Method for preparing strontium ruthenate film with highly (001) preferred orientation at low temperature

A technology of preferred orientation and thin film, which is applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the difficult problems of semiconductor integration process compatibility, etc., and achieve the effect of low resistivity and low crystallization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] B. LaNiO 3 Preparation of (LNO) target: LaNiO 3 (LNO) targets can be prepared by referring to existing methods in the prior art, for example: using La 2 o 3 and Ni 2 o 3 The powder is mixed according to the atomic ratio of La and Ni of 0.45:0.55, synthesized at a high temperature of 1000-1150°C, ground and pressed into a block, and then sintered at a high temperature of 1100-1300°C for 2 to 4 hours to make an LNO target.

[0023] C. LaNiO 3 (LNO) buffer layer preparation.

[0024] Firstly, the silicon substrate cleaned by the conventional method is put into the sputtering apparatus, and the vacuum is evacuated to 10 -4 Below Pa; then heat the silicon substrate to keep it at 300-450°C; then feed oxygen and argon as the sputtering gas, the partial pressure of oxygen is 15-25%, and the total pressure of the sputtering gas Keep it at 2.5~3.5Pa, using LaNiO 3 The target material was deposited LNO thin film by DC sputtering, the sputtering power was 80W, and the sputt...

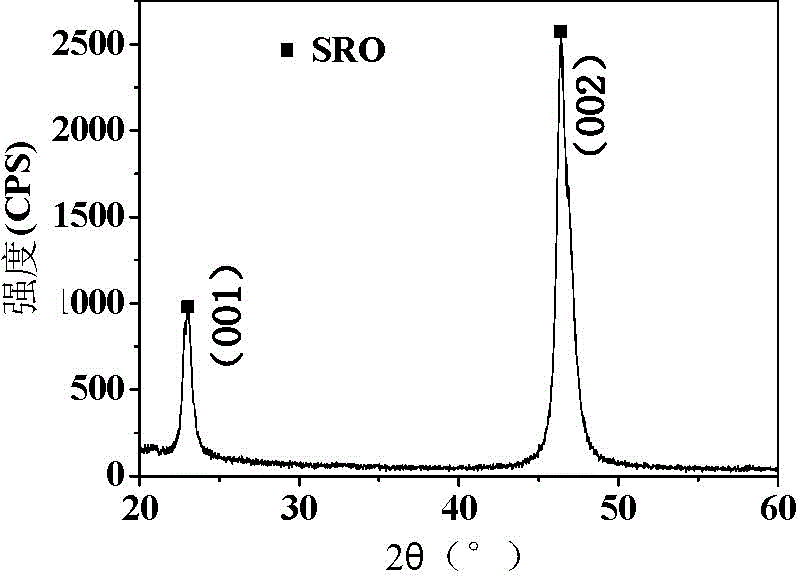

Embodiment 1

[0034] 1) SrRuO 3 (SRO) target preparation: SrCO with a purity of 99.0% 3 and Ru content greater than 75% RuO x The powder is mixed and ground at an atomic ratio of Sr and Ru of 1:1, pressed into a block, and then sintered at a high temperature of 1500°C for 12 hours to make an SRO target;

[0035] 2) LaNiO 3 (LNO) target preparation: using La 2 o 3 and Ni 2 o 3 The powder is mixed according to the atomic ratio of La and Ni of 0.45:0.55, synthesized at 1100°C, ground and pressed into a block, and then sintered at 1200°C for 2 hours to make a LNO target; 3) LaNiO 3 Preparation of (LNO) buffer layer

[0036] The silicon substrate was cleaned in sequence by absolute ethanol and distilled water, then placed in the sputtering apparatus, and vacuumed to 10 -4 Pa; then heat the silicon substrate to keep it at 350°C; then pass in oxygen and argon, the oxygen partial pressure is 20%, and the pressure is kept at 3.0Pa, using LaNiO 3 (LNO) target is deposited LNO film by DC sput...

Embodiment 2

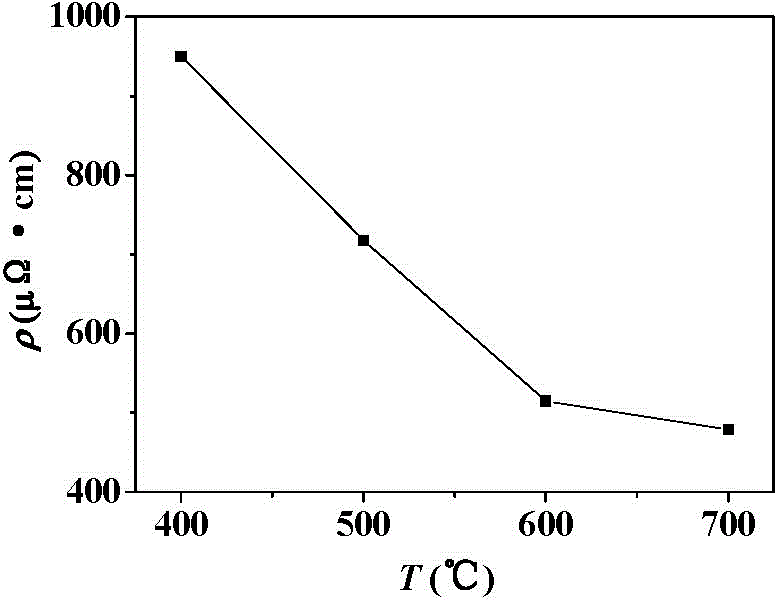

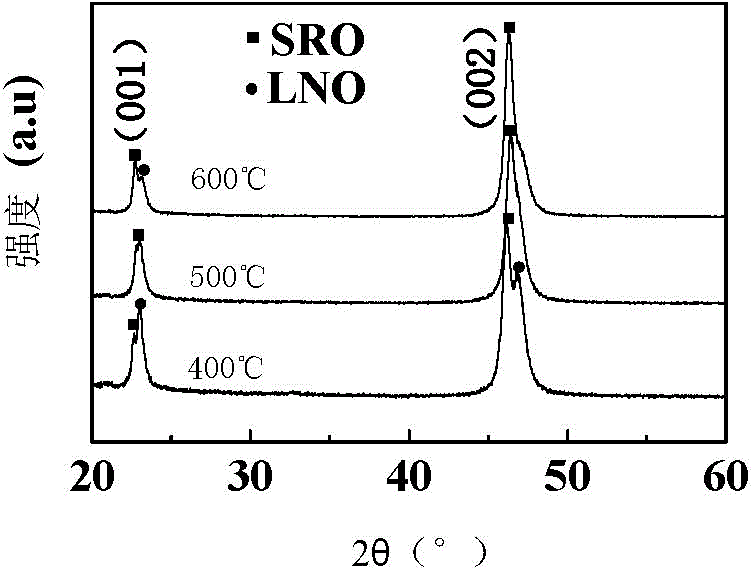

[0040] The procedure of Example 1 was repeated, but in step 4), the temperature of the substrate was raised to 400°C. see figure 2 , the SRO thin film has a high (001) preferred orientation, and its surface resistivity is 718μΩ·cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com