Lead zirconate titanate piezoelectric film, and preparation method and application thereof

A lead zirconate titanate piezoelectric and thin film technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc. It can solve the problems of process complexity, piezoelectric performance degradation, domain instability and reversal, and influence on driving accuracy, etc., and achieve the effects of easy industrialization, stable performance, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

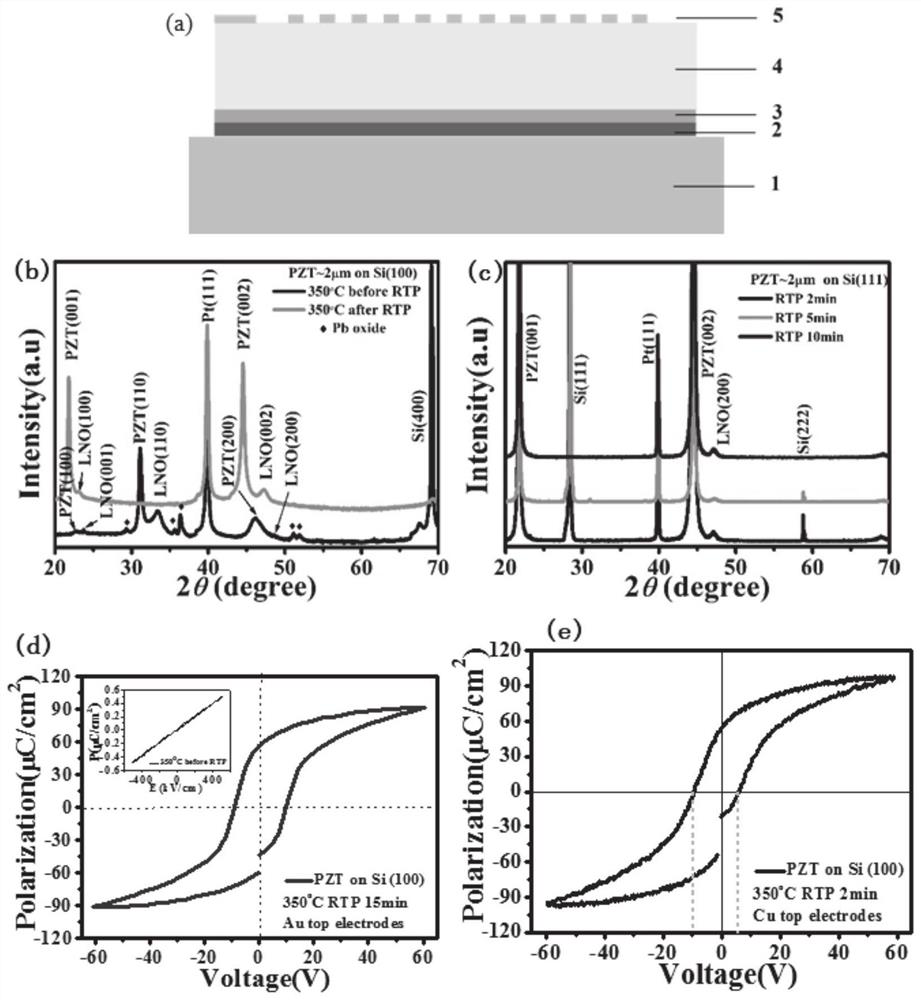

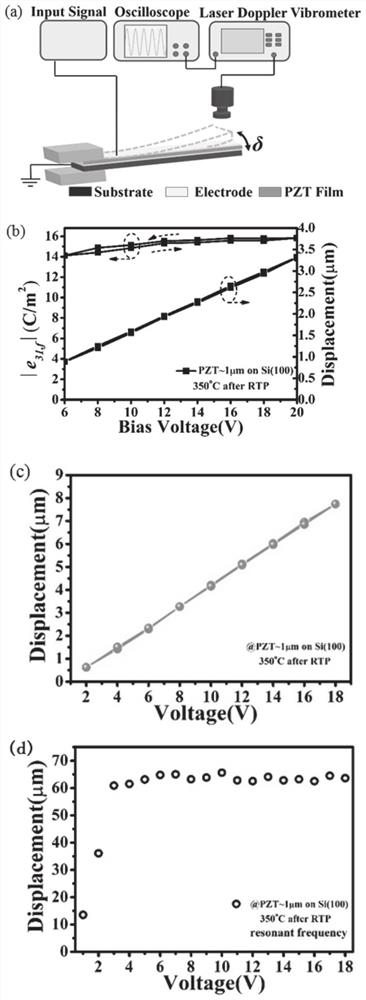

[0040] In a second aspect, the present invention provides a method for preparing the lead zirconate titanate piezoelectric thin film, comprising the following steps:

[0041]Deposit the bottom electrode and buffer layer sequentially on the substrate, and radio frequency magnetron sputtering PZT dielectric layer on the buffer layer;

[0042] Then the deposited PZT thin film system is subjected to rapid annealing;

[0043] After annealing and cooling down, a top electrode is deposited on the PZT dielectric layer.

