Ternary material, preparation method and application thereof

A ternary material and ternary composite technology, which is applied in device material selection, information storage, instruments, etc., can solve the problems of limited improvement in magnetism and electricity, and achieve reduced coercive field, strong stability, and good research value and practical value effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 Sample P1 # ~P9 # and F1 # ~F9 # preparation of

[0044] Sample P1 # ~P9 # The preparation process is as follows

[0045] a) PbO, Bi 2 o 3 , Fe 2 o 3 、Nd 2 o 3 and TiO 2 Add alcohol and mix and grind for two hours to obtain a mixture I with the following molar ratio: Pb: Bi: Fe: Nd: Ti=z: x: (x+y): y: z, z=1-x-y;

[0046] b) after the mixture I obtained in step a) is compressed and calcined, a precursor is obtained;

[0047] c) adding alcohol to the precursor obtained in step b), mixing and grinding for two hours, adding 5% PVA binder and mixing evenly to obtain mixture II;

[0048] d) After the mixture II obtained in step c) is compressed into tablets at 12 MPa, debinding at 400°C to 600°C;

[0049] e) Put the debinding sample obtained in step d) at 1000°C to 1100°C for 4 hours and bake for 4 hours to obtain ceramic sample sheets of the ternary material, which are respectively designated as sample P1 # ~P9 # .

[0050] Table 1 shows the relati...

Embodiment 2

[0055] The structural characterization of embodiment 2 sample

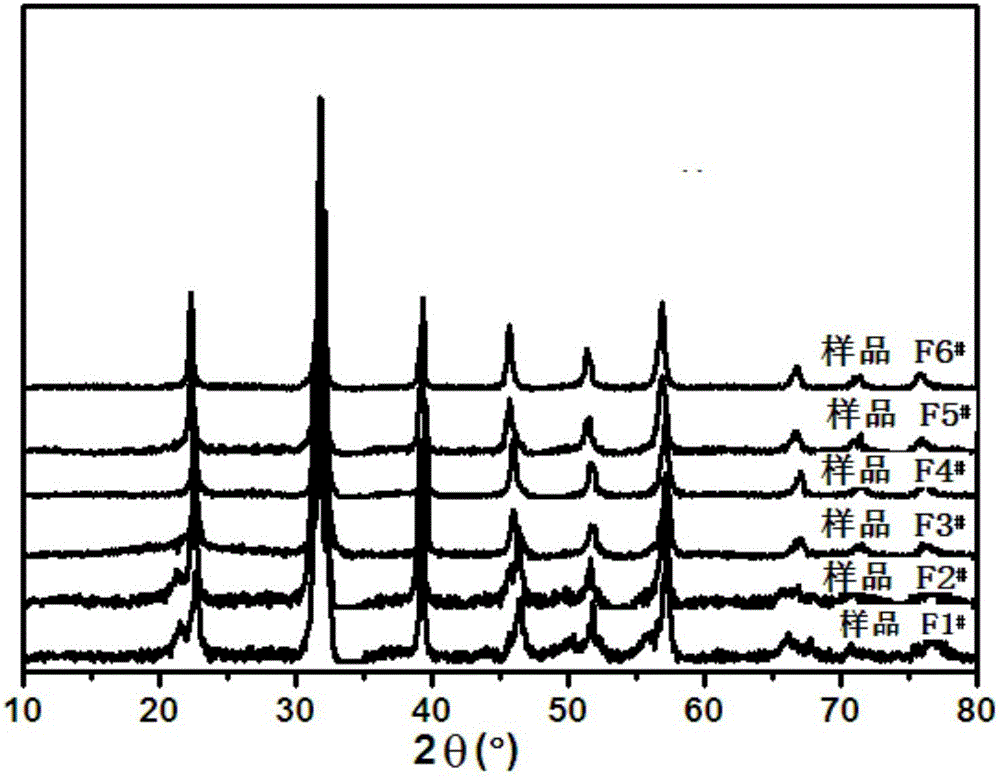

[0056] Sample F1 was analyzed by X-ray powder diffraction (XRD) method. # ~F9 # characterize the structure. The instrument used is Japan RIGAKU-DMAX2500 powder diffractometer (Cu target, λ=0.154056nm, graphite monochromator), the specific test conditions are at room temperature, the measurement angle range is 10-80°, and the step size used is 0.02° (2θ ), the time is 2s per step.

[0057] Sample F1 # ~F6 # The XRD pattern such as figure 1 shown. As can be seen from the figure, sample F1 # ~F6 # There are characteristic diffraction peaks of perovskite structure on the XRD pattern of the sample F1 # ~F6 # All are high-purity samples with a perovskite structure. Sample F7 # ~F9 # XRD pattern of sample F1 # The chromatograms are similar, that is, the peak positions are basically the same, and the peak intensity varies in the range of ±10% according to different synthesis conditions.

Embodiment 3

[0058] The electrical property measurement of embodiment 3 samples

[0059] The ceramic sample piece P1 # ~P9 # The grinding thickness is 0.4~0.6mm, and silver glue is coated on both sides after polishing, which is used for the determination of electrical properties.

