Inverse spinel zinc ferrite and preparation method thereof

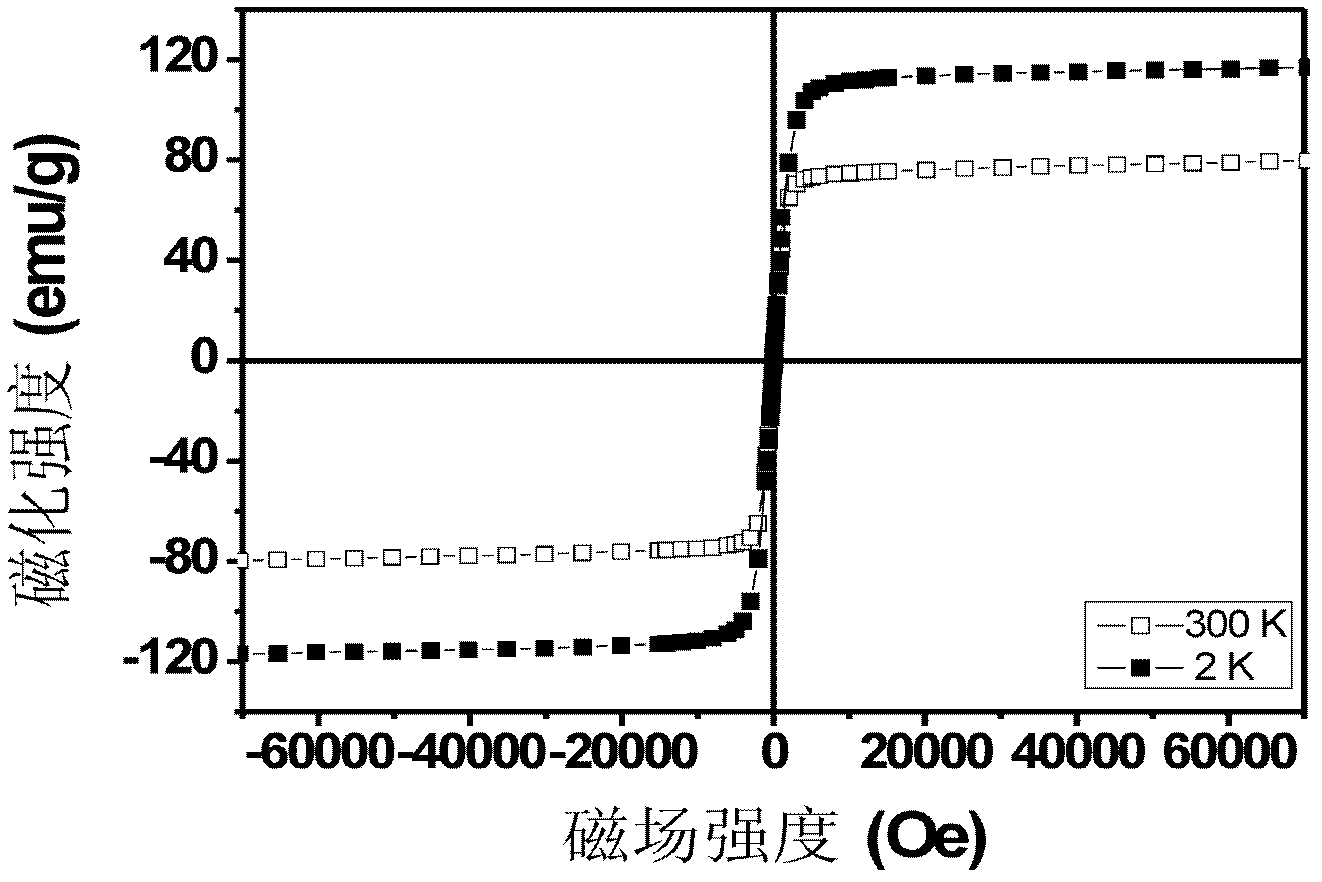

An anti-spinel, zinc ferrite technology, applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve the problem of large coercive field of Zn ferrite, nanoparticles not suitable for long-term high temperature treatment, unsuitable for Soft magnetic materials and other problems, to achieve the effect of high saturation magnetic susceptibility, excellent properties, simple process steps and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific steps are given below:

[0031] 1) After mixing zinc sulfate heptahydrate and ferric sulfate in a mortar and mortar with the same amount of substance, add lithium chloride with 100 times the amount of substance of zinc sulfate heptahydrate, and mix the three evenly.

