Method for preparing texture-controllable lead magnesium niobate-lead titanate ferroelectric thin film

A lead magnesium niobate and ferroelectric thin film technology is applied in the field of preparation of lead magnesium niobate-lead titanate ferroelectric thin films, and can solve the problem of poor density and poor texture of lead magnesium niobate-lead titanate ferroelectric thin films. control issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

