A kind of zinc oxide/strontium ruthenate core-shell nanowire and its preparation method

A zinc oxide nanowire, core-shell nanotechnology, applied in the directions of zinc oxide/zinc hydroxide, chemical instruments and methods, nanotechnology, etc., to achieve the effect of simple and easy process, good application prospect and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

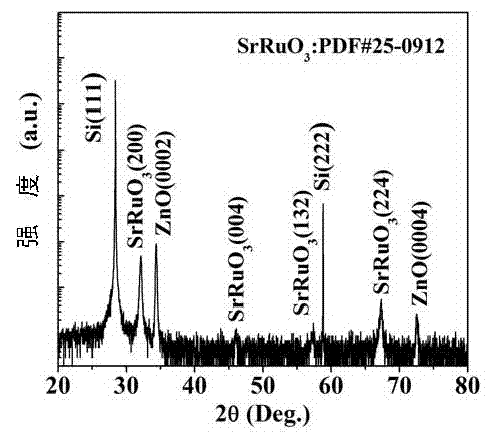

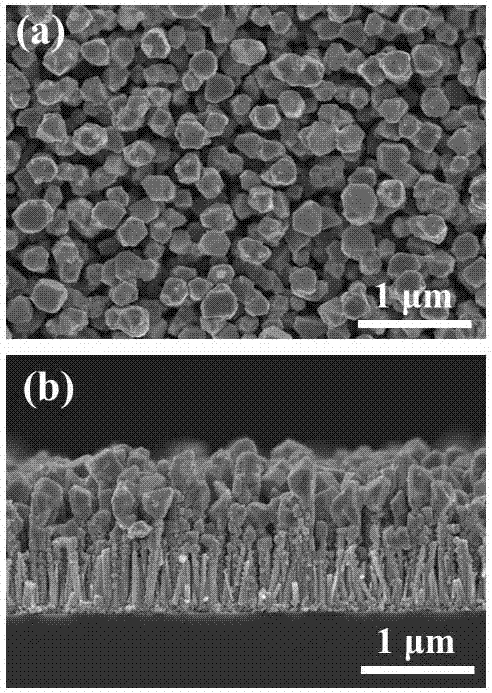

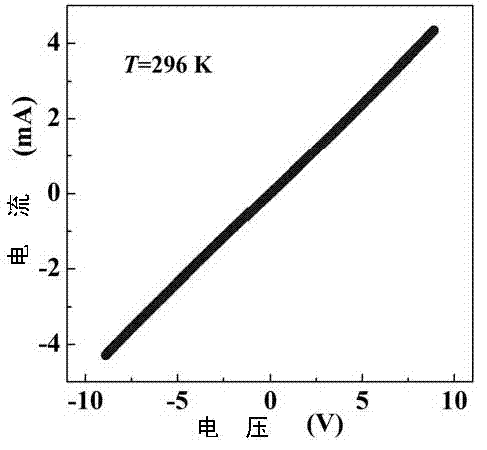

[0031] The invention relates to a method for preparing zinc oxide / strontium ruthenate core-shell nanowires, and belongs to the technical field of low-dimensional nanomaterial preparation. The realization process of the present invention includes three parts, namely the preparation of the ZnO seed layer, the preparation of the ZnO nanowires and the ZnO / SrRuO 3 Preparation of core-shell nanowires. The specific steps are: ①Prepare a dense ZnO seed layer on the Si substrate by the sol-gel method; ②Grow the one-dimensional ZnO nanowires with good uprightness by the aqueous solution method; ③Use the ZnO nanowires as templates and pulse Preparation of SrRuO by laser deposition 3 Thin film to obtain ZnO / SrRuO 3 Core-shell nanowires. The Si substrate adopted in the invention is low in price, the aqueous solution method can be used to realize the large-area preparation of ZnO nanowires, and the ZnO nanowire template does not need high-temperature processing, and the process of the method...

Embodiment 1

[0050] The specific steps of the method provided by the invention are:

[0051] 1) Preparation of ZnO seed layer by sol-gel method

[0052] Dissolve 8.92g of monoethanolamine in 200ml of ethylene glycol methyl ether solvent, add 32.8g of zinc acetate, stir well in a 65℃ water bath for 35 minutes, and prepare 0.75mol / L sol precursor (a mixed solution of monoethanolamine and zinc acetate) . After immersing the Si substrate cleaned with hydrofluoric acid in the prepared sol for 1 minute, the gel film was formed at a pulling speed of 1 cm / min, and then heat-treated at 320°C for 20 minutes. After the second pulling, the gel film was heated at 2°C / min. Slowly heat up to 540°C at a minute rate, and form a dense ZnO seed layer after holding for 1 hour;

[0053] 2) Preparation of ZnO nanowires by aqueous solution method

[0054] Dissolve 1.4g of hexamethylenetetramine in 200mL of deionized water, add 1.6mL of polyvinylamine and stir, after dissolving, add 200mL of 2.97g of zinc nitrate aqueo...

Embodiment 2

[0060] The specific steps of the method provided by the invention are:

[0061] 1) Preparation of ZnO seed layer by sol-gel method

[0062] Dissolve 9.51g of monoethanolamine in 200ml of ethylene glycol methyl ether solvent, add 34.99g of zinc acetate, fully stir in a water bath at 75°C for 45 minutes, and prepare a 0.8mol / L sol precursor. After immersing the Si substrate cleaned with hydrofluoric acid in the prepared sol for 2 minutes, the gel film was formed at a pulling speed of 2 cm / min, and then heat-treated at 340°C for 25 minutes. After the second pulling at 3°C / min. Slowly heat up to 560°C at a minute rate, and form a dense ZnO seed layer after holding for 2 hours;

[0063] 2) Preparation of ZnO nanowires by aqueous solution method

[0064] Dissolve 1.68g of hexamethylenetetramine in 200mL of deionized water, add 1.8mL of polyvinylamine and stir, after dissolving, add 200mL of 3.57g of zinc nitrate aqueous solution, stir well for 40 minutes, and prepare a 0.03mol / L growth sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com