Method for improving photocatalytic performance of graphite phase carbon nitride

A phase carbon nitride light and catalytic performance technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problem of low dielectric properties, high resistivity, large surface active site migration resistance, etc. problems, to achieve the effect of improving electrical properties and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

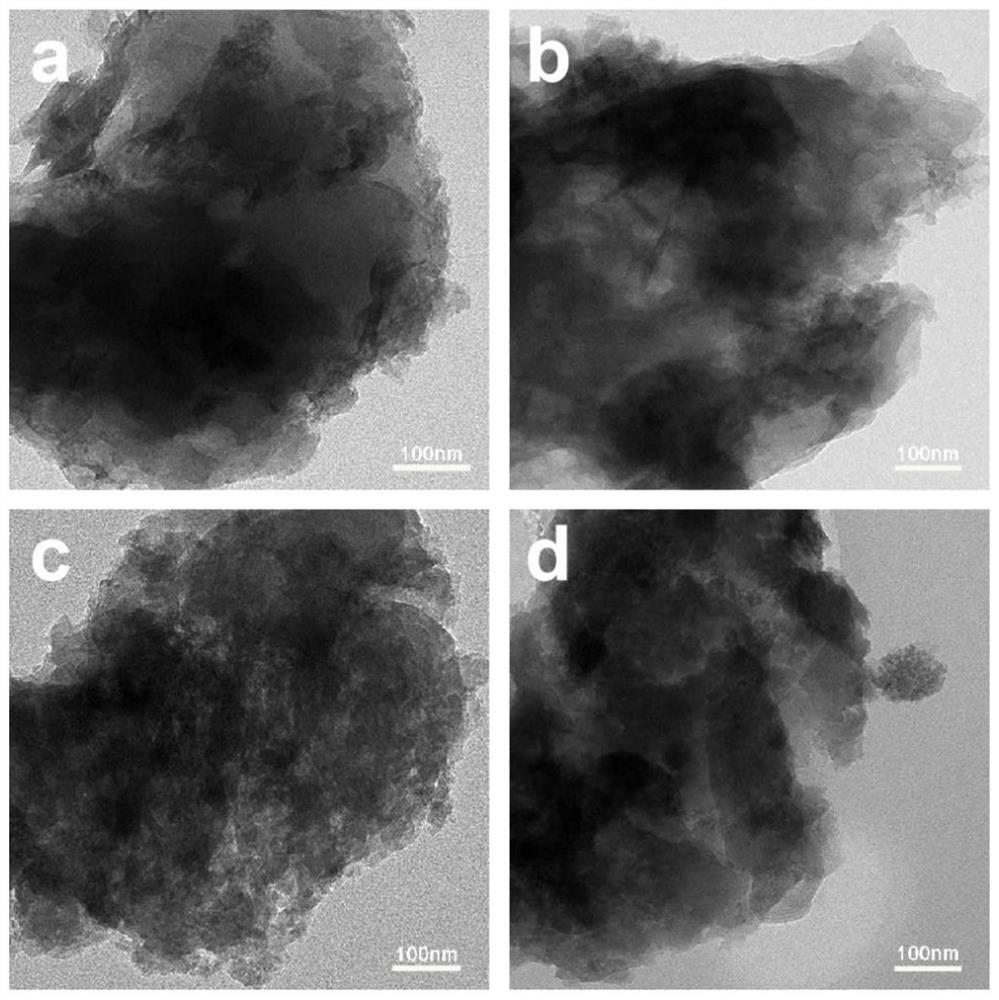

[0036] Example 1: +2 valence and +4 valence molybdenum ion doping g-C 3 N 4 preparation of

[0037] 10 μL of 0.1 M MoCl 5Mix and dissolve 10 μmol of aqueous solution and 500 mg of dicyandiamide in 2 mL of deionized water, ultrasonically disperse evenly, stir magnetically at room temperature, the stirring speed is 400 rpm, and the stirring time is 2 h, then transfer the mixed solution to a porcelain boat and place it in a vacuum oven at 45 °C for drying A white powder solid is obtained. After the dried sample is fully ground, it is heated in an Ar atmosphere in a tube furnace, and the temperature is raised to 520°C at 5°C / min for 2 hours. After the sample is naturally cooled to room temperature, it is ground, washed, and dried. After that, the +2-valent and +4-valent molybdenum ions doped g-C 3 N 4 As for the photocatalyst, the mass fraction of molybdenum ions doped in the catalyst is 0.21wt.%.

