Method for fabricating film of aluminum zirconate titanate with high orientating (111)

A lead zirconate titanate and orientation technology, which is applied to ceramics and inorganic insulators, can solve the problems of poor repeatability and complicated preparation methods of lead zirconate titanate films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

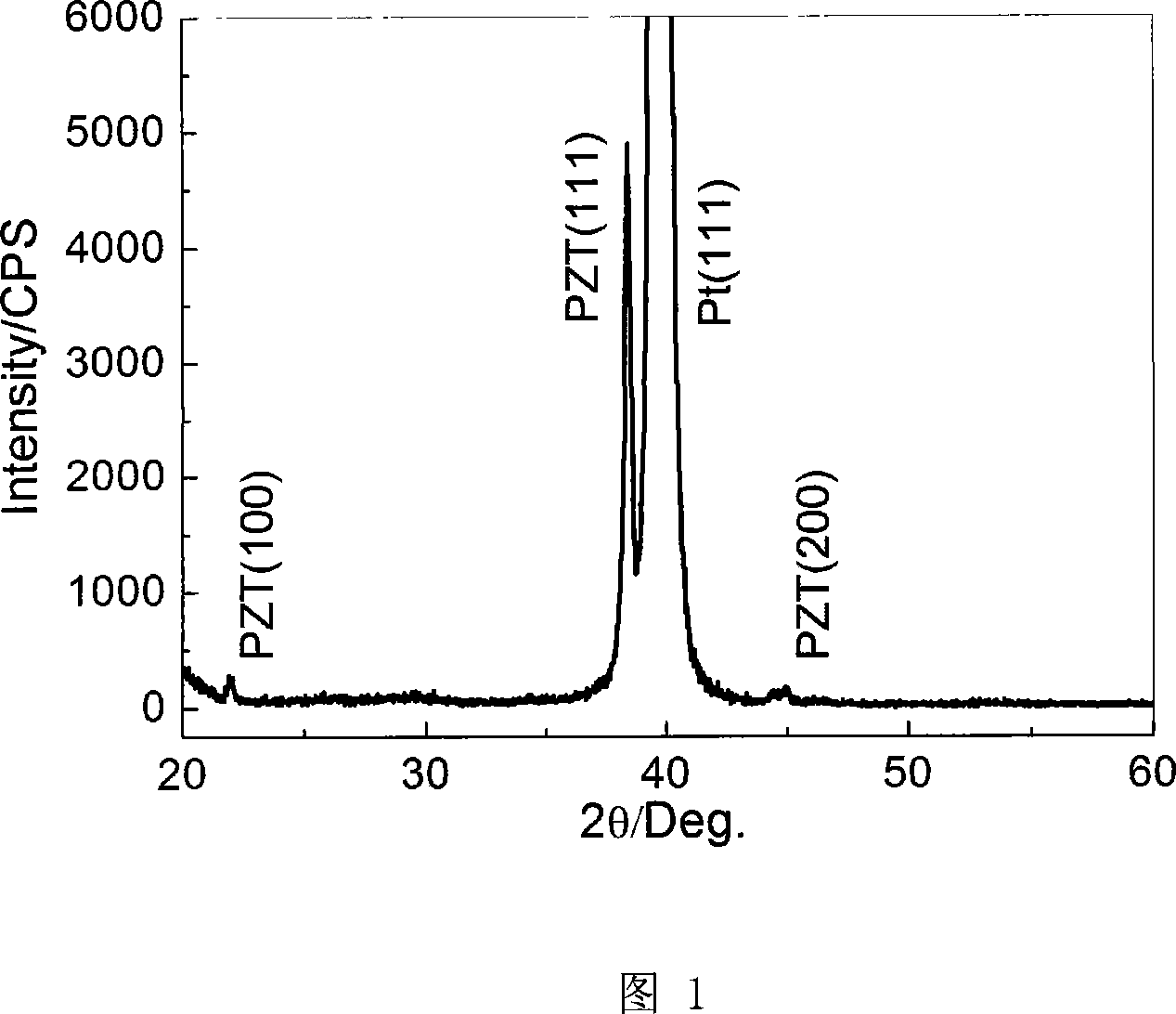

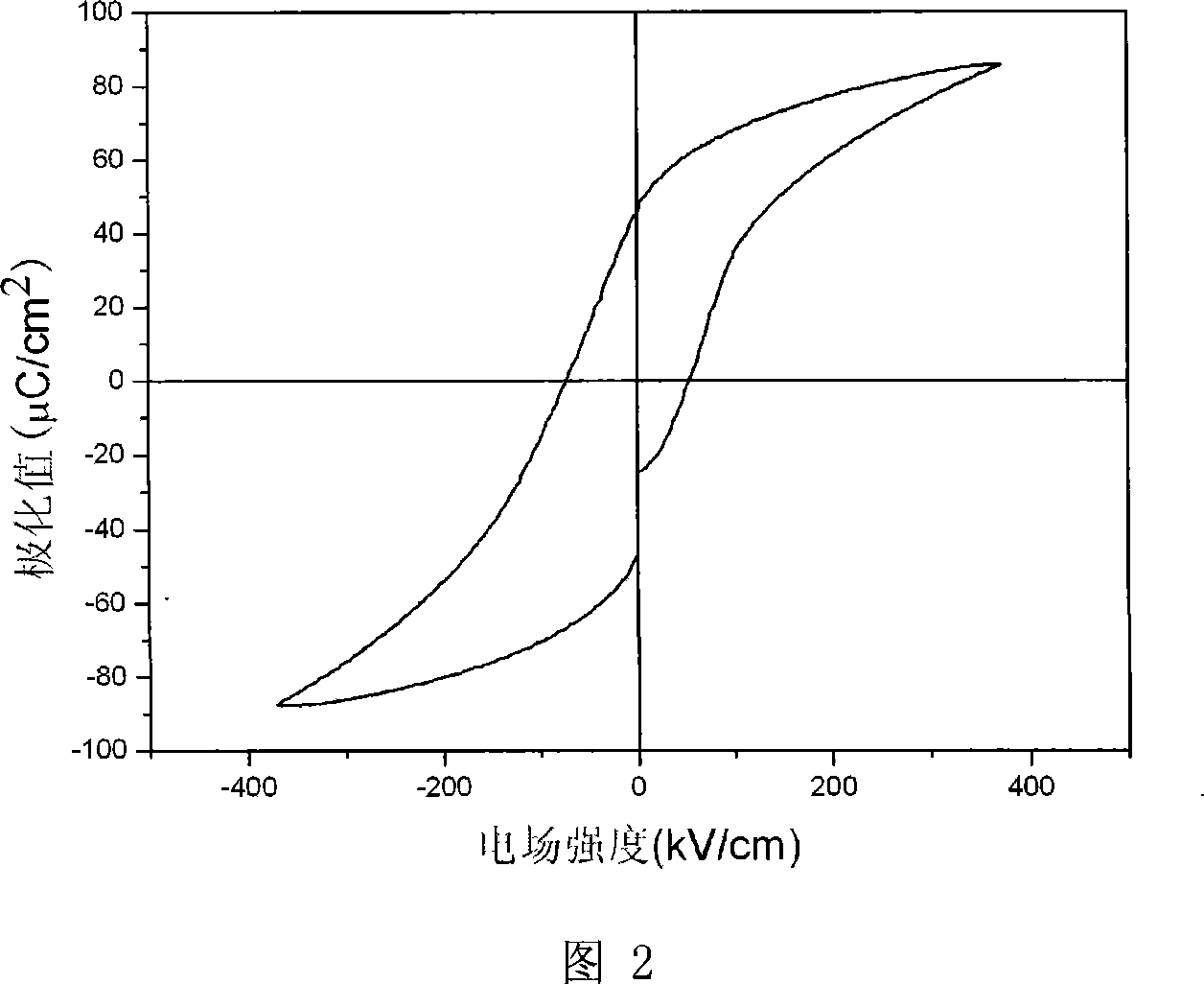

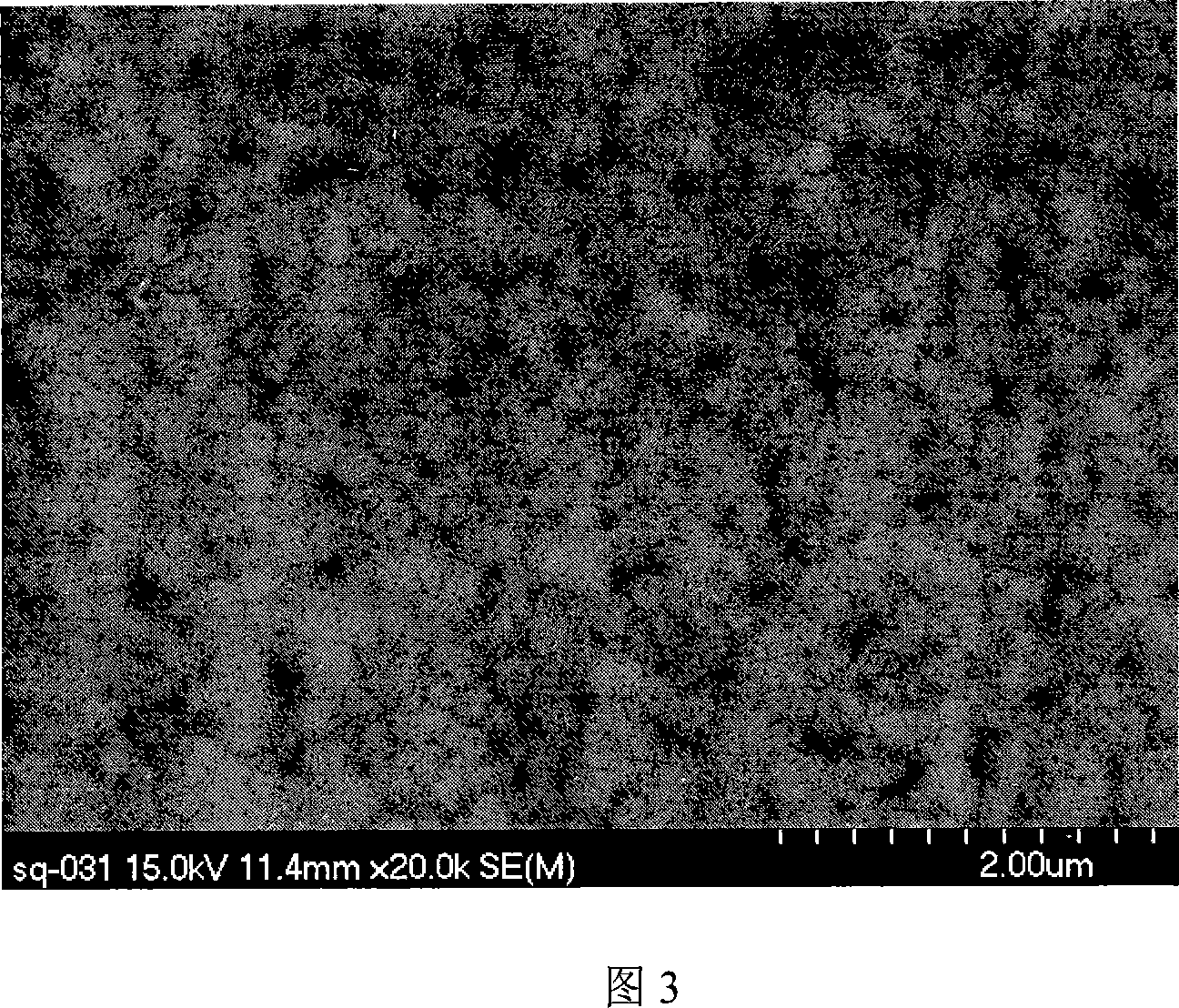

[0005] Specific embodiment one: the preparation method of the lead zirconate titanate ferroelectric thin film of a kind of height (111) orientation in the present embodiment is realized through the following steps: one, 0.022 moles of Pb (OOCH 3 ) 2 ·3H 2 O was added to 50ml of ethylene glycol methyl ether, and then 5ml fraction was distilled at 123°C, then the mixed solution was cooled to room temperature, the mixed solution was stirred and zirconium propoxide and tetrabutyl titanate were added successively, zirconium propoxide The sum of the moles of zirconium propoxide and tetrabutyl titanate is 0.02 moles, the molar ratio of zirconium propoxide to tetrabutyl titanate is between 95:5 and 30:70, and then the mixture is heated to boiling for 5 to 15 minutes Cool the mixed solution to room temperature, add ethylene glycol methyl ether to make the volume of the mixed solution reach 50ml, and obtain the PZT precursor sol; 2. Drop the PZT precursor sol onto the Pt(111) / Ti / SiO 2...

specific Embodiment approach 2

[0006] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step one, 0.022 moles of Pb(OOCH 3 ) 2 ·3H 2 While O is added to 50ml of ethylene glycol methyl ether, 0.0002 to 0.001 mole of rare earth nitrate La(NO 3 ) 3 ·6H 2 O, Nd(NO 3 ) 3 ·6H 2 O, Sm(NO 3 ) 3 ·6H 2 O, Gd(NO 3 ) 3 ·6H 2 O, Eu(NO 3 ) 3 ·6H 2 O or Yb(NO 3 ) 3 ·6H 2 One of O is added to ethylene glycol methyl ether. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0007] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 is that in step 2, the wet film is placed on a 360-440° C. flat furnace and heated for 3.5-4.5 minutes. Other steps are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com