Multiferroic heterojunction and preparation method thereof

A technology of multiferroic heterojunction and ferroelectric layer, which is applied in the manufacture/processing of electromagnetic devices and the selection of materials, etc., can solve the problems of limited antiferromagnetic order and low temperature conditions due to the electric control magnetic effect, and achieve saving The effect of cumbersome processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention provides a method for preparing a multiferroic heterojunction described in the above technical solution, comprising the following steps:

[0036] Using STO as the target material, the first deposition is performed on the upper surface of the STO substrate by pulsed laser deposition to form the SRO bottom electrode layer;

[0037] Using BTO as a target, a second deposition is performed on the upper surface of the SRO bottom electrode layer by a pulsed laser deposition method to form a BTO ferroelectric layer;

[0038] Place a mask plate on the upper surface of the BTO ferroelectric layer, with Fe 3 o 4 As the target material, the third deposition is carried out on the surface of the BTO ferroelectric layer with the mask plate placed by the pulsed laser deposition method to form Fe 3 o 4 Magnetic nanocolumn array, removing the mask plate to obtain a multiferroic heterojunction.

[0039] In the present invention, SRO is used as a target material, ...

Embodiment 1

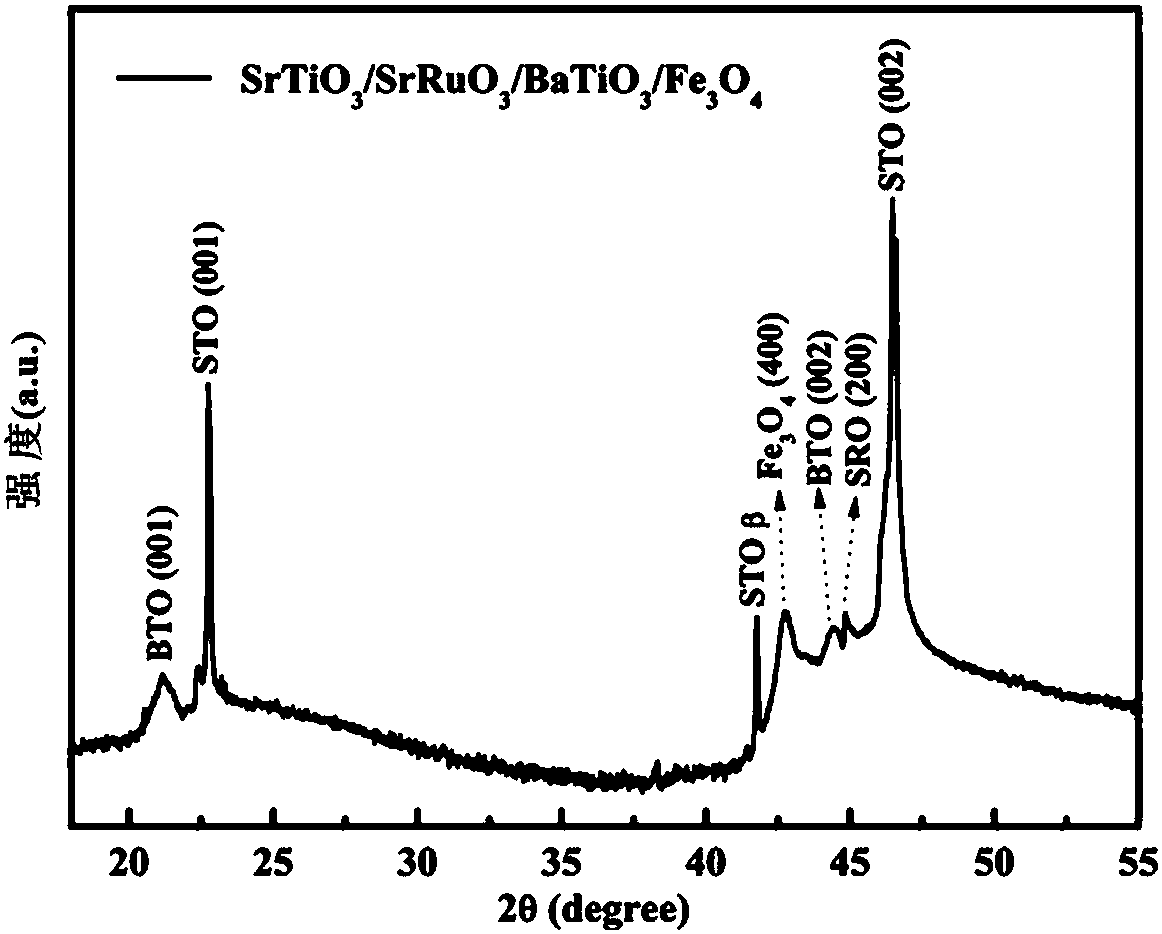

[0049] (1) Place the STO substrate on the pedestal in the growth chamber of the pulsed laser deposition system, place the SRO target on the target position of the pulsed laser deposition system, and adjust the target position directly above the STO substrate, The distance between the STO substrate and the SRO target is 60cm; the cavity is closed, the temperature of the STO substrate is heated to 700°C, and the pulsed laser deposition method is adopted under the conditions of laser energy of 300mJ, frequency of 10Hz, and oxygen partial pressure of 100mTorr Growing an SRO bottom electrode layer on the upper surface of the STO substrate, to a thickness of 30nm to the SRO bottom electrode layer;

[0050] (2) At 750°C, the laser energy is 300mJ, the frequency is 10Hz, and the oxygen partial pressure is 5×10 -3 Under the condition of Torr, utilize BTO target material to grow tetragonal phase BTO ferroelectric layer on the upper surface of the SRO bottom electrode layer that describe...

Embodiment 2

[0053] The multiferroic heterojunction was prepared according to the method of Example 1, except that the temperature was lowered to 350°C in step (2), and Fe was grown at 350°C in step (3). 3 o 4 Magnetic nanopillar arrays.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com