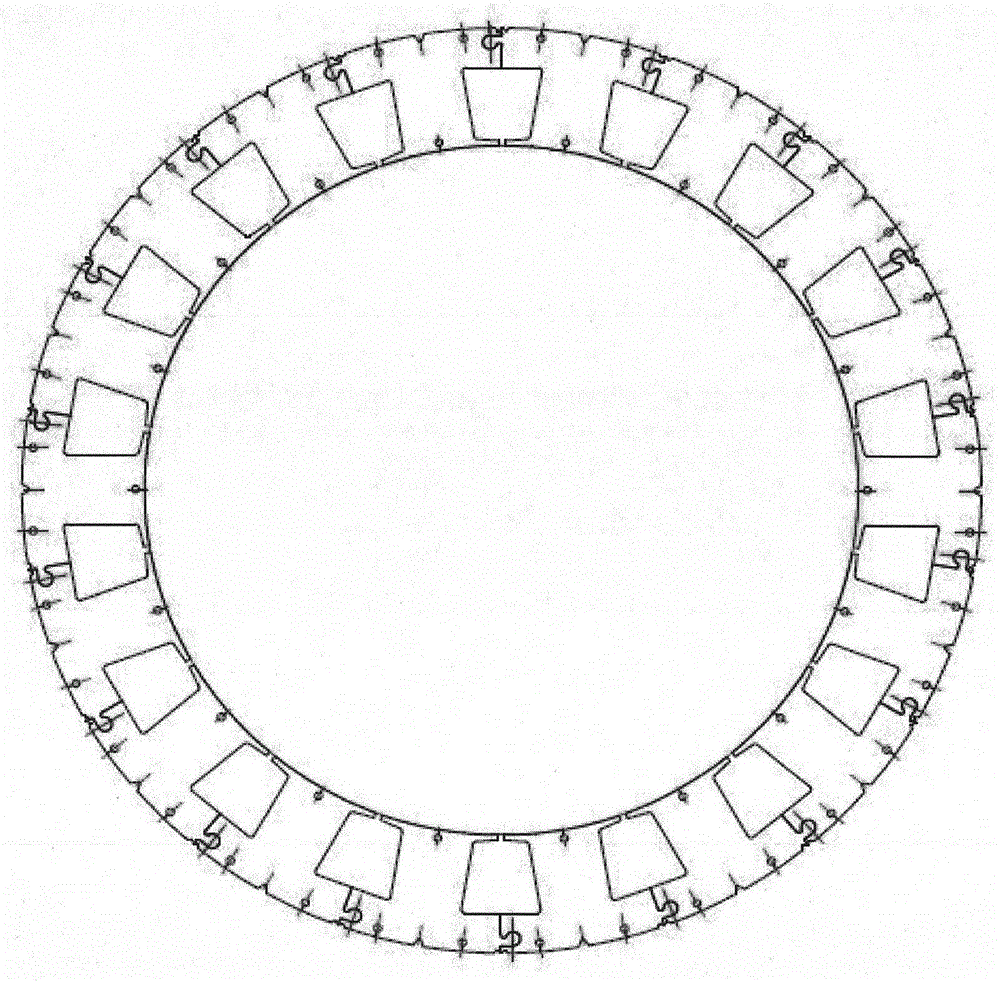

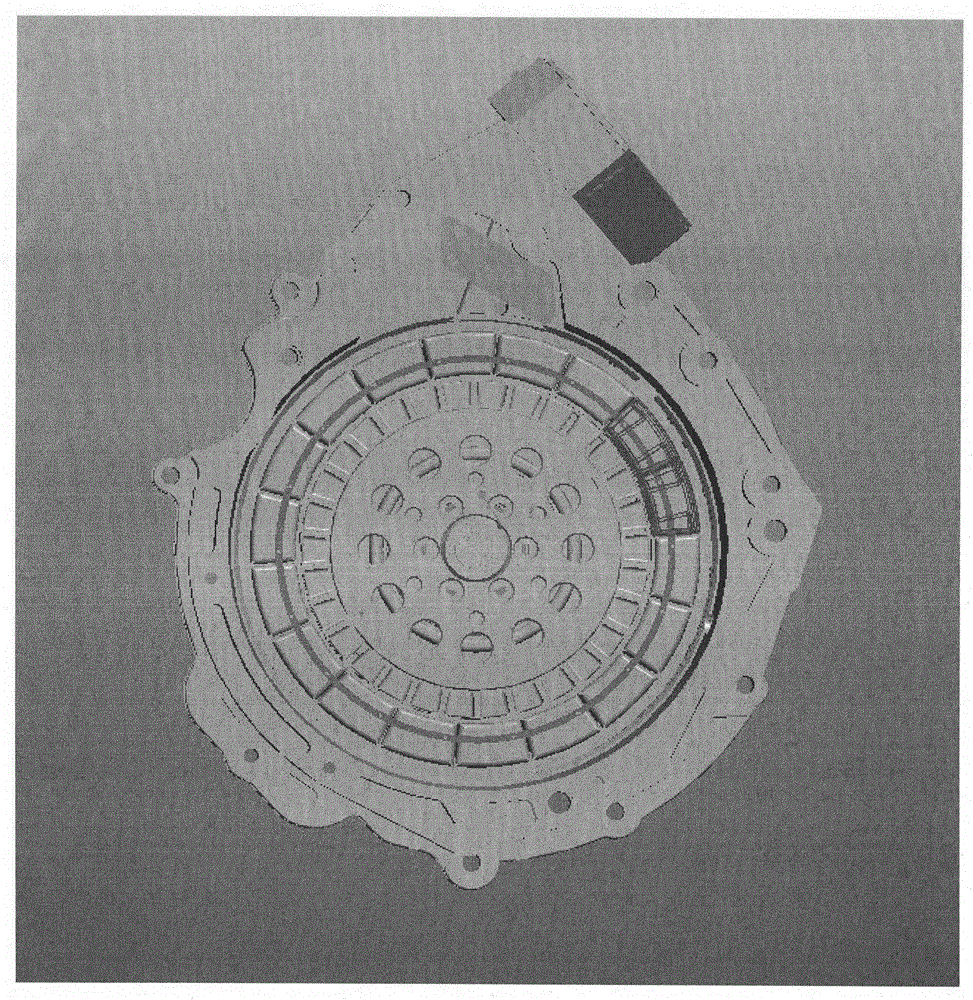

[0019] First refer to Figure 4 , The automotive alternator of the present invention includes a stator winding assembly 41 , a rotor assembly 42 , a fixed housing 43 , a rotary transformer 44 and a junction box assembly 45 . The stator winding assembly includes a stator core and a stator winding, and the stator core is composed of segmented iron sheets. On the basis of the advantages of block punching, a buckle-type block punching is designed, which saves welding process and can be assembled into stator components by direct buckling, which greatly speeds up the production efficiency. specific reference figure 1 Enlarged view of the iron chip, the left side of the iron chip is provided with a circular protrusion with a diameter of 4 mm, and the right side is provided with a circular concave part with a diameter of 4 mm, thereby forming a buckle structure, and the adjacent iron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com