Ferroelectric film capacity used for ferroelectric memorizer and its manufacturing method

A technology of ferroelectric memory and ferroelectric thin film, which is applied in the fields of electric solid device, semiconductor/solid state device manufacturing, circuit, etc. Large polarization, good fatigue characteristics, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

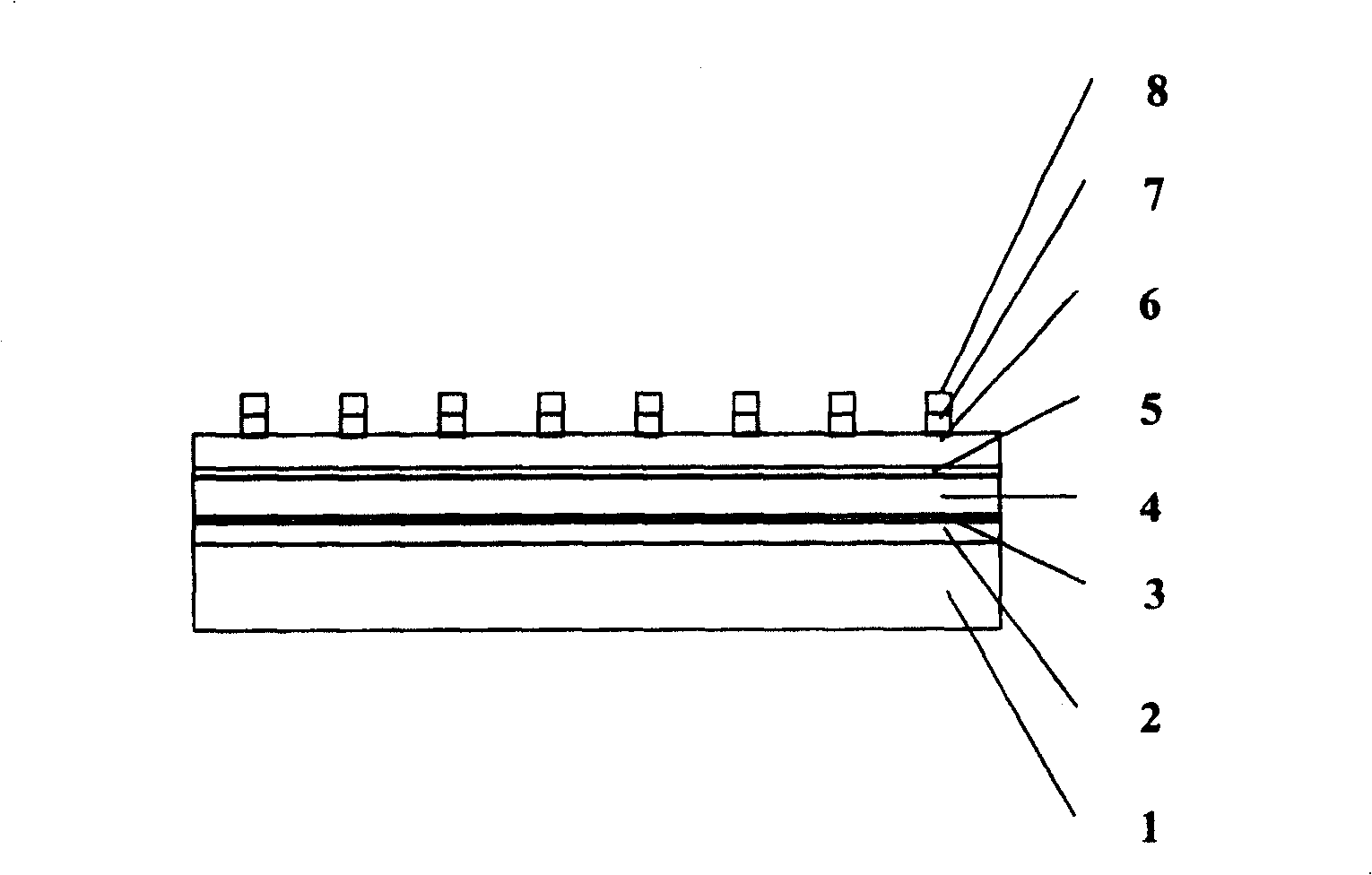

[0031] Embodiment 1 A method for preparing a ferroelectric film capacitor for ferroelectric memory, including

[0032] ① Surface treatment and cleaning of silicon substrate 1 according to standard CMOS process;

[0033] ② Using the thermal oxidation method, a 150nm thick silicon dioxide barrier layer 2 is formed on the surface of the silicon substrate 1;

[0034] ③Use magnetron sputtering method to prepare 20nm thick titanium dioxide bonding layer 3 on the silicon dioxide barrier layer 2. The magnetron sputtering process conditions are: sputtering pressure 1.5Pa, sputtering substrate temperature 200℃, sputtering Shooting atmosphere is O 2 :Ar=1:9;

[0035] ④Prepare 150nm thick bottom electrode metal layer Pt4 on the titanium dioxide bonding layer 3 by magnetron sputtering. The process conditions of magnetron sputtering are: sputtering pressure 1Pa, sputtering substrate temperature 200℃, sputtering atmosphere Is Ar gas;