Embodiment 2

[0038] Example 2: +2 valence and +4 valence molybdenum ion doping g-C 3 N 4 preparation of

[0039] 20 μL of 0.1 M MoCl 5 Mix and dissolve 20 μmol of aqueous solution and 500 mg of dicyandiamide in 2 mL of deionized water, disperse evenly by ultrasonic, stir magnetically at room temperature, the stirring speed is 400 rpm, and the stirring time is 2 h, then transfer the mixed solution to a porcelain boat and place it in a vacuum oven at 45 °C for drying A white powder solid is obtained. After the dried sample is fully ground, it is heated in an Ar atmosphere in a tube furnace, and the temperature is raised to 520°C at 5°C / min for 2 hours. After the sample is naturally cooled to room temperature, it is ground, washed, and dried. After that, the +2-valent and +4-valent molybdenum ions doped g-C 3 N 4 As for the photocatalyst, the mass fraction of molybdenum ions doped in the catalyst is 0.41wt.%.

Embodiment 3

[0040] Example 3: +2 valence and +4 valence molybdenum ion doping g-C 3 N 4 preparation of

[0041] Mix and dissolve 40 μL of 0.1M MoCl5 aqueous solution, 40 μmol, and 500 mg of dicyandiamide in 2 mL of deionized water, ultrasonically disperse evenly, stir magnetically at room temperature, the stirring speed is 400 rpm, and the stirring time is 2 h, and then transfer the mixed solution to a porcelain boat Place it in a vacuum oven at 45°C to obtain a white powder solid. After the dried sample is fully ground, it is heated in a tube furnace in an Ar atmosphere, and the temperature is raised to 520°C at 5°C / min for 2 hours, and then naturally cooled to room temperature. The samples were ground, washed with water, and dried to obtain +2-valent and +4-valent molybdenum ion-doped g-C 3 N 4 As for the photocatalyst, the mass fraction of molybdenum ions doped in the catalyst is 0.89wt.%.

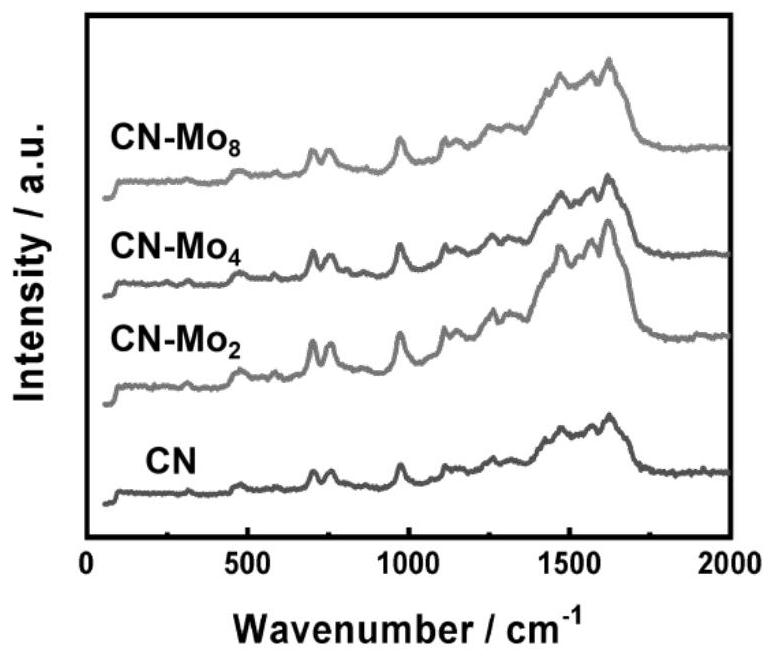

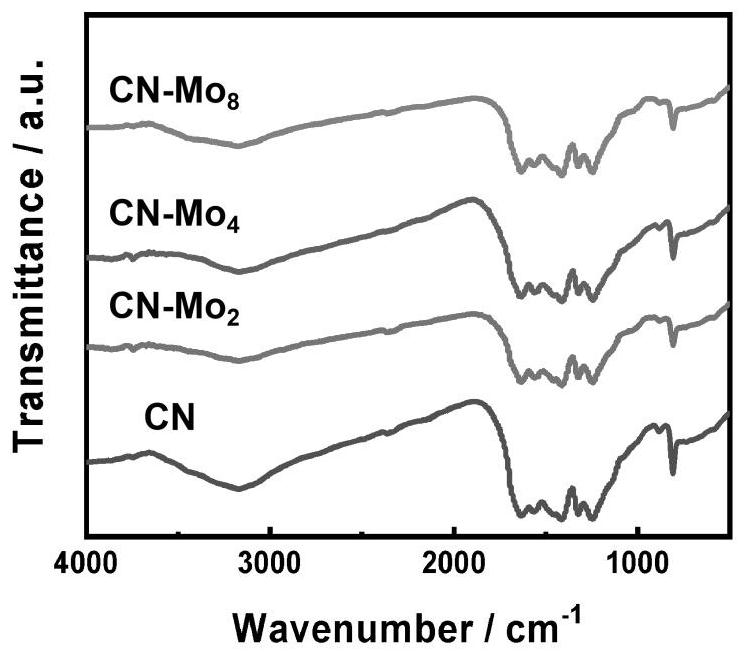

[0042] Ontology g-C 3 N 4 Preparation process of photodoped g-C with +2 and +4 bivalent m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com