Ferroelectric-antiferroelectric phase transition leadless ferroelectric ceramic material, ceramic element and preparation method of ferroelectric ceramic material

A ferroelectric ceramic and antiferroelectric technology, applied in the field of ferroelectric ceramics, can solve the problems of impurity phase in BNT-BA and no research, and achieve the effect of preventing volatilization and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention also provides a method for preparing the above-mentioned ferroelectric ceramic material, which includes the following steps as an example.

[0030] (a) by Bi 2 o 3 、TiO 2 、Na 2 CO 3 and Al 2 o 3 The powder is the raw material, according to (1-x)Bi 0.5 Na 0.5 TiO 3 -xBiAlO 3 The stoichiometric ratio of the corresponding elements is prepared, mixed by wet ball milling; dried, compacted, and sintered to obtain ceramic powder.

[0031] In the mixing of the wet ball milling method described in the step (a), according to the raw material: milling ball: ethanol=1: (1.8~2.2): (0.7~1.0) mass ratio mixing 20~28 hours, wherein milling ball (ball milling medium ) is a steel ball, a zirconium ball or an agate ball, and ethanol is, for example, AR grade absolute ethanol.

[0032] The sintering conditions in step (a) can be raised to 820-880° C. at a heating rate of 1-2.5° C. / min, and kept for 1-3 hours.

[0033] (b) The ceramic powder obtained in the...

Embodiment 1

[0044] The composition of the ferroelectric-antiferroelectric ferroelectric ceramic material is: 0.95Bi 0.5 Na 0.5 TiO 3 -0.05BiAlO 3 , the preparation steps are as follows:

[0045] (1) Calculate the composition Bi in the powder raw material according to the composition of the above chemical formula 2 o 3 、Na 2 CO 3 、TiO 2 and Al 2 o 3 The mass is prepared according to the composition ratio, mixed by wet ball milling, and mixed for 24 hours according to the mass ratio of raw materials: ball: water = 1:2:0.8, so that the components are mixed evenly. After drying, pass through a 40-mesh sieve, briquette in an air atmosphere, raise the temperature to 850°C at a rate of 2°C / min, and keep it warm for 2 hours to synthesize a composition of 0.95Bi 0.5 Na 0.5 TiO 3 -0.05BiAlO 3 ceramic powder;

[0046] (2) smash the ceramic powder obtained in step (1), pass through a 40-mesh sieve, and finely grind for 24 hours by wet ball milling, dry the ceramic powder after fine grin...

Embodiment 2

[0051] The composition of the ferroelectric-antiferroelectric ferroelectric ceramic material is: 0.92Bi 0.5 Na 0.5 TiO 3 -0.08BiAlO 3

[0052] The preparation method of Example 1 was repeated according to the above chemical formula, and the product was tested.