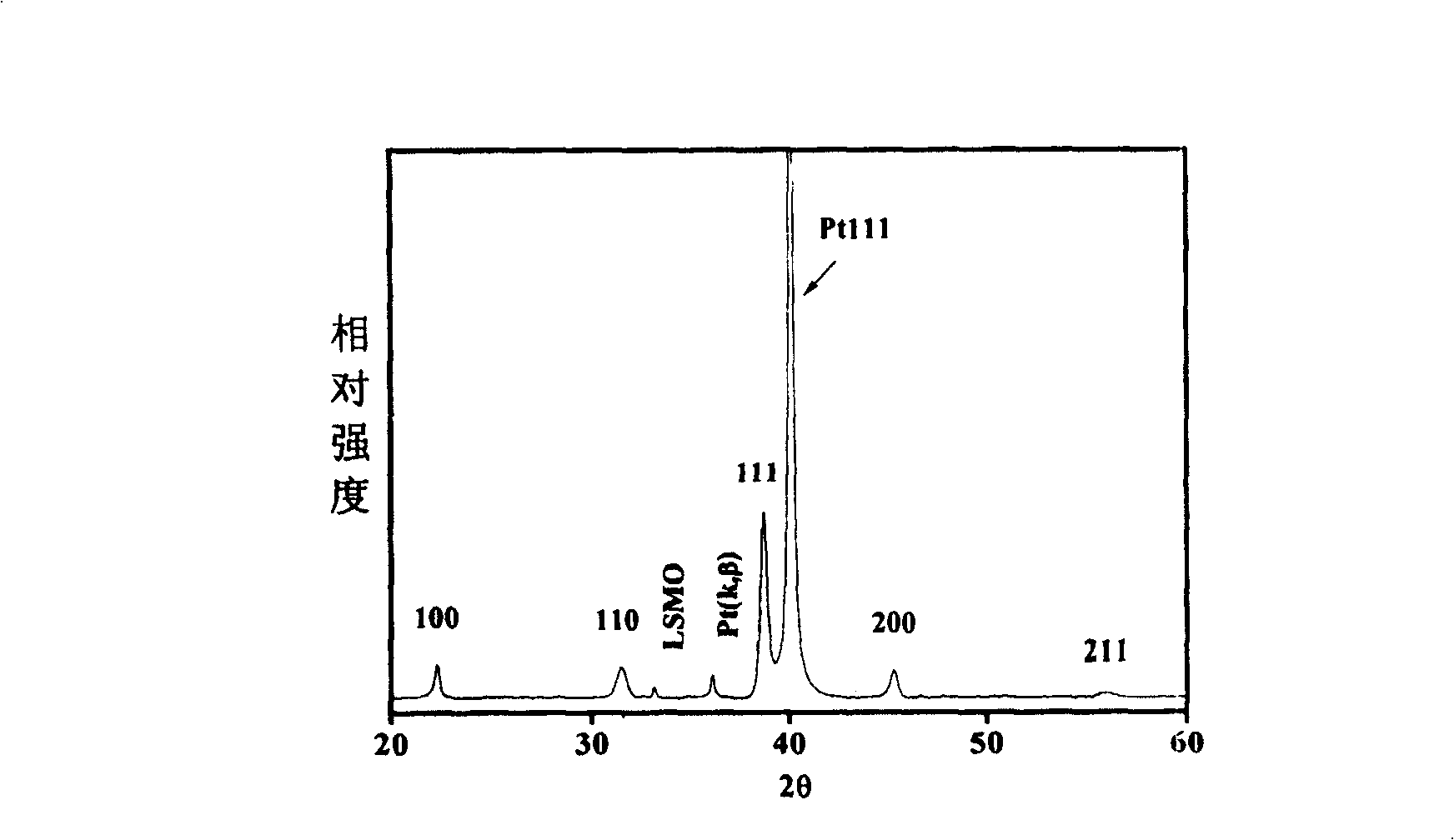

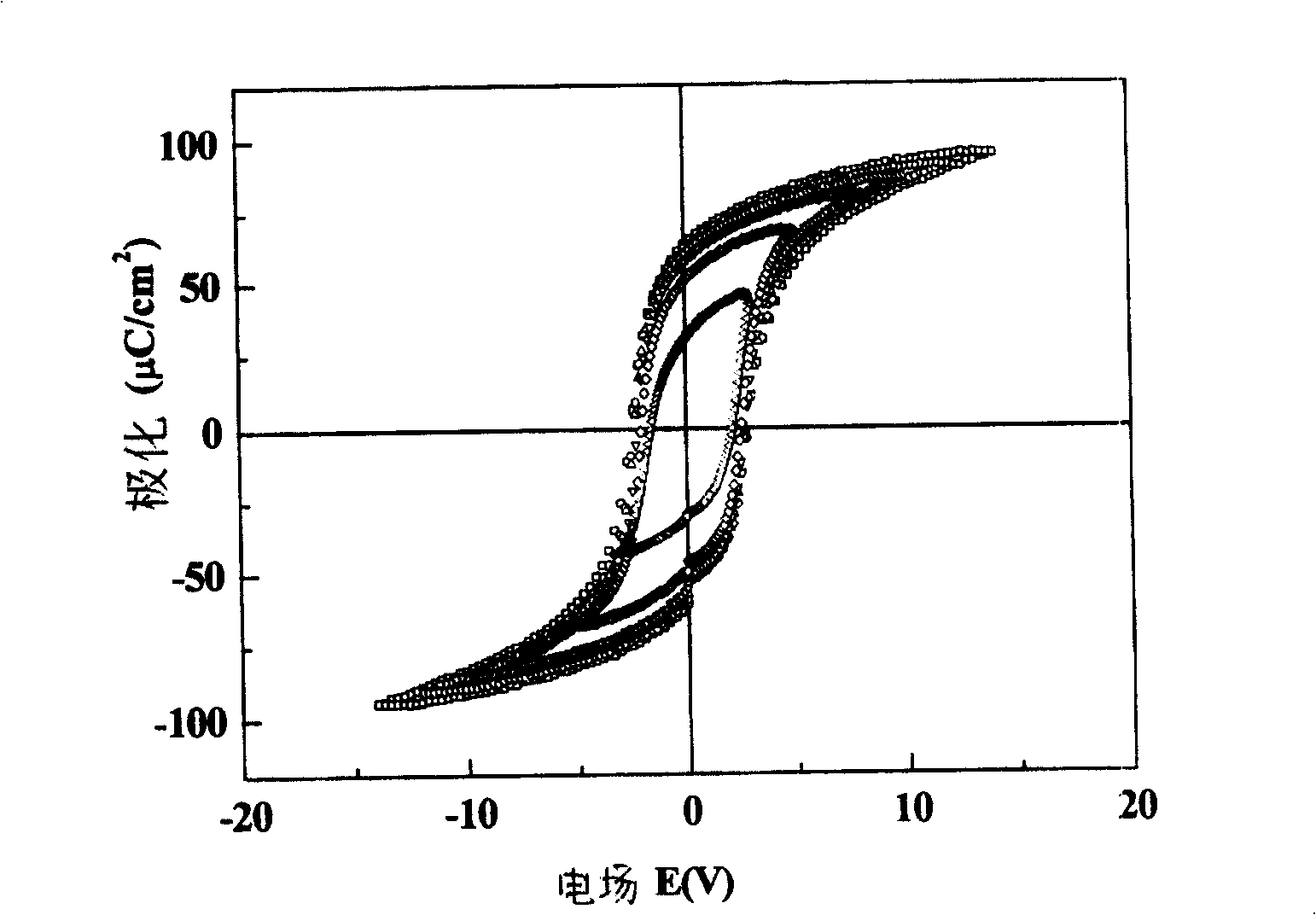

[0036] ⑤ LSMO target material is prepared by standard solid ...

Embodiment 2

[0047] Embodiment 2 A method for preparing a ferroelectric film capacitor for ferroelectric memory, including

[0048] ① Surface treatment and cleaning of silicon substrate 1 according to standard CMOS process;

[0049] ② Using thermal oxidation method, a 120nm thick silicon dioxide barrier layer 2 is formed on the surface of the silicon substrate 1;

[0050] ③ Use magnetron sputtering method to prepare 30nm thick titania bonding layer 3 on the silicon dioxide barrier layer 2. The magnetron sputtering process conditions are: sputtering pressure 0.5Pa, sputtering substrate temperature 300℃, sputtering Shooting atmosphere is O 2 :Ar=2:9;

[0051] ④A 150nm thick lower electrode metal layer Pt4 is prepared on the titanium dioxide bonding layer 3 by magnetron sputtering. The magnetron sputtering process conditions are: sputtering pressure 0.5Pa, sputtering substrate temperature 300℃, sputtering The atmosphere is Ar gas;

[0052] ⑤Prepare the LSMO target by standard solid-phase reaction...

Embodiment 3

[0059] Embodiment 3 A method for preparing a ferroelectric film capacitor for ferroelectric memory, including

[0060] ① Surface treatment and cleaning of silicon substrate 1 according to standard CMOS process;

[0061] ②Using thermal oxidation method to generate 200nm thick silicon dioxide barrier layer 2 on the surface of silicon substrate 1;

[0062] ③Use magnetron sputtering method to prepare 20nm thick titania bonding layer 3 on the silicon dioxide barrier layer 2. The magnetron sputtering process conditions are: sputtering pressure 1Pa, sputtering substrate temperature 200℃, sputtering The atmosphere is O 2 :Ar=1:9;

[0063] ④ Use magnetron sputtering method to prepare 100nm thick bottom electrode metal layer Pt4 on the titanium dioxide bonding layer 3. The process conditions of magnetron sputtering are: sputtering pressure 1Pa, sputtering substrate temperature 200℃, sputtering atmosphere Is Ar gas;

[0064] ⑤Prepare the LSMO target by standard solid-phase reaction method, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com