Gradient silicon steel and preparation method thereof

A silicon steel and gradient technology, applied in the field of gradient silicon steel and its preparation, can solve the problem that high silicon steel cannot be rolled, and achieve the effect of avoiding processing difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of gradient silicon steel of the present embodiment, its preparation method is specifically implemented according to the following steps:

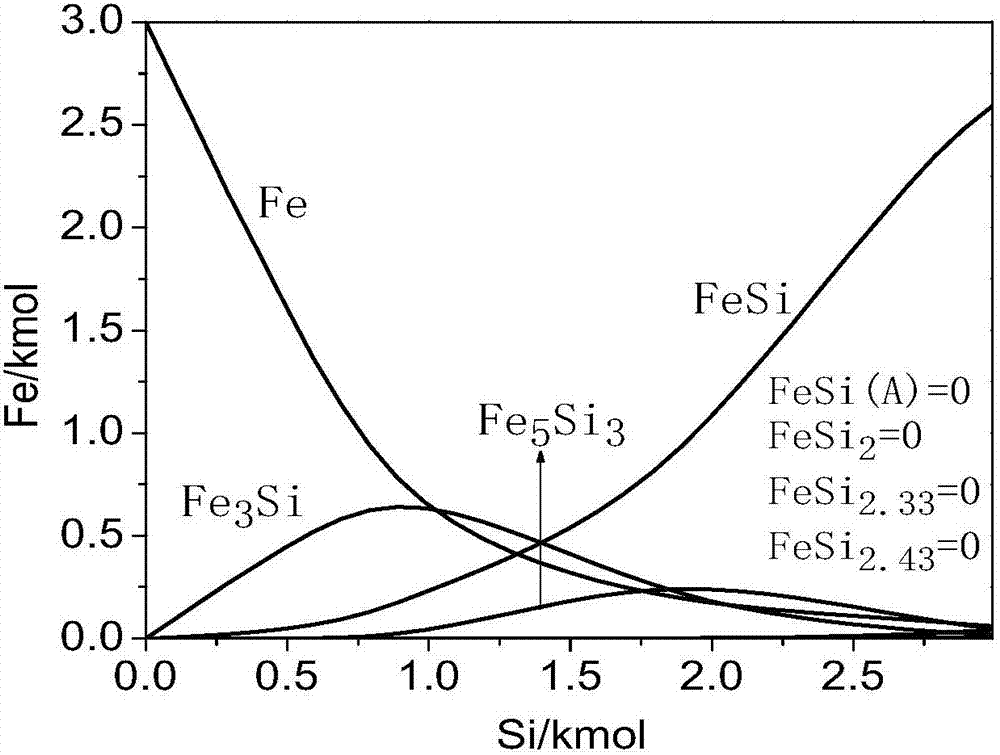

[0027] Choose from NaCl, KCl, NaF and SiO 2 As raw material, prepare NaCl-KCl-NaF-SiO 2 For the molten salt system, first dry the above-mentioned raw materials in a DZF-6020 vacuum oven at 200°C for 12 hours, cool and grind them for later use; then grind NaCl, KCl and NaF into powders according to the molar ratio of 1:1: 2 to form a mixed powder, and then add SiO according to 2% of the mixed powder mass 2 , after mixing evenly, put the graphite crucible into the graphite crucible, put the crucible into the tubular resistance heating furnace and raise the temperature with the furnace, and pass in the flowing argon gas for protection. 2 The dissolution in the molten salt system can reach equilibrium, and NaCl-KCl-NaF-SiO can be obtained 2 molten salt system.