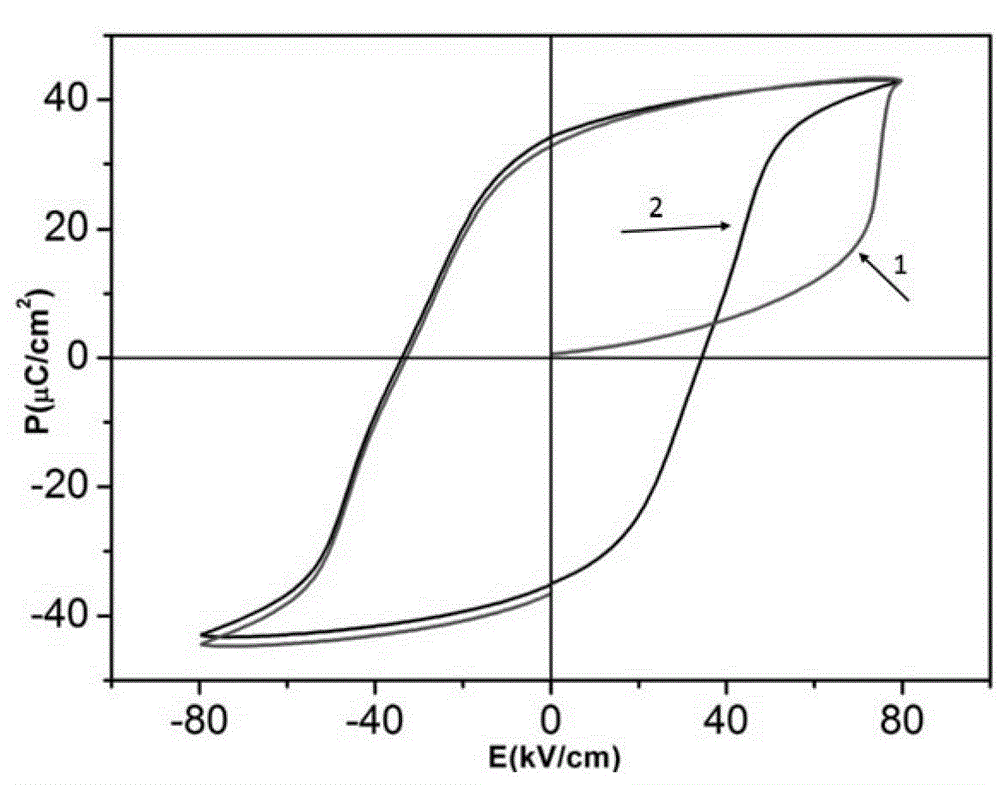

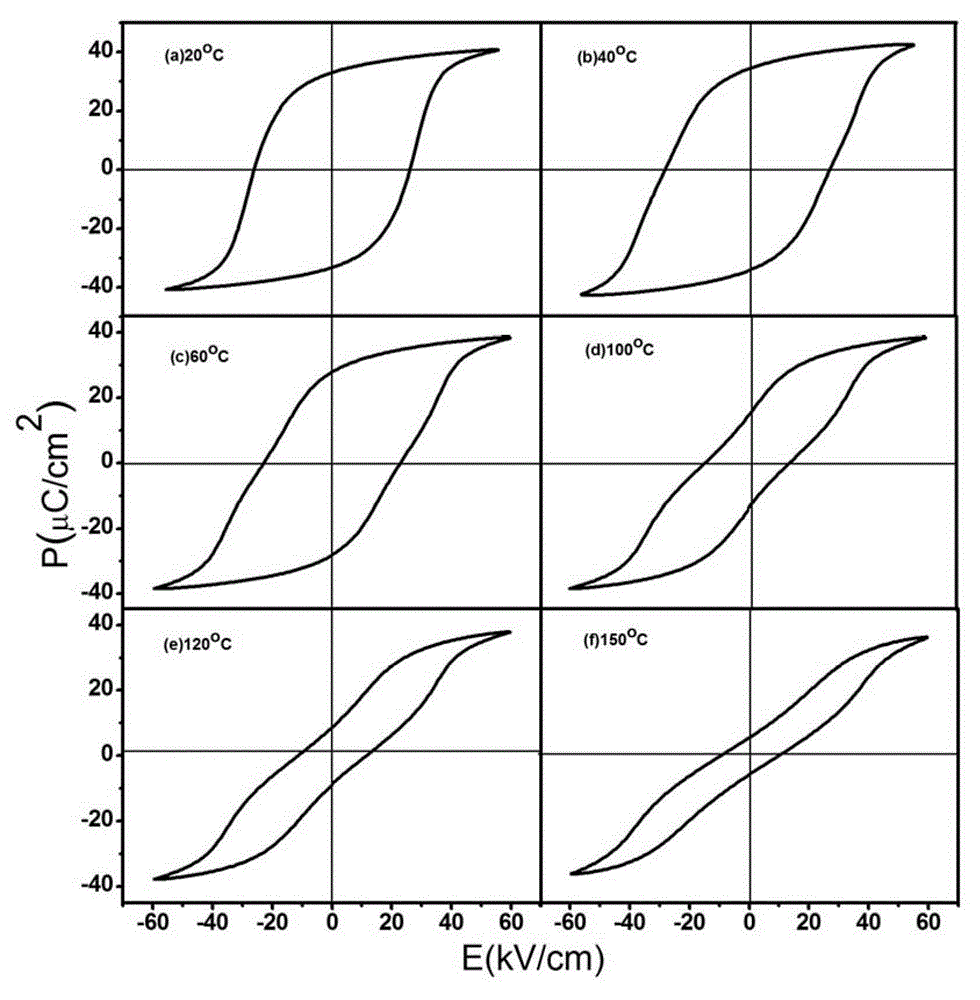

[0053] The hysteresis loop test was carried out at room temperature to the ceramic element of this embodiment, and the test results are shown in Table 1, and the remanent polarization P r Up to 47μC / cm 2 . The ceramic element of the present embodiment has carried out the measurement of electric hysteresis loop under different temperatures, and measurement result is as follows figure 2 . Depend on figure 2 It can be seen that as the temperature increases, the shape of the hysteresis loop gradually changes into a "beam waist" shape, transitioning to a double hysteresis loop, that is, as the temperature increases, the system gradually changes from ferroelectric phase to antiferroelectric phase. phase transition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| remanent polarization | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com