Potassium-sodium lithium niobate-base lead-free piezoelectric ceramic complex with good temperature stability

A potassium-sodium-lithium niobate-based lead-free piezoelectric technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., to achieve high remanent polarization, good ferroelectricity, good Effect of Piezoelectric Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

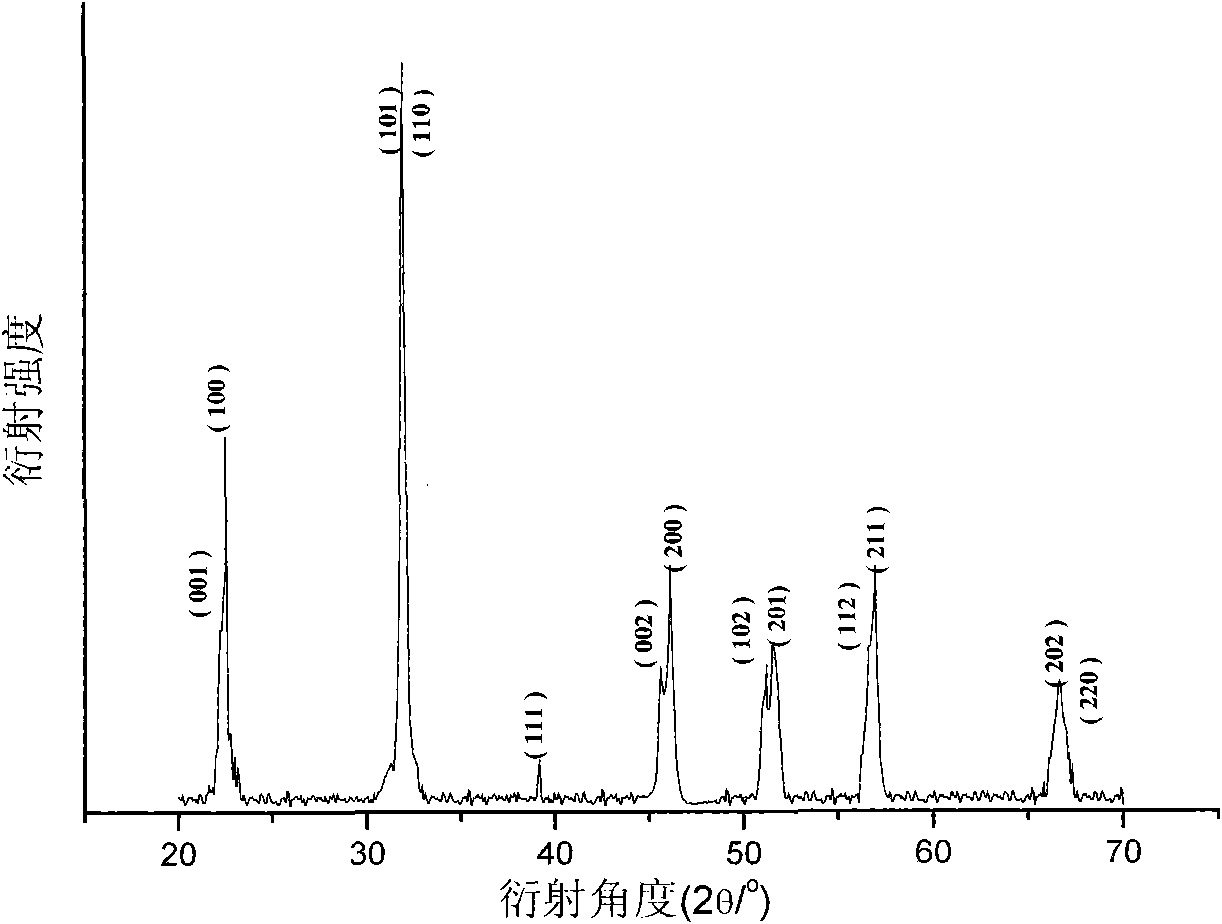

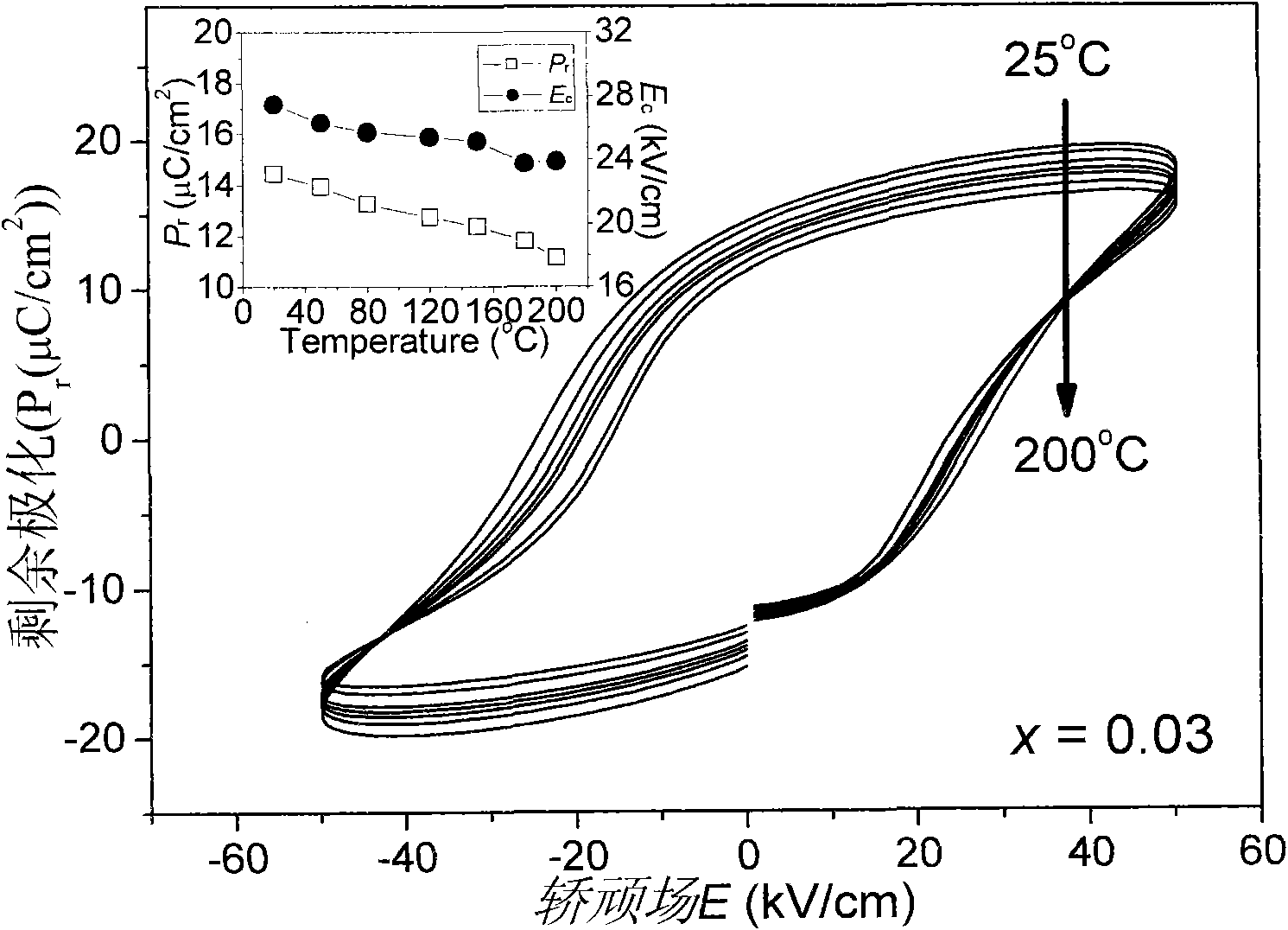

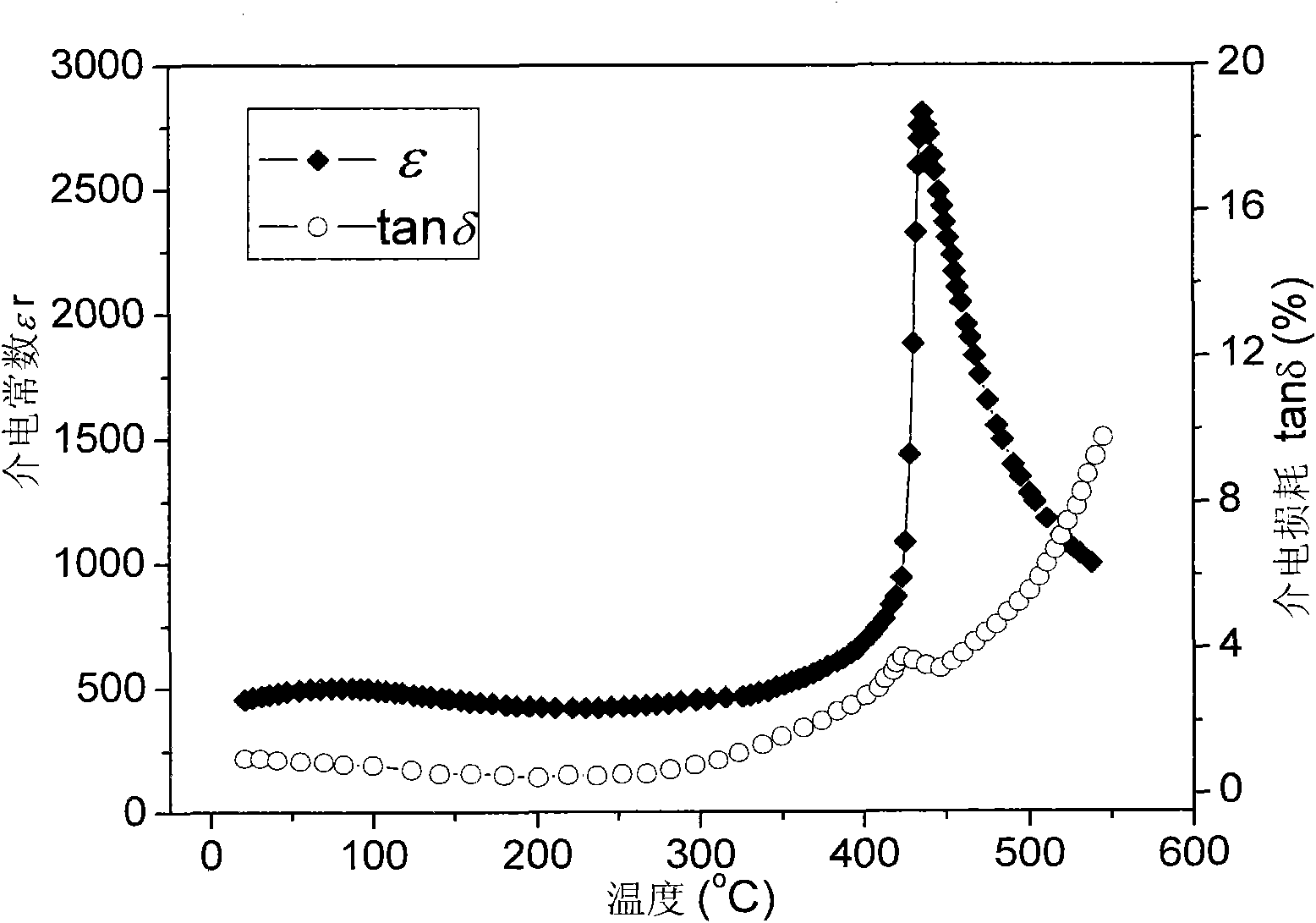

[0032] Example: with Na 2 CO 3 、K 2 CO 3 , Li 2 CO 3 , Nb 2 o 5 、 Bi 2 o 3 、TiO 2 As raw materials, the purity of all raw materials is analytically pure. Press (1-x)(K 0.5 Na 0.5 ) 0.94 Li 0.06 NbO 3 -x(Na 0.5 Bi 0.5 )TiO 3 (x=0-0.05) stoichiometric weighing, batching according to the solid phase synthesis method, ball milling and mixing for 4 hours, drying, heat preservation at 850°C for 2 hours pre-synthesis, fine grinding, drying, adding binder, molding, plastic discharge (850° C. / 2 hours), sintering at 1060-1130° C. for 2 hours, and then forming the perovskite structure ceramic composite with the above formula. The relevant properties are listed in Table 1. figure 1 Is the resulting piezoelectric ceramic composite 0.96 (K 0.5 Na 0.5 ) 0.94 Li 0.06 NbO 3 -0.04 (Na 0.5 Bi 0.5 )TiO 3 It can be seen from the XRD pattern that it is a typical single tetragonal phase perovskite structure. figure 2 Is the resulting piezoelectric ceramic composite 0.97 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com