Method for realizing coercive field reduction and pressure resistance improvement of sodium bismuth titanate-based film

A technology of sodium bismuth titanate base and coercive field is applied in the field of reducing the coercive field of sodium bismuth titanate base film and improving its pressure resistance, which can solve the problems of large coercive field of the base film, and achieve low coercive field. , Strong pressure resistance, the effect of improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) According to Na 0.5 Bi 0.5 Ti 0.995 mn 0.005 o 3-δ The stoichiometric ratio, accurately weighed 0.1673g of CH 3 COONa (excess 1%), 1.0191g of Bi(NO 3 ) 3 ·5H 2 O (excess 4%), 0.0050g of C 4 h 6 MnO 4 4H 2 O and the polyethylene glycol 20000 of 0.25g, standby. Accurately measure 1.38ml of acetylacetone in a beaker, then measure 1.38ml of tetra-n-butyl titanate dropwise into acetylacetone, stir on a magnetic stirrer for 4 hours to complete the chelation of titanium, defined as solution 1 . The weighed CH 3 COONa, Bi(NO 3 ) 3 ·5H 2 O, C 4 h 6 MnO 4 4H 2 O was added to a beaker containing 10 ml of ethylene glycol and heated and stirred at 40° C. until all dissolved, which was defined as solution 2. Add the weighed polyethylene glycol 20000 into a beaker filled with 5ml of glacial acetic acid, heat and stir at 50°C until it is completely dissolved, which is defined as solution 3. After all the solutions were cooled, solutions 2 and 3 were slowly add...

Embodiment 2

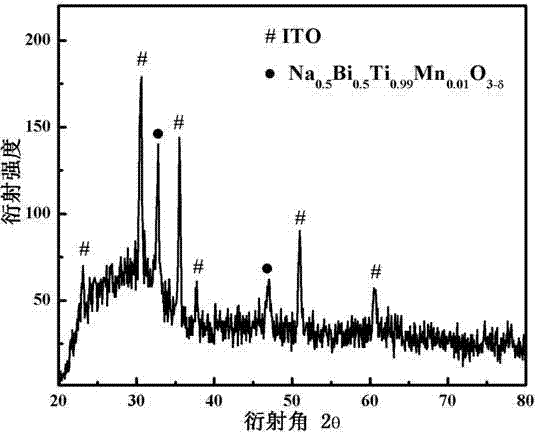

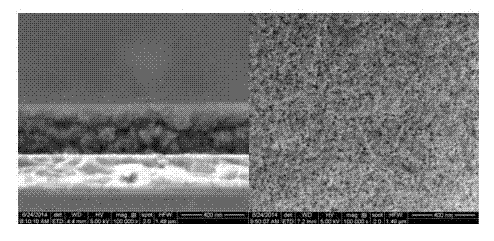

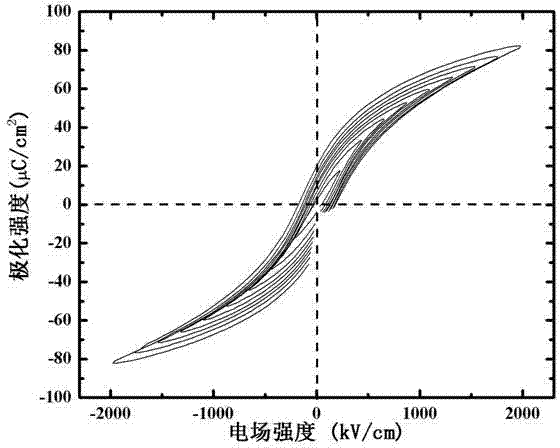

[0036] (1) According to Na 0.5 Bi 0.5 Ti 0.99 mn 0.01 o 3-δ The stoichiometric ratio, accurately weighed 0.3347g of CH 3 COONa (1 % in excess), 2.0775 g of Bi(NO 3 ) 3 ·5H 2 O (excess 6%), 0.0198g of C 4 h 6 MnO 4 4H 2 O and the polyethylene glycol 20000 of 0.51g, standby. Accurately measure 2.75ml of acetylacetone in a beaker, then measure 2.75ml of tetra-n-butyl titanate dropwise into acetylacetone, stir on a magnetic stirrer for 6 hours to complete the chelation of titanium, defined as solution 1 . The weighed CH 3 COONa, Bi(NO 3 ) 3 ·5H 2 O, C 4 h 6 MnO 4 4H 2O was added into a beaker containing 10ml of ethylene glycol and heated and stirred at 50°C until it was completely dissolved, which was defined as solution 2. Add the weighed polyethylene glycol 20000 into a beaker containing 5ml of glacial acetic acid, heat and stir at 60°C until it is completely dissolved, which is defined as solution 3. After all the solutions were cooled, solutions 2 and 3 w...

Embodiment 3

[0040] (1) According to Na 0.5 Bi 0.5 Ti 0.99 mn 0.01 o 3-δ The stoichiometric ratio, accurately weigh 0.1690g of CH 3 COONa (2% in excess), 1.0290g of Bi(NO 3 ) 3 ·5H 2 O (5% excess), 0.0099g of C 4 h 6 MnO 4 4H 2 O and the polyethylene glycol 20000 of 0.25g, standby. Accurately measure 1.38ml of acetylacetone in a beaker, then measure 1.38ml of tetra-n-butyl titanate dropwise into acetylacetone, stir on a magnetic stirrer for 6 hours to complete the chelation of titanium, defined as solution 1 . The weighed CH 3 COONa, Bi(NO 3 ) 3 ·5H 2 O, C 4 h 6 MnO 4 4H 2 O was added into a beaker containing 10ml of ethylene glycol and heated and stirred at 60°C until it was completely dissolved, which was defined as solution 2. The weighed polyethylene glycol 20000 was added into a beaker filled with 5ml of glacial acetic acid, heated and stirred at 70°C until it was completely dissolved, which was defined as solution 3. After all the solutions were cooled, solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com