Reactive flame-retardant block copolymer and preparing method thereof

A block copolymer, reactive flame retardant technology, applied in the field of polymer halogen-free flame retardant, can solve the problems of difficult adjustment of silicon content, few functional groups, poor matrix compatibility, etc., to achieve improved compatibility and Effects of flame retardancy, mild reaction conditions, and rich molecular design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

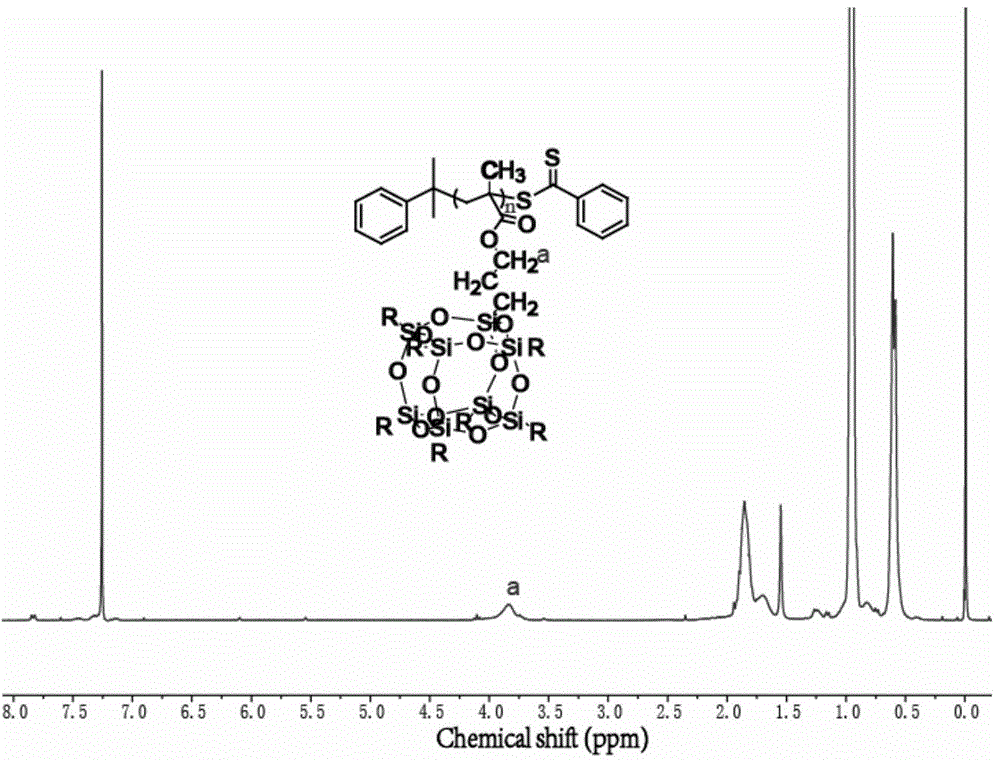

[0029] 1) Preparation of macromolecular chain transfer agent: Dissolve 2.26 g (2.4 mmol) of methacryloxypropyl heptaisobutyl POSS (MAPOSS) in 2 ml of the first solvent toluene, and then add chain transfer agent dithiobenzene Cumyl formate (CDB) 54mg (0.2mmol) and initiator azobisisobutyronitrile (AIBN) 0.0016g (0.01mmol) were placed in a RAFT tube and degassed 3 to 5 times by continuous freezing and thawing. Polymerize at 65°C under the protection of gas argon. After 12-48 hours of reaction, liquid nitrogen is quenched to stop the reaction. The first precipitant is a blend of methanol and ethyl acetate (the volume ratio of methanol to ethyl acetate is 8: 1) Precipitate repeatedly 3 times and dry to obtain a macromolecular chain transfer agent with a degree of polymerization of 12, namely PMAPOSS 12 ;

[0030] 2) Synthesis of reactive flame retardant block copolymer: the PMAPOSS obtained in step 1) 12 0.35g (0.03mmol), methacrylate-2-hydroxyethyl phosphate (MOEP) 0.36g (1.8mm...

Embodiment 2

[0035] 1) Preparation of macromolecular chain transfer agent: the preparation steps are the same as step 1) in Example 1 to obtain macromolecular chain transfer agent PMAPOSS 12 ;

