Patents

Literature

38 results about "Strontium ruthenate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Strontium ruthenate (SRO) is an oxide of strontium and ruthenium with the chemical formula Sr₂RuO₄. It was the first reported perovskite superconductor that did not contain copper. Strontium ruthenate is structurally very similar to the high-temperature cuprate superconductors, and in particular, is almost identical to the lanthanum doped superconductor (La, Sr)₂CuO₄. However, the transition temperature for the superconducting phase transition is 0.93 K, which is much lower than the corresponding value for cuprates.

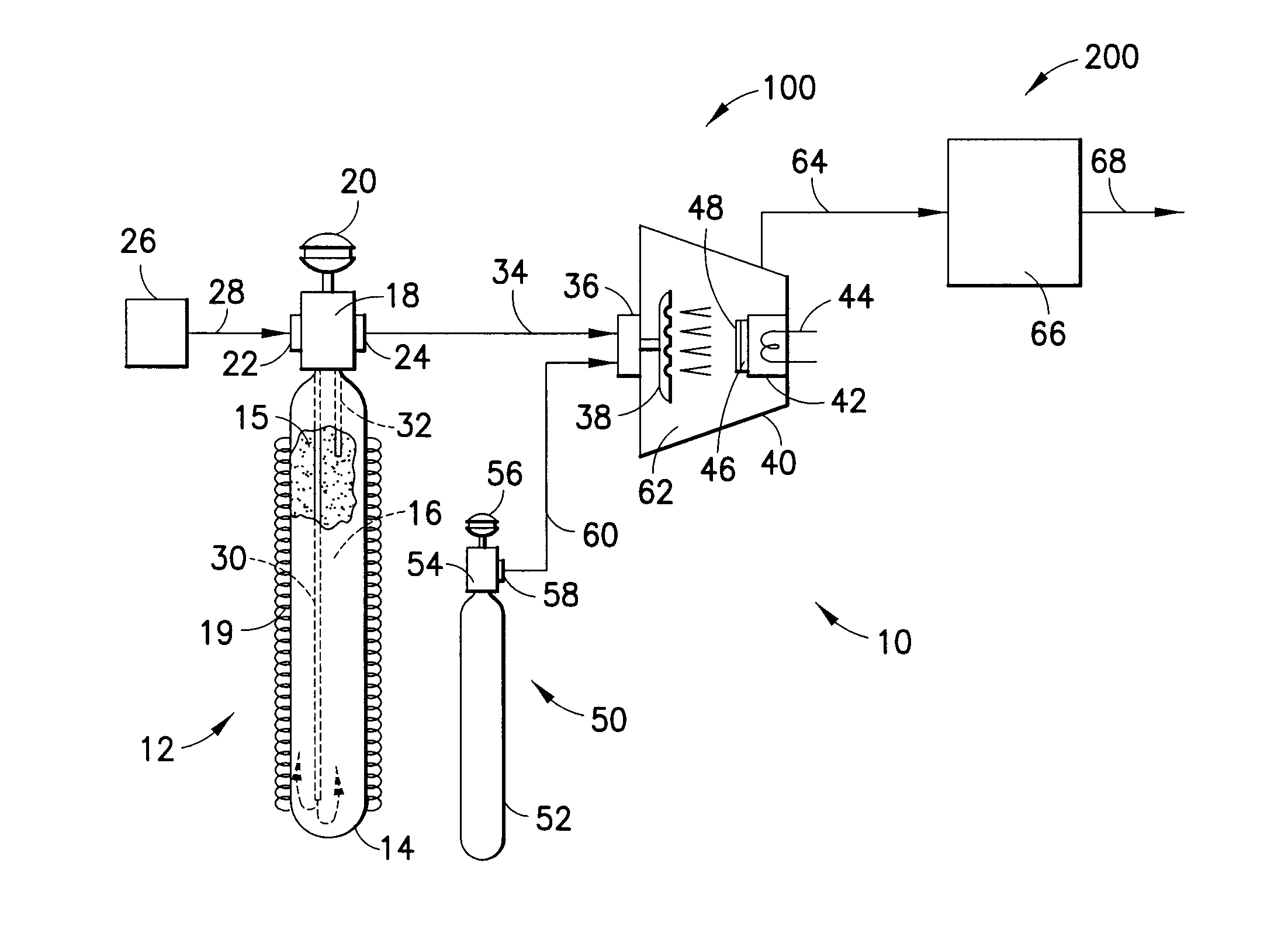

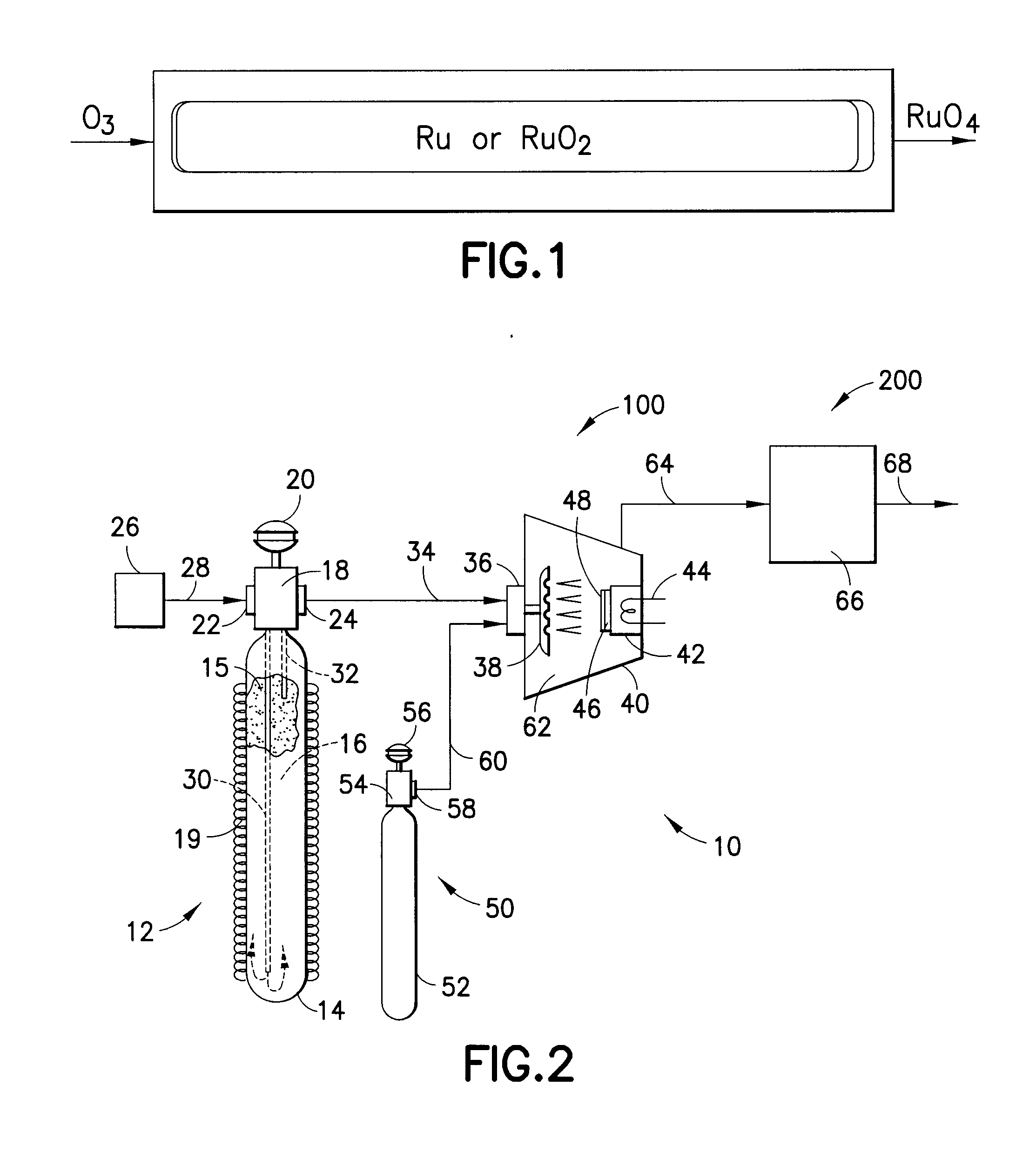

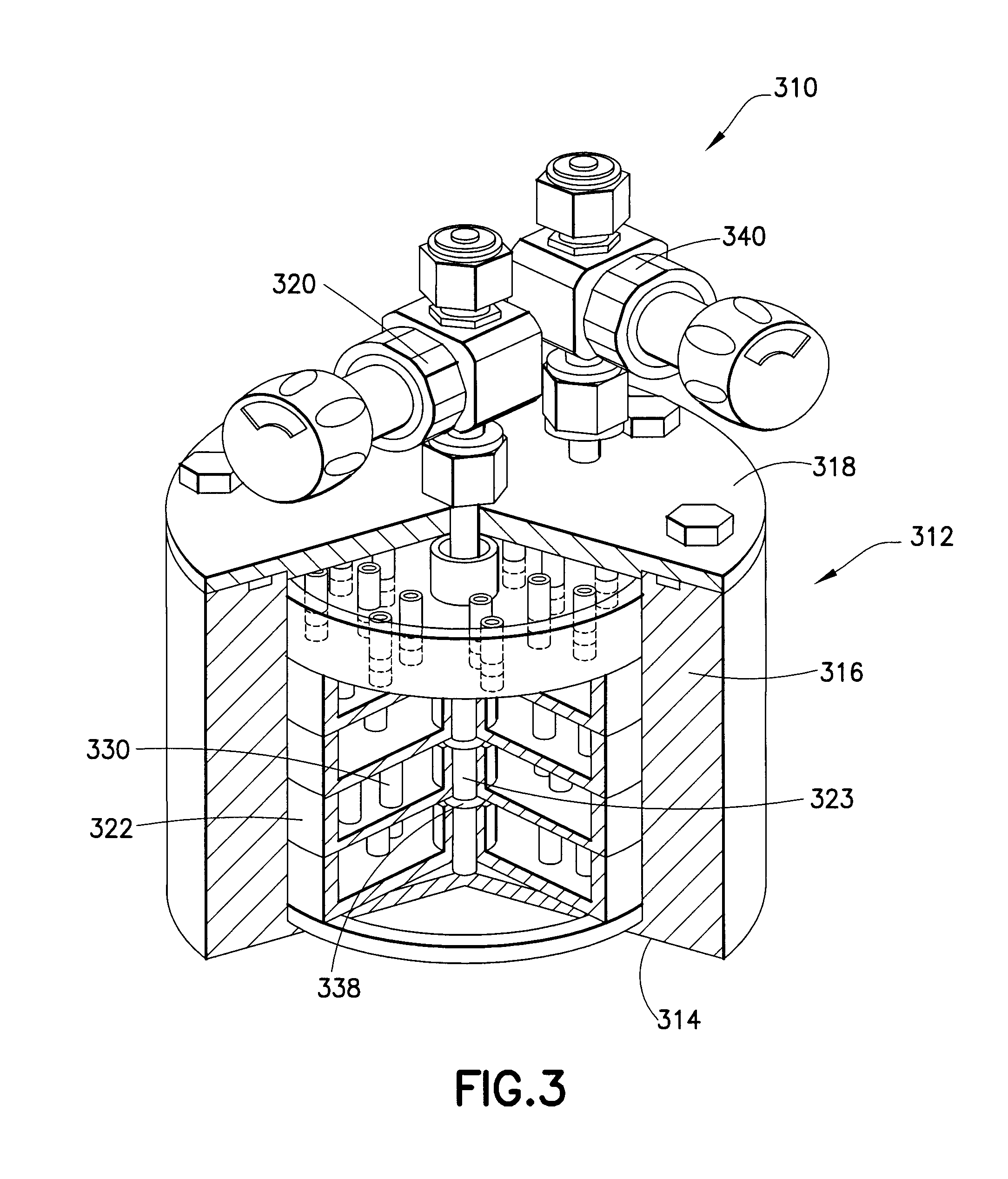

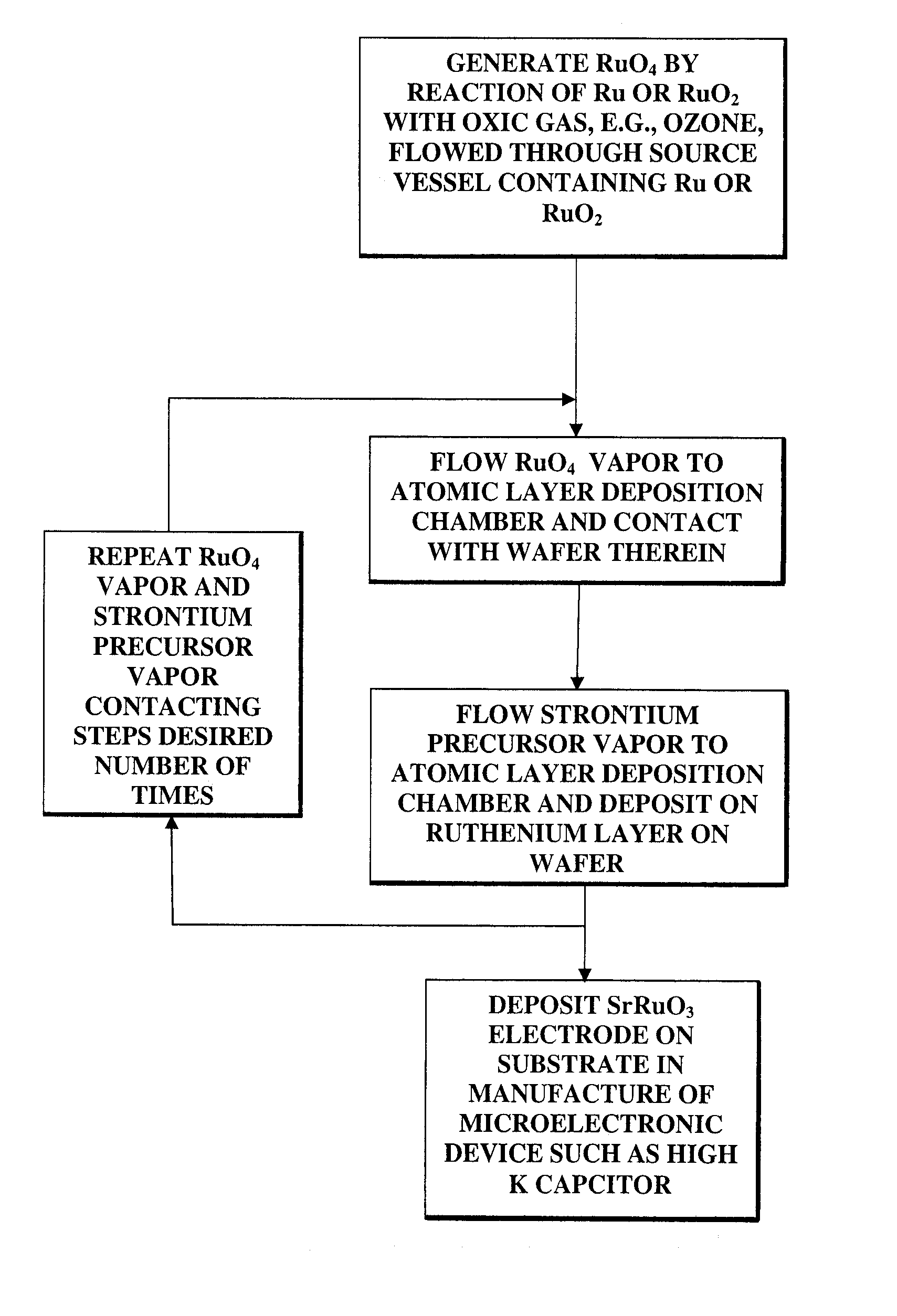

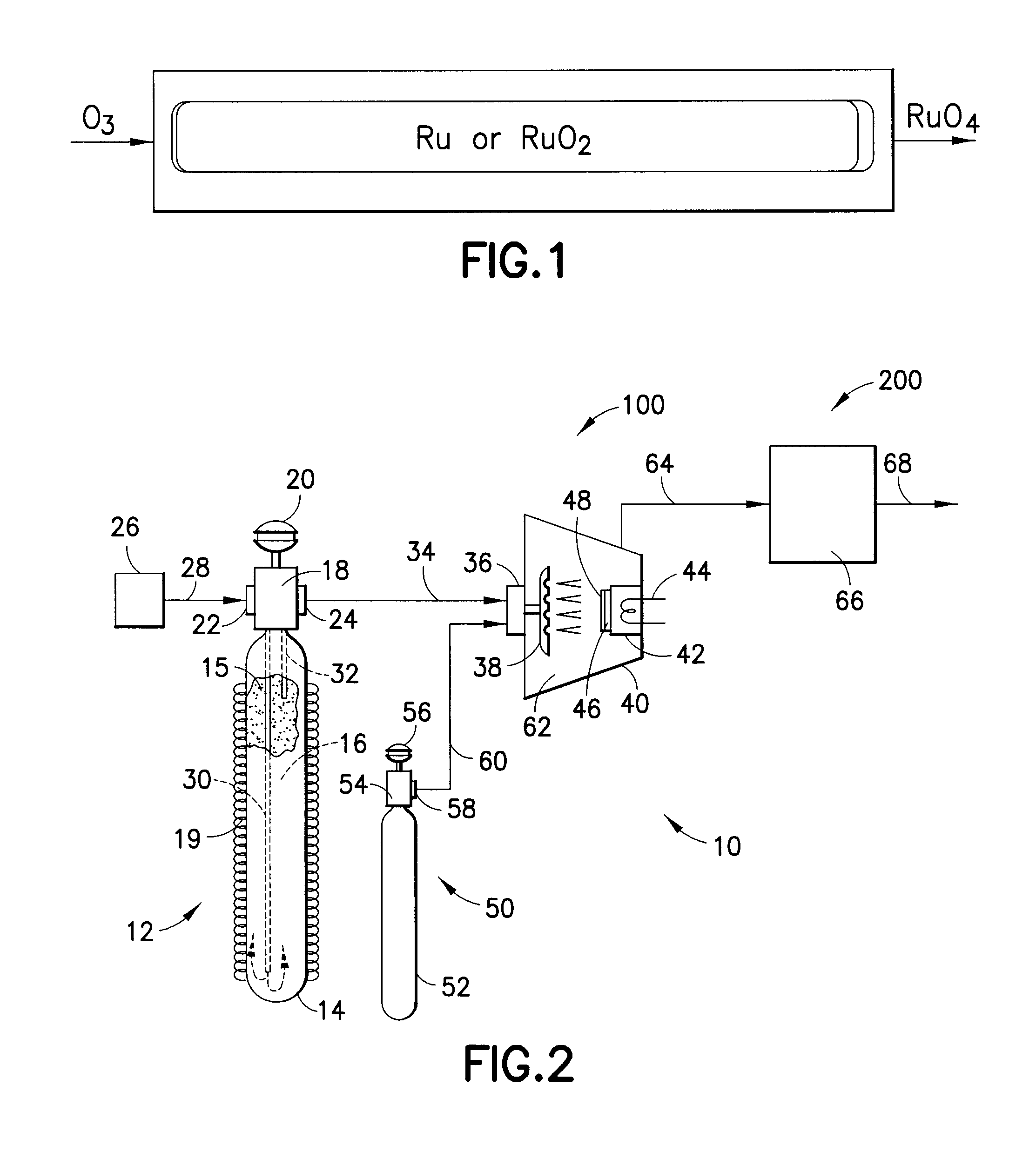

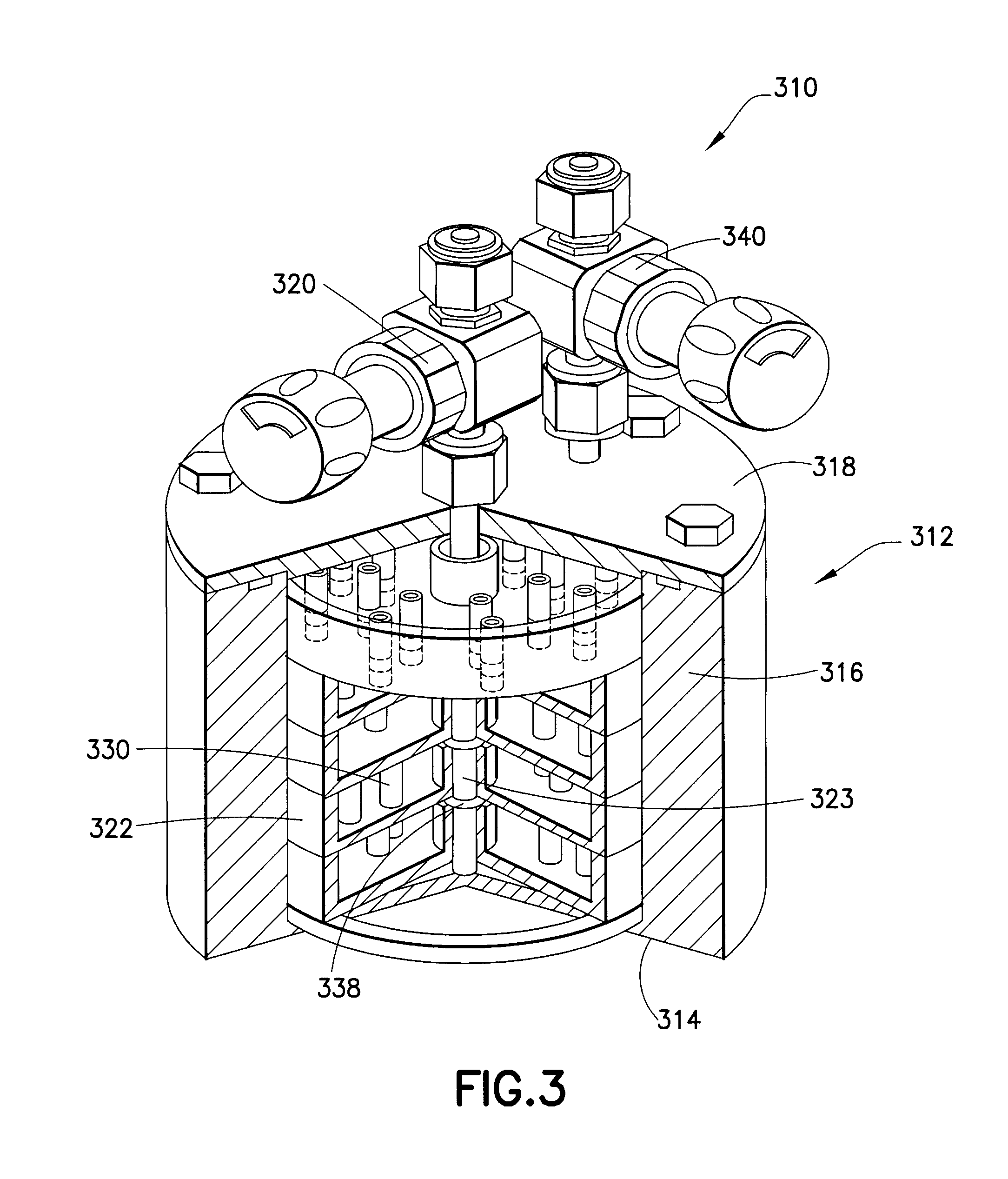

IN SITU GENERATION OF RuO4 FOR ALD OF Ru AND Ru RELATED MATERIALS

Apparatus and method for generating ruthenium tetraoxide in situ for use in vapor deposition, e.g., atomic layer deposition (ALD), of ruthenium-containing films on microelectronic device substrates. The ruthenium tetraoxide can be generated on demand by reaction of ruthenium or ruthenium dioxide with an oxic gas such as oxygen or ozone. In one implementation, ruthenium tetraoxide thus generated is utilized with a strontium organometallic precursor for atomic layer deposition of strontium ruthenate films of extremely high smoothness and purity.

