Orthogonal crystal system crystal material and preparation method thereof

A technology of crystal material and orthorhombic system, which is applied in the field of orthorhombic crystal material and its preparation, and can solve the problems of increased growth and obstruction of binary manganese germanide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A second aspect of the invention provides a method of preparing a orthogonal crystal crystal material according to the first aspect of the present invention, the method comprising the steps of:

[0044] S1, raw manganese with single germplasm, after the tablet, then wrap the hexagonal boron tank protective cover;

[0045] S2, the inclusion of the inclusions in step S1 at 4 to 6 GPa pressure, 800 to 1000 ° C, prepared a orthogonal alcoholic crystal material.

[0046] In the preparation method of the orthogonal crystal crystal material provided by the present invention, in step S1, the monomer manganese and single germplasm are mixed in a suitable molar ratio under an inert gas protection conditions (argon environments in the specifically available suitcase). And in a mortar in Agate, 30-60 min, mixed a uniform powder into a stainless steel mold (powder tableting machine), pressurized to 5 MPa, press the mixed powder to be 2.5 ~ 4.5mm, height of 2.2 ~ 4.2mm cylindrical shape....

Embodiment 1

[0064] 1) Cylindrical mixture preparing manganese and germanium under normal pressure

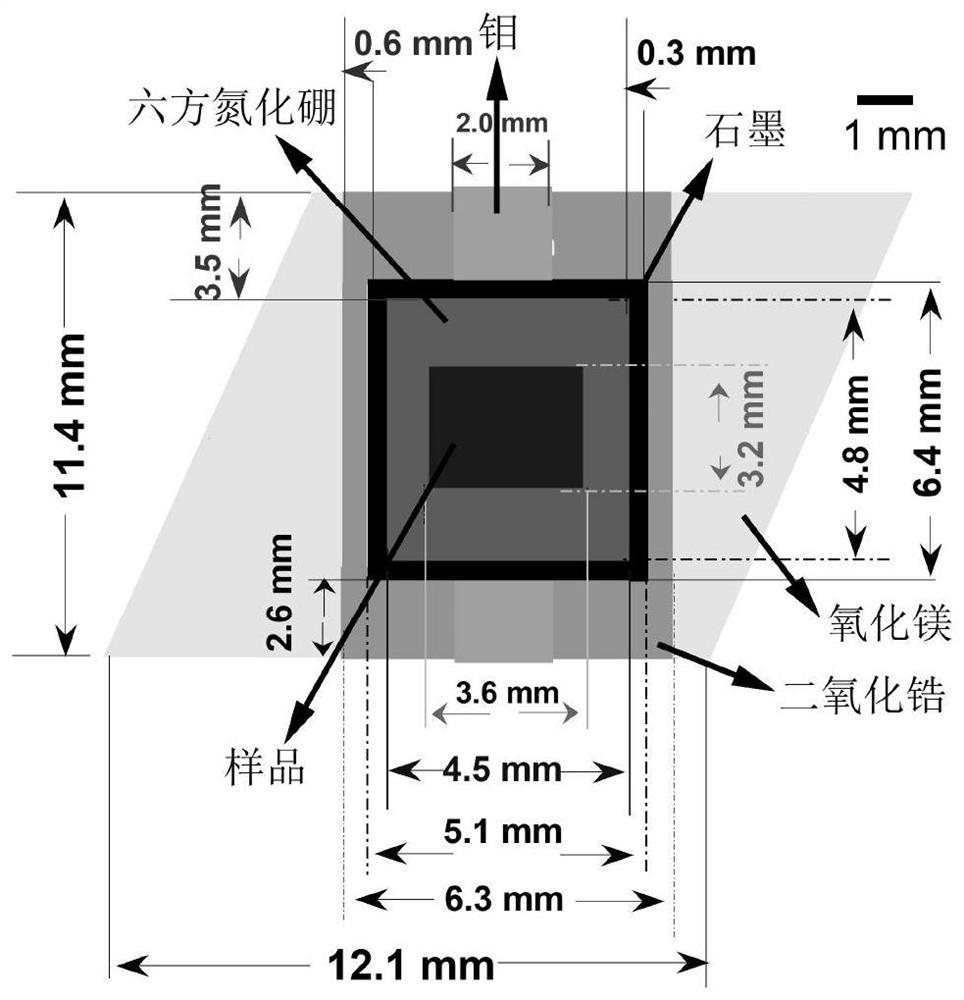

[0065] Chemical pure manganese with single germplasm is mixed in a glove box (argon environment) in a glove box (argon environment) in a molar ratio of 1: 4.8. The mixture powder was pressed into a cylindrical sample having a diameter of 3.5 mm and a height of 3.2 mm by a powder tableting machine (pressure: 5 MP). In order to ensure a pure reaction environment, a hexagonal boron nitride (wall thickness: 0.5 mm) and hexagonal boron nitride wafer (thickness: 0.5mm) are used to reduce the chance of generating an inclusion phase.

[0066] 2) The above-mentioned cylindrical sample and hexagonal boron boron protective cover are loaded into the high pressure assembly.

[0067] First, a sample was wrapped by a hexagonized boron, and then wrapped in graphite, the outer layer was wrapped by zirconia and placed in magnesium oxide octahedron, and constituting a complete assembly. The sample is then loaded ...

Embodiment 2

[0082] 1) Cylindrical mixture preparing manganese and germanium under normal pressure

[0083] Chemical pure manganese with single germplasm is mixed in a glove box (argon environment) in a glove box (argon environment) in a molar ratio of 1: 4.8. The mixture powder was pressed into a cylindrical sample having a diameter of 3.5 mm and a height of 3.2 mm by a powder tableting machine (pressure: 5 MP). In order to ensure a pure reaction environment, a hexagonal boron nitride (wall thickness: 0.5 mm) and hexagonal boron nitride wafer (thickness: 0.5mm) are used to reduce the chance of generating an inclusion phase.

[0084] 2) The above-mentioned cylindrical sample and the hexagonal boron boron protective sleeve are loaded into the high pressure group.

[0085] First, a sample was wrapped by a hexagonized boron, and then wrapped in graphite, the outer layer was wrapped by zirconia and placed in magnesium oxide octahedron, and constituting a complete assembly. The sample is then loade...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com