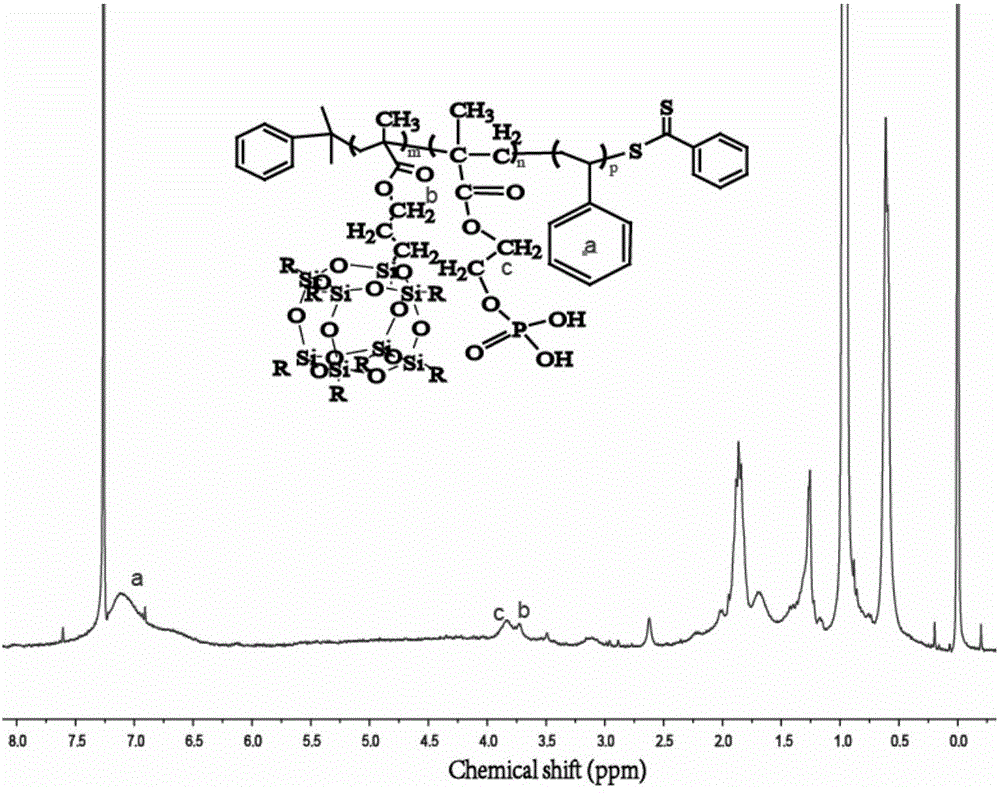

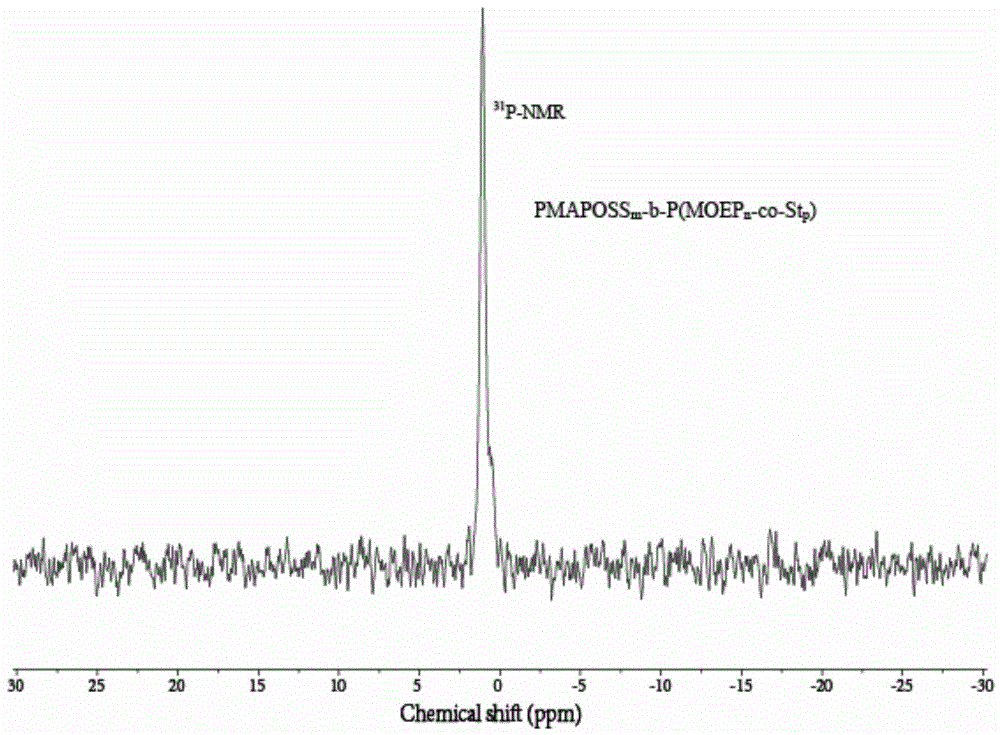

[0036] 2) Synthesis of reactive flame retardant block copolymer: the PMAPOSS obtained in step 1) 12 0.35g (0.03mmol), 0.36g (1.8mmol) of MOEP, 0.31ml (3mmol) of St, 1mg (0.006mmol) of initiator AIBN were dissolved in 3ml of the second solvent anhydrous THF, and degassed by continuous freezing and thawing for 3-5 After the second time, it was polymerized at 65°C under the protection of inert gas argon, and after 24 hours of reaction, it was quenched with liquid nitrogen to stop the reaction, and the second precipitant methanol was used for repeated precipitation twice, and dried to obtain a reactive flame-retardant block copolymer PMAPOSS m -b-P(MOEP n -co-St p ), its chemical structural formula is as shown in (I) formula:

[0037]

[0038] Wherein, m is the total number of units occupied by...

Embodiment 3

[0040] 1) Preparation of macromolecular chain transfer agent: 2.83g (3mmol) of MAPOSS was dissolved in 2ml of the first solvent toluene, then 54mg (0.2mmol) of chain transfer agent CDB and 0.0016g (0.01mmol) of initiator AIBN were added, placed in After continuous freezing and thawing and degassing for 3 to 5 times in the RAFT tube, polymerize at 65°C under the protection of inert gas argon. After reacting for 12 to 48 hours, quench with liquid nitrogen to stop the reaction. Use methanol and ethyl acetate as the first precipitant The ester blend (the volume ratio of methanol to ethyl acetate is 8:1) is precipitated repeatedly 3 times to obtain a macromolecular chain transfer agent with a degree of polymerization of 15, namely PMAPOSS 15 ;

[0041] 2) Synthesis of reactive flame retardant block copolymer: the PMAPOSS obtained in step 1) 15 0.44g (0.03mmol), MOEP 0.48g (2.4mmol), St 0.38ml (3.6mmol), initiator AIBN 1mg (0.006mmol) were dissolved in 3ml of the second solvent anh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com