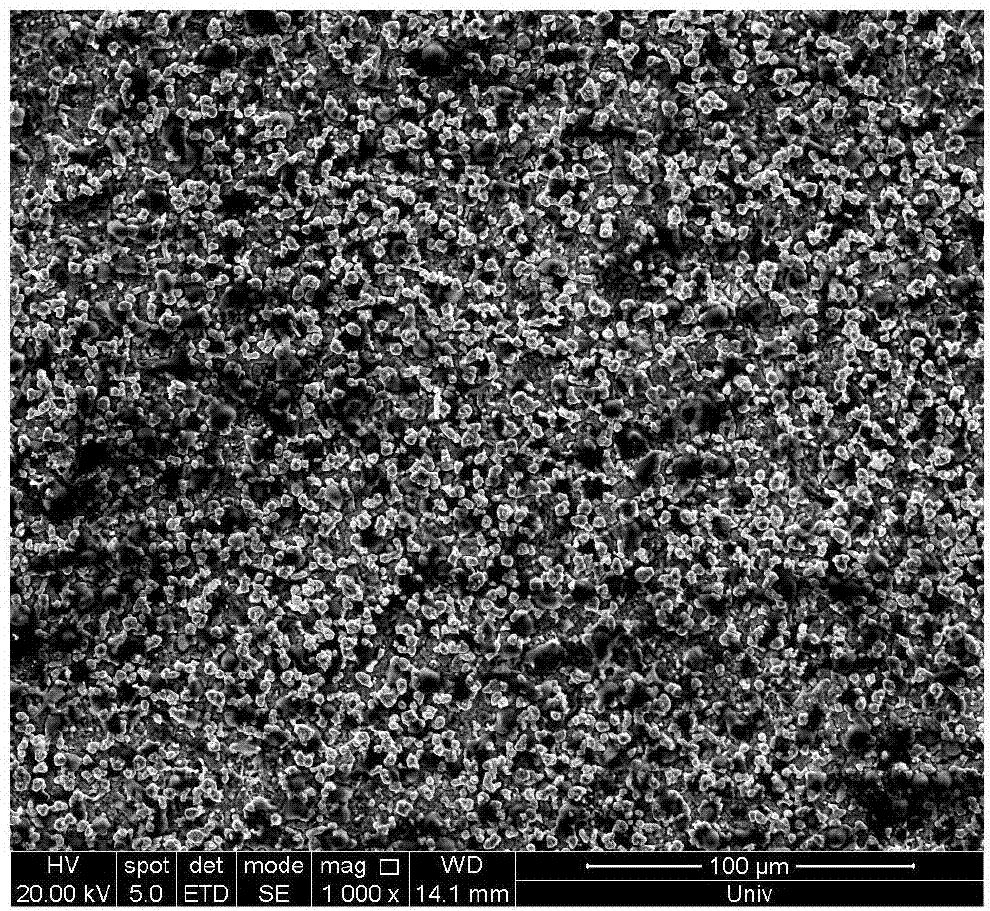

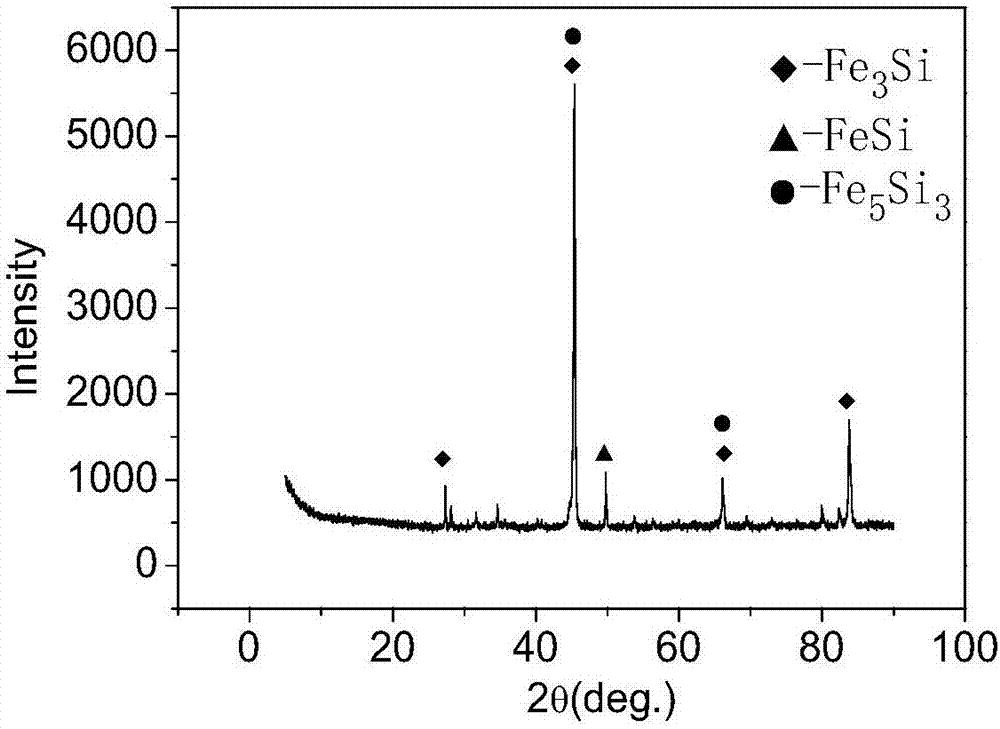

[0028] With the 1.2% Si low-silicon steel sheet as the cathode a...

Embodiment 2

[0034] This embodiment is a kind of gradient silicon steel, the specific steps of its preparation method are the same as in Example 1, the only difference is that the electrodeposition process is different, that is, during electrodeposition, the current density is 200mA cm -2 , the time is 60min, and the temperature is 800°C for electrodeposition.

Embodiment 3

[0036] This embodiment is a kind of gradient silicon steel. The specific steps of its preparation method are the same as in Example 1, the only difference is that the electrodeposition process is different, that is, during electrodeposition, the current density is 280mA cm -2 , the time is 60min, and the temperature is 800°C for electrodeposition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com