Method for forming optical waveguide quantum chip on gradual periodically polarized lithium tantalate by proton exchange method

A technology of proton exchange and periodic polarization, applied in the direction of optical waveguide light guide, light guide, optics, etc., can solve the problems of complex processing steps, improper process control, waveguide scattering loss, etc., to improve process stability, easy large-scale production, and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

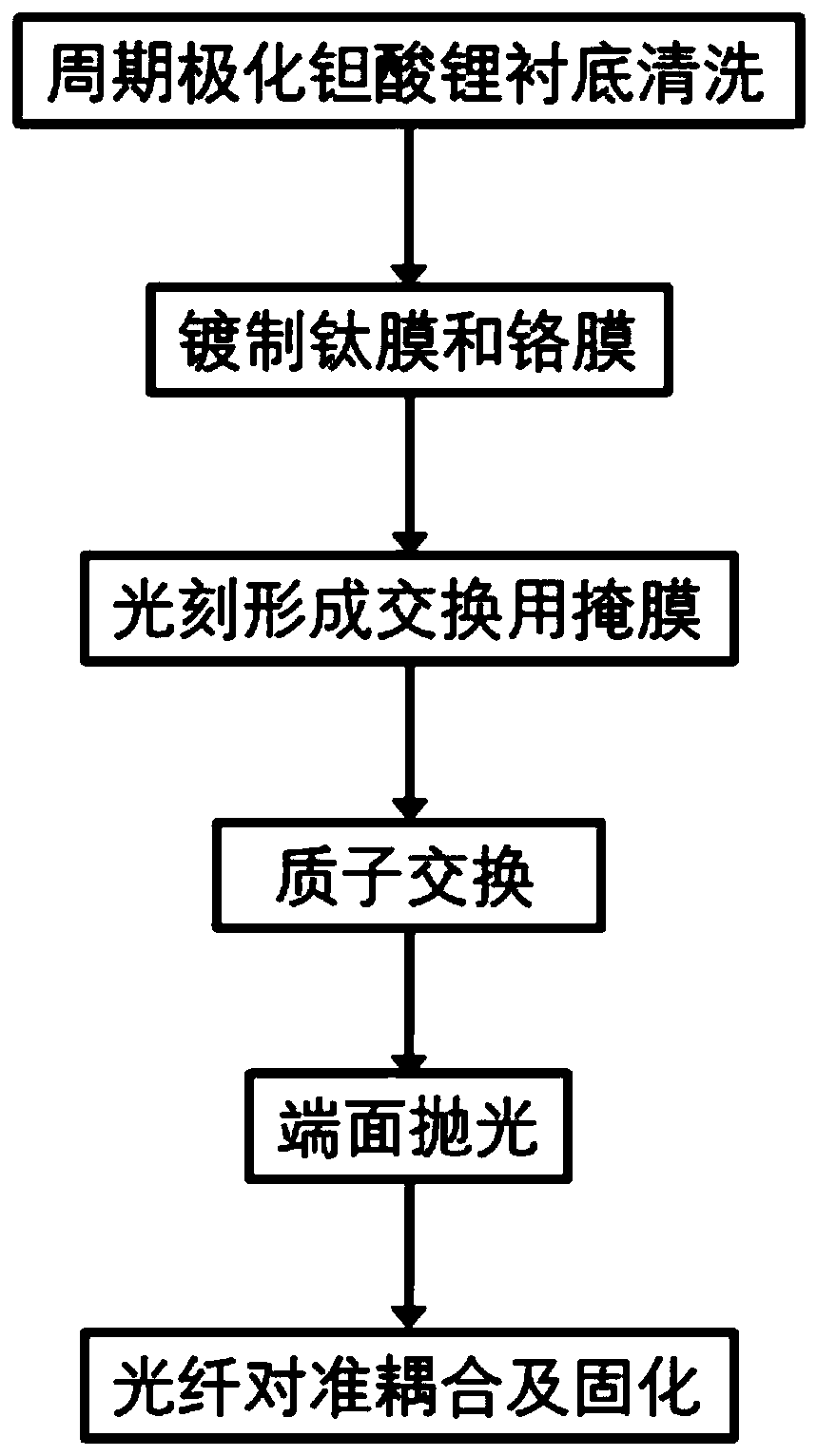

[0049] A method of forming an optical waveguide quantum chip on a graded periodic poled lithium tantalate by using a proton exchange method, such as figure 1 shown, including the following steps:

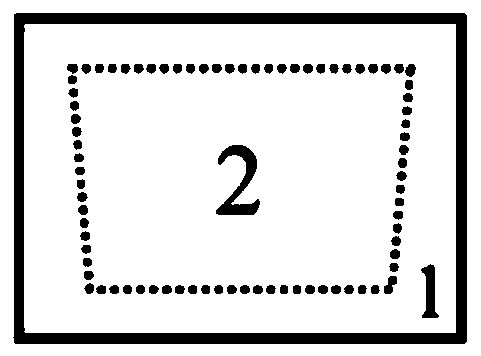

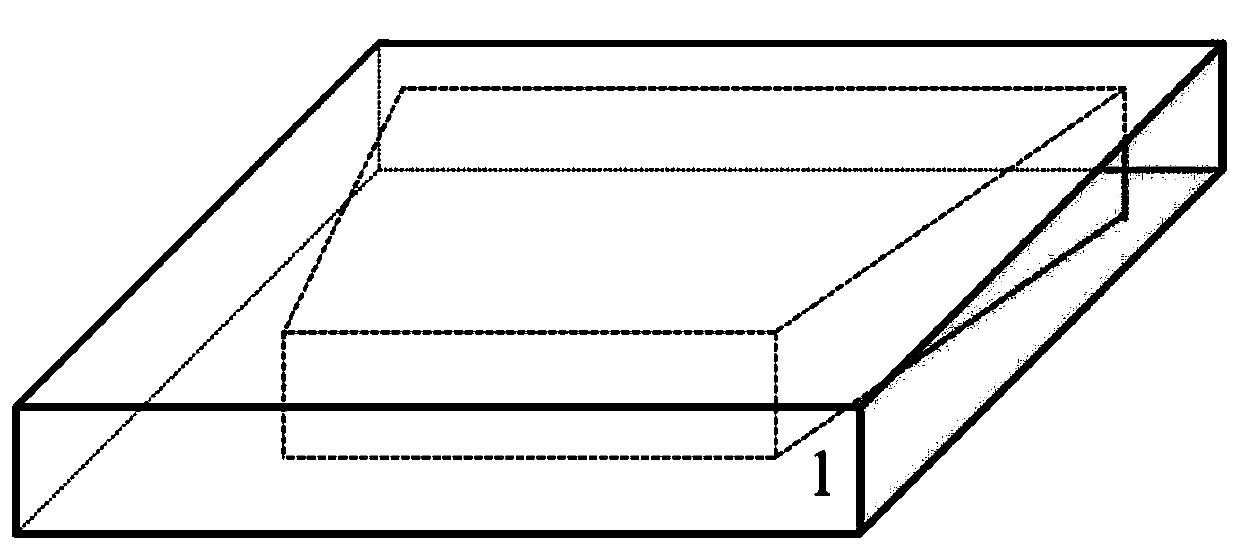

[0050] (1) Clean the magnesium-doped gradual periodic poled lithium tantalate (polarization period 18-22 microns) substrate 1 with a length of 2 cm and a width of 0.7 cm, and dry the sample with nitrogen gas. The substrate structure is as follows: Figure 2(a) , 2(b) As shown, wherein 2(a) is a top view, and Fig. 2(b) is a side view;

[0051] (2) Utilize an electron beam evaporation coating machine to plate a 15nm thick titanium film on the substrate surface;

[0052] (3) Utilize an electron beam evaporation coating machine to plate a 100nm thick chromium film on the substrate surface;

[0053] (4) Use a commercial ultraviolet exposure machine to photolithographically form a 9-micron-wide strip-shaped optical waveguide pattern on the surface of lithium tantalate, such as image ...

Embodiment 2

[0060] A method for forming an optical waveguide quantum chip on a graded periodic poled lithium tantalate by using a proton exchange method, comprising the following steps:

[0061] (1) Clean the magnesium-doped gradual periodic poled lithium tantalate (polarization period 7.5-8.2 microns) substrate with a length of 1.2 cm and a width of 0.7 cm, and dry the sample with nitrogen;

[0062] (2) Utilize an electron beam evaporation coating machine to plate a 10nm thick titanium film on the substrate surface;

[0063] (3) Utilize an electron beam evaporation coating machine to plate an 80nm thick chromium film on the substrate surface;

[0064] (4) Use a commercial ultraviolet exposure machine to photolithographically form a 6.6-micron-wide strip-shaped optical waveguide pattern on the surface of lithium tantalate, and corrode to form a mask sample for proton exchange;

[0065] (5) Exchange the mask sample in benzoic acid for 60 minutes at 200 degrees Celsius;

[0066] (6) Optic...

Embodiment 3

[0070] A method for forming an optical waveguide quantum chip on a graded periodic poled lithium tantalate by using a proton exchange method, comprising the following steps:

[0071] (1) Clean the magnesium-doped gradual periodic poled lithium tantalate (polarization period 8.8-9.7 microns) substrate with a length of 1.2 cm and a width of 0.7 cm, and dry the sample with nitrogen;

[0072] (2) Utilize an electron beam evaporation coating machine to plate a 10nm thick titanium film on the substrate surface;

[0073] (3) Utilize an electron beam evaporation coating machine to plate a 70nm thick chromium film on the substrate surface;

[0074] (4) Use a commercial ultraviolet exposure machine to photolithographically form a 5-micron-wide strip-shaped optical waveguide pattern on the surface of lithium tantalate, and corrode to form a mask sample for proton exchange;

[0075] (5) Exchange the mask sample in benzoic acid for 50 minutes at 200 degrees Celsius;

[0076] (6) Opticall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com