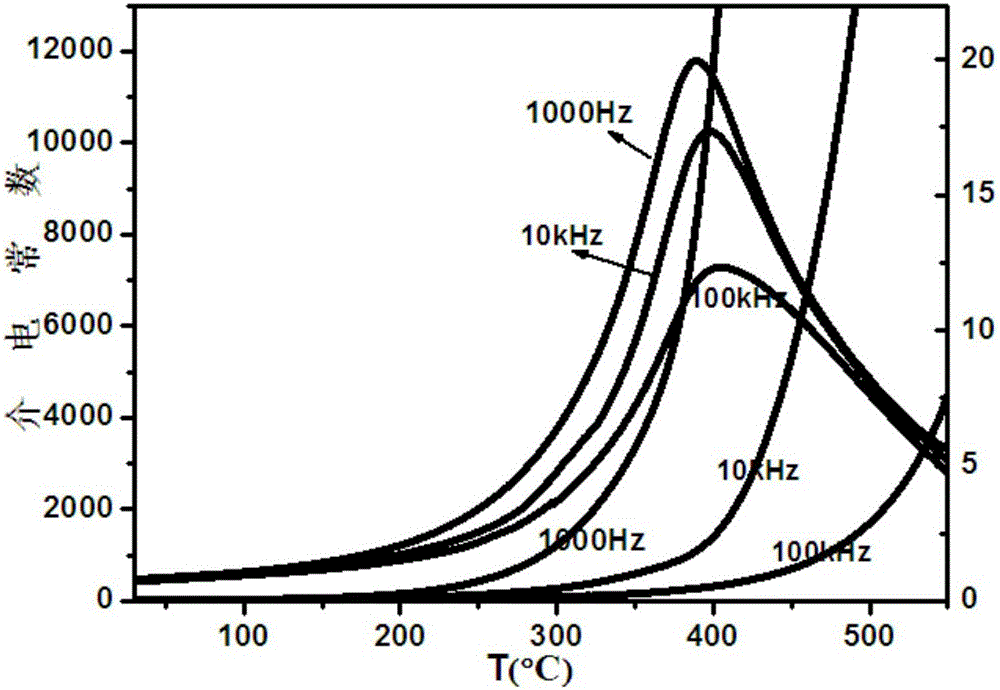

[0060] The measurement of the dielectric properties of the samples was carried out on an Alpha dielectric / impedance high-resolution analyzer (Novolcontrol, German), with a temperature range of 30-500°C, a frequency range of 1-10kHz, and a small-signal test voltage of 1Vrms.

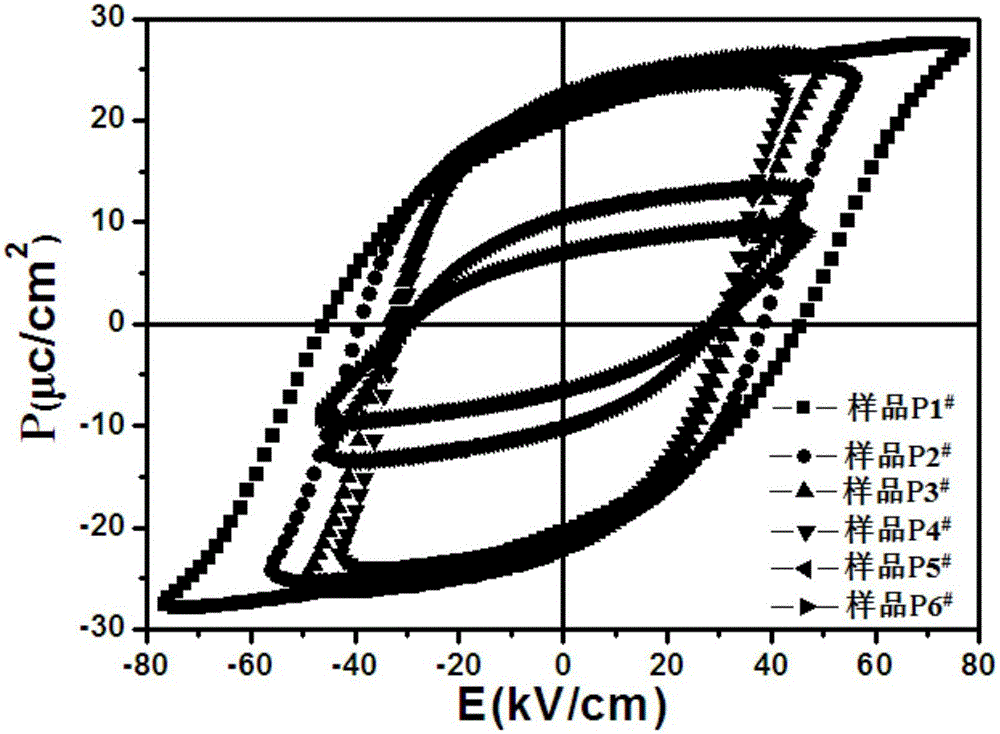

[0061] The measurement of the ferroelectricity of the sample was carried out in the TF2000 standard ferroelectric measurement system produced by aixACCT Company in Germany, the temperature condition was room temperature, and the applied frequency was 10 Hz.

[0062] The result is as figure 2 and image 3 as shown, figure 2 is sample P1 # The dielectric temperature spectrum; image 3 is sample P1 # ~P6 # hysteresis loop. It can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com