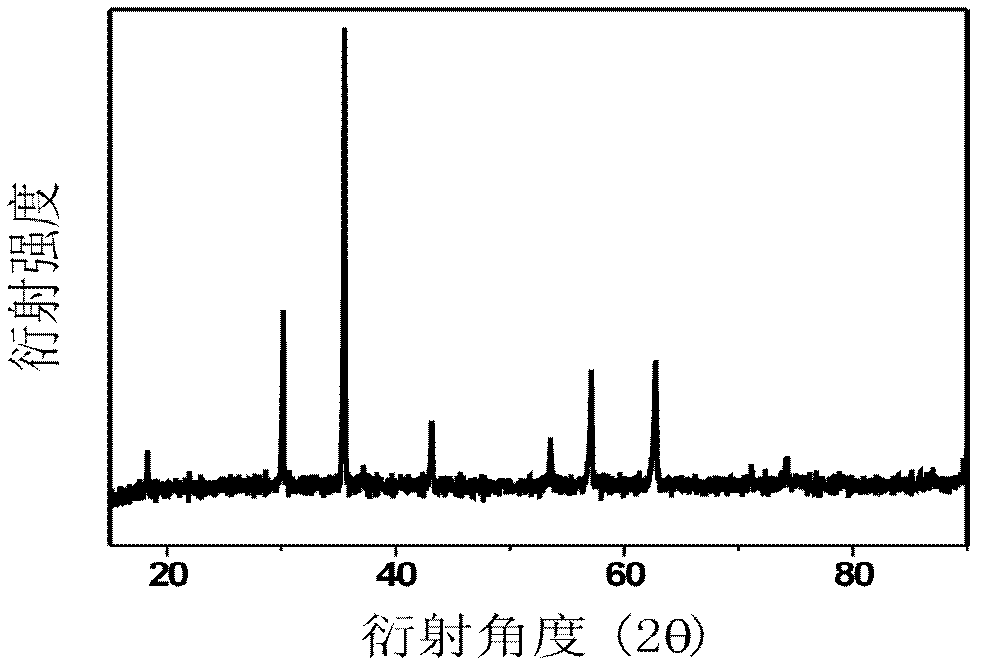

[0032] 2) Put the mixture in step 1) into a high-temperature furnace preheated to 850° C., keep the temperature constant for 1 hour, and take out the product to cool. The process takes place chemical reaction 5Fe 2 (SO 4 ) 3 +2LiCl→2LiFe 5 o 8 +15SO 2 +Cl 2 +7O 2 ;5ZnSO 4 +2LiFe 5 o 8 →5ZnFe 2 o 4 +Li 2 SO 4 +4SO 2 +2O 2 .

[0033] 3) After step 2) is cooled, add deionized water to wash at least once, disperse the solid obtained in step 2) in ethanol, and use a magnet to separate the magnetic product, which is the zinc ferrite powder referred to in the present invention .

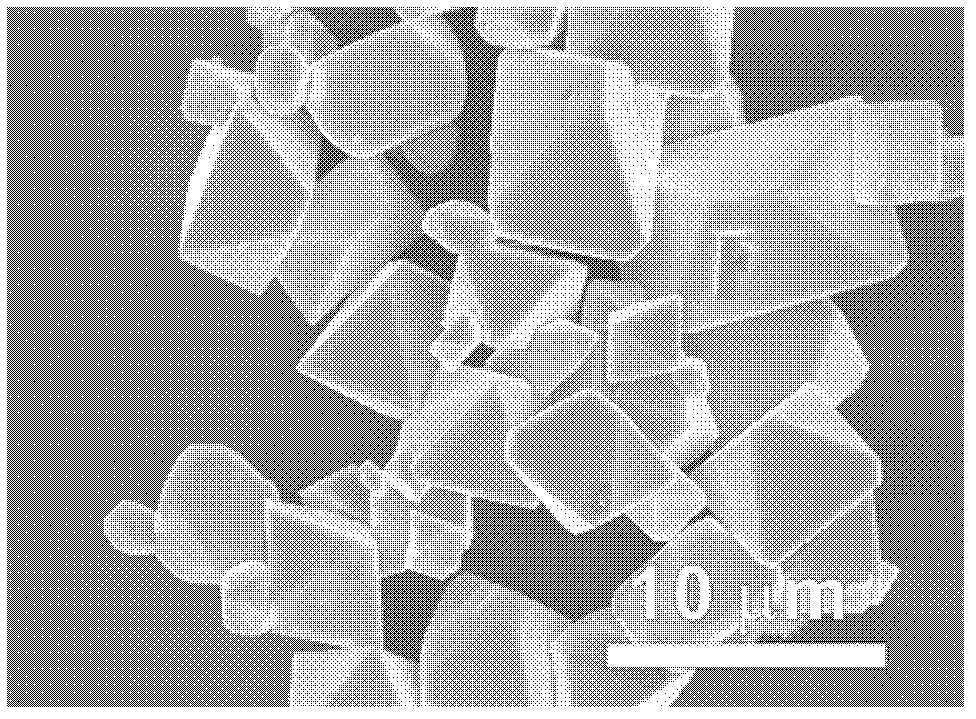

[0034] 4) The powder obtained in step 3) is ball-milled with a 400r / min ball mill for 12 hours, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com