Owner:ENTEGRIS INC

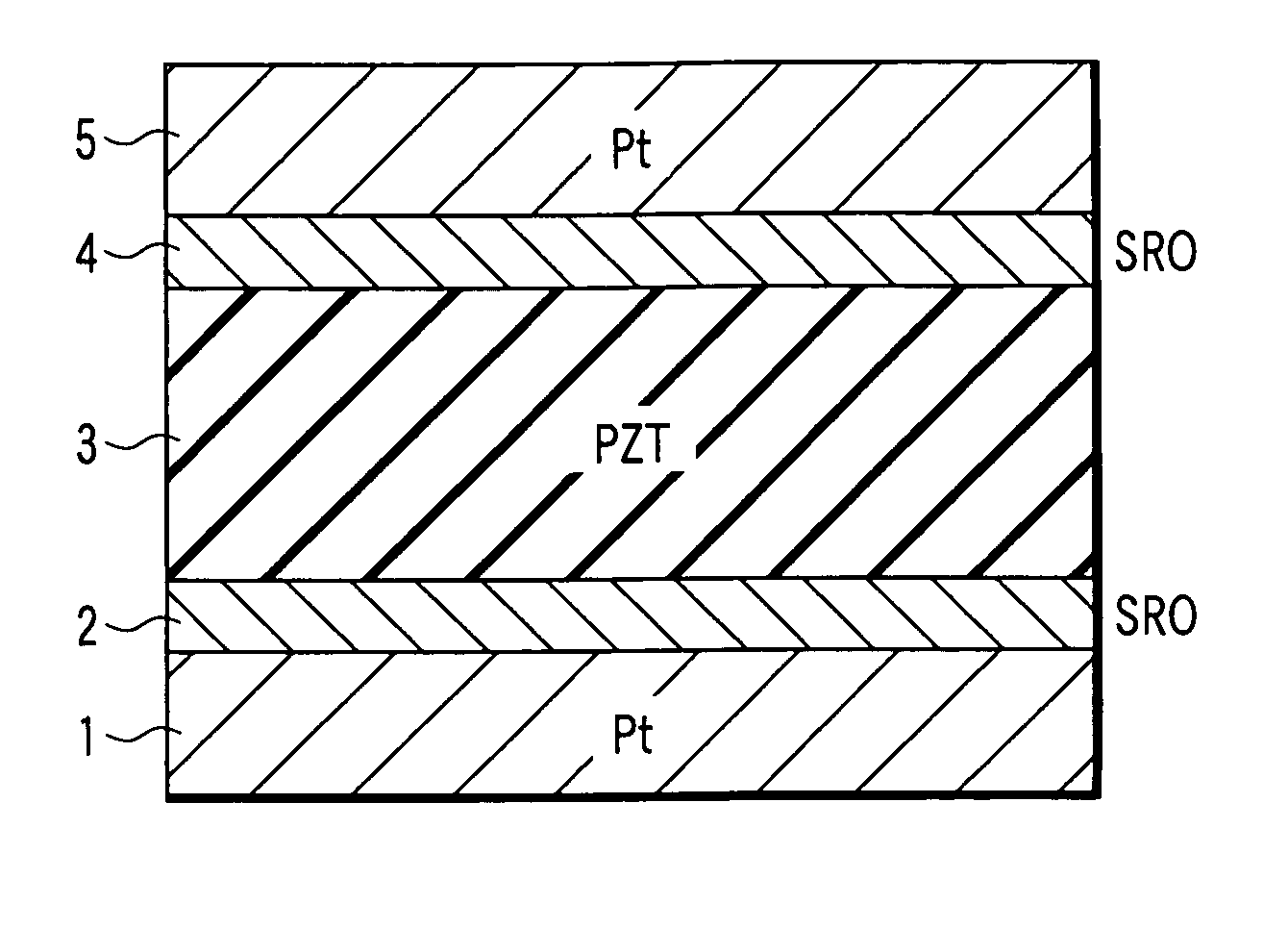

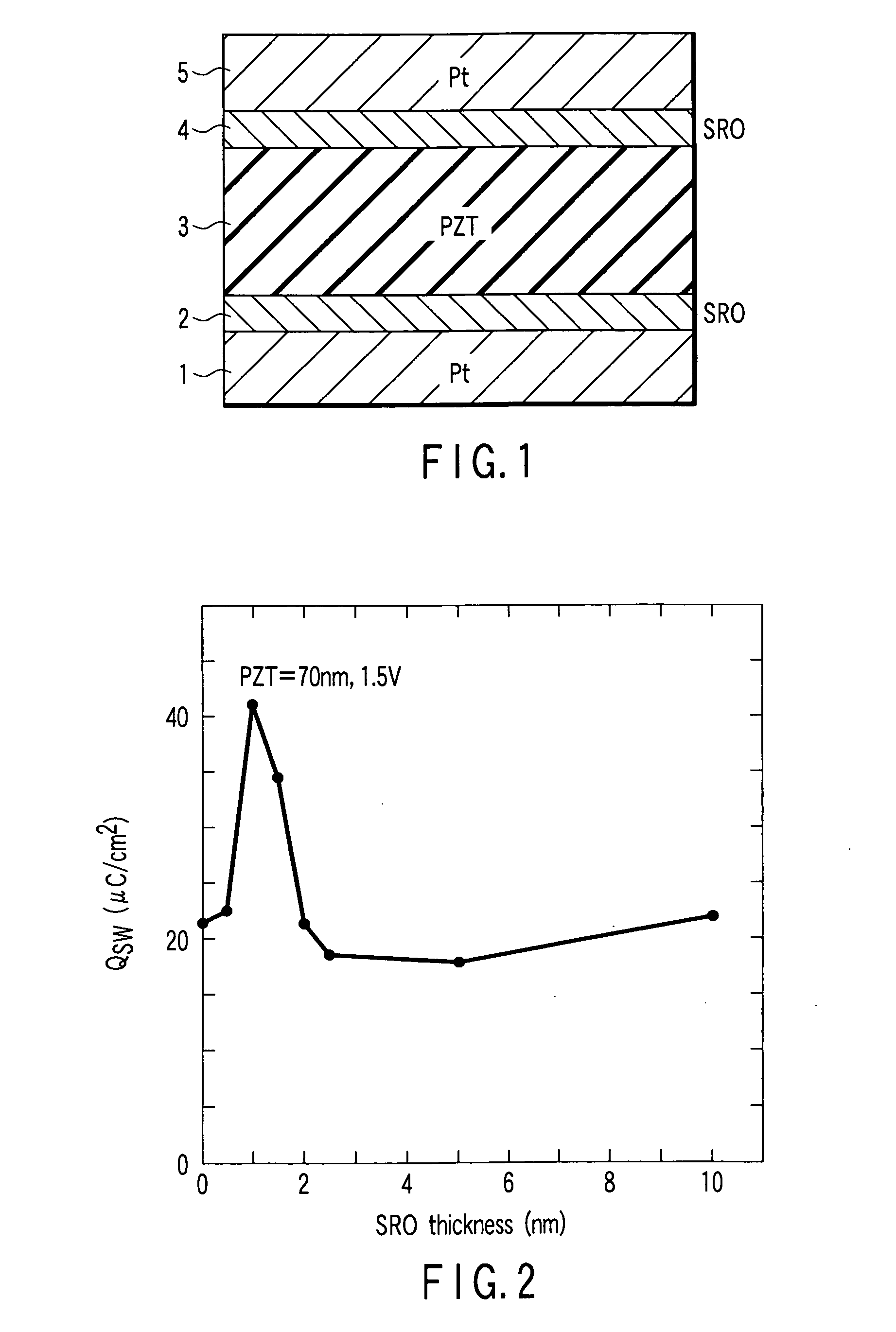

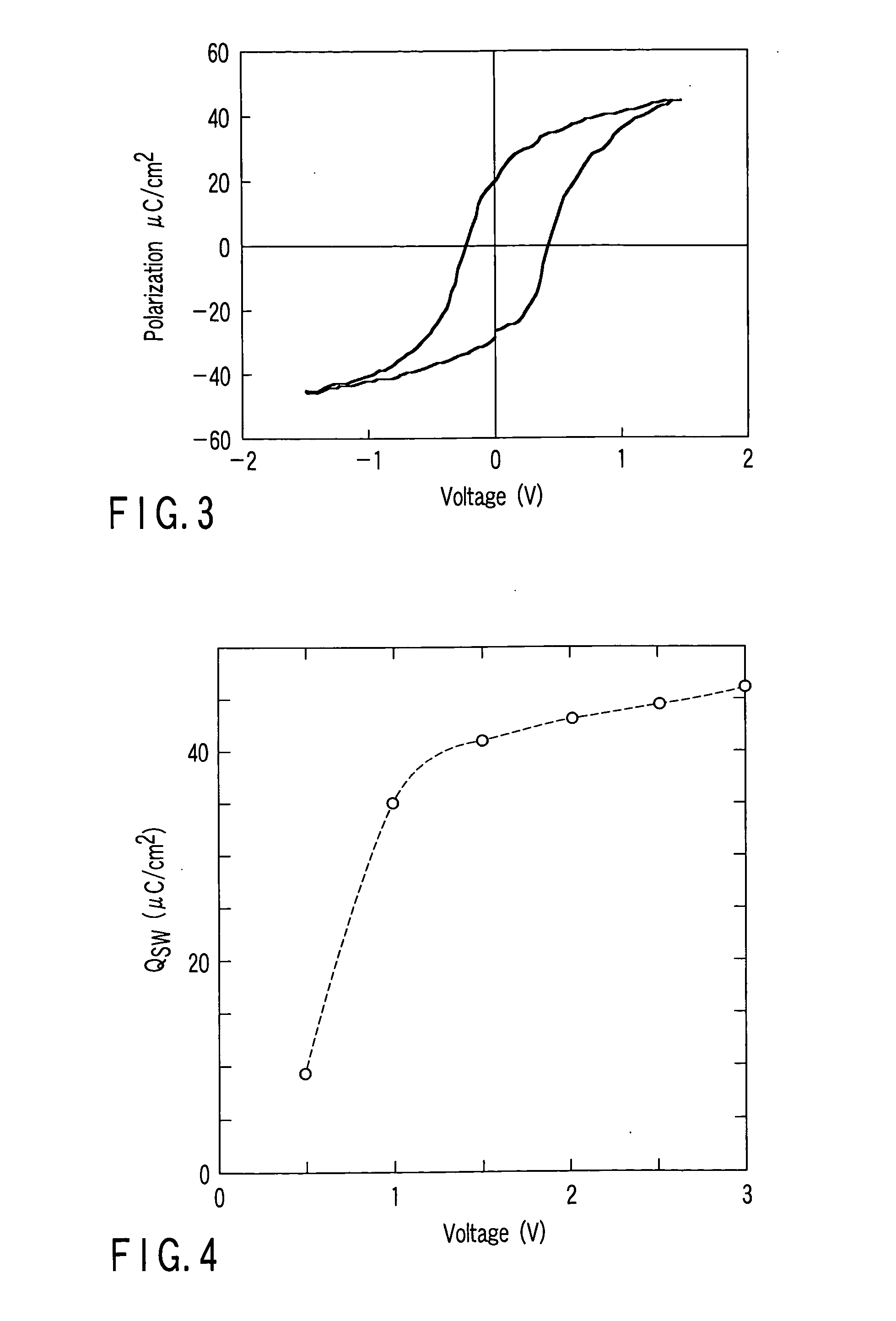

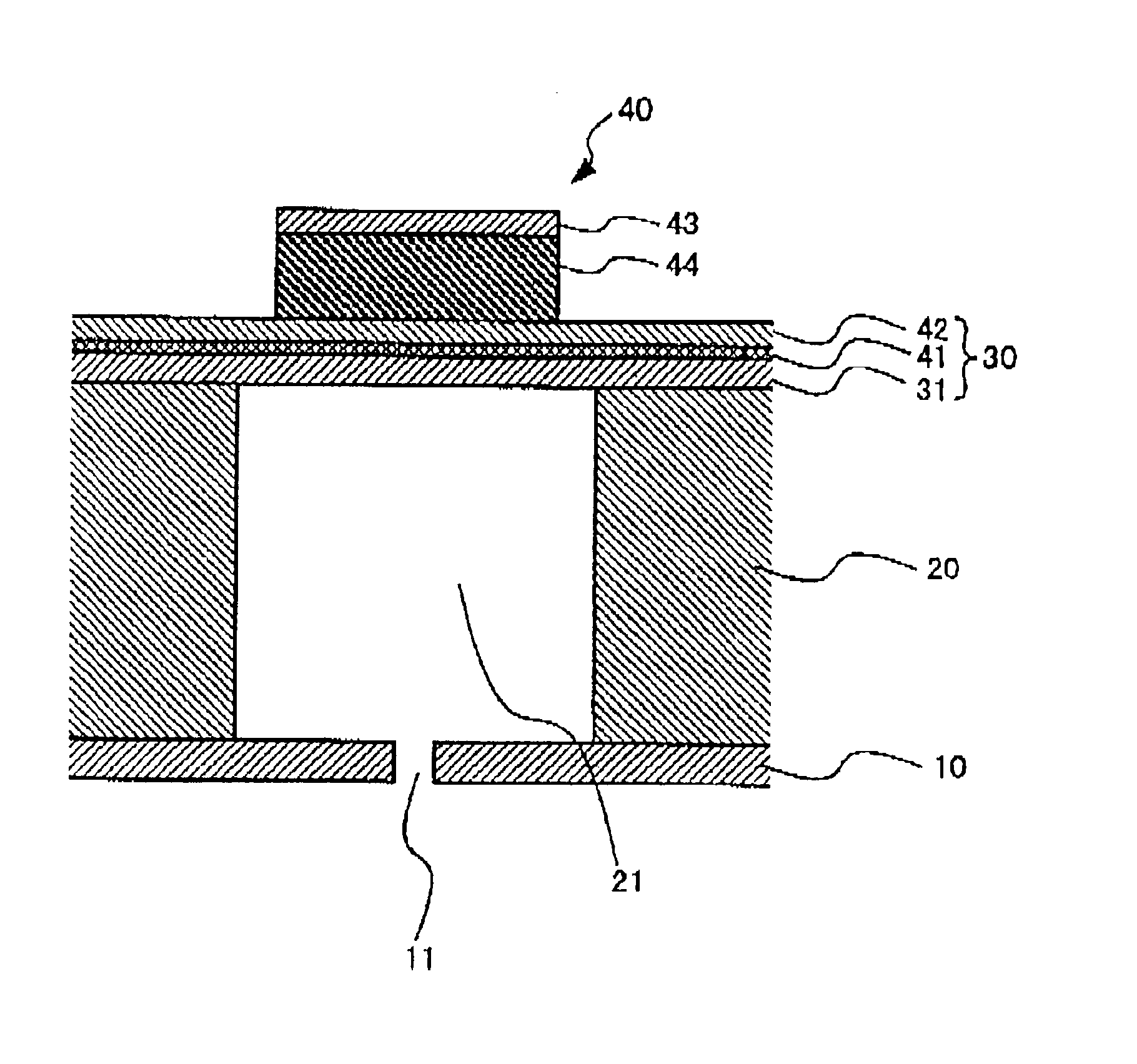

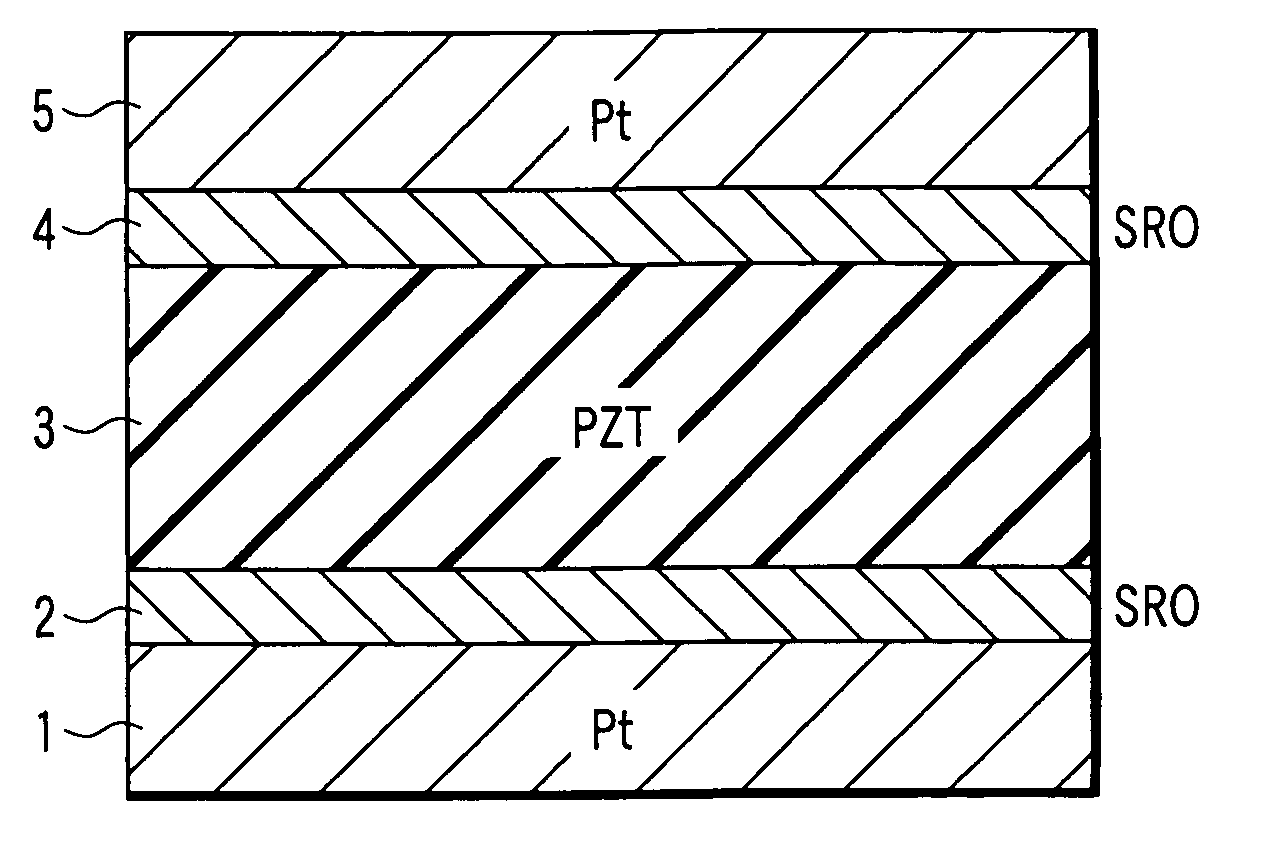

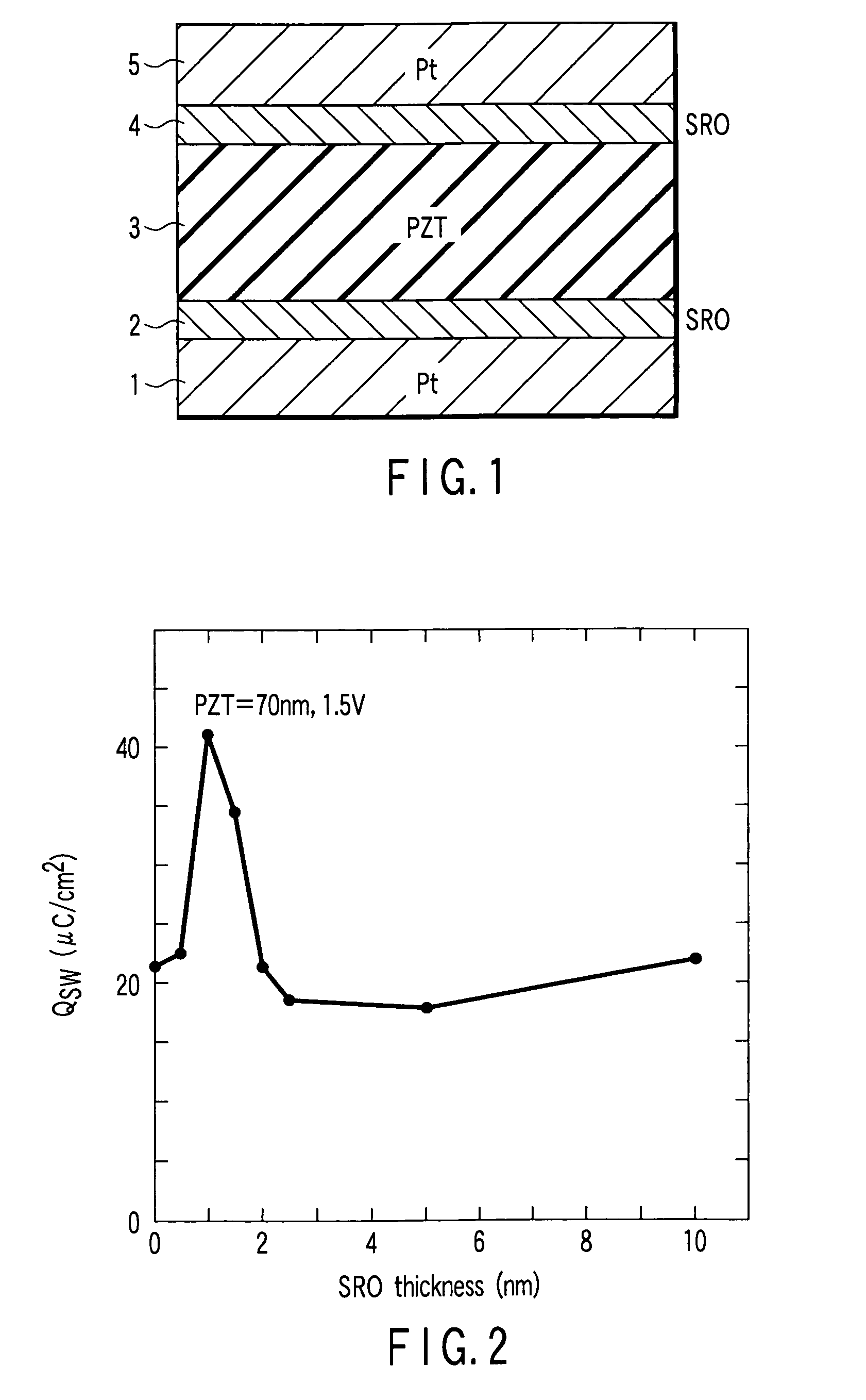

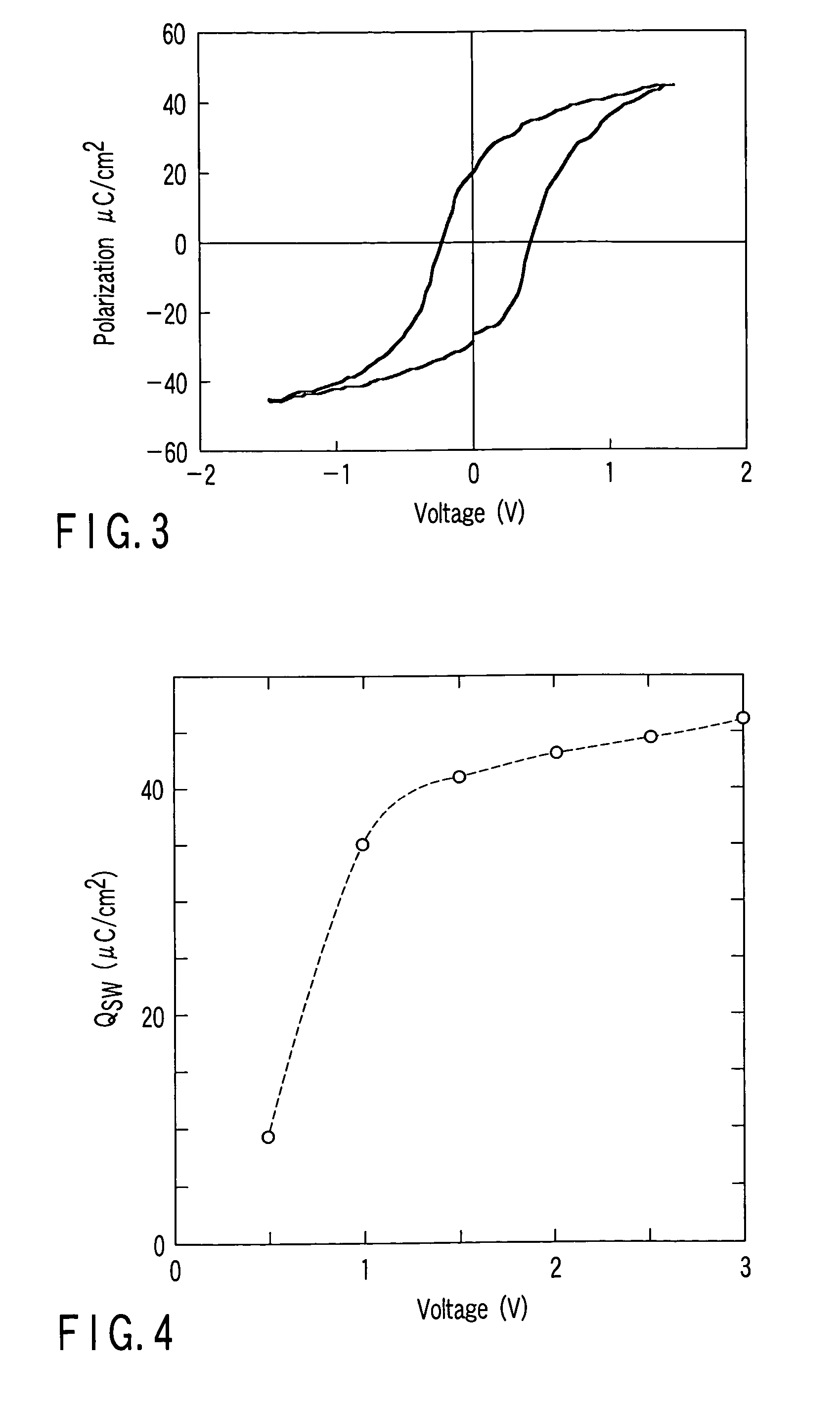

Semiconductor device and method for manufacturing thereof

InactiveUS20050224851A1Semiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

Disclosed in a semiconductor device comprising a semiconductor substrate, and a ferroelectric layer provided above the semiconductor substrate and sandwiched between a lower electrode and an upper electrode, the lower electrode comprising a strontium ruthenate film having a thickness of 2 nm or less.

Owner:KK TOSHIBA

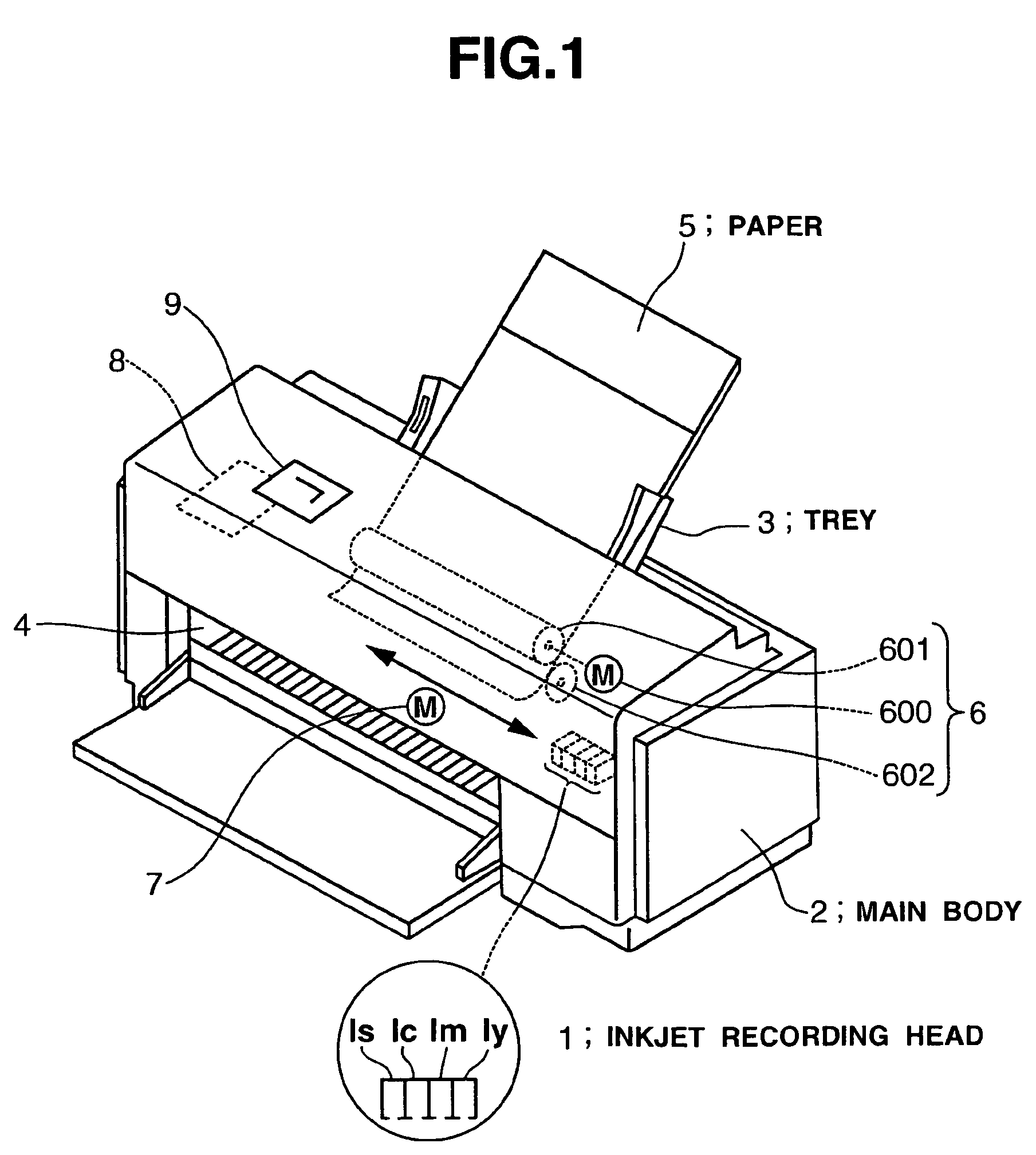

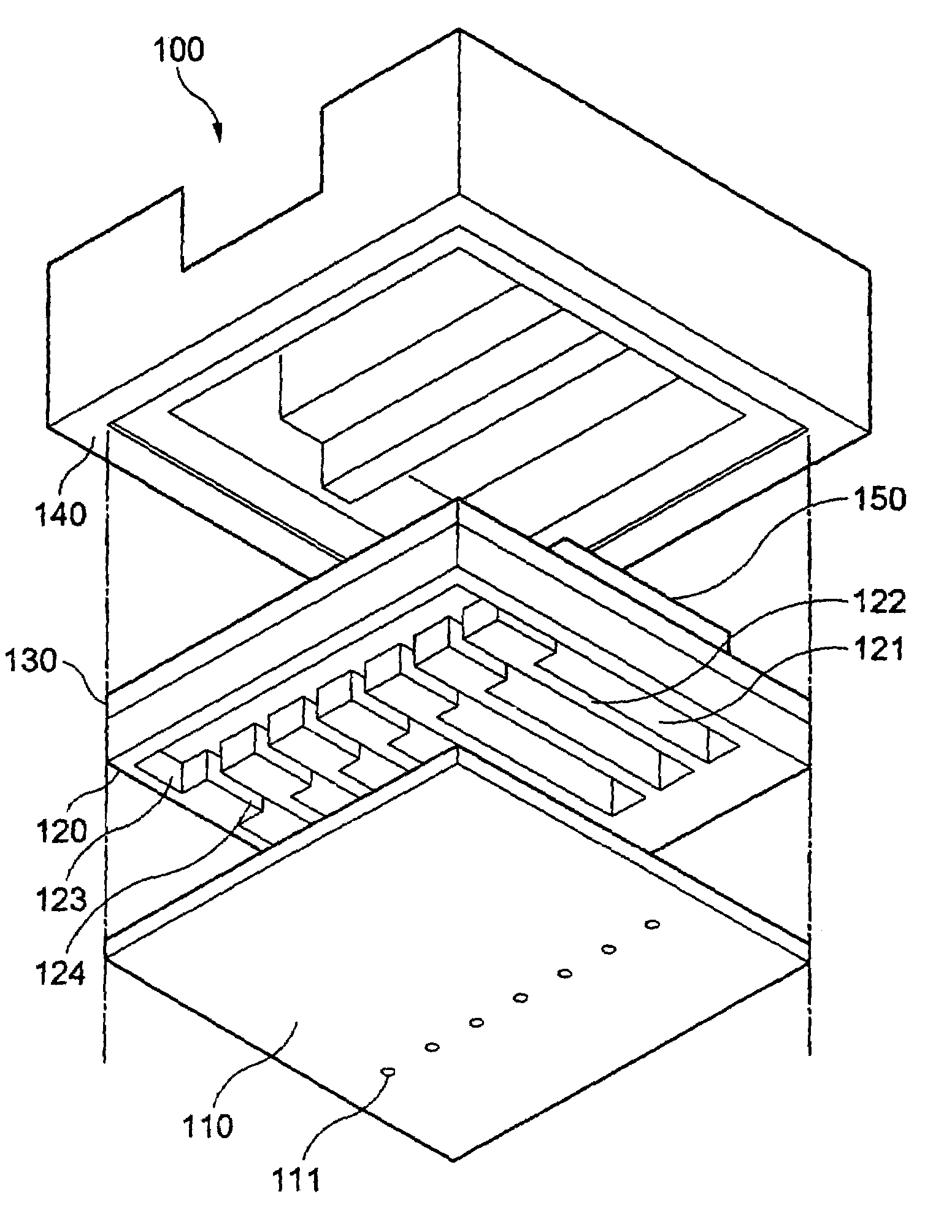

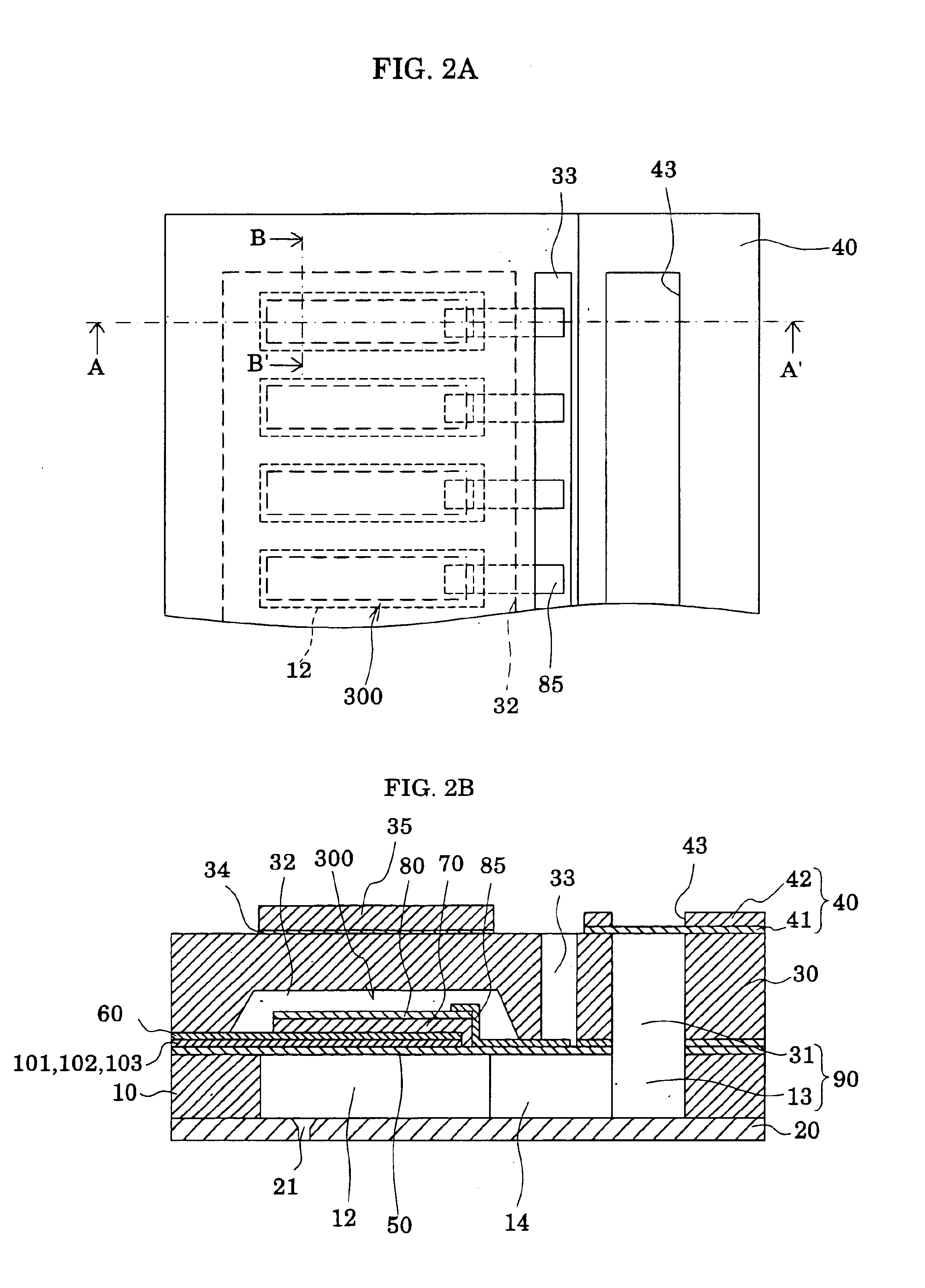

Piezoelectric actuator, liquid jetting head and liquid jetting device using the same

