Lead-free piezoelectric ceramic and preparation method thereof

A lead-free piezoelectric and ceramic technology, applied in the field of electrochemistry, can solve the problems of poor piezoelectric ceramic performance, complex production process, and difficult sintering, and achieve the effect of improving polarizability, good performance, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

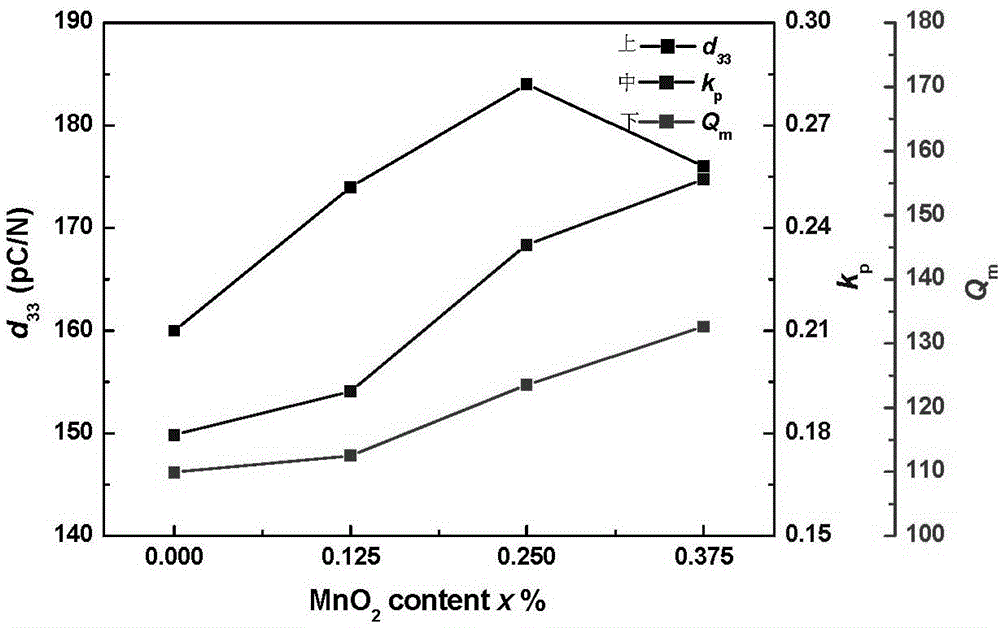

Image

Examples

Embodiment 1

[0026] In concrete implementation, the present invention is realized by the following steps:

[0027] (1) Ingredients: BaCO in molar ratio 3 : ZrO 2 : TiO 2 =1:0.055:0.945 mixed together to make powder;

[0028] (2) Put the powder prepared in step (1) into a ball mill tank, use absolute ethanol as the medium, and use a planetary ball mill to mill for 24 hours to form a slurry;

[0029] (3) Dry the slurry prepared in step (2) in a drying oven at 105°C, press it into a Ф60 disc, put it into a corundum crucible, and then put it into a muffle furnace for pre-firing. The pre-firing temperature is 1200°C. The burning time is 2h, and the reaction synthesizes BaZr 0.055 Ti 0.945 o 3 ;

[0030] (4) With Bi 2 o 3 、Na 2 CO 3 、TiO 2 , MnO 2 and BaZr 0.055 Ti 0.945 o 3 Powder is the raw material, according to the chemical formula 0.93BNT-0.07BZT+0.125%MnO 2 , according to Bi 2 o 3 : Na 2 CO 3 : TiO 2 : BaZr 0.055 Ti 0.945 o 3 The molar ratio is 0.465:0.465:0.93:0.0...

Embodiment 2

[0042] In concrete implementation, the present invention is realized by the following steps:

[0043] (1) Ingredients: BaCO in molar ratio 3 : ZrO 2 : TiO 2 =1:0.055:0.945 mixed together to make powder;

[0044] (2) Put the powder prepared in step (1) into a ball mill tank, use absolute ethanol as the medium, and use a planetary ball mill to mill for 36 hours to form a slurry;

[0045] (3) Dry the slurry prepared in step (2) in a drying oven at 105°C, press it into a Ф60 disc, put it into a corundum crucible, and then put it into a muffle furnace for pre-firing. The pre-firing temperature is 1200°C. The burning time is 2h, and the reaction synthesizes BaZr 0.055 Ti 0.945 o 3 ;

[0046] (4) With Bi 2 o 3 、Na 2 CO 3 、TiO 2 , MnO 2 and BaZr 0.055 Ti 0.945 o 3 Powder is the raw material, according to the chemical formula 0.93BNT-0.07BZT+0.125%MnO 2 , according to Bi 2 o 3 : Na 2 CO 3 : TiO 2 : BaZr 0.055 Ti 0.945 o 3 The molar ratio is 0.465:0.465:0.93:0.0...

Embodiment 3

[0058] In concrete implementation, the present invention is realized by the following steps:

[0059] (1) Ingredients: BaCO in molar ratio 3 : ZrO 2 : TiO 2 =1:0.055:0.945 mixed together to make powder;

[0060] (2) Put the powder prepared in step (1) into a ball mill tank, use absolute ethanol as the medium, and use a planetary ball mill to mill for 36 hours to form a slurry;

[0061] (3) Dry the slurry prepared in step (2) in a drying oven at 105°C, press it into a Ф60 disc, put it into a corundum crucible, and then put it into a muffle furnace for pre-firing. The pre-firing temperature is 1200°C. The burning time is 2h, and the reaction synthesizes BaZr 0.055 Ti 0.945 o 3 ;

[0062] (4) With Bi 2 o 3 、Na 2 CO 3 、TiO 2 , MnO 2 and BaZr 0.055 Ti 0.945 o 3 Powder is the raw material, according to the chemical formula 0.93BNT-0.07BZT+0.375%MnO 2 , according to Bi 2 o 3 : Na 2 CO 3 : TiO 2 : BaZr 0.055 Ti 0.945 o 3 The molar ratio is 0.465:0.465:0.93:0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com