Flexible piezoelectric sensor and preparation method thereof

A flexible piezoelectric and sensor technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve complex and diverse use environments, The film density is not high, the piezoelectric ceramics are brittle, etc., so as to avoid processing difficulties, simple structure and high piezoelectric constant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

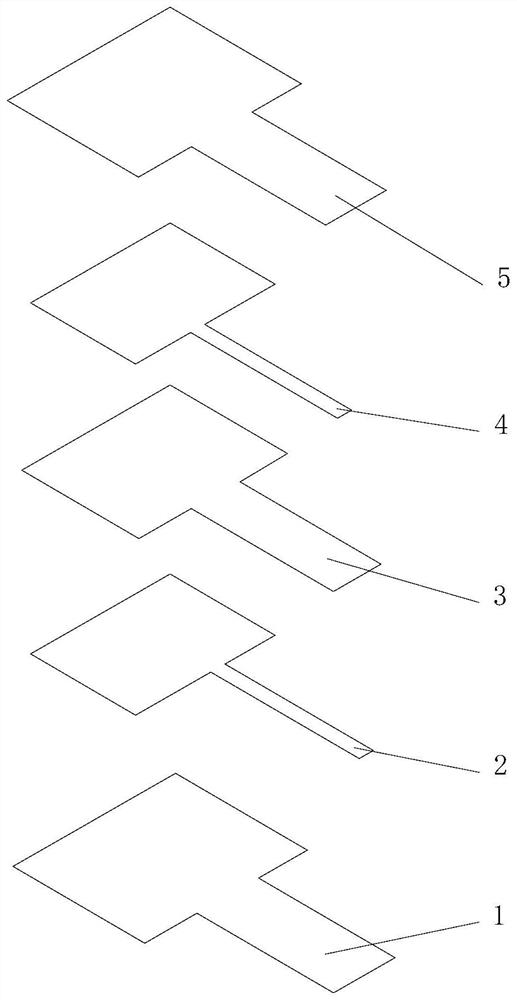

[0037] A flexible piezoelectric sensor, comprising a flexible substrate 1, a first electrode 2 is provided on the upper surface of the flexible substrate 1, a piezoelectric film layer 3 is provided on the upper surface of the first electrode 2, and a second electrode is provided on the upper surface of the piezoelectric film layer 3 4. A protective layer 5 is provided on the upper surface of the second electrode 4; the signal transmission sections of the first electrode 2 and the second electrode 4 are arranged separately and dislocated.