InactiveUS6943485B2Improve featuresAdhesive layerInking apparatusPiezoelectric/electrostriction/magnetostriction machinesLiquid jetDielectric

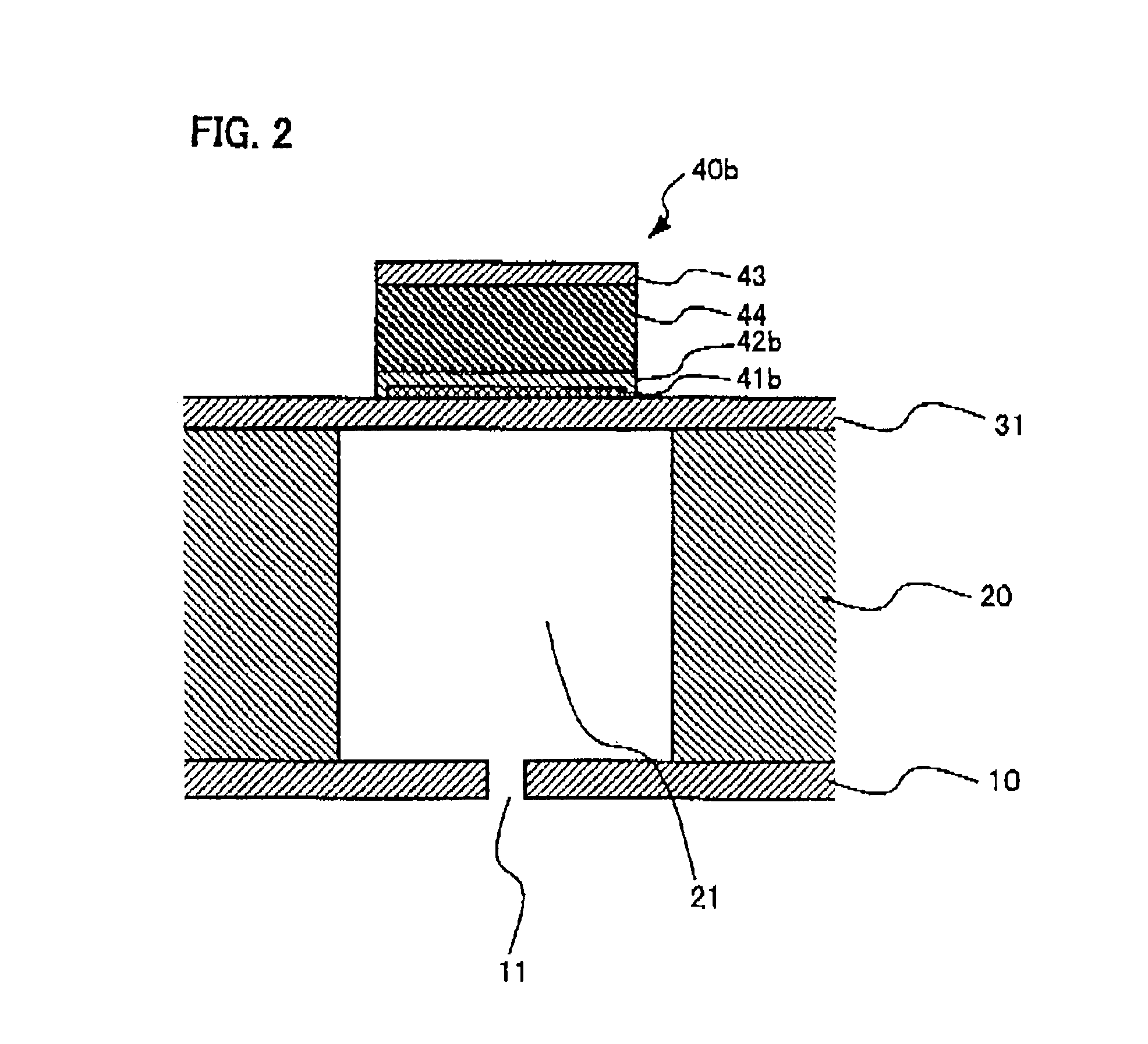

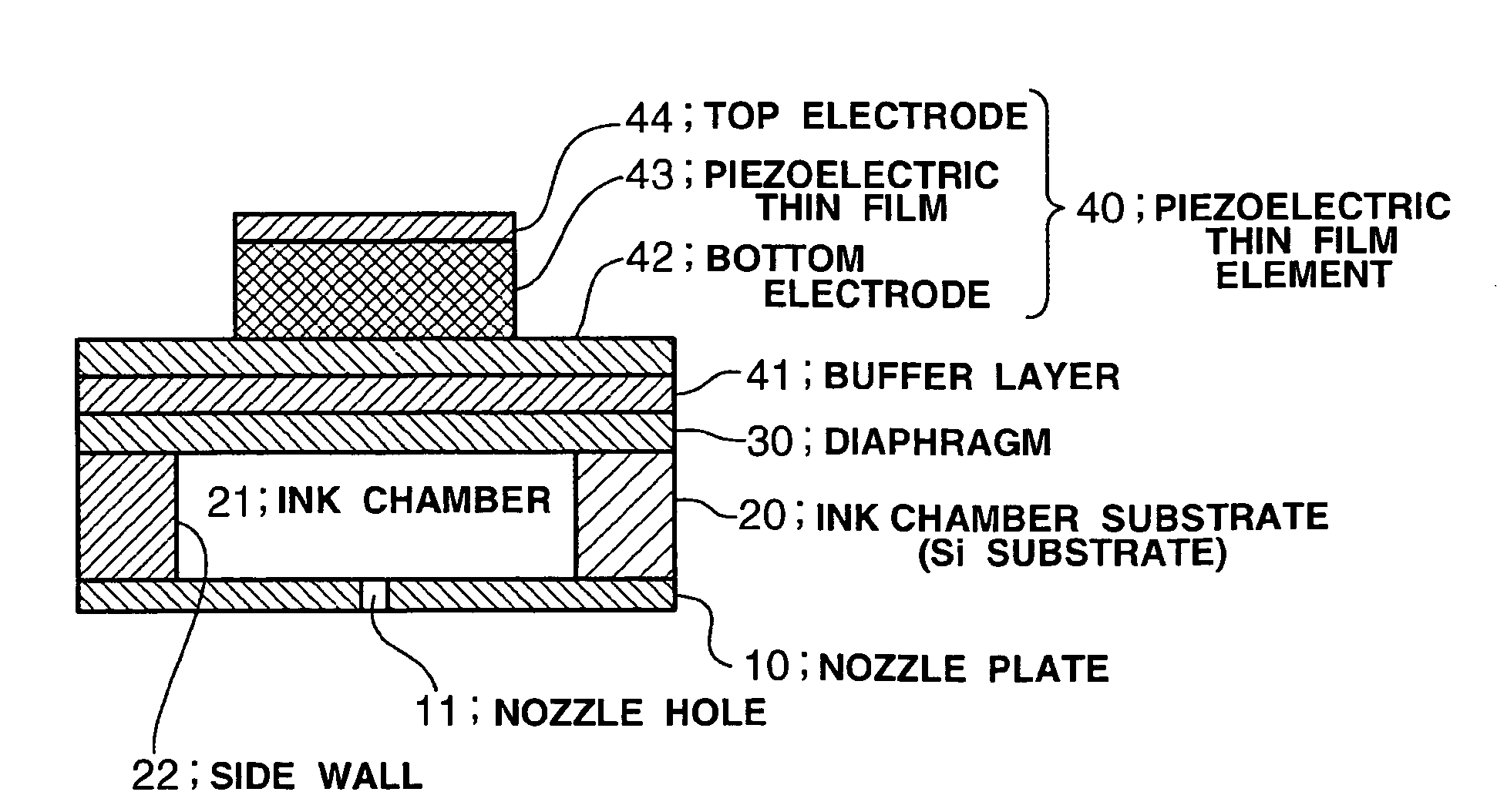

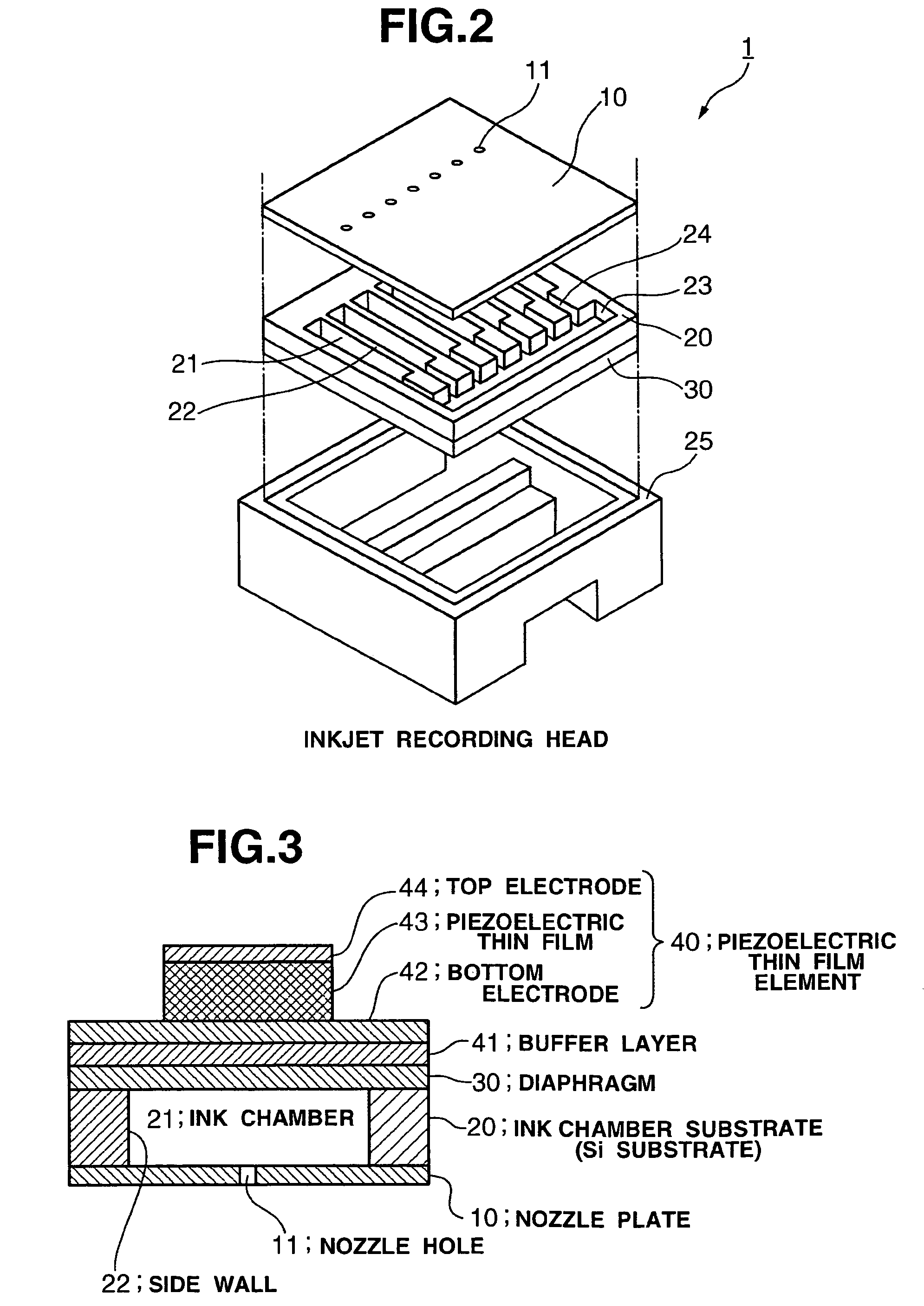

It is an object of the present invention to provide a piezoelectric actuator which uses strontium ruthenate as the material of the bottom electrode, and which uses PMN-PT as the material of the piezoelectric layer. This piezoelectric actuator comprises a base layer (31, 20) of SiO2 or Si ((100) orientation or (110) orientation), a buffer layer (41) constituted by strontium ruthenate (SRO), and a piezoelectric layer (44) constituted by a relaxor dielectric (PMN-PT) with a rhombohedral or quasi-cubic crystal structure oriented in the (001) direction at room temperature.

Owner:SEIKO EPSON CORP

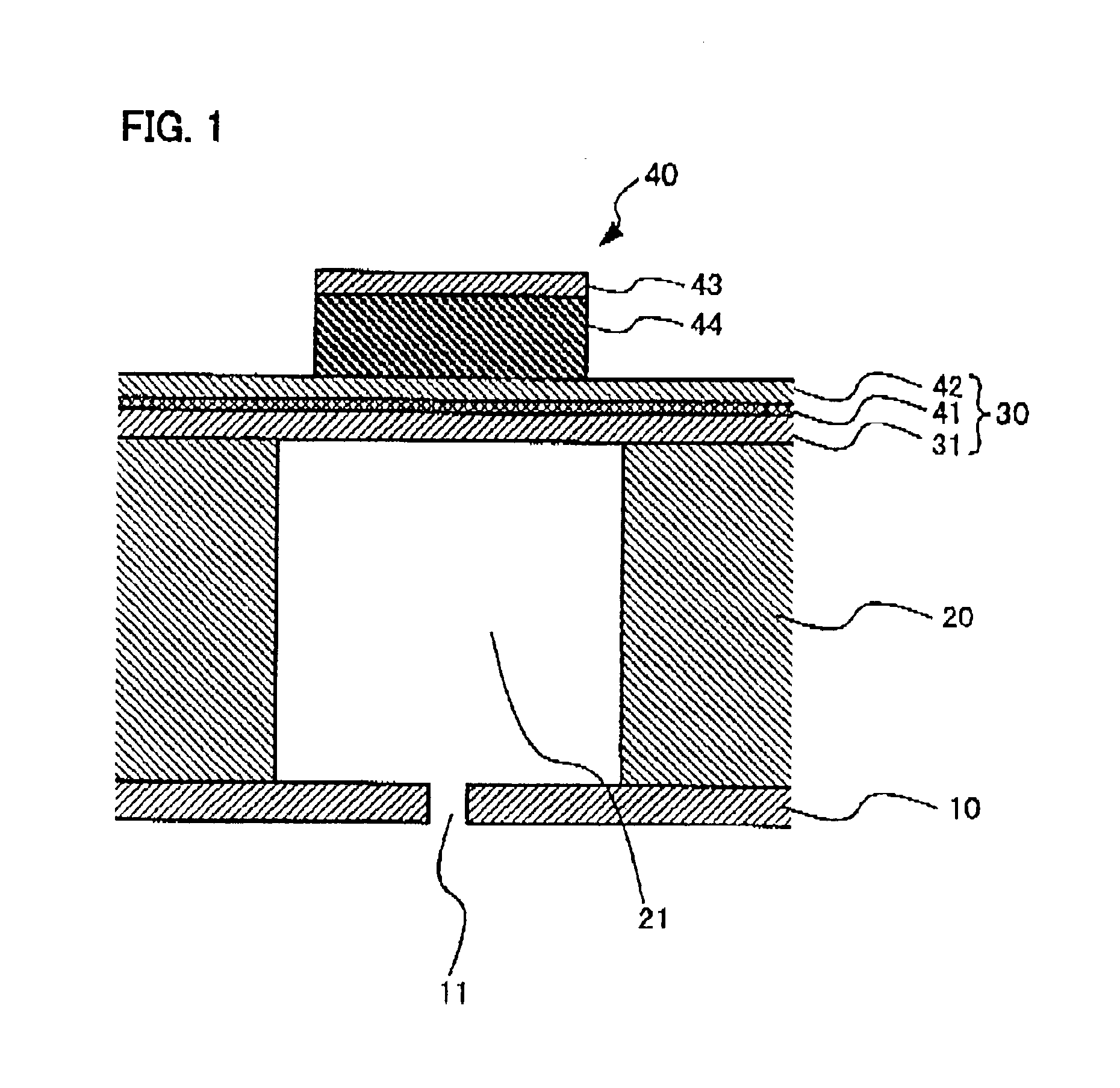

Piezoelectric actuator and liquid jet head

ActiveUS7279823B2Improve toughnessBreakage can be suppressedPiezoelectric/electrostrictive device manufacture/assemblyInking apparatusLiquid jetPiezoelectric actuators

A piezoelectric actuator comprising an optimum layer structure when (100) orientation strontium ruthenate is used as a bottom electrode is provided. This piezoelectric actuator comprises a diaphragm 30 that is constituted by (100) orientation yttria-stabilized zirconia, CeO2, or ZrO2, that is grown epitaxially on a (100) orientation Si substrate 20, a buffer layer 41 formed on the diaphragm and constituted by (001) orientation REBa2Cu3Ox, a bottom electrode 42 formed on the buffer layer and constituted by (100) orientation strontium ruthenate, a piezoelectric layer 43 formed on the bottom electrode and constituted by (100) orientation PZT, and a top electrode 44 formed on the piezoelectric layer.

Owner:SEIKO EPSON CORP

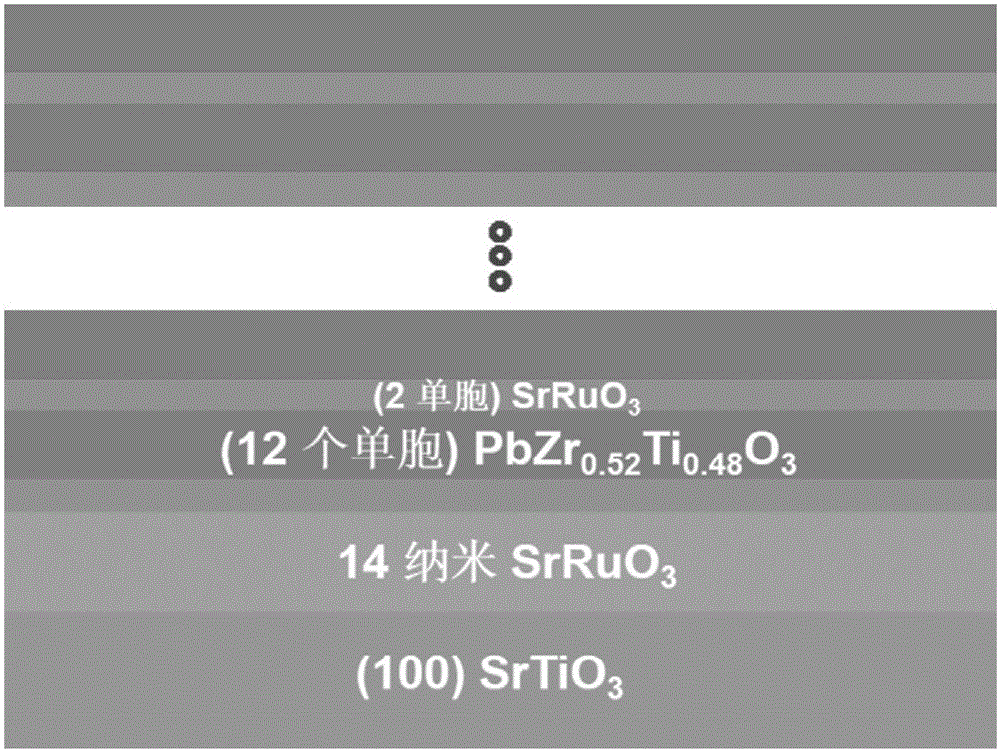

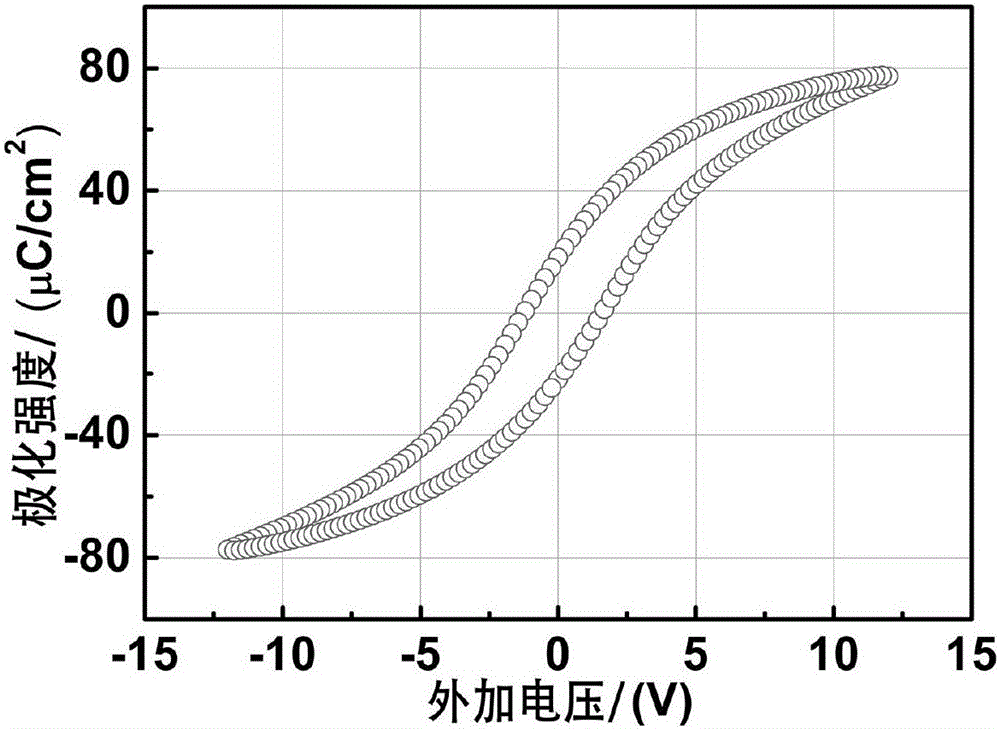

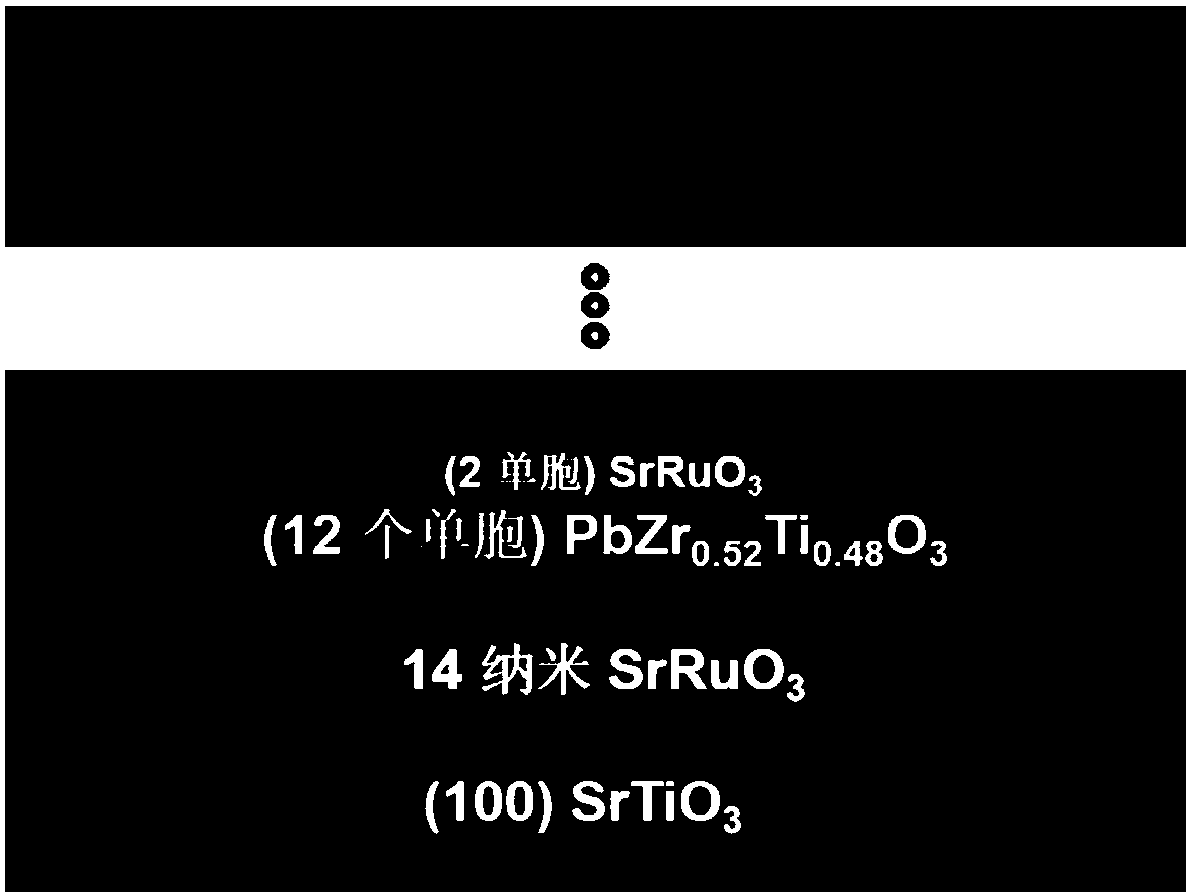

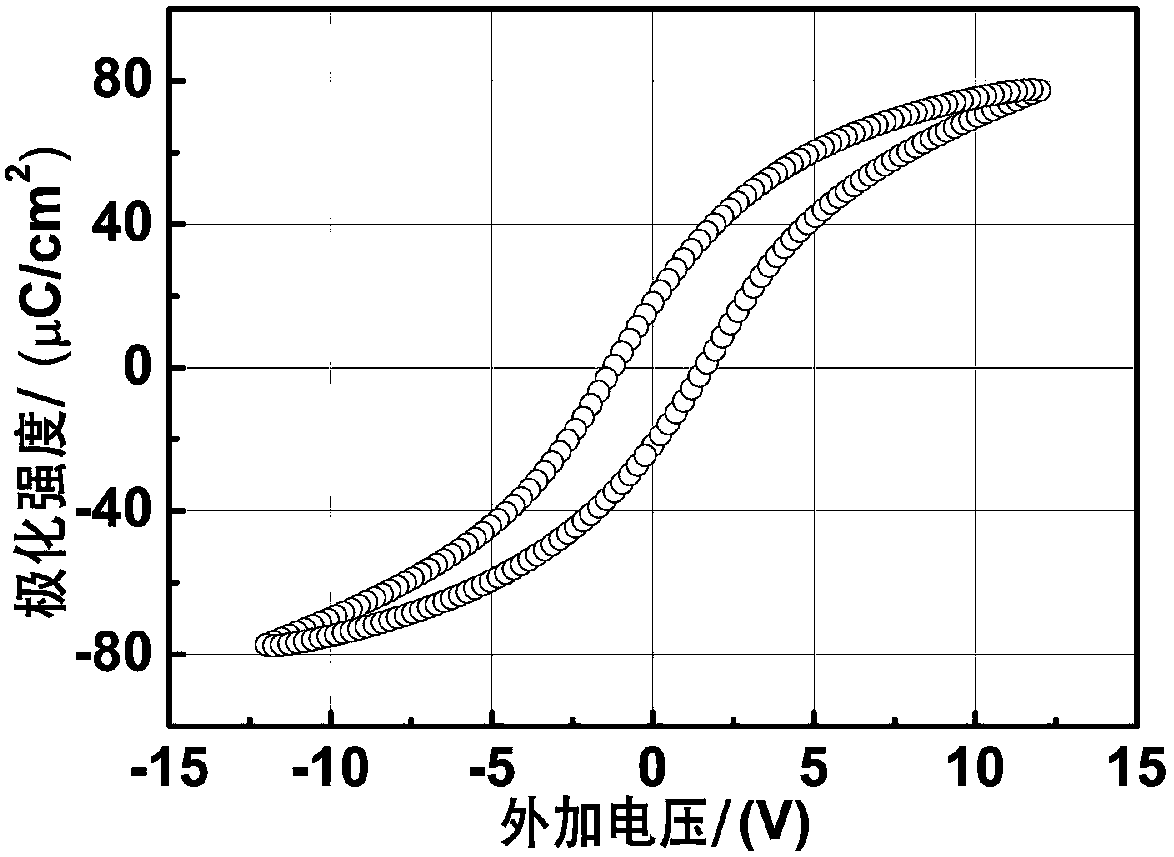

Lead zirconate titanate/ruthenium acid strontium ferroelectric superlattice material and preparation method thereof

ActiveCN106058039AGood dielectricImprove ferroelectric propertiesPiezoelectric/electrostrictive/magnetostrictive devicesLead zirconate titanateMetallic conductivity

The objective of the invention is to provide lead zirconate titanate / ruthenium acid strontium ferroelectric superlattice material and a preparation method thereof. The material is formed by periodically grown ferroelectric material lead zirconate titanate and metallically conductive oxide material ruthenium acid strontium. The advantages of the lead zirconate titanate / ruthenium acid strontium ferroelectric superlattice material are that the dielectric constant is increased for 2-10 times than that of a pure PZT film; and the material has great ferroelectric polarization performance, and its saturated polarization value is higher than that of the pure PZT film and can be 80muC / cm2. The preparation method of the material is that ruthenium acid strontium and lead zirconate titanate are alternately grown on a monocrystal substrate by using a pulse laser deposition method, and the periodic thickness of the superlattice is accurately regulated and controlled by controlling bombardment time of laser for different target material. The ferroelectric superlattice material has wide application prospect in sensors, storage devices and other integrated ferroelectric devices.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