[0044] In some embodiments, choose SiO 2 / (100)Si substrate is used as the substrate, and after ultrasonic cleaning with acetone and alcohol to remove surface organic impurities, it is cleaned with deionized water and dried, and finally placed in a vacuum coating chamber and heated to 200 ~400°C.

[0045] In some embodiments, the deposition method of the bottom electrode is as follows: using metal Ti and Pt targets, sequentially sputtering on the silicon substrate ...

Embodiment

[0063] (1) Treatment of the substrate

[0064] Cleaning and mounting: SiO with (100) or (111) orientation 2 / Si substrate, the substrate was ultrasonically cleaned with acetone and alcohol in turn, rinsed with deionized water, and finally dried and placed on the substrate holder in the vacuum chamber. After the chamber is closed, the system is pumped to 3Pa with a mechanical pump, and then vacuumed to 10 Pa with a molecular pump. -4 Pa.

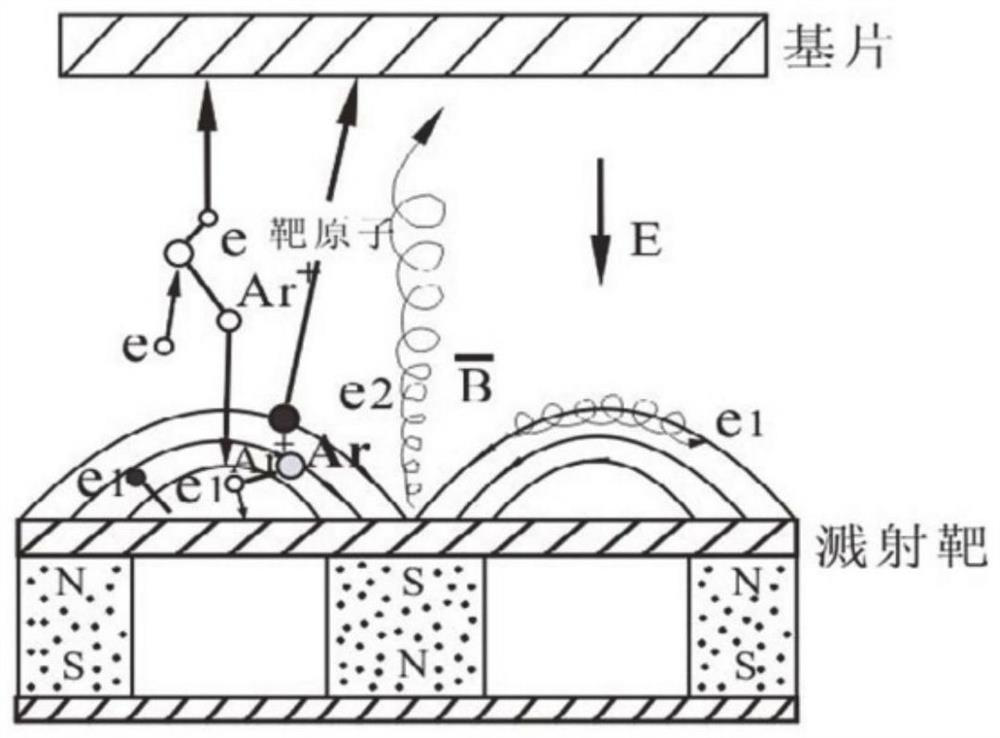

[0065] Heating: Introduce Ar gas into the vacuum chamber, adjust the flow rate, control the air pressure at 0.8-3Pa, and then heat the substrate to reach a temperature of 200-400°C.

[0066] (2) Preparation of pure metal bottom electrode

[0067] Using Ti target and Pt target, they were sequentially deposited on the substrate (Pt on Ti) by radio frequency magnetron sputtering in a vacuum chamber. The Ar gas flow during sputtering deposition is controlled at 30-100 sccm, the gas pressure during sputtering is kept at 0.1-3Pa, and the target...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power density | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

| Remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com