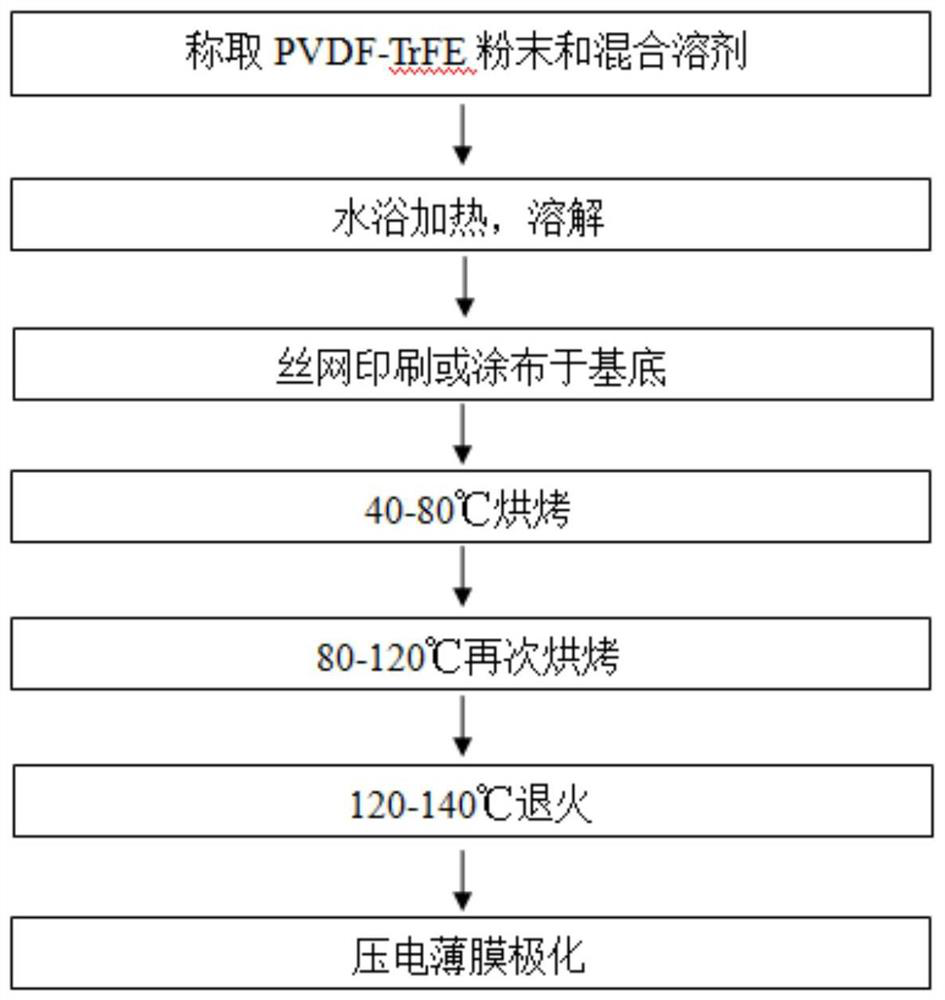

[0038] Wherein, piezoelectric thin film layer 3 adopts following preparation method to make:

[0039] S1. Weigh polyvinylidene fluoride-trifluoroethylene (PVDF-TrFE) powder with a content of 18%wt;

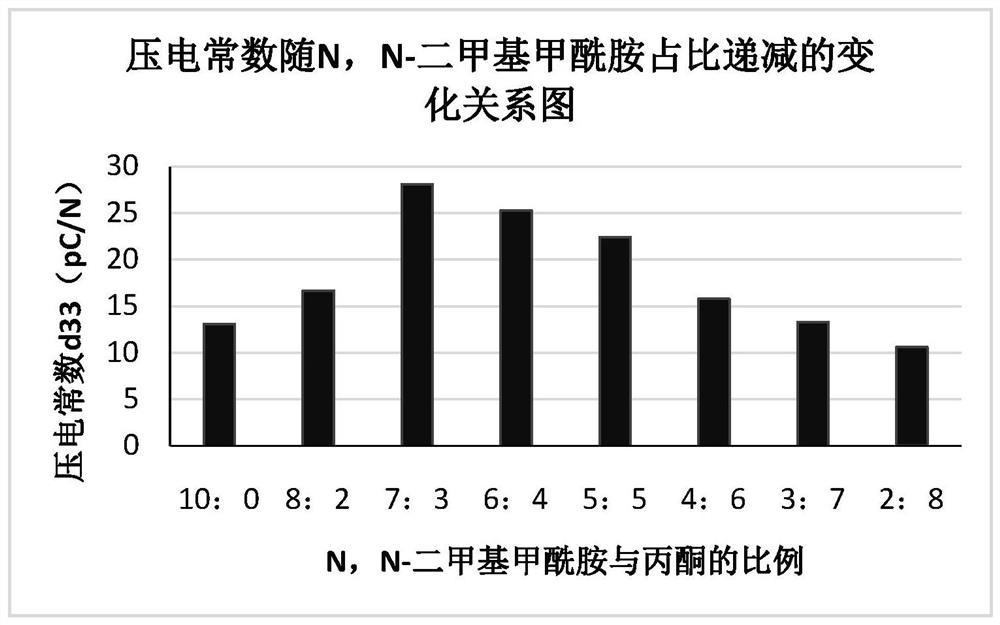

[0040] S2. Take N, N-dimethylformamide solvent and acetone solvent according to the ratio in Table 1 and mix them to prepare a mixed solvent;

[0041] S3. Dissolving polyvinylidene fluoride-trifluoroethylene (PVDF-TrFE) powder in a mixed solven...

Embodiment 2

[0054] The difference from Example 1 is that a method for preparing a flexible piezoelectric film comprises the following steps:

[0055] S1. Weigh polyvinylidene fluoride-trifluoroethylene (PVDF-TrFE) powder with a content of 15%wt;

[0056] S2, take triethyl phosphate solvent and acetone solvent and mix according to the ratio in table 2, make mixed solvent;

[0057] S3. Dissolving polyvinylidene fluoride-trifluoroethylene (PVDF-TrFE) powder in the mixed solvent, stirring continuously, and heating in a water bath for 1 hour, the temperature of the water bath is 70° C.;

[0058] S4, bonded to the substrate by coating, first baked at 80°C for 60 minutes, then baked at 110°C for 60 minutes, and finally annealed at 140°C for 4 hours to obtain a semi-finished flexible piezoelectric film;

[0059] S5. Polarizing the annealed semi-finished flexible piezoelectric film in air at room temperature with a polarization voltage of 35 MV / cm for 10 minutes to obtain a finished flexible piez...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com