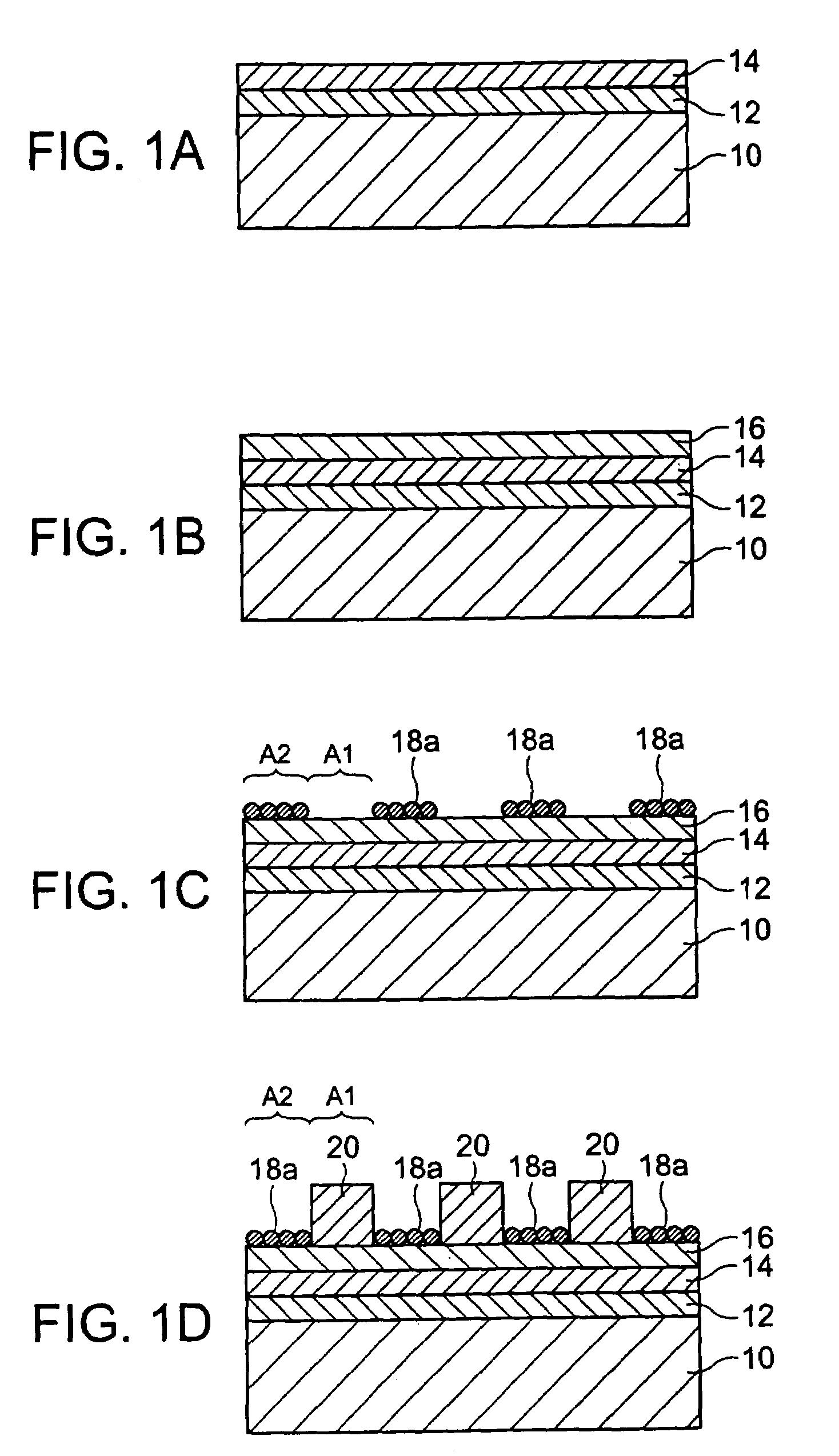

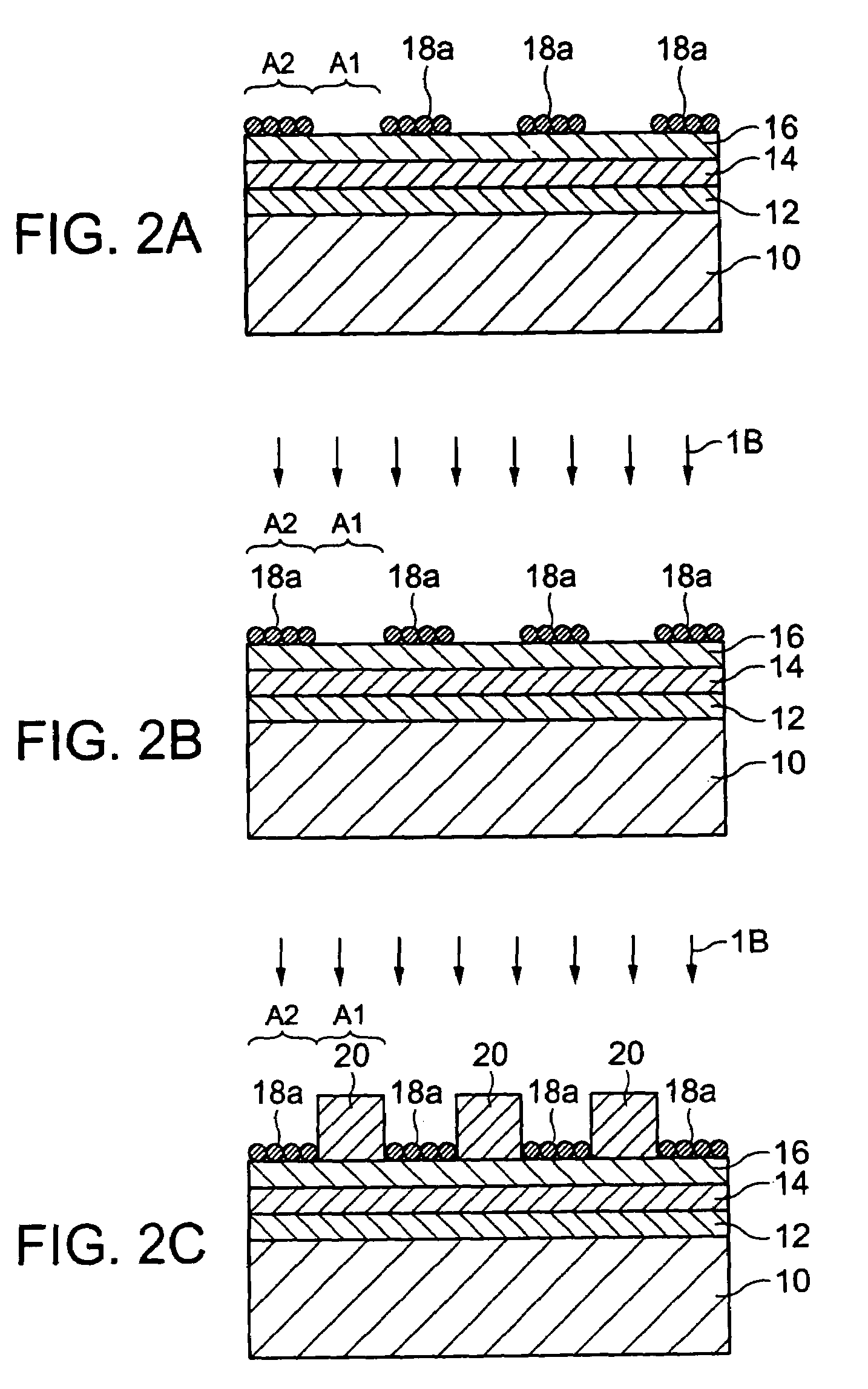

Method of manufacturing piezoelectric device

ActiveUS7200907B2High crystallinityImprove reliabilityMaterial nanotechnologyPiezoelectric/electrostrictive device manufacture/assemblySelf-assembled monolayerCrystal orientation

Exemplary embodiments of the present invention provide a method of manufacturing a piezoelectric device that includes a piezoelectric layer having high crystallinity in which crystal orientation is aligned to a desired direction, a method of manufacturing a ferroelectric device that includes a ferroelectric layer having the similar high crystallinity, and so forth. Exemplary embodiments include an insulating layer composed of SiO2 and so forth and a buffer layer composed of strontium oxide (SrO) and so forth are formed on a substrate such as a silicon single crystal wafer in sequence, and then a lower electrode composed of strontium ruthenate (SRO) is formed on the buffer layer. By forming self-assembled monolayers on the lower electrode, high affinity regions A1 and low affinity regions A2 are formed. Then, piezoelectric layers are selectively formed only on the high affinity regions A1.

Owner:SEIKO EPSON CORP

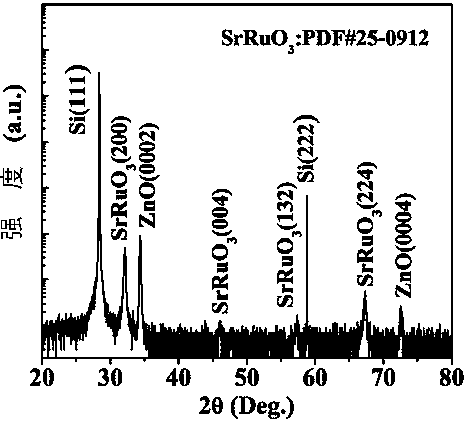

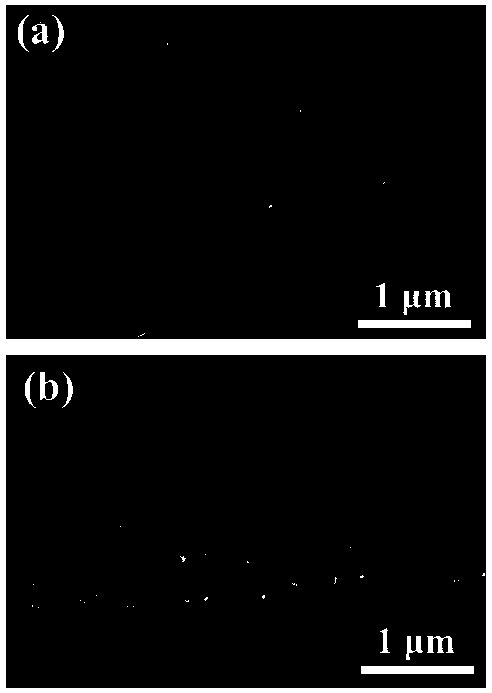

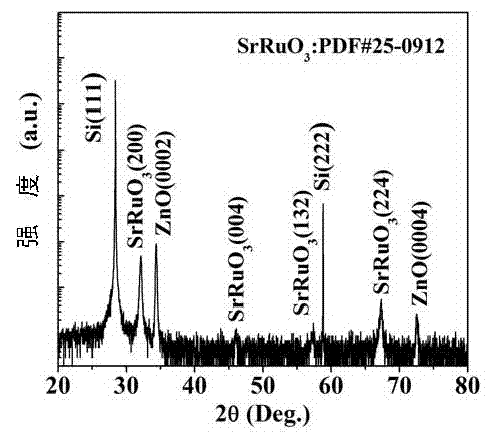

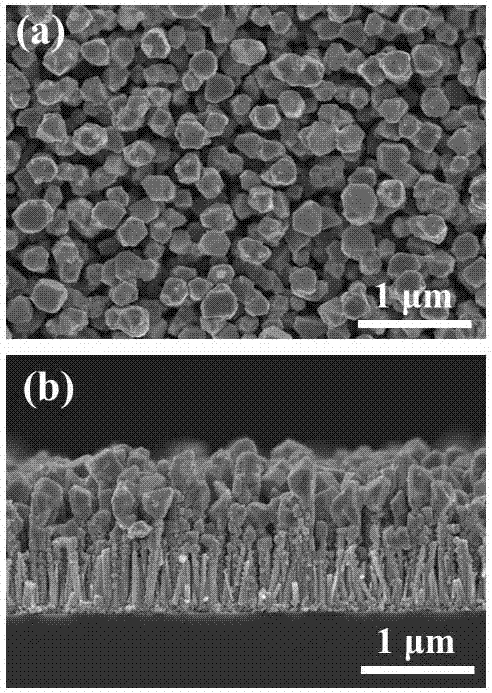

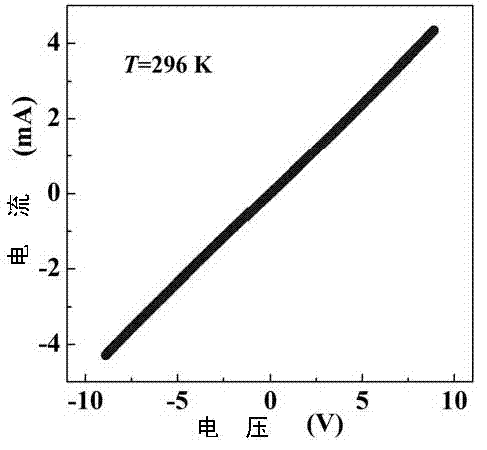

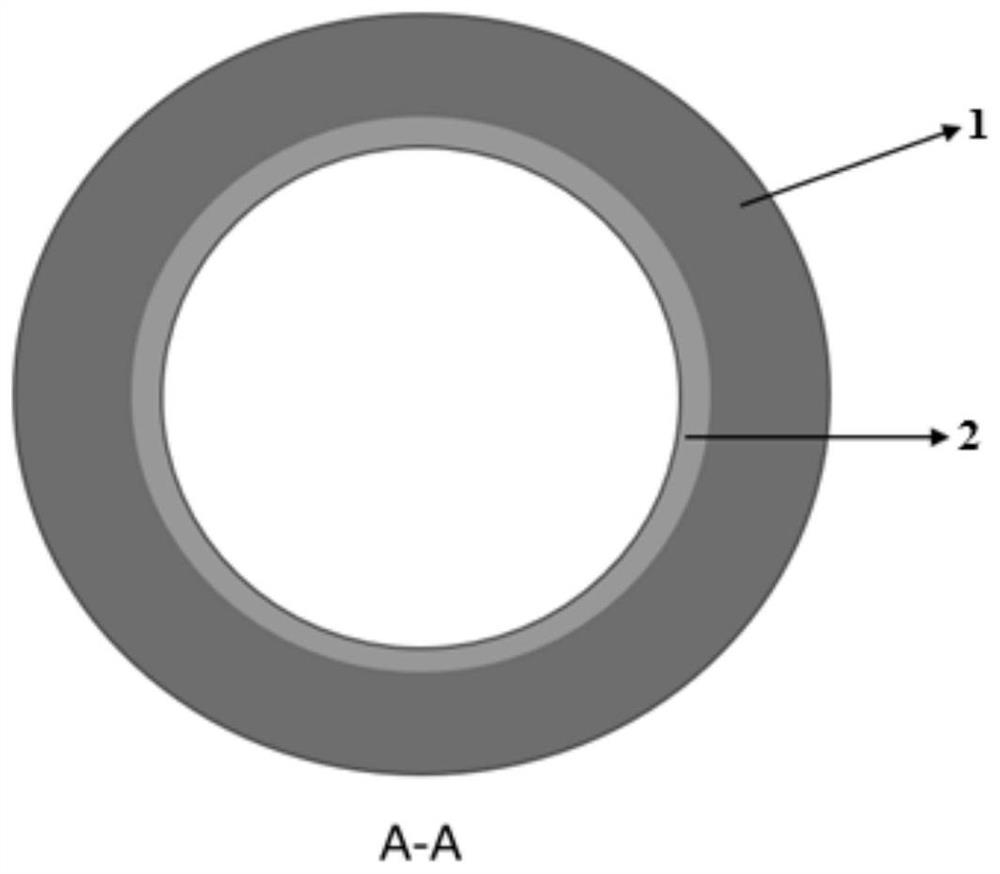

Zinc oxide/strontium ruthenate core-shell nanowire and preparation method thereof

ActiveCN104229867ALow priceRealize large area preparationMaterial nanotechnologyZinc oxides/hydroxidesStrontium ruthenateOxide

The invention relates to a zinc oxide / strontium ruthenate core-shell nanowire and a preparation method thereof. The zinc oxide / strontium ruthenate core-shell nanowire comprises a zinc oxide nanowire layer constituted by a zinc oxide nanowire growing vertically and a strontium ruthenate film covered on the zinc oxide nanowire layer.

Owner:江苏先进无机材料研究院

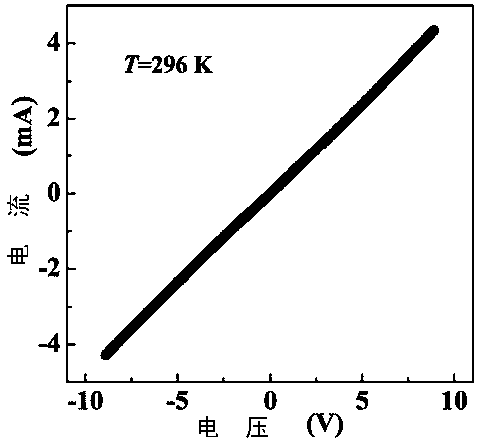

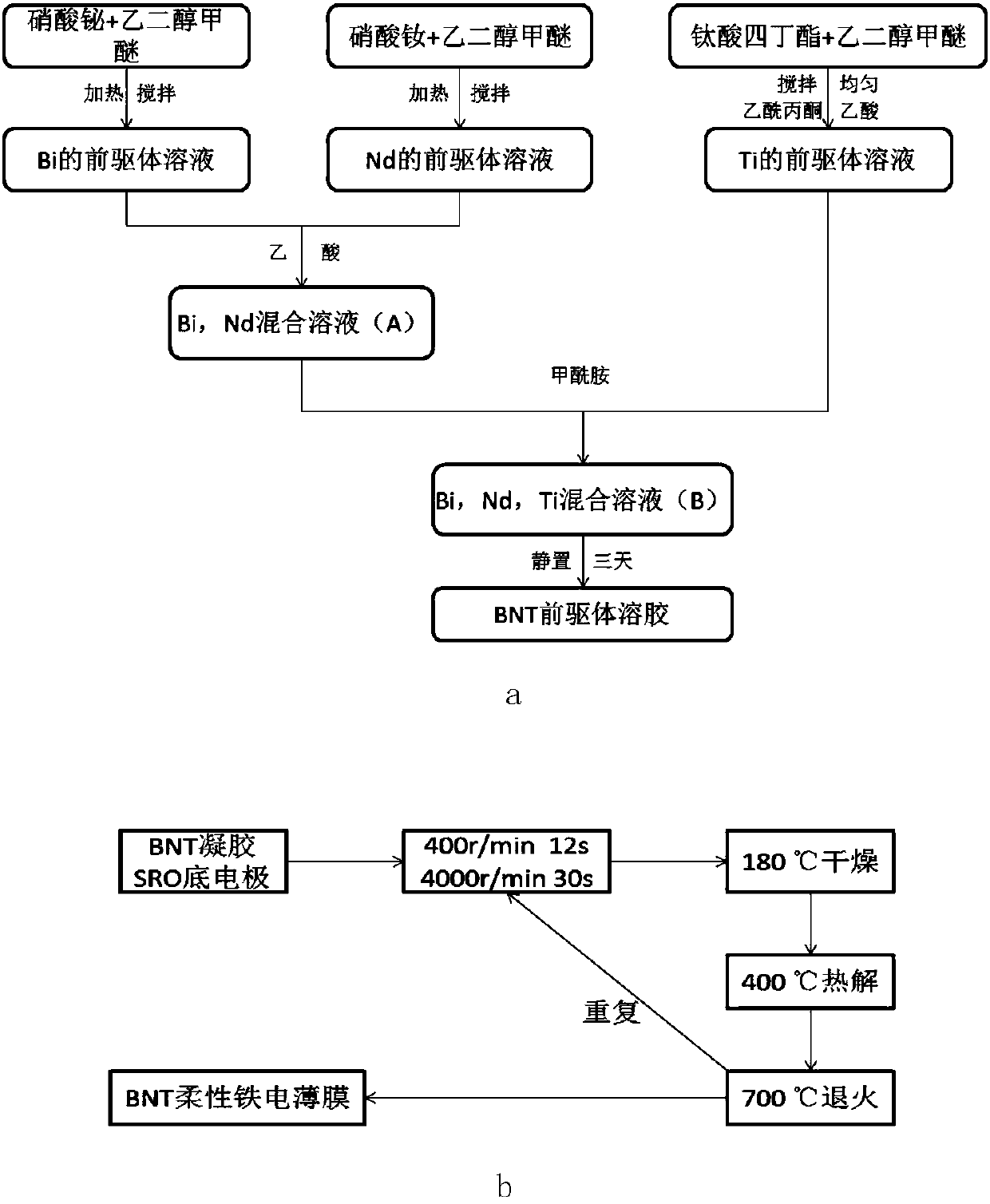

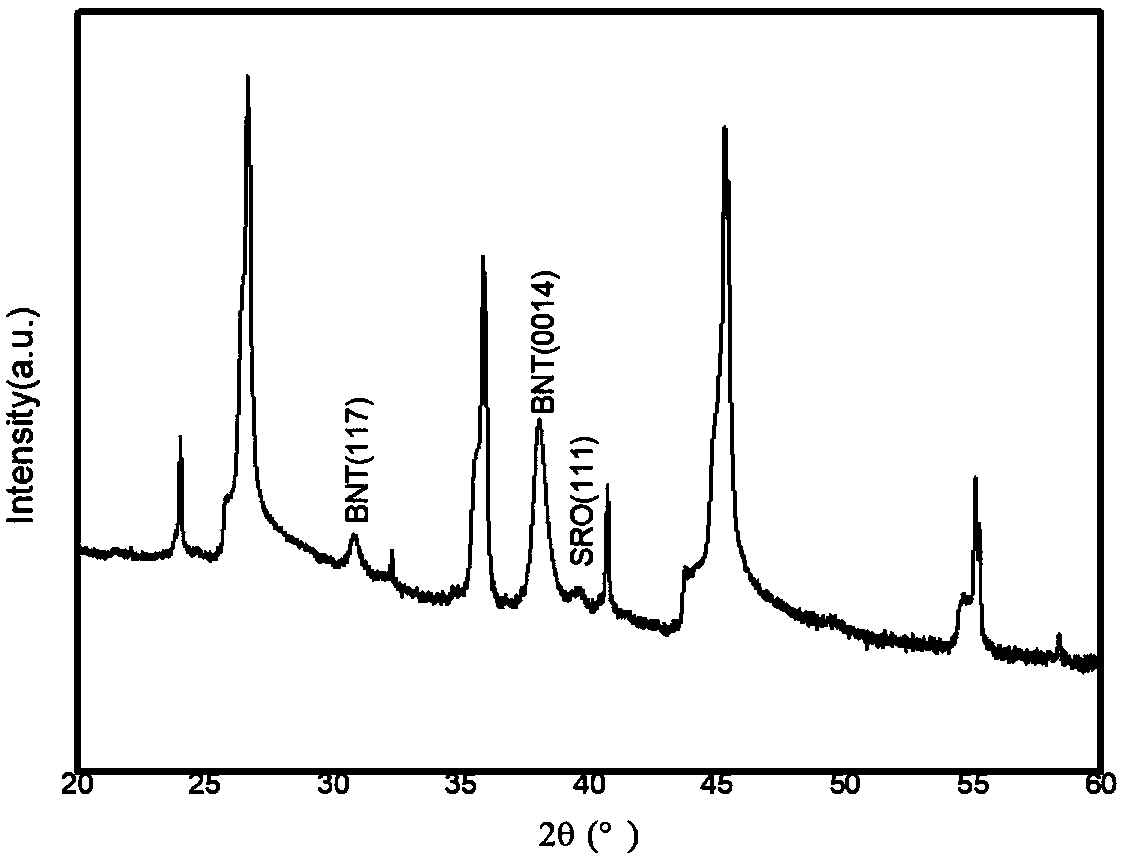

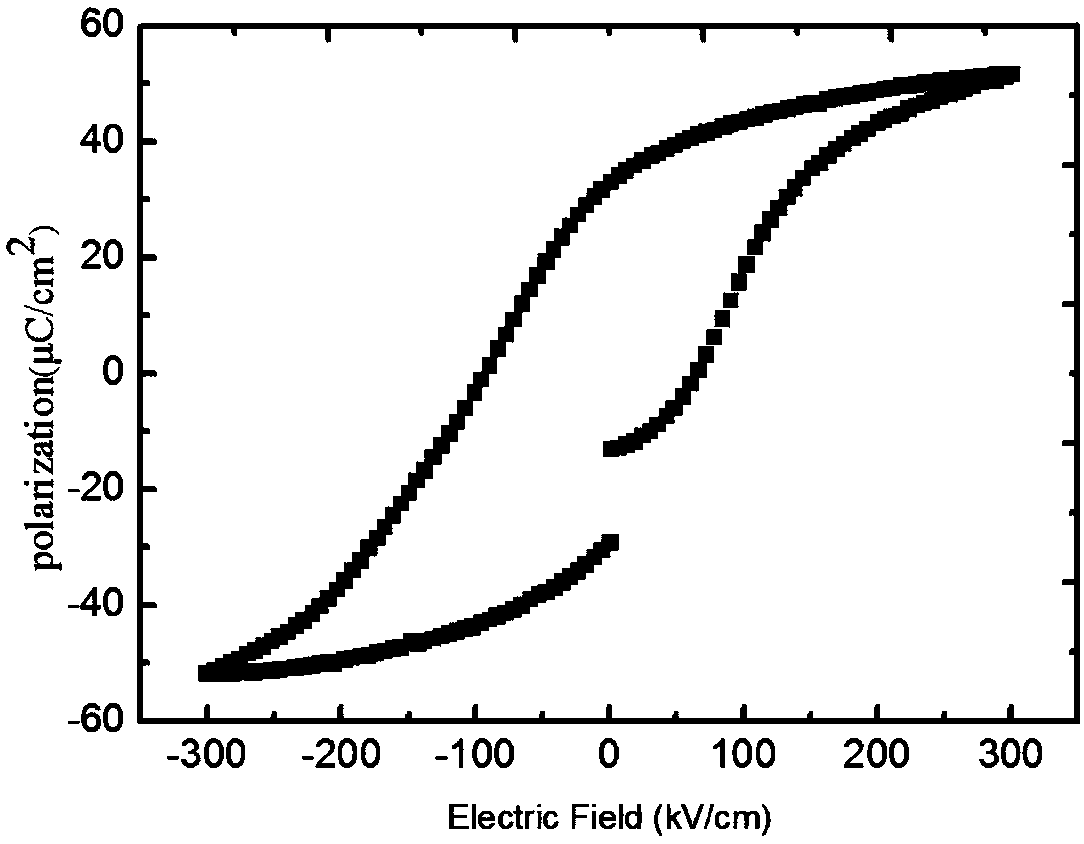

Preparation method of flexible BNT (Bi(4-x)NdxTi3O12) ferroelectric-thin-film

ActiveCN107910030AWon't crackImprove ferroelectric propertiesMagnetic-field-controlled resistorsDigital storageFerroelectric thin filmsStrontium ruthenate

The invention discloses a preparation method of a flexible BNT (Bi(4-x)NdxTi3O12) ferroelectric-thin-film. The method includes the following steps: 1) using a laser pulse deposition method to preparea strontium ruthenate bottom electrode on a muscovite-mica substrate; 2) adopting a sol-gel method to prepare a precursor solution of the BNT ferroelectric-thin-film, wherein concentration of the precursor solution is 0.05-0.1mol / L; 3) adopting a spin coating method to carry out spin coating of the BNT precursor solution on the above-mentioned strontium ruthenate bottom electrode to obtain a uniform wet film; 4) drying, pyrolyzing and annealing the above-mentioned uniform wet film obtained by preparation; and (5) repeating the step 3)-the step 4) for 4-6 times to obtain the flexible BNT ferroelectric-thin-film, wherein thickness of the thin film is in a range of 200nm-300nm.The method provides a flexible BNT ferroelectric-thin-film material of simple technology and excellent ferroelectricperformance.

