Preparation method of potassium sodium niobate based piezoelectric ceramics

A potassium-sodium niobate-based, piezoelectric ceramic technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problems of poor preparation process, easy volatilization, narrow sintering temperature, etc. To achieve the effect of improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

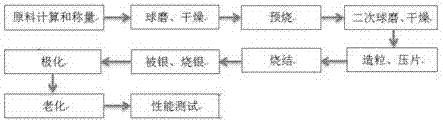

[0020] A preparation method of potassium sodium niobate-based piezoelectric ceramics (such as figure 1 shown), specifically include the following steps:

[0021] (1) Weigh 0.48mol of K respectively 2 CO 3 , 0.52mol of Na 2 CO 3 , 0.96mol of Nb 2 o 5 , 0.04mol of Sb 2 o 3 , put the accurately weighed raw materials in a nylon tank, add zirconia balls, use absolute ethanol as the ball milling medium, and ball mill for 20 hours according to the mass ratio of materials: balls: ethanol = 1:2:2.

[0022] (2) Put the ball-milled slurry into a drying oven at 60°C for drying, and press it into Φ A 30 mm disc was pre-fired at 700 °C for 2.5 h to synthesize KNNS powder ((K 0.48 Na 0.52 )Nb 0.96 Sb 0.04 o 3 ); the pre-burned powder is subjected to secondary ball milling and dried.

[0023] (3) Weigh 7 wt% PVA aqueous solution according to the mass of KNNS powder for grinding, and use a tablet press to make the granulated powder under a pressure of 150 MPa Φ 12.7 mm x 1.3 m...

Embodiment 2

[0026] A preparation method of potassium sodium niobate-based piezoelectric ceramics (such as figure 1 shown), specifically include the following steps:

[0027] (1) Weigh 0.5mol of K respectively 2 CO 3 , 0.5mol of Na 2 CO 3 , 0.98mol of Nb 2 o 5 , 0.02mol of Sb 2 o 3 , put the accurately weighed raw materials in a nylon tank, add zirconia balls, use absolute ethanol as the ball milling medium, and ball mill for 10 hours according to the mass ratio of material: balls: ethanol = 1:2:2.

[0028] (2) Put the ball-milled slurry into a drying oven at 50°C for drying, and press it into Φ A 30 mm disc was pre-fired at 800 °C for 1.5 h to synthesize KNNS powder ((K 0.5 Na 0.5 )Nb 0.98 Sb 0.02 o 3 ).

[0029] (3) Perform secondary ball milling on the pre-calcined powder, dry it, then add polyvinyl alcohol aqueous solution (the mass is 7wt% of the KNNS powder mass) for grinding, and use a tablet machine to granulate the powder at a pressure of 250MPa Made under Φ 12.7...

Embodiment 3

[0032] A preparation method of potassium sodium niobate-based piezoelectric ceramics (such as figure 1 shown), specifically include the following steps:

[0033] (1) Weigh 0.5mol of K respectively 2 CO 3 , 0.5mol of Na 2 CO 3 , 0.97mol of Nb 2 o 5 , 0.03mol of Sb 2 o 3 , put the accurately weighed raw materials in a nylon tank, add zirconia balls, use absolute ethanol as the ball milling medium, and ball mill for 30 hours according to the mass ratio of materials: balls: ethanol = 1:2:2.

[0034] (2) Put the ball-milled slurry into a drying oven at 70°C for drying, and press it into Φ A 30 mm disc was pre-fired at 900 °C for 2 h to synthesize KNNS powder ((K0.5 Na 0.5 )Nb 0.97 Sb 0.03 o 3 ). The pre-fired powder is subjected to secondary ball milling and dried.

[0035] (3) Perform secondary ball milling on the pre-calcined powder, dry it, then add polyvinyl alcohol aqueous solution (the mass is 7 wt% of the KNNS powder mass) for grinding, and use a tablet machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com