Owner:XIANGTAN UNIV

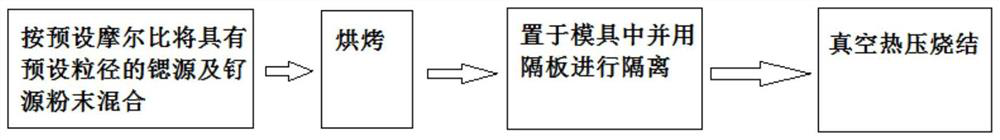

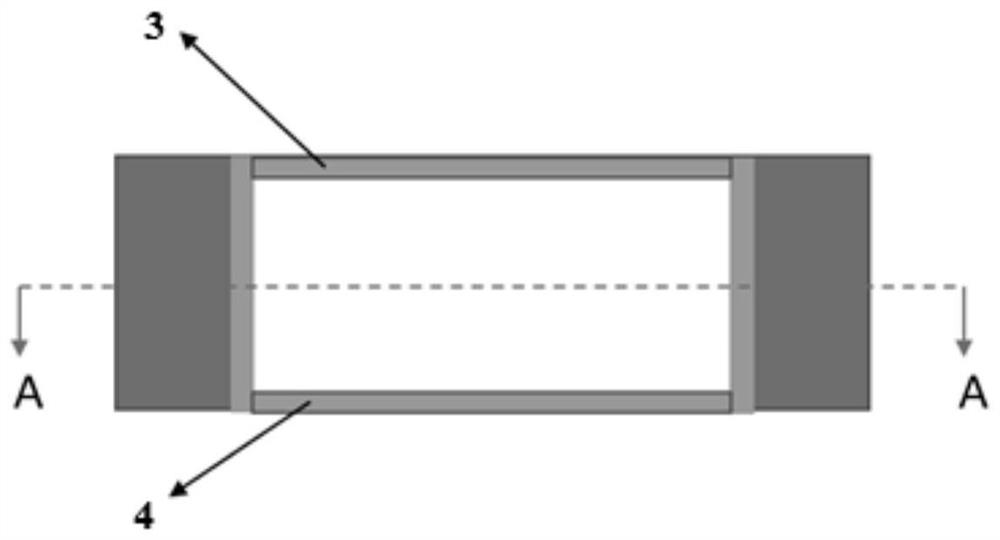

A kind of preparation method of strontium ruthenate target

ActiveCN102259937AWeak crystallinityHigh activityRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsVacuum evaporation coatingHigh densityTwo step

The invention relates to a method for preparing a strontium ruthenate target. A high-density SRO (SrRuO3) ceramic target is prepared by a low-temperature presintering and high-temperature pressure sintering two-step method, and has the density which is 86 to 88 percent of theoretical density. The SRO ceramic target prepared by the method can be applied to processes such as sputtering, molecular beam epitaxy, pulsed laser deposition and the like to form an SRO film, and has the characteristics that: 1) a low temperature and short time are adopted in the process of pressing and presintering a raw material, so that the prepared precursor has low crystallinity, high activity and a small particle size; and 2) a preset sheet is directly heated and pressurized at the same position to be subjected to high-temperature hot pressed sintering after glue is discharged and stress is released, so that a dense and well formed target is obtained.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

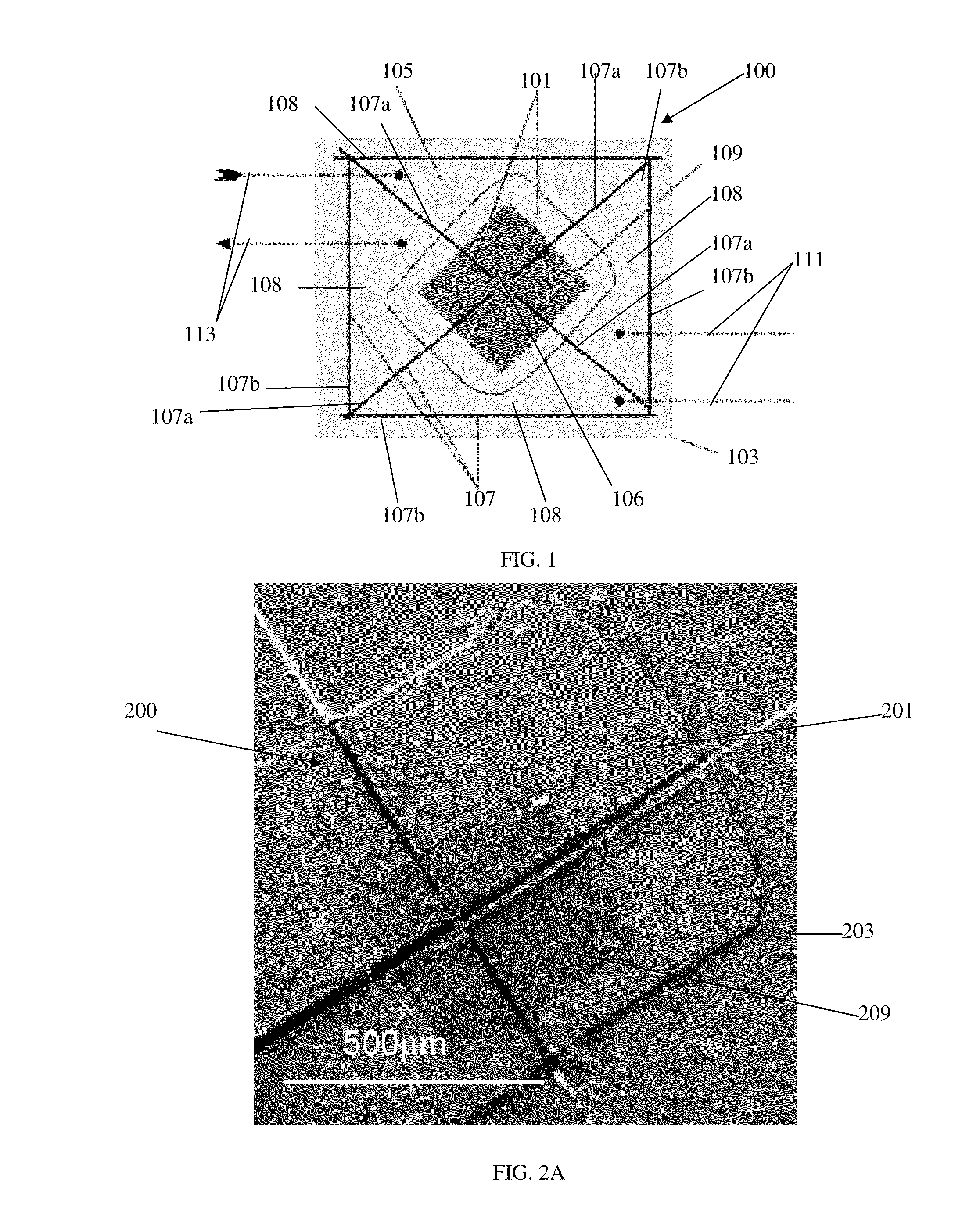

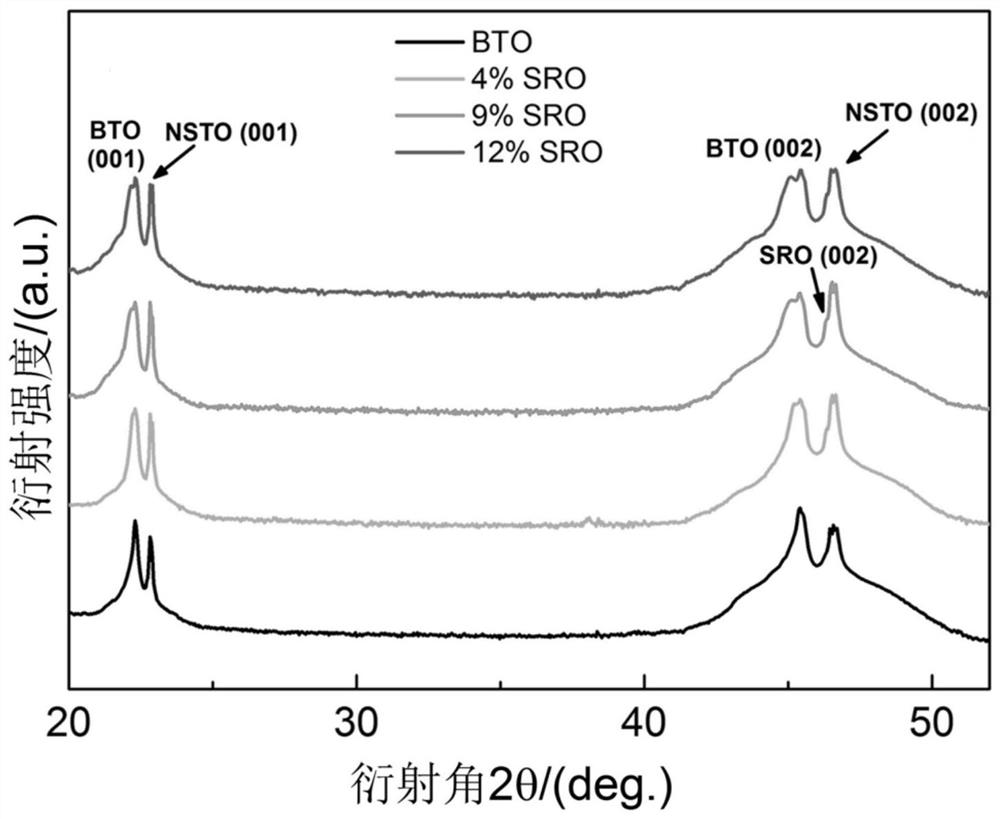

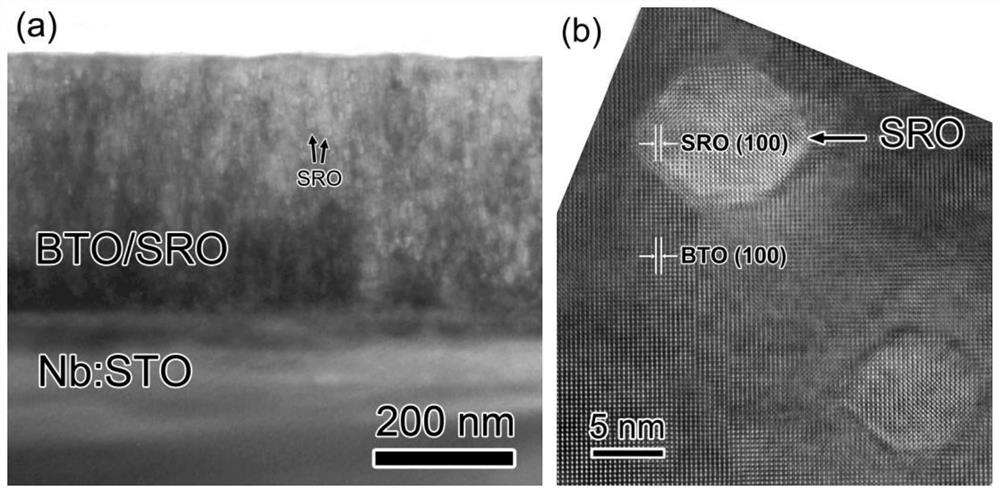

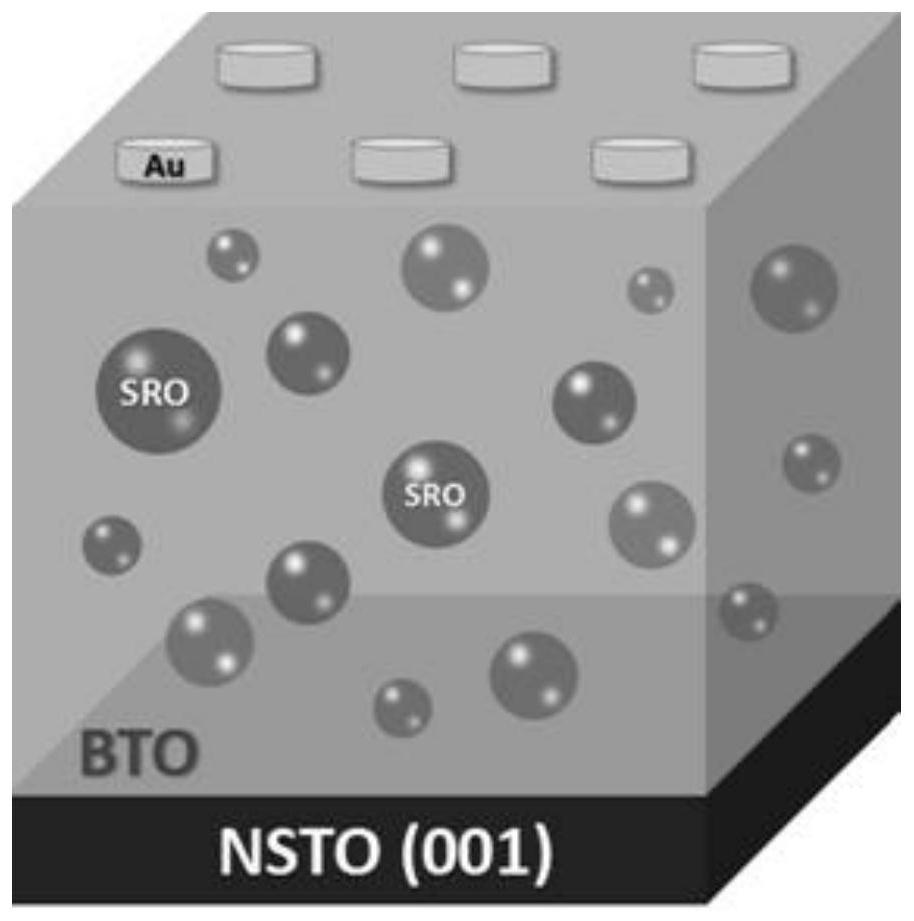

Barium titanate-strontium titanate nano composite film material and preparation method thereof

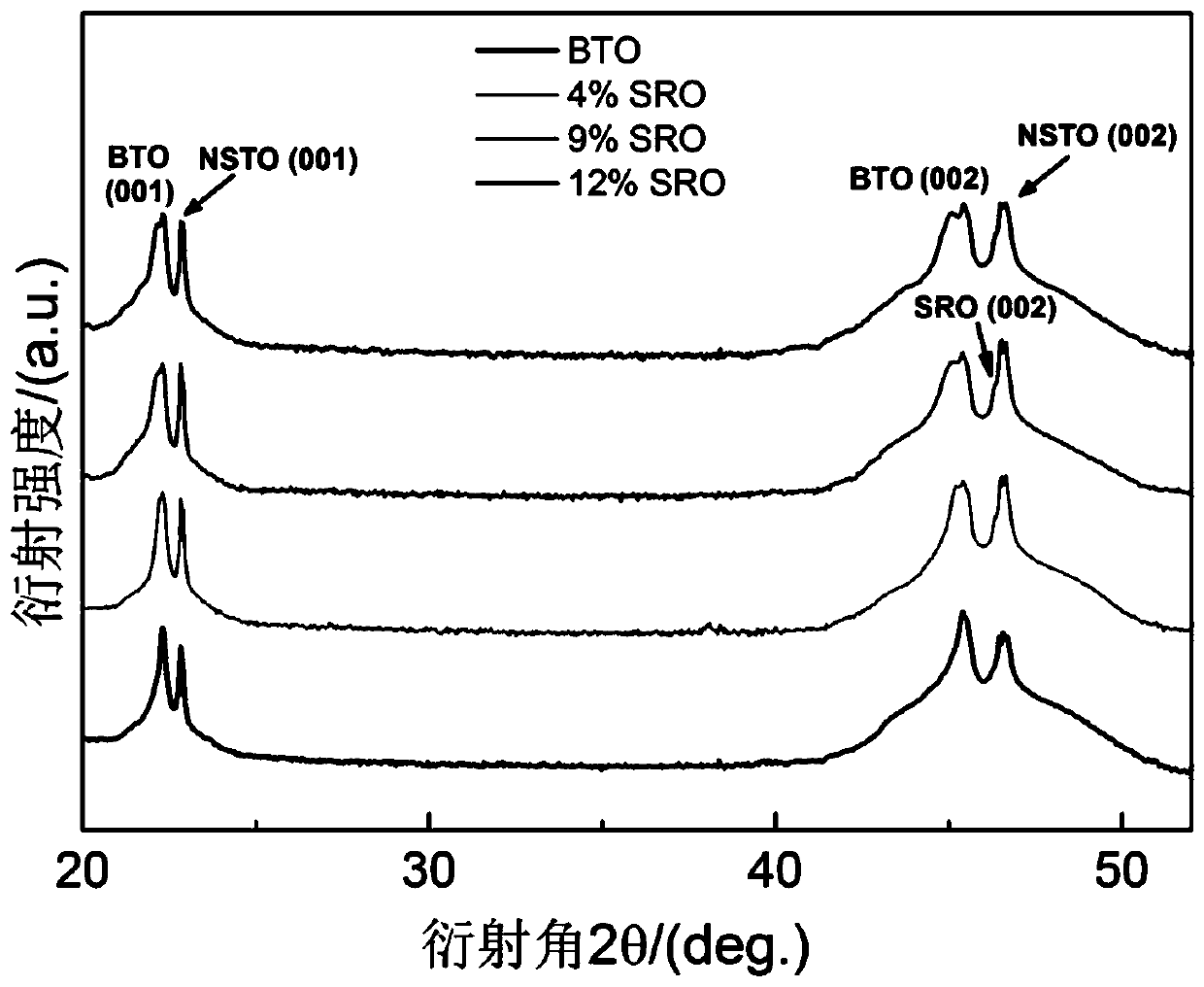

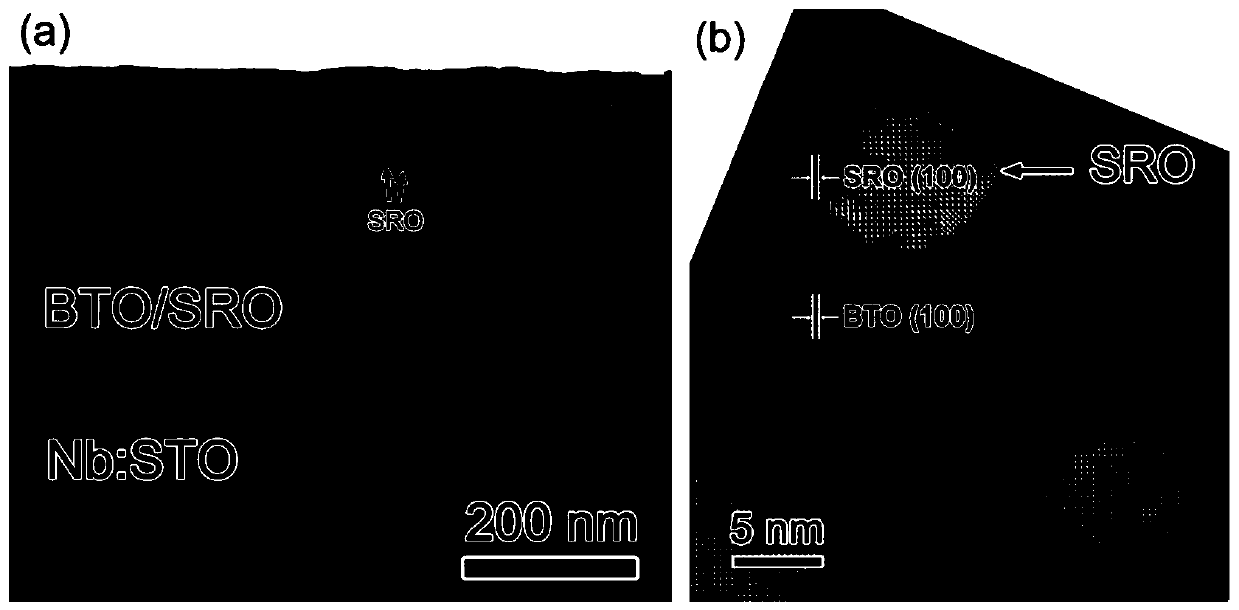

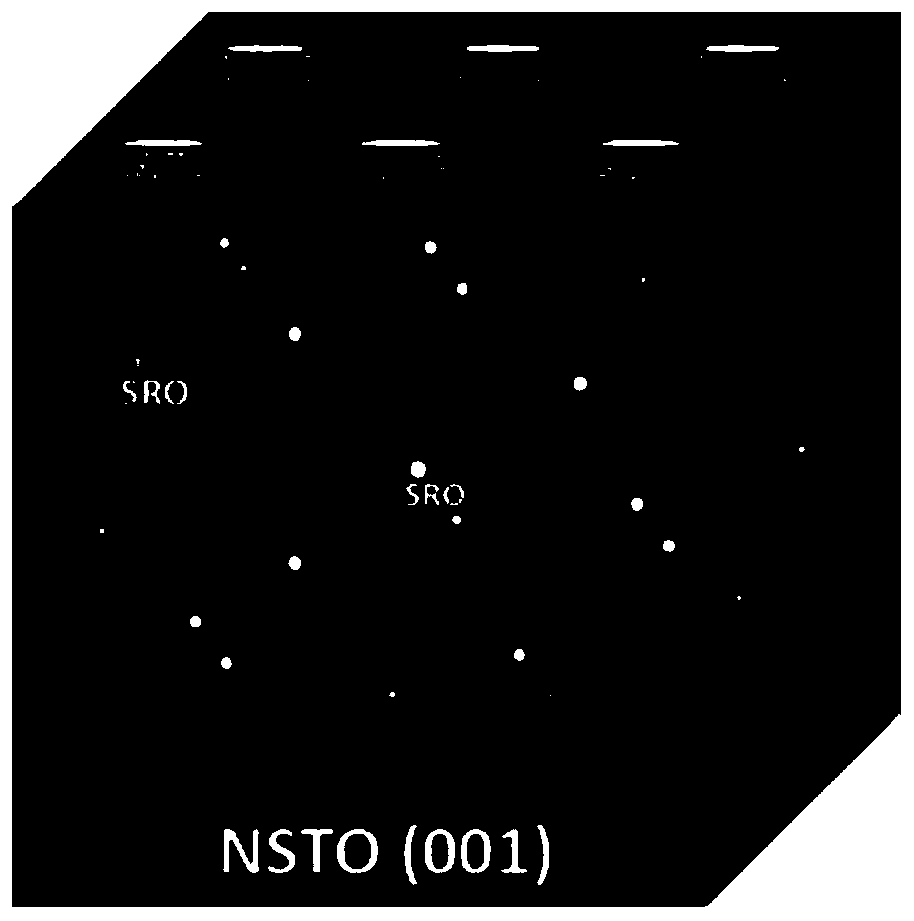

ActiveCN110607501AGood electrical propertiesGood crystallographic epitaxy relationshipVacuum evaporation coatingSputtering coatingStrontium titanateComposite film

The invention provides a barium titanate-strontium titanate nano composite film material and a preparation method thereof. The material comprises the components of, in volume ratio, 2%-9% of SrRuO3, 91%-98% of BaTiO3, and the material microstructure is characterized in that SrRuO3 nano particles are uniformly distributed on a BaTiO3 matrix. The barium titanate-strontium titanate nano composite film material has the advantages that the dielectric constant increases by 10%-24% compared with a pure barium titanate film; the material has good ferroelectric polarization performance, the remanent polarization intensity of the material reaches 40.3 microcoulomb / cm<2>, saturated polarization strength reaches 47. 8 microcoulomb / cm<2>, and compared with the barium titanate film, the remanent polarization intensity increases by 950%, and the saturated polarization intensity increase by 140%; and as a lead-free ferroelectric material, a composite film has a wide application prospect in integratedferroelectric devices such as a ferroelectric random access memory, a film capacitor, a sensor, an actuator.

Owner:SHENYANG POLYTECHNIC UNIV

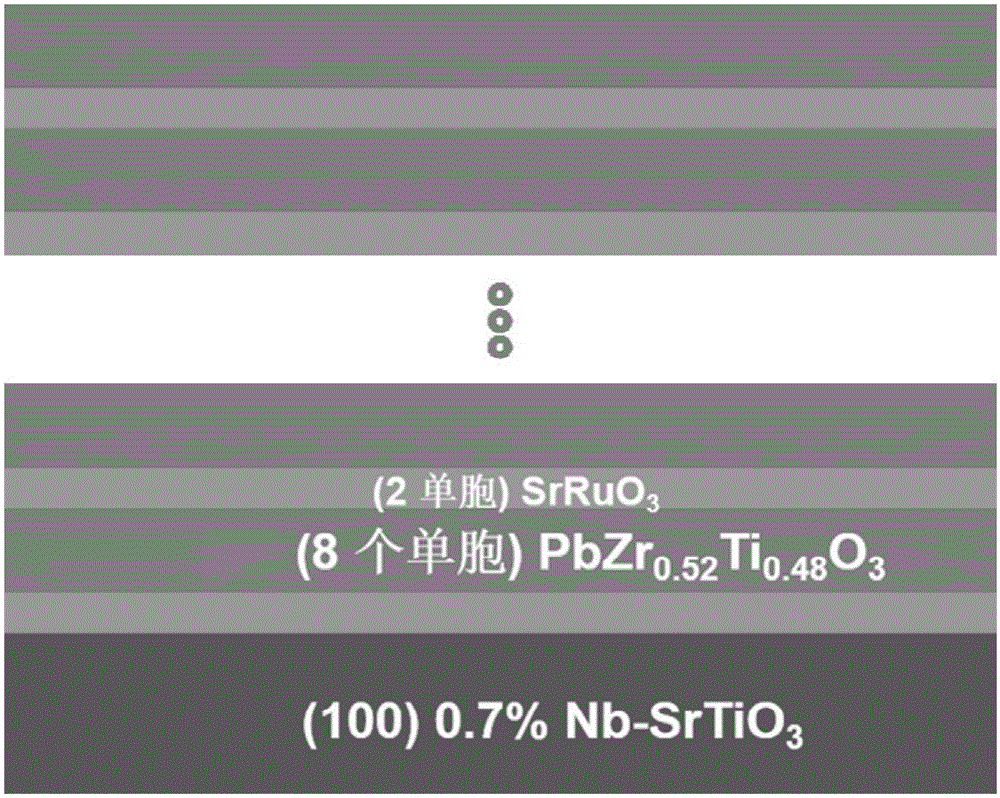

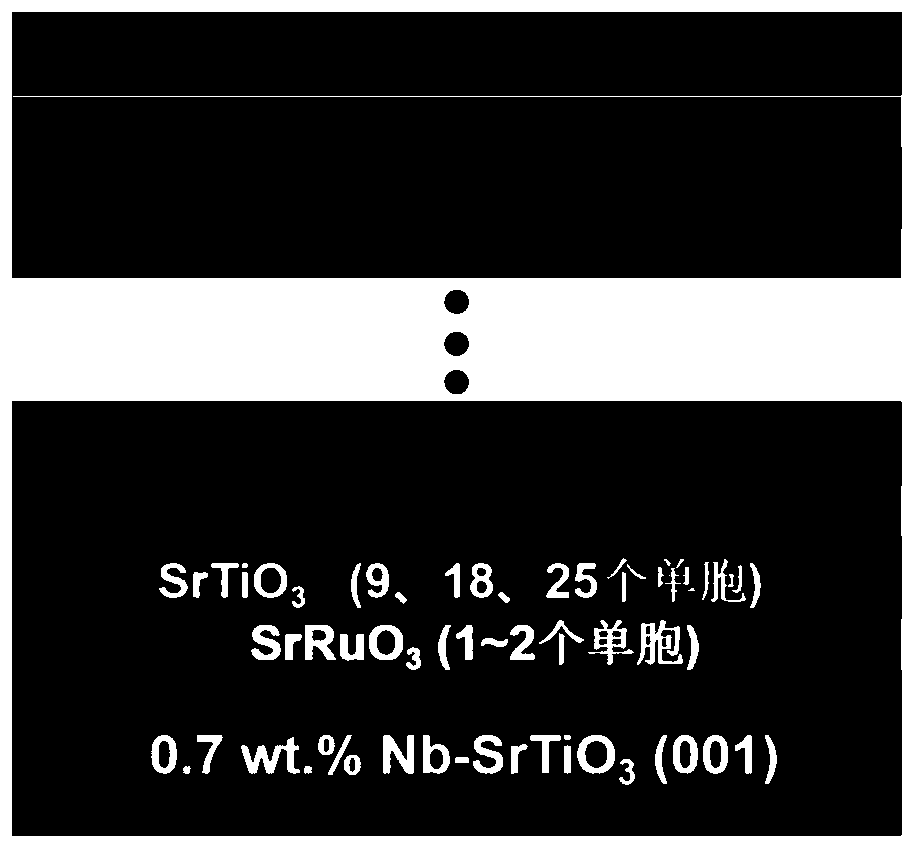

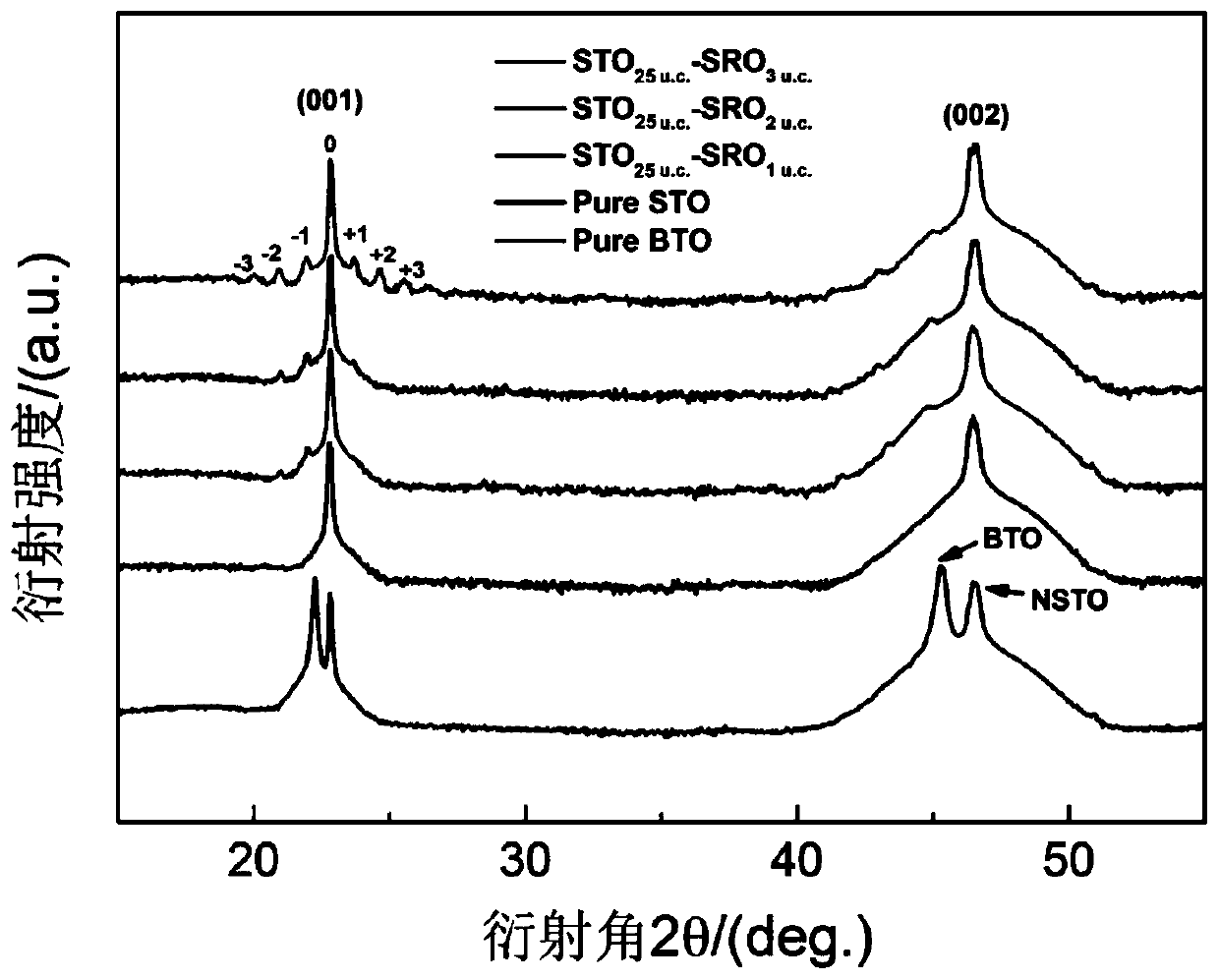

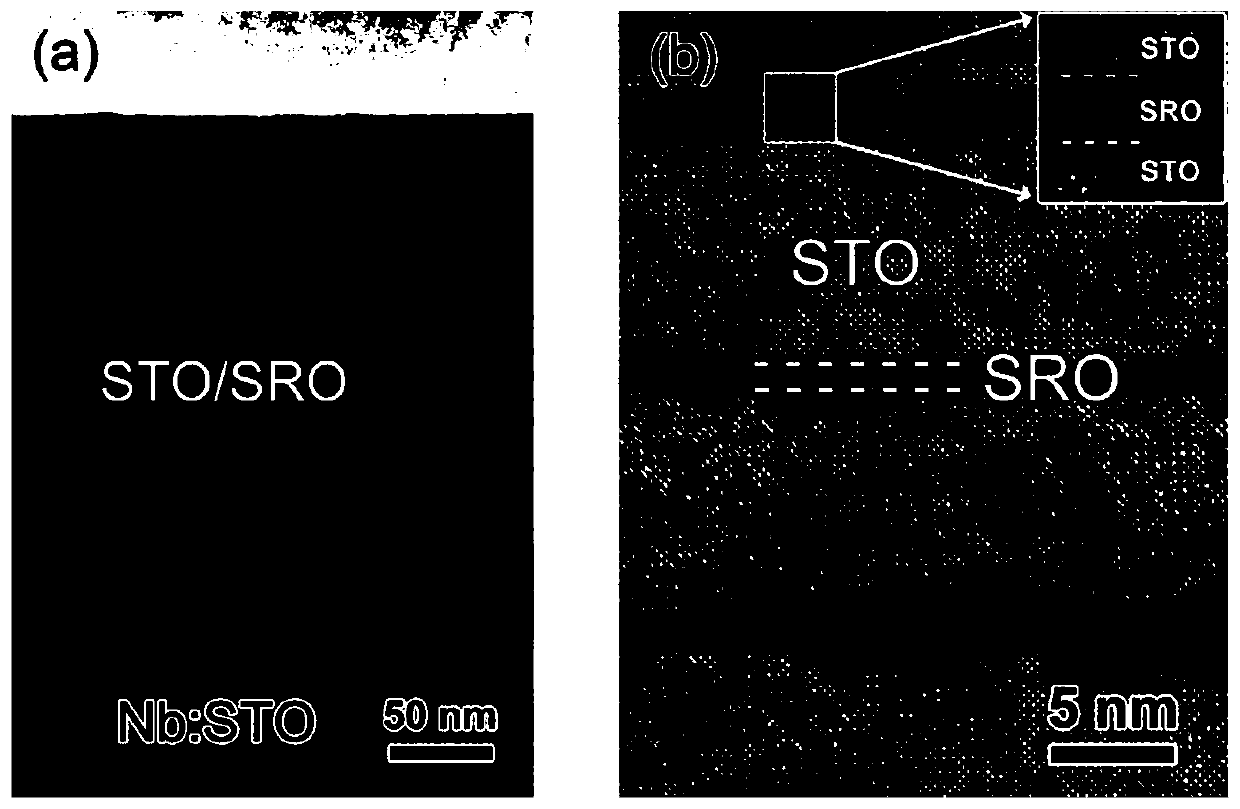

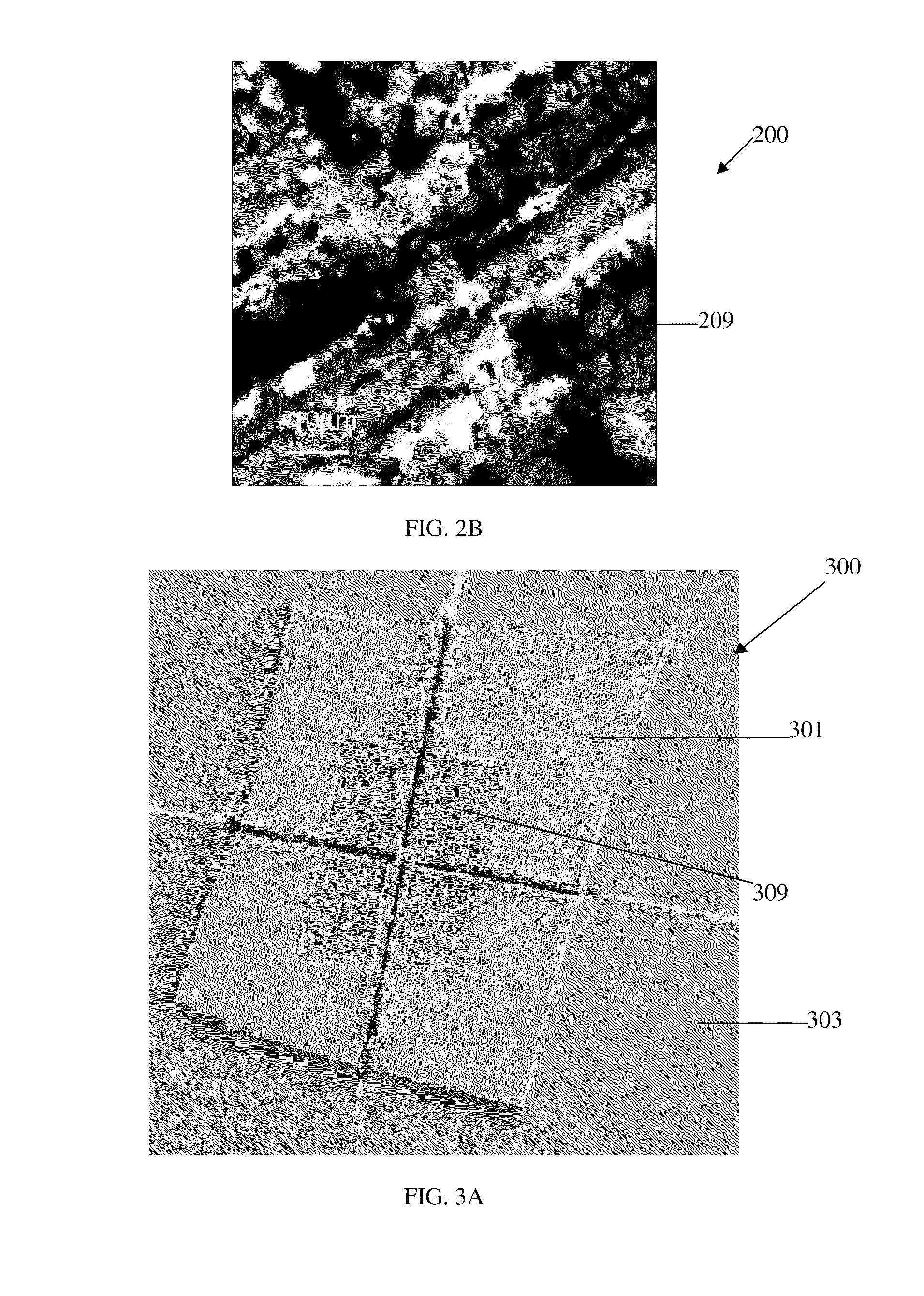

Strontium titanate/strontium ruthenate ferroelectric superlattice film material and preparation method thereof

PendingCN110643948AEffective regulation of ferroelectricityEffective regulation of dielectricVacuum evaporation coatingSputtering coatingLead zirconate titanateFerroelectric thin films

The invention aims to provide a strontium titanate / strontium ruthenate ferroelectric superlattice film material and a preparation method thereof. The material is composed of periodically grown quantumparaelectric insulator strontium titanate and metal conductive oxide strontium ruthenate. The strontium titanate / strontium ruthenate ferroelectric superlattice film material is a high-performance lead-free ferroelectric material, and the residual polarization strength of the high-performance lead-free ferroelectric material reaches 33.0 [mu]C / cm<2>, is 750% higher than that of a traditional lead-free ferroelectric material barium titanate film, and is as excellent as that of a lead zirconate titanate (Pb(ZrxTil-x)O3) lead-based ferroelectric film material that is commonly used at the present.According to the preparation method of the material, strontium ruthenate and strontium titanate are alternately grown on a single crystal substrate through a pulse laser deposition method, and the period thicknesses of a superlattice is accurately adjusted and controlled by controlling the time of laser ablation on different targets. The strontium titanate / strontium ruthenate ferroelectric superlattice film material can be used as the high-performance lead-free ferroelectric material to replace the Pb(ZrxTil-x)O3 lead-based ferroelectric film and has broad application prospects in integratedferroelectric devices such as ferroelectric memories, sensors and actuators.

Owner:SHENYANG POLYTECHNIC UNIV

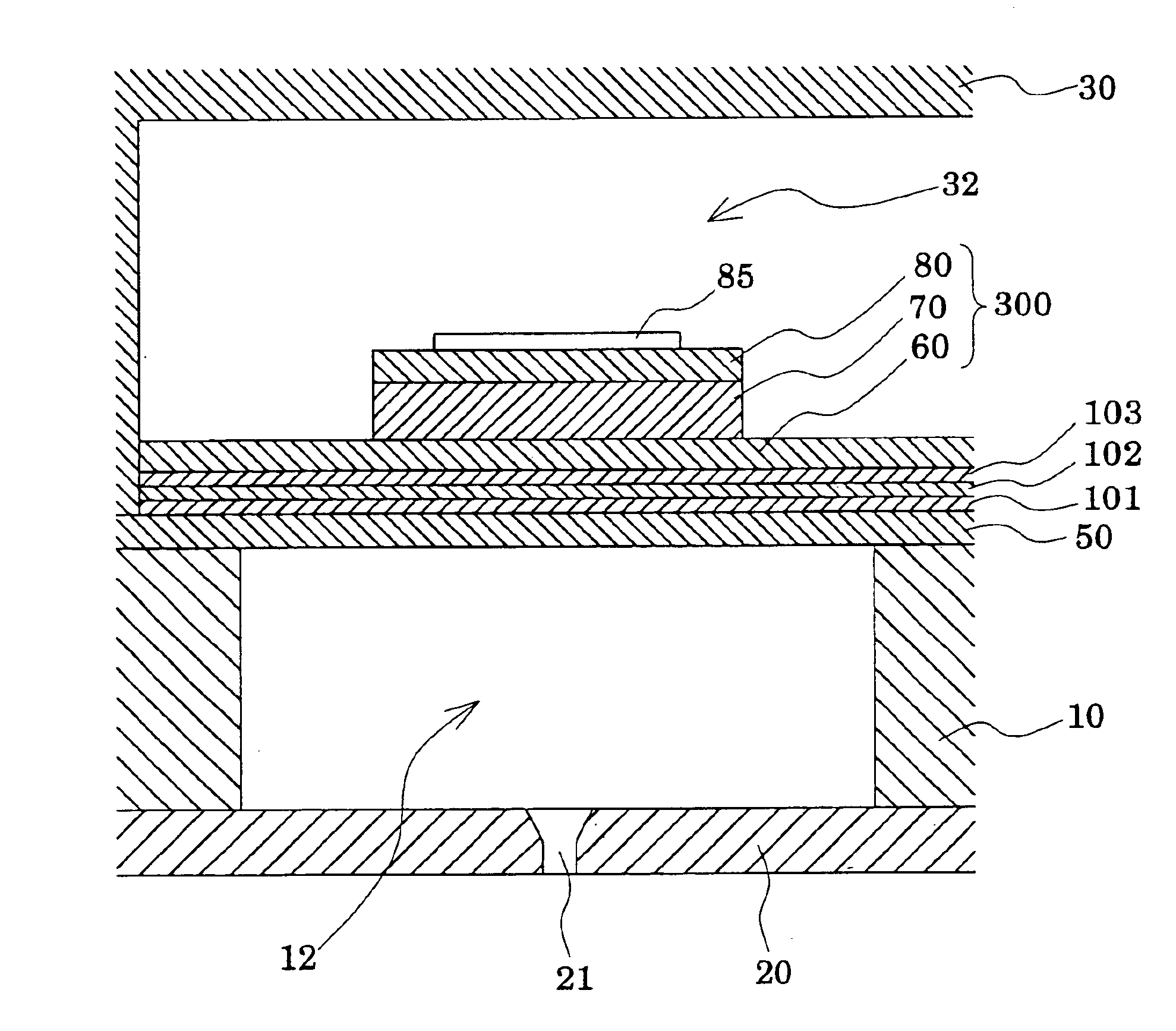

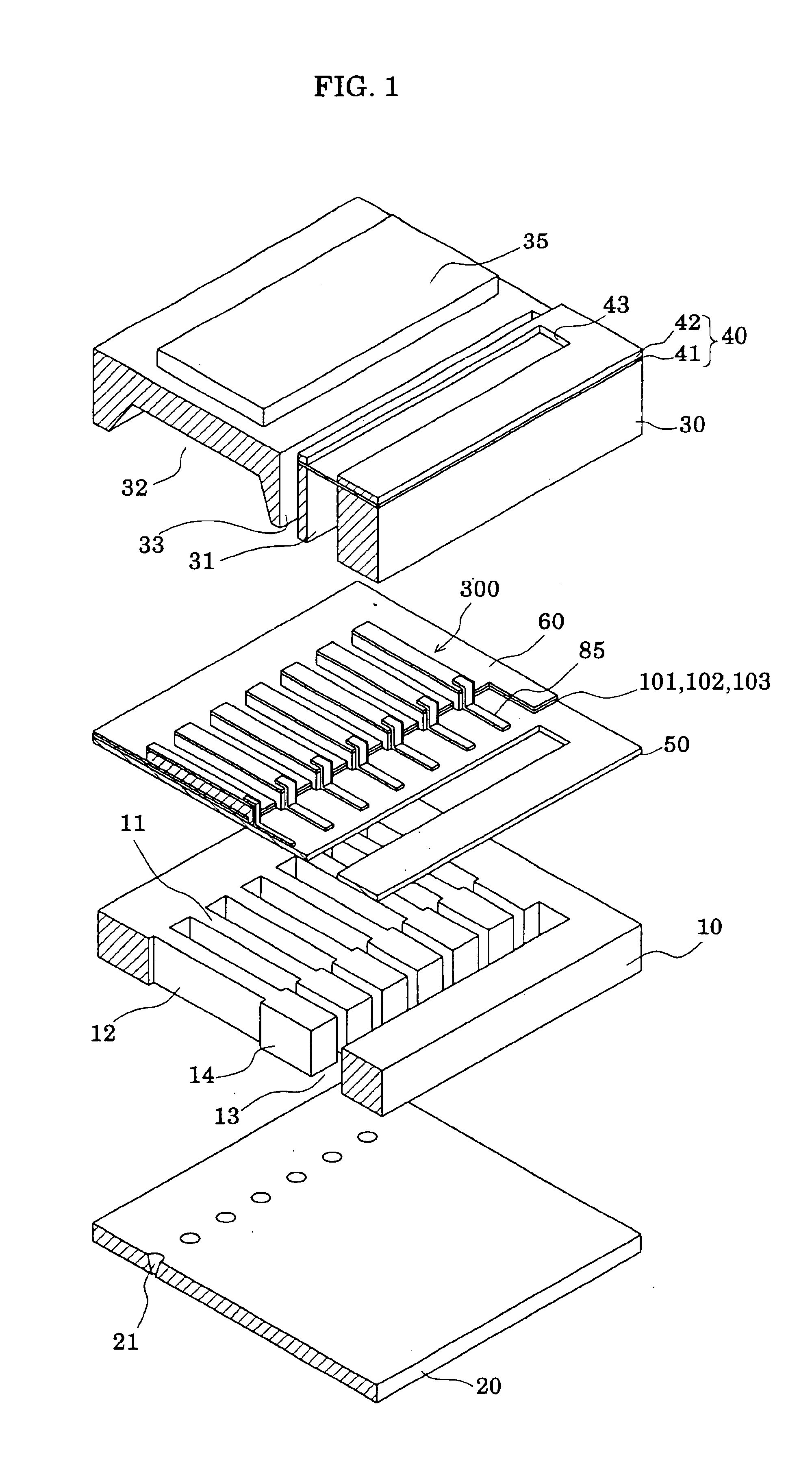

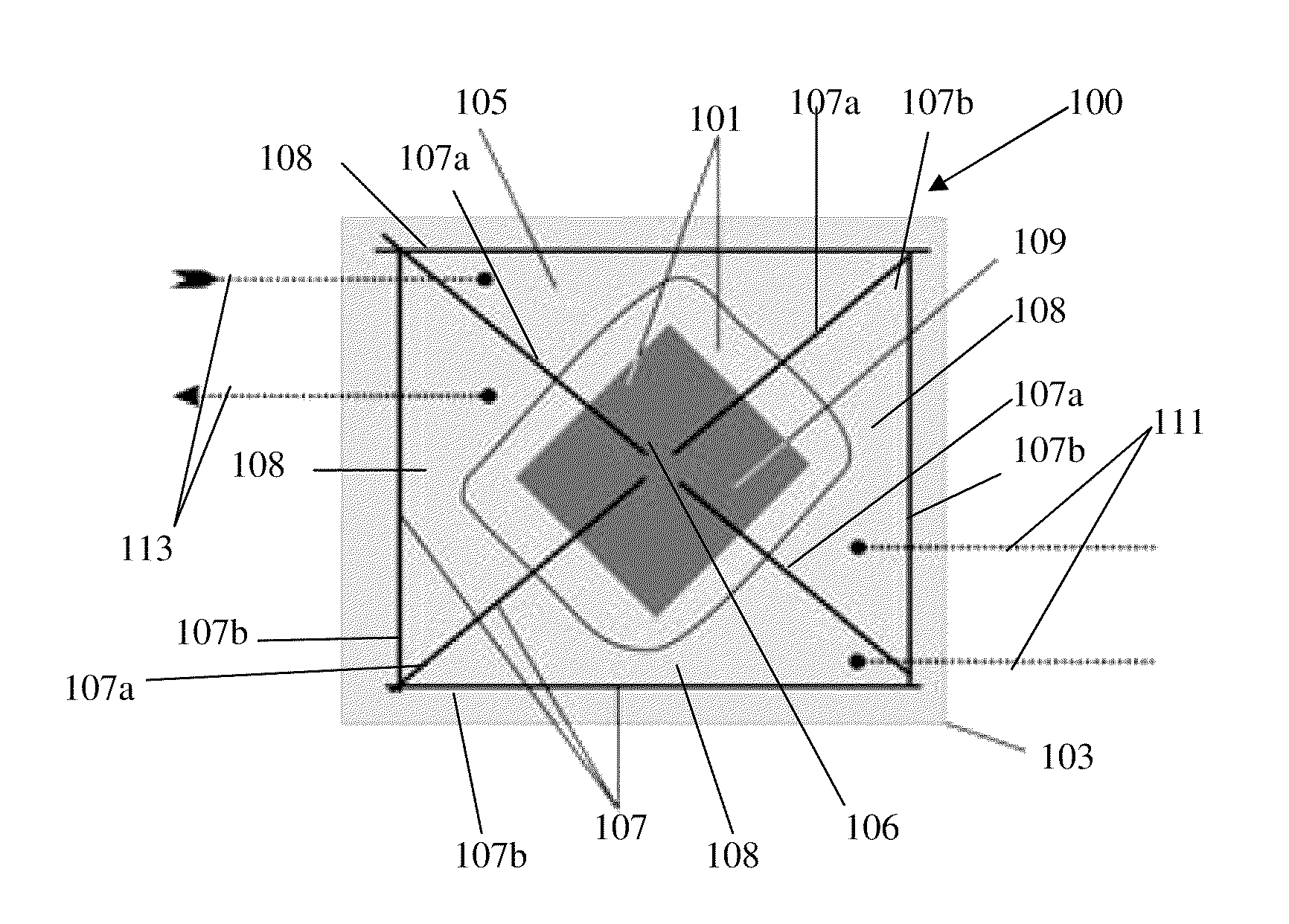

Piezoelectric liquid-jet head having a superconductor layer

InactiveUS6883902B2Improve featuresReliable formingInking apparatusPiezoelectric/electrostriction/magnetostriction machinesLiquid jetYttrium barium copper oxide

A piezoelectric liquid-jet head apparatus, which provides a nearly uniform piezoelectric element and enables ejection of liquid at maximum output, is disclosed. The piezoelectric liquid-jet head has a piezoelectric element 300 provided on one surface of a passage forming substrate 10 via a vibration plate. The piezoelectric liquid jet head includes: a zirconium oxide layer 101 formed on the surface of the passage forming substrate 10; a cerium oxide layer 102 formed on the zirconium oxide layer 101; a superconductor layer 103 formed on the cerium oxide layer 102 and composed of a yttrium-barium-copper-oxygen-based material (YBCO); a lower electrode 60 formed on the superconductor layer 103 and composed of strontium ruthenate; and a piezoelectric layer 70 which is a single crystal epitaxially grown on the lower electrode 60.

Owner:SEIKO EPSON CORP

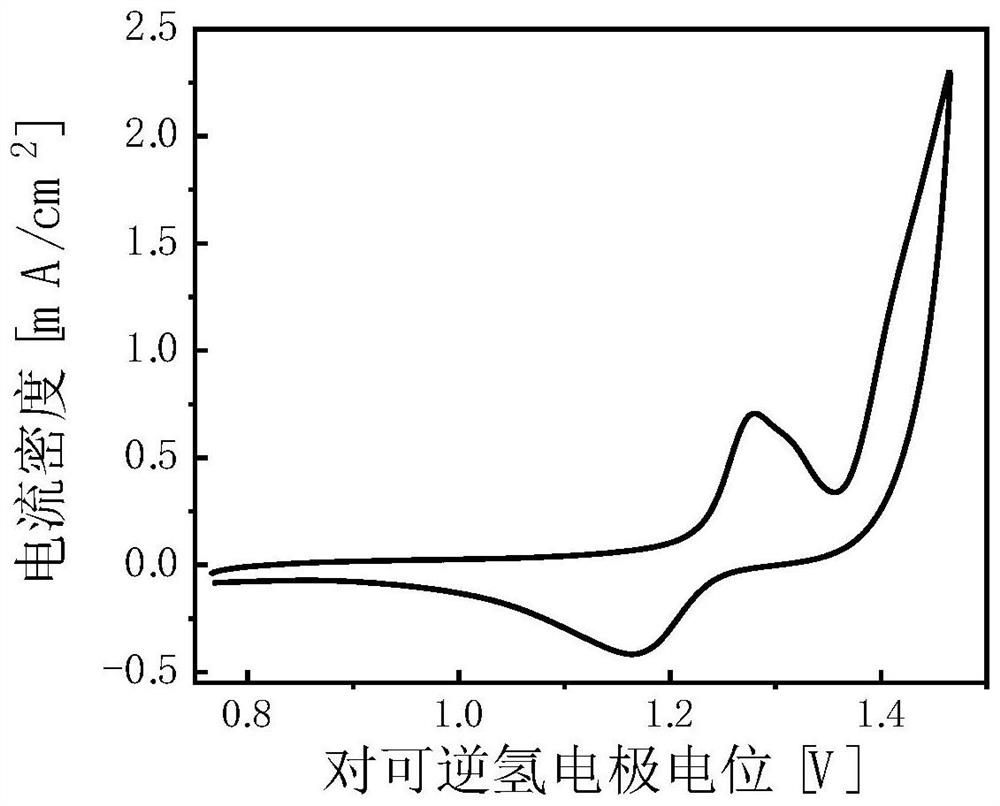

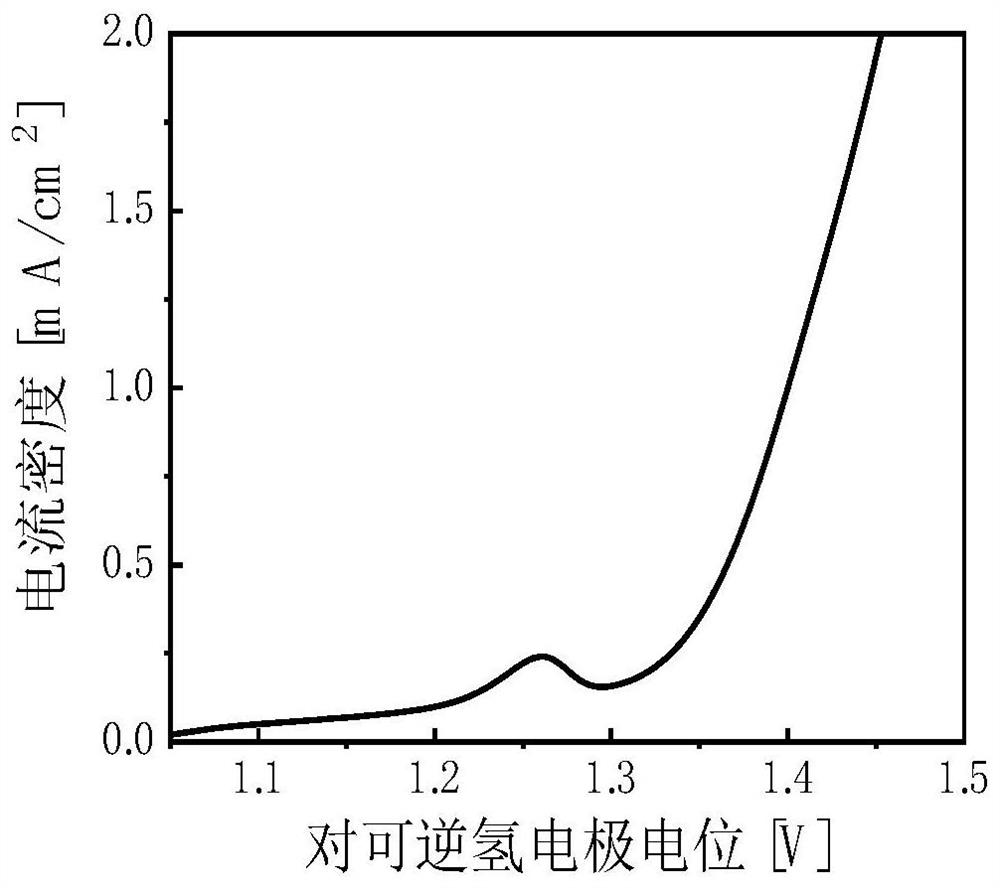

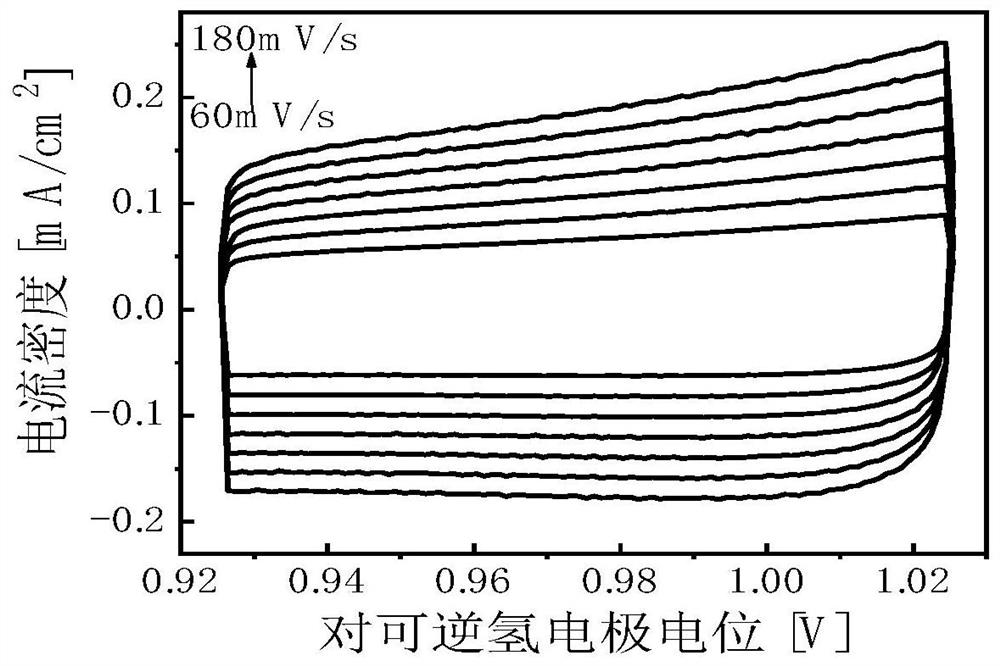

Amorphous strontium ruthenate film composite electrode, preparation method and application thereof

The invention discloses an amorphous strontium ruthenate film composite electrode, a preparation method and application thereof. The preparation method comprises the following steps: fully grinding a glassy carbon substrate by using aluminum oxide polishing powder, cleaning by using ultrasonic waves, and blow-drying by using inert gas; and fixing on a sample table of a pulse laser deposition system, pre-burning strontium ruthenate serving as a target material under the conditions of constant oxygen partial pressure and constant laser energy density, then taking down a baffle plate for deposition, and taking out a sample in a nitrogen atmosphere to obtain the strontium ruthenate film composite electrode. According to the invention, amorphous strontium ruthenate is deposited and grown on a glassy carbon substrate through laser pulses, so that the obtained electrode material is high in binding force and good in stability; when the amorphous strontium ruthenate film composite electrode is applied to an electrocatalytic water electrolysis oxygen evolution reaction system, the water electrolysis oxygen evolution reaction can be effectively catalyzed and promoted; and the results show that the amorphous structure engineering can become an effective and general strategy for designing a high-performance catalyst applied to the next generation of electrolysis water oxygen evolution reaction.

Owner:YANGTZE DELTA REGION INST OF UNIV OF ELECTRONICS SCI & TECH OF CHINE HUZHOU

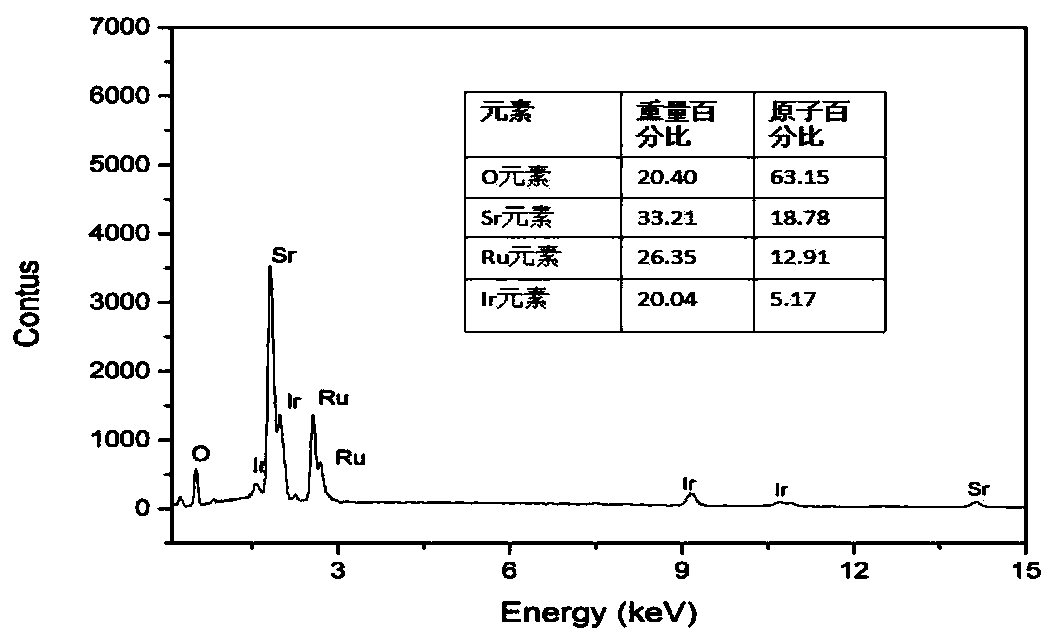

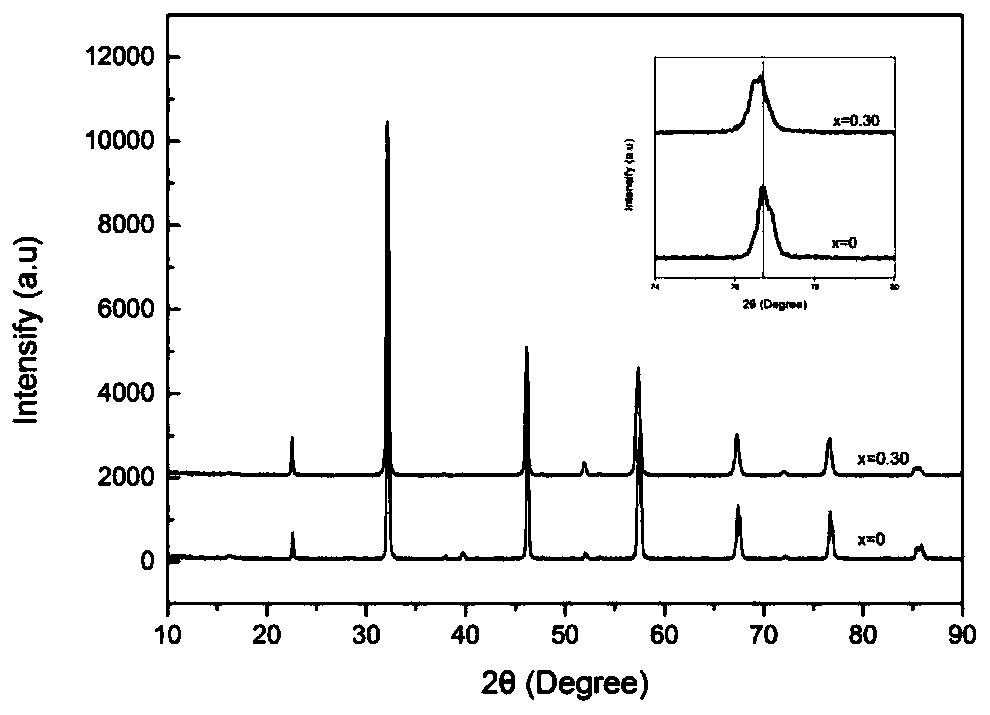

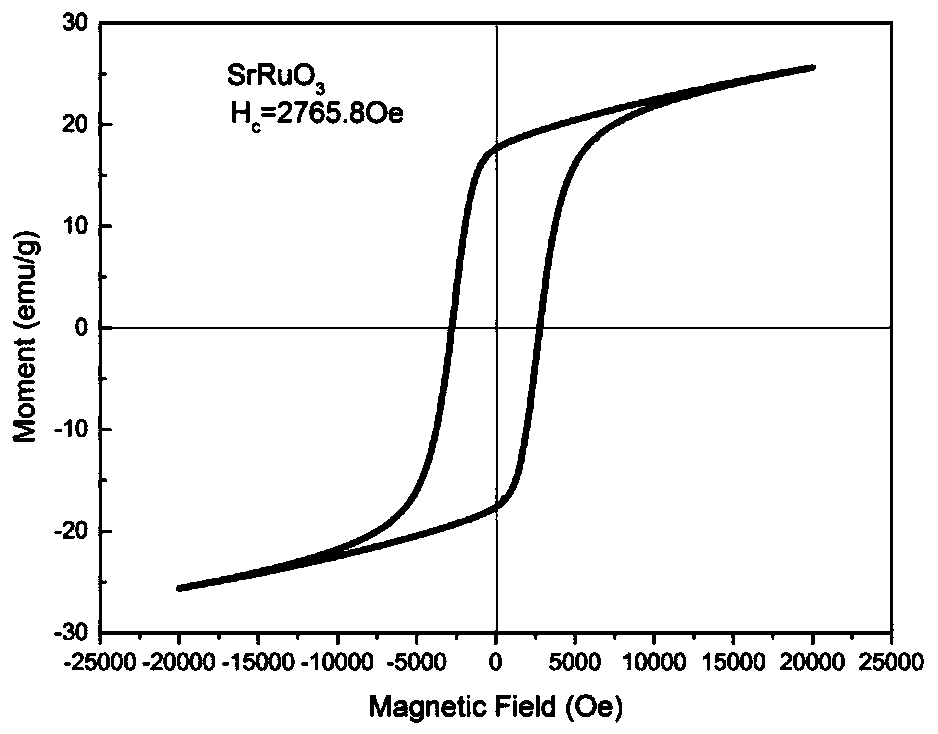

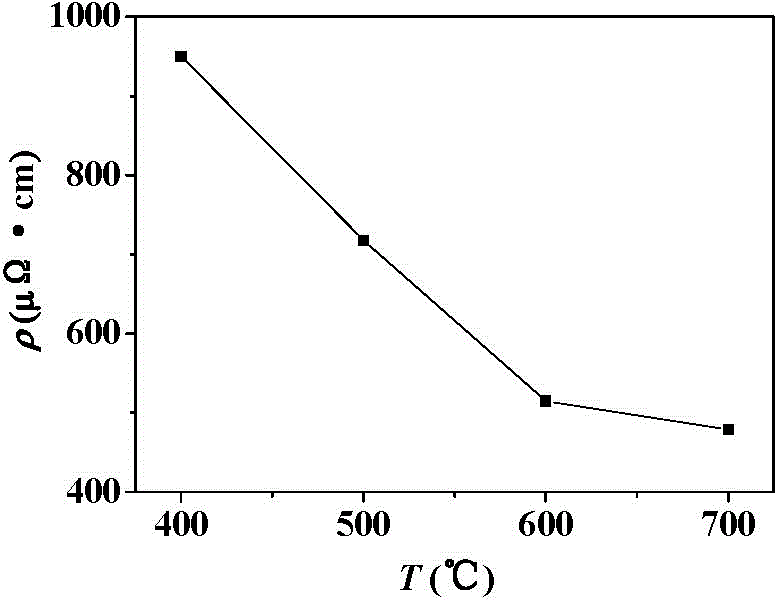

Ir-doped SrRuO3 doped material, preparation method and application

InactiveCN109911950AHas an exchange bias effectMagnetic-field-controlled resistorsRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsMagnetic storageHemt circuits

The invention discloses an Ir-doped SrRuO3 doped material, a preparation method and an application. The Ir-doped SrRuO3 doped material is an oxide containing metallic elements Sr, Ru and Ir, the chemical formula is SrRu0.7Ir0.3O3, the material has an antiferromagnetic area and a ferromagnetic area, Sr and Ru are main elements, Ir is a doping element and partially replaces the position of Ru for doping, Ir doping content is 30%, and the material has an exchange bias effect when the temperature is 10 K. According to the Ir-doped SrRuO3 doped material, the preparation method and the application,the Ir-doped SrRuO3 doped material can replace an existing spin valve with a multilayered structure to be applied to the field of magnetic storage, and the Ir-doped SrRuO3 doped material can realize metal-insulation phase change by controlling temperature change and is applied to the field of preparation of a circuit switch.

Owner:NANJING UNIV OF POSTS & TELECOMM +1

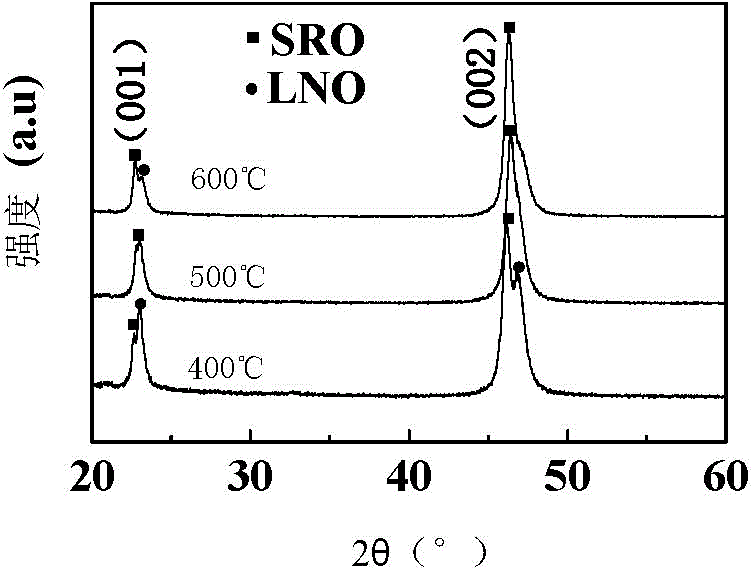

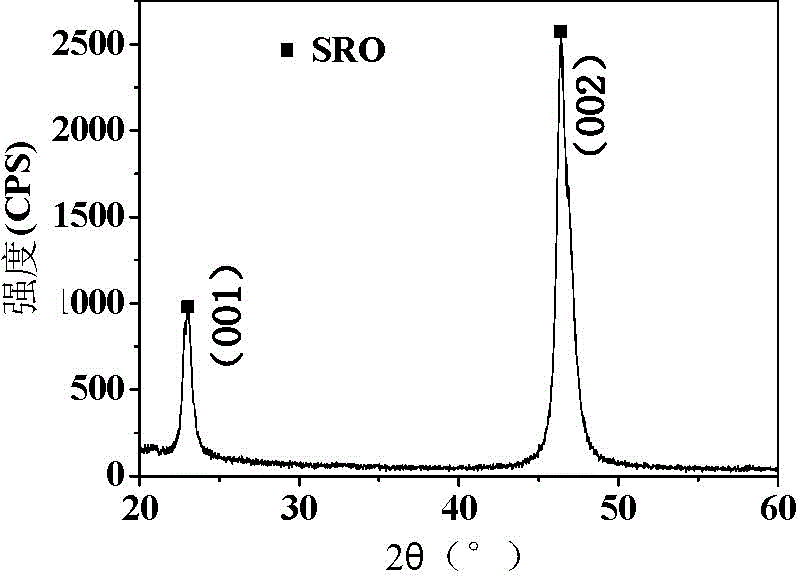

Method for preparing strontium ruthenate film with highly (001) preferred orientation at low temperature

ActiveCN104419895ALower crystallization temperatureLow resistivityVacuum evaporation coatingSputtering coatingSputteringOptoelectronics

The invention relates to a method for preparing a strontium ruthenate film with highly (001) preferred orientation at a low temperature. A silicon chip is used as a substrate; and after a LaNiO3 buffer layer is introduced, a SrRuO3 target is sputtered at 400-600 DEG C to obtain the SrRuO3 with highly (001) preferred orientation.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

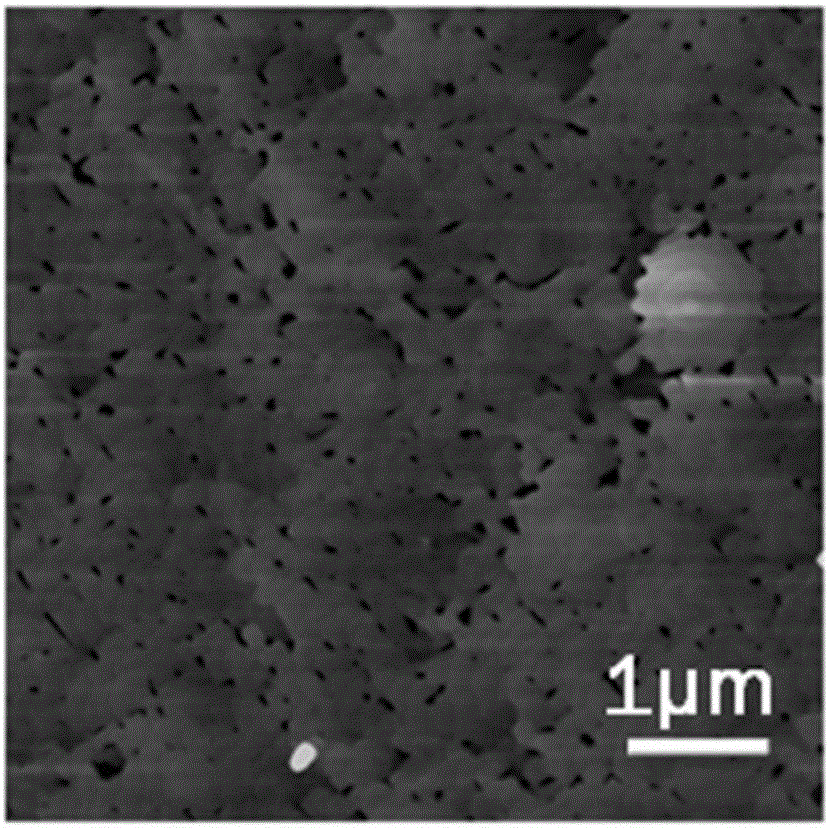

Material for promoting mesenchymal stem cell osteoblastic differentiation and preparation method and application thereof

ActiveCN106047802AHigh polarizationHigh affinityVacuum evaporation coatingSputtering coatingStrontium titanateNatural bone

The invention relates to a material for promoting mesenchymal stem cell osteoblastic differentiation and solves the technical problem that electrical characteristics of existing electrical active materials cannot match with natural bone healing process. The material is a thin film using strontium titanate as a substrate and strontium ruthenate as a middle layer and having bismuth ferrite deposited on the surface. The invention further provides and a preparation method and application of the material. The material can be used in the technical field of promoting mesenchymal stem cell osteoblastic differentiation.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

Semiconductor device and method for manufacturing thereof

InactiveUS7183601B2Semiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

Owner:KK TOSHIBA

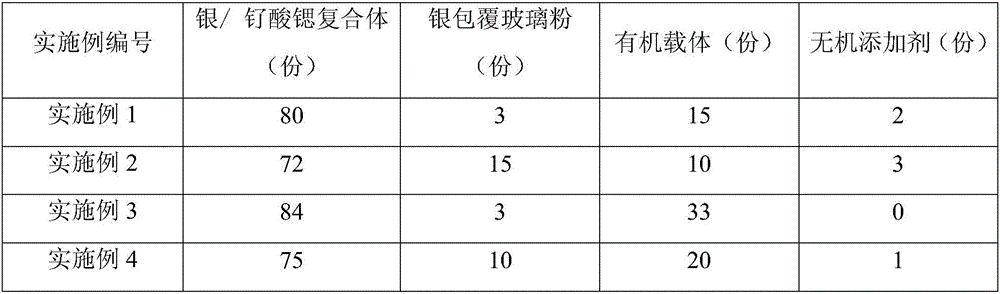

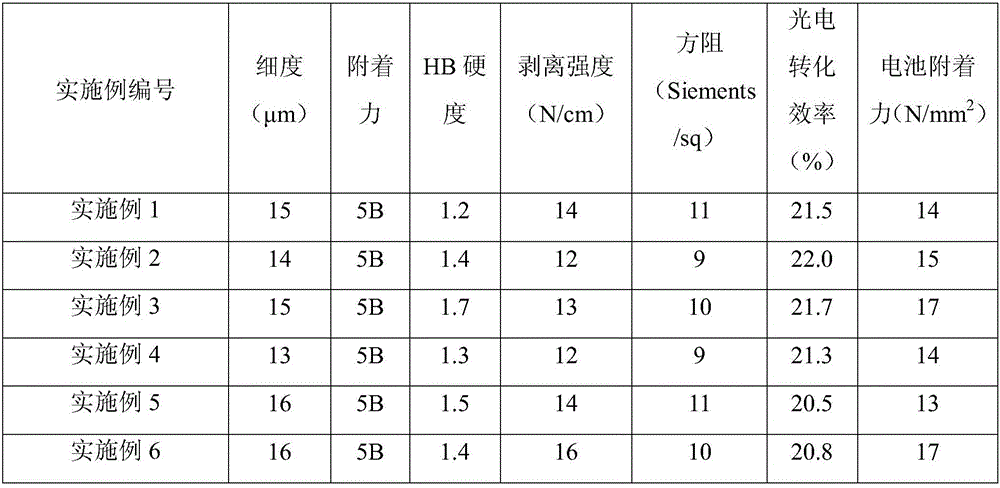

Strontium ruthenate nanoparticle composite silver paste and preparation method thereof

ActiveCN106128546AImprove electrical performanceImprove stabilityMaterial nanotechnologyNon-conductive material with dispersed conductive materialSilver pasteNanoparticle

The invention relates to strontium ruthenate nanoparticle composite silver paste and a preparation method thereof, belongs to the technical field of conductive silver paste, and aims at solving the technical problem of providing the strontium ruthenate nanoparticle composite silver paste. The strontium ruthenate nanoparticle composite silver paste is prepared from the following components in parts by weight: 72-84 parts of silver / strontium ruthenate complex, 3-15 parts of silver-coated glass powder, 10-33 parts of organic carriers and 0-3 parts of inorganic additives. Compared with existing conductive silver paste, the strontium ruthenate nanoparticle composite silver paste provided by the invention has better electrical property and better stability.

Owner:SICHUAN AIERFATAIKE TECH CO LTD

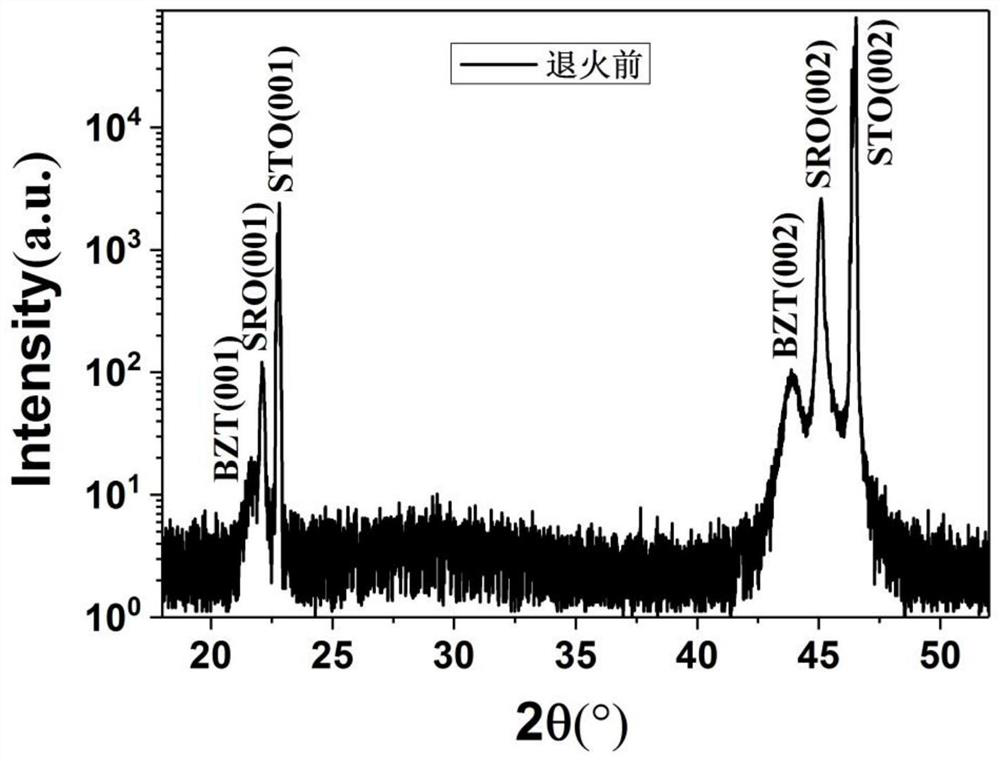

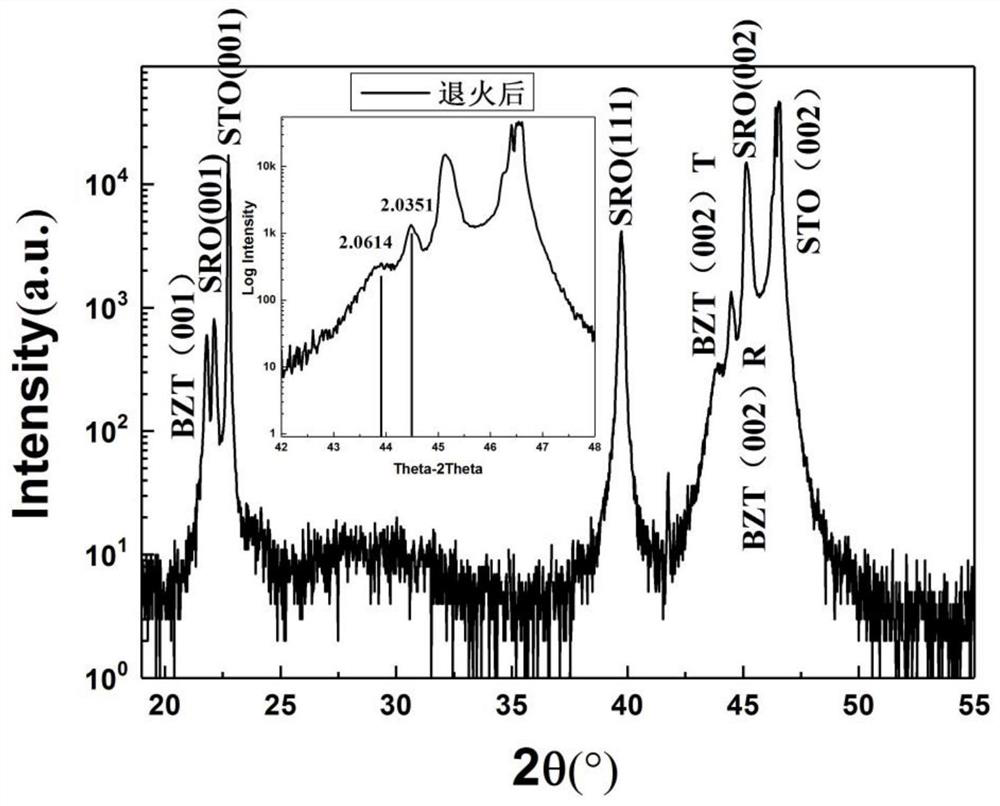

Barium zirconate titanate film annealing method based on radio frequency magnetron sputtering

PendingCN113215549AHigh crystallinityHigh strengthVacuum evaporation coatingSemiconductor/solid-state device manufacturingStrontium titanium oxideSputtering

The invention discloses a barium zirconate titanate film annealing method based on radio frequency magnetron sputtering, and belongs to the technical field of barium zirconate titanate preparation. Strontium titanate is used as a matrix, a strontium ruthenate material is sputtered to be used as a substrate, the substrate is sputtered to the surface of the matrix by using a magnetron sputtering technology, and then a barium zirconate titanate target material is used for sputtering a barium zirconate titanate material to be plated on the surface, wherein the zirconium content in the barium zirconate titanate target material is 20 mol.%. In the strontium ruthenate electrode deposition process, mixed atmosphere sputtering is adopted to obtain a film, in the barium zirconate titanate film deposition process, mixed atmosphere sputtering is adopted to obtain the film with the thickness of 280 nm, after sputtering is finished, a sample is subjected to heat preservation treatment, and then part of the sample is taken out to be subjected to annealing treatment. By means of the annealing process, the intensity of the diffraction peak of the barium zirconate titanate film is effectively enhanced, the crystallinity of the barium zirconate titanate film is improved, then the quality of the film is improved, and the ferroelectric performance of the film is obviously improved.

Owner:NANJING UNIV OF POSTS & TELECOMM

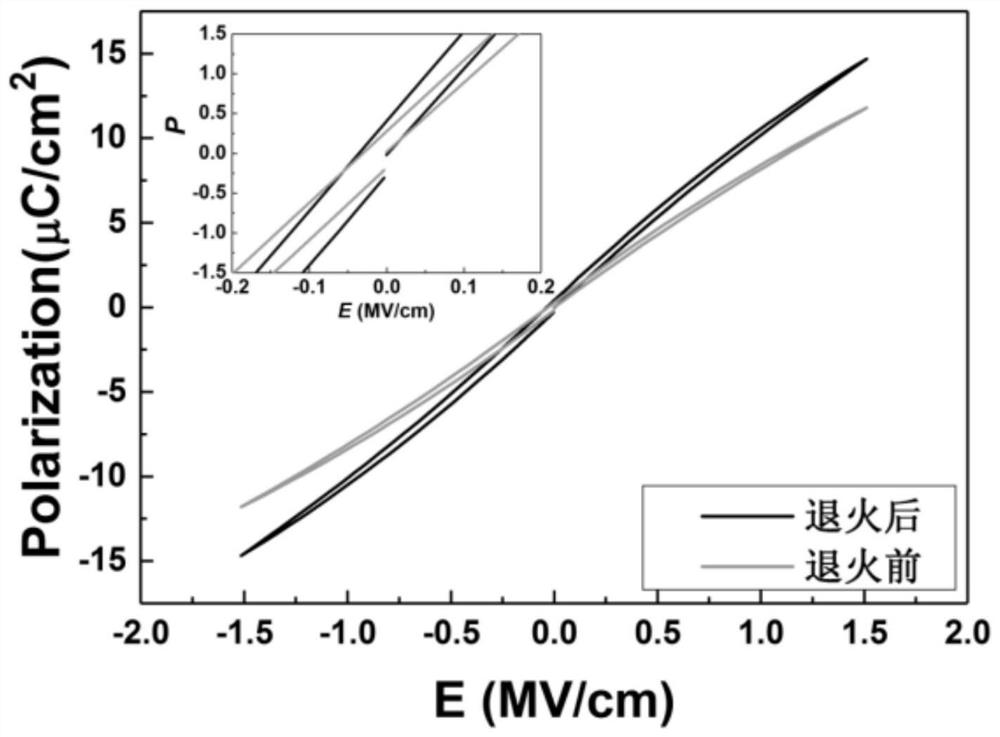

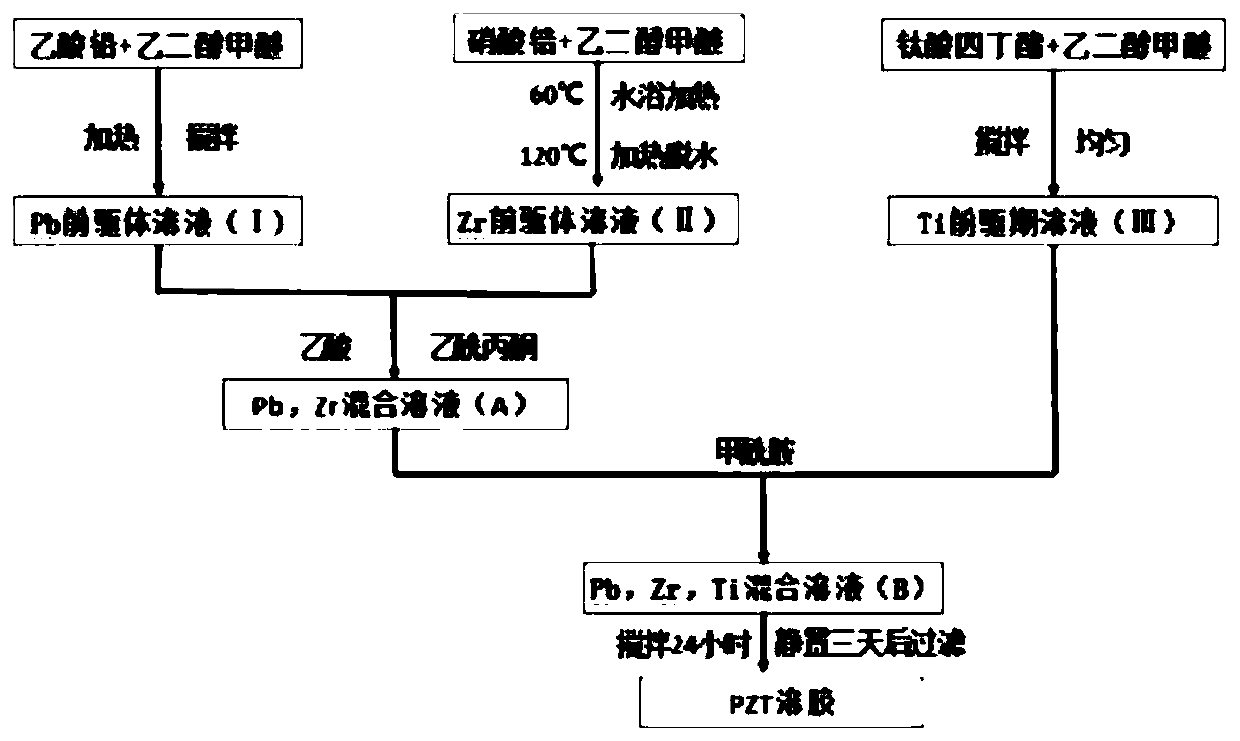

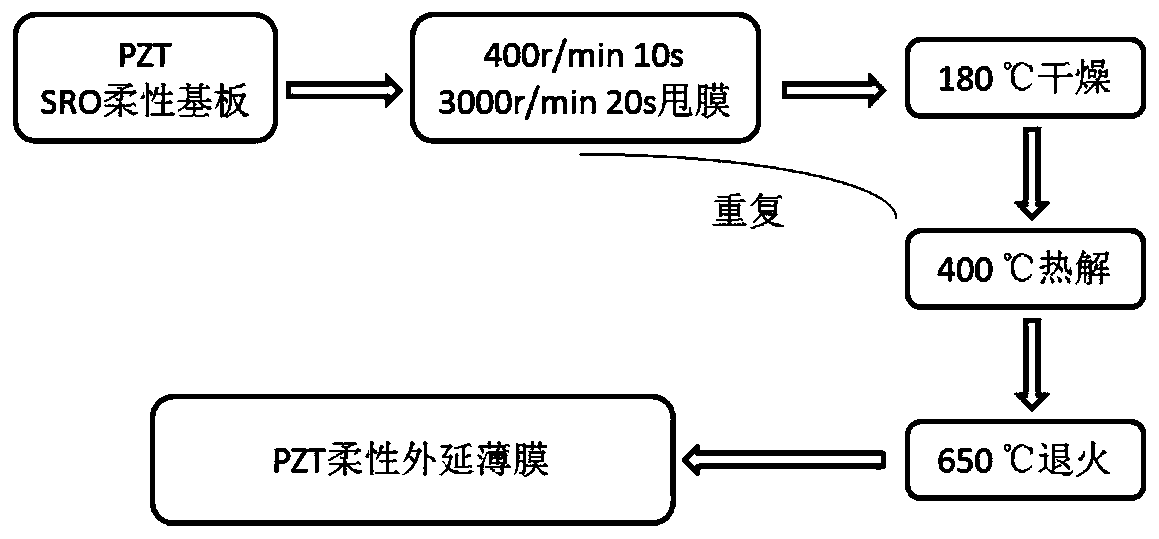

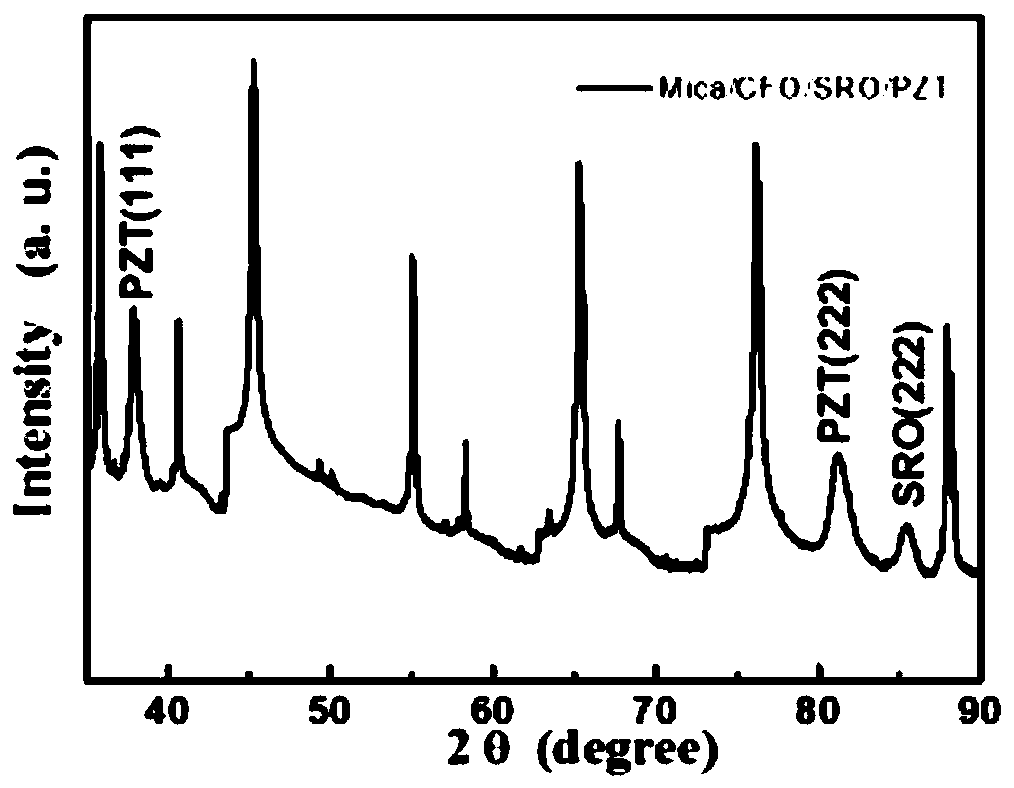

A kind of preparation method of flexible epitaxial ferroelectric thin film

ActiveCN107256866BWon't crackImprove ferroelectric propertiesSolid-state devicesVacuum evaporation coatingLead zirconate titanateFerroelectric thin films

Owner:XIANGTAN UNIV

In situ generation of RuO4 for ALD of Ru and Ru related materials

Apparatus and method for generating ruthenium tetraoxide in situ for use in vapor deposition, e.g., atomic layer deposition (ALD), of ruthenium-containing films on microelectronic device substrates. The ruthenium tetraoxide can be generated on demand by reaction of ruthenium or ruthenium dioxide with an oxic gas such as oxygen or ozone. In one implementation, ruthenium tetraoxide thus generated is utilized with a strontium organometallic precursor for atomic layer deposition of strontium ruthenate films of extremely high smoothness and purity.

Owner:ENTEGRIS INC

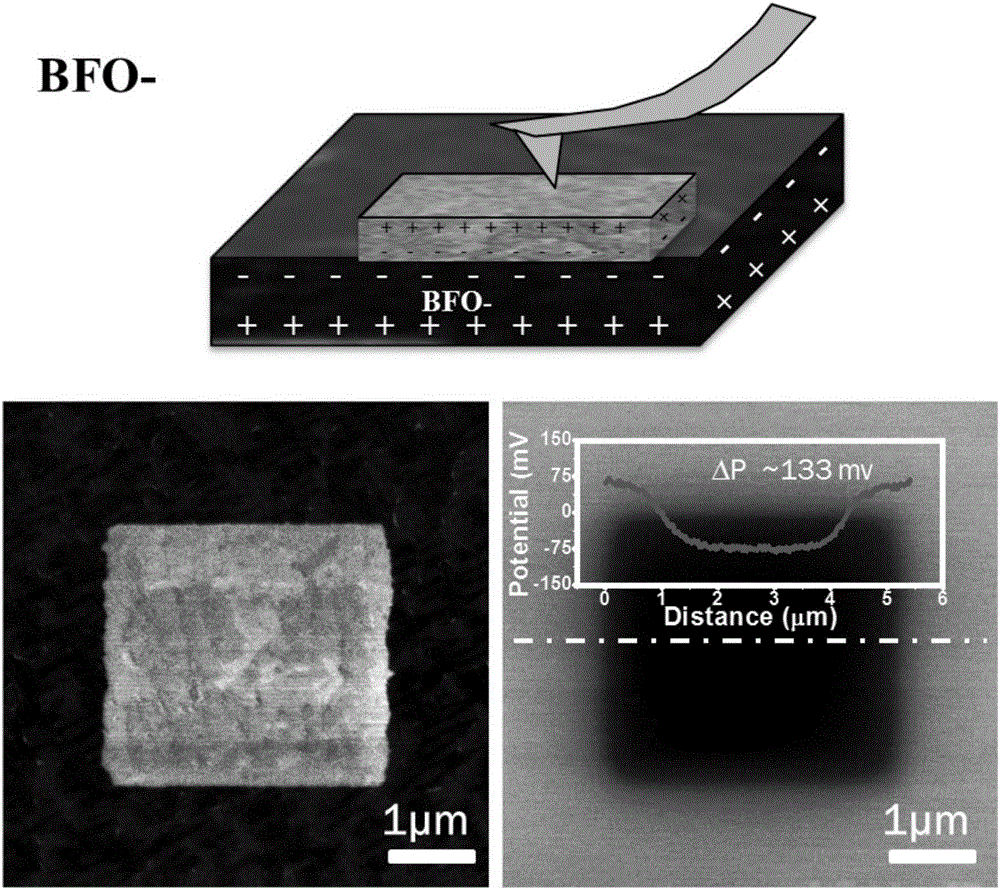

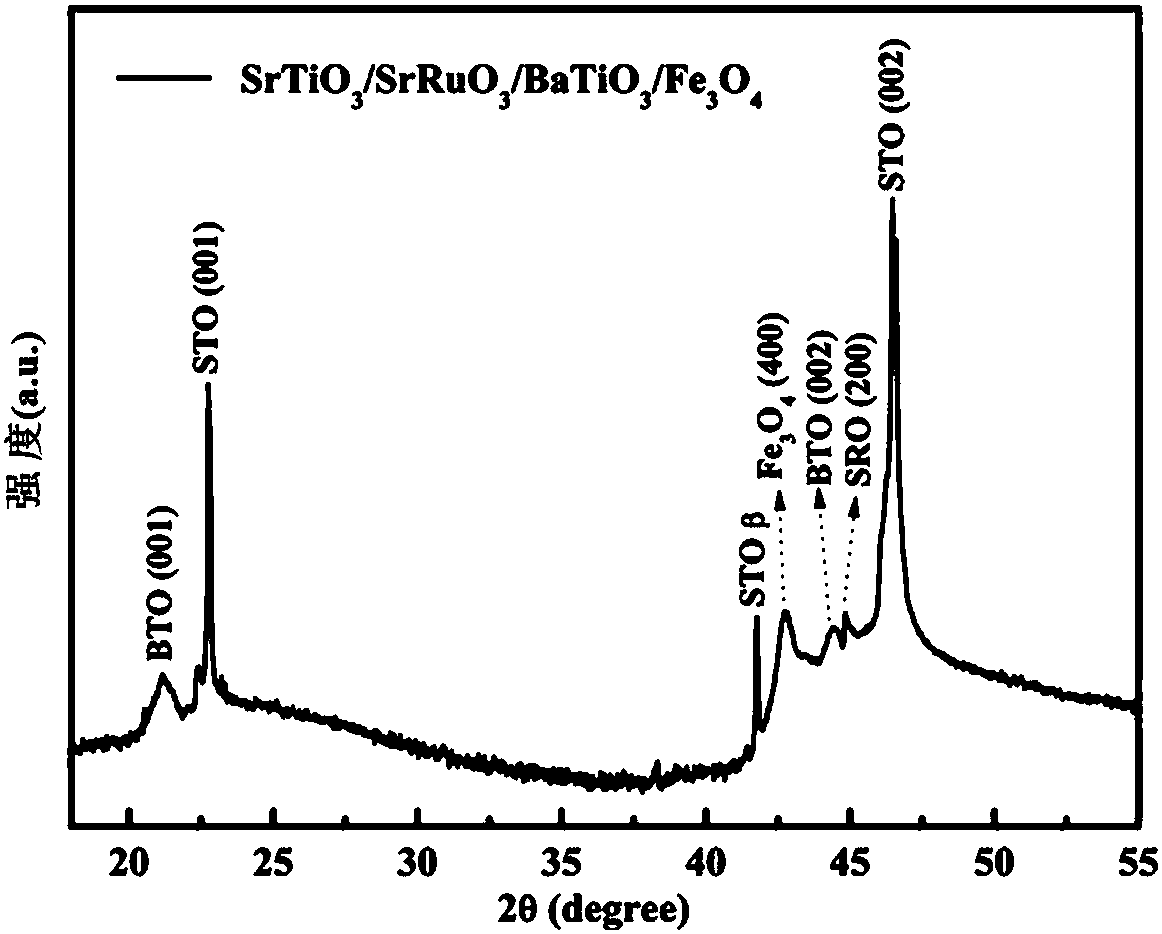

Multiferroic heterojunction and preparation method thereof

InactiveCN108598255AExcellent ferroelectricImprove ferromagnetic propertiesGalvano-magnetic material selectionGalvano-magnetic device manufacture/treatmentHeterojunctionBarium titanate

The invention provides a multiferroic heterojunction, sequentially comprising a strontium titanate substrate, a strontium ruthenate bottom electrode layer, a barium titanate ferroelectric layer and aferroferric oxide magnetic nano-column array from bottom to top. According to the scheme of the invention, barium titanate is used as the ferroelectric layer and ferroferric oxide is used as the magnetic nano-column array, so that the formed multiferroic heterojunction has excellent ferroelectric and ferromagnetic properties; ferroferric oxide can not only regulate and control the magnetic properties through ion movement, but also can be used as an electrode during flipping ferroelectric polarization; and the process of adopting an electric field to control the magnetization orientation at room temperature in a stable, reversible and nonvolatile mode can be achieved, and the scheme is beneficial to the development of memories and spin-electronic devices in the future, and lays a foundationfor realizing ultra-fast data storage and processing with high density and low power consumption.

Owner:XIANGTAN UNIV

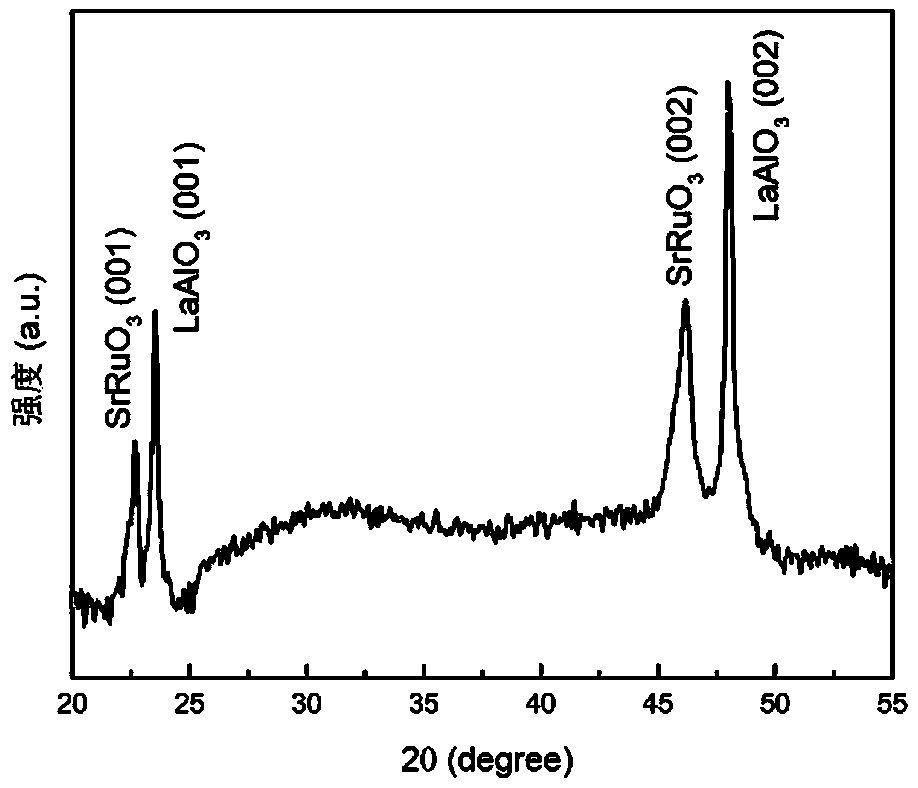

A kind of lead zirconate titanate/strontium ruthenate ferroelectric superlattice material and preparation method thereof

ActiveCN106058039BGood dielectricImprove ferroelectric propertiesPiezoelectric/electrostrictive/magnetostrictive devicesLead zirconate titanateSingle crystal

The object of the present invention is to provide a kind of lead zirconate titanate / strontium ruthenate ferroelectric superlattice material and preparation method thereof, this material is made of periodically grown ferroelectric material lead zirconate titanate and metal conductive oxide material ruthenium Composed of strontium oxide. The advantages of the lead zirconate titanate / strontium ruthenate ferroelectric superlattice material of the present invention are: the dielectric constant is increased by 2 to 10 times compared with the pure PZT film; and it has good ferroelectric polarization performance, and its saturation polarization value Higher than pure PZT film, it can reach 80μC / cm2. The preparation method of the material is to alternately grow strontium ruthenate and lead zirconate titanate on a single crystal substrate by pulsed laser deposition, and precisely regulate the periodic thickness of the superlattice by controlling the time of laser bombardment of different targets. The ferroelectric superlattice material has broad application prospects in integrated ferroelectric devices such as sensors and memories.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing strontium ruthenate target

ActiveCN102259937BWeak crystallinityHigh activityRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsVacuum evaporation coatingHigh densityVolumetric Mass Density

The invention relates to a method for preparing a strontium ruthenate target. A high-density SRO (SrRuO3) ceramic target is prepared by a low-temperature presintering and high-temperature pressure sintering two-step method, and has the density which is 86 to 88 percent of theoretical density. The SRO ceramic target prepared by the method can be applied to processes such as sputtering, molecular beam epitaxy, pulsed laser deposition and the like to form an SRO film, and has the characteristics that: 1) a low temperature and short time are adopted in the process of pressing and presintering a raw material, so that the prepared precursor has low crystallinity, high activity and a small particle size; and 2) a preset sheet is directly heated and pressurized at the same position to be subjected to high-temperature hot pressed sintering after glue is discharged and stress is released, so that a dense and well formed target is obtained.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

A kind of zinc oxide/strontium ruthenate core-shell nanowire and its preparation method

ActiveCN104229867BLow priceRealize large area preparationMaterial nanotechnologyZinc oxides/hydroxidesZinc oxide nanowireStrontium ruthenate

The invention relates to a zinc oxide / strontium ruthenate core-shell nanowire and a preparation method thereof. The zinc oxide / strontium ruthenate core-shell nanowire comprises a zinc oxide nanowire layer constituted by a zinc oxide nanowire growing vertically and a strontium ruthenate film covered on the zinc oxide nanowire layer.

Owner:江苏先进无机材料研究院

Method of making material exhibiting superconductivity characteristics

InactiveUS7884051B1Ruthenium/rhodium/palladium/osmium/iridium/platinum compoundsSuperconductor device manufacture/treatmentProcess regionOxygen content

The invention herein is directed towards a method of making material exhibiting superconductivity characteristics which includes a laser processed region of a metal oxide crystal. The material has a transition temperature greater than a transition temperature of the metal oxide crystal, preferably greater than 140K. The transition temperature of the material may be considered greater than the transition temperature of the metal oxide crystal if the material has a transition temperature and the metal oxide crystal has no transition temperature. The present invention is also directed to a material which includes a laser processed strontium ruthenate crystal wherein the material has a greater oxygen content than the starting strontium ruthenate crystal. The present invention is also directed towards a method for manufacturing a material exhibiting superconductivity characteristics that includes providing a metal oxide crystal and laser ablating the metal oxide crystal and a material made by this process.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

A kind of barium titanate-strontium ruthenate nanocomposite film material and preparation method thereof

ActiveCN110607501BGood electrical propertiesGood crystallographic epitaxy relationshipVacuum evaporation coatingSputtering coatingComposite filmBarium titanate

The invention provides a barium titanate-strontium ruthenate nanocomposite film material and a preparation method thereof, wherein the volume ratio of the material composition is SrRuO 3 :2~9%, BaTiO 3 :91~98%, the material microstructure is characterized by SrRuO 3 Nanoparticles are uniformly distributed in BaTiO 3 on the substrate. The advantages of the barium titanate-strontium ruthenate nanocomposite film material of the present invention are: the dielectric constant increases by 10% to 24% compared with the pure barium titanate film; and it has good ferroelectric polarization performance, and its remanent polarization Reach 40.3μC / cm 2 , the saturation polarization reaches 47.8μC / cm 2 , Compared with the barium titanate thin film, the remnant polarization increased by 950%, and the saturated polarization increased by 140%. As a lead-free ferroelectric material, the composite thin film has broad application prospects in integrated ferroelectric devices such as ferroelectric random access memories, thin film capacitors, sensors and actuators.

Owner:SHENYANG POLYTECHNIC UNIV

Strontium ruthenate material, and preparation method and application thereof

ActiveCN113735566AHigh densityHigh purityVacuum evaporation coatingSputtering coatingHigh densityStrontium ruthenate

The invention discloses a strontium ruthenate material, and a preparation method and application thereof, and belongs to the technical field of strontium ruthenate materials. The preparation method comprises the following steps: performing vacuum hot pressing sintering on raw materials for preparing the strontium ruthenate material, wherein the vacuum hot pressing sintering conditions are as follows: the vacuum degree is less than or equal to 10<-3> Pa, the hot pressing temperature is 600-850 DEG C, the hot pressing pressure is 58.5-100MPa, and the hot pressing time is 3-3.5 h. Vacuum hot pressed sintering is carried out under the conditions, and the strontium ruthenate material with high density, high purity and strict atomic proportion can be prepared. The strontium ruthenate material can be used for processing sputtering target materials and the like, and in the sputtering process, particle defects are reduced, and the product quality is improved.

Owner:PIONEER MATERIALS INC CHENGDU

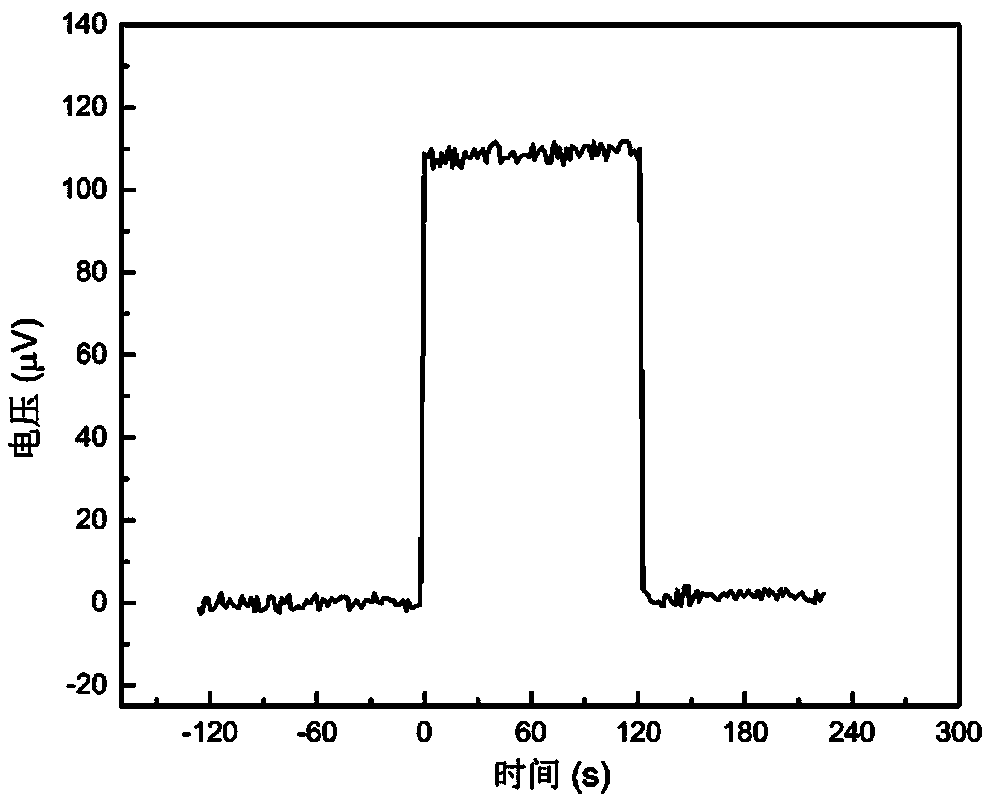

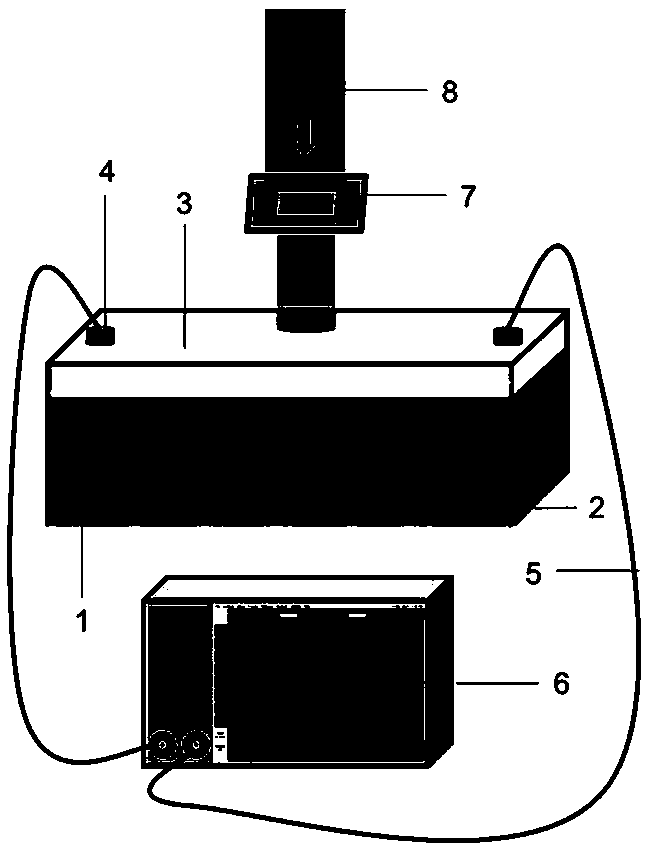

Optical and thermal detector based on strontium ruthenate film and preparation method of optical and thermal detector

ActiveCN111403587AHigh sensitivityImprove responsivenessThermoelectric device manufacture/treatmentFinal product manufactureMetallic electrodeResponsivity

The invention provides an optical and thermal detector based on a strontium ruthenate film and a preparation method of the optical and thermal detector. The optical and thermal detector sequentially comprises a beveled substrate, a transverse thermoelectric element, a metal electrode and a lead connected with the metal electrode and used for outputting a voltage signal from bottom to top, the transverse thermoelectric element is a strontium ruthenate thin film which is prepared on the beveled substrate by adopting a pulse laser deposition technology and grows obliquely on a c axis, and the thickness of the strontium ruthenate thin film is 20-200nm. The strontium ruthenate film thermoelectric element has excellent detection performance such as sensitivity and responsivity, has excellent performance such as high sensitivity and short response time when being applied to manufacturing of broadband optical and thermal detectors, has the advantages of simple preparation process and low production cost, and has a wide application prospect in the field of optical and thermal detectors.

Owner:HEBEI UNIVERSITY

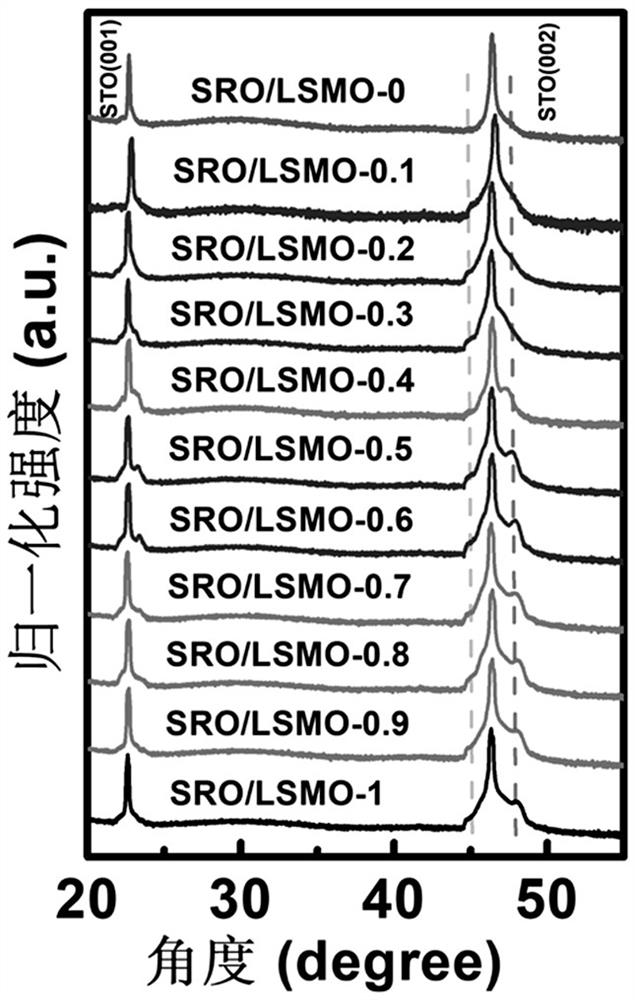

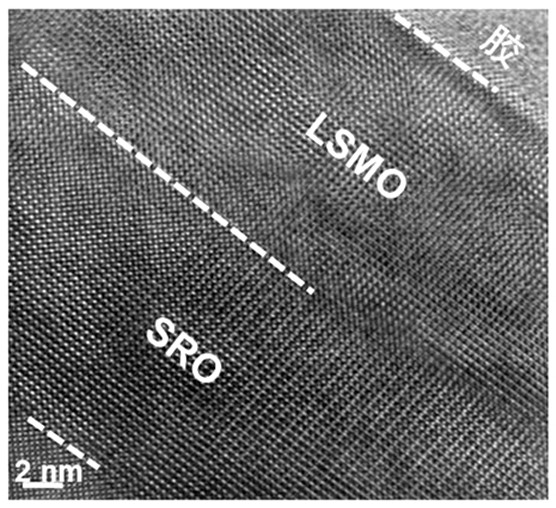

A strontium ruthenate/lanthanum strontium manganese oxide transition metal oxide heterojunction and preparation method thereof

ActiveCN109628890BSimple preparation processCost-effective methodMagnetic-field-controlled resistorsVacuum evaporation coatingHeterojunctionPhysical chemistry

The invention provides a strontium ruthenate / lanthanum strontium manganese transition metal oxide heterojunction and a preparation method thereof, wherein the thickness of the strontium ruthenate / lanthanum strontium manganese transition metal oxide heterojunction is 30-60 nm , which includes a strontium ruthenate film and a lanthanum strontium manganese oxide film, the molar ratio of each component in the lanthanum strontium manganese oxide film La:Sr:Mn:O=1-x:x:1:3, 0≤x≤1 ; The strontium ruthenate / lanthanum strontium manganese oxide transition metal oxide heterojunction is prepared by pulsed laser deposition. The preparation process of the strontium ruthenate / lanthanum strontium manganese oxide transition metal oxide heterojunction is simple and the production cost is low, and the strontium ruthenate / lanthanum strontium oxide can be accurately and effectively regulated by changing the doping content of Sr element in the lanthanum strontium manganese oxide thin film The lateral and vertical exchange bias directions and values of manganese-oxygen transition metal oxide heterojunctions have broad application prospects.

Owner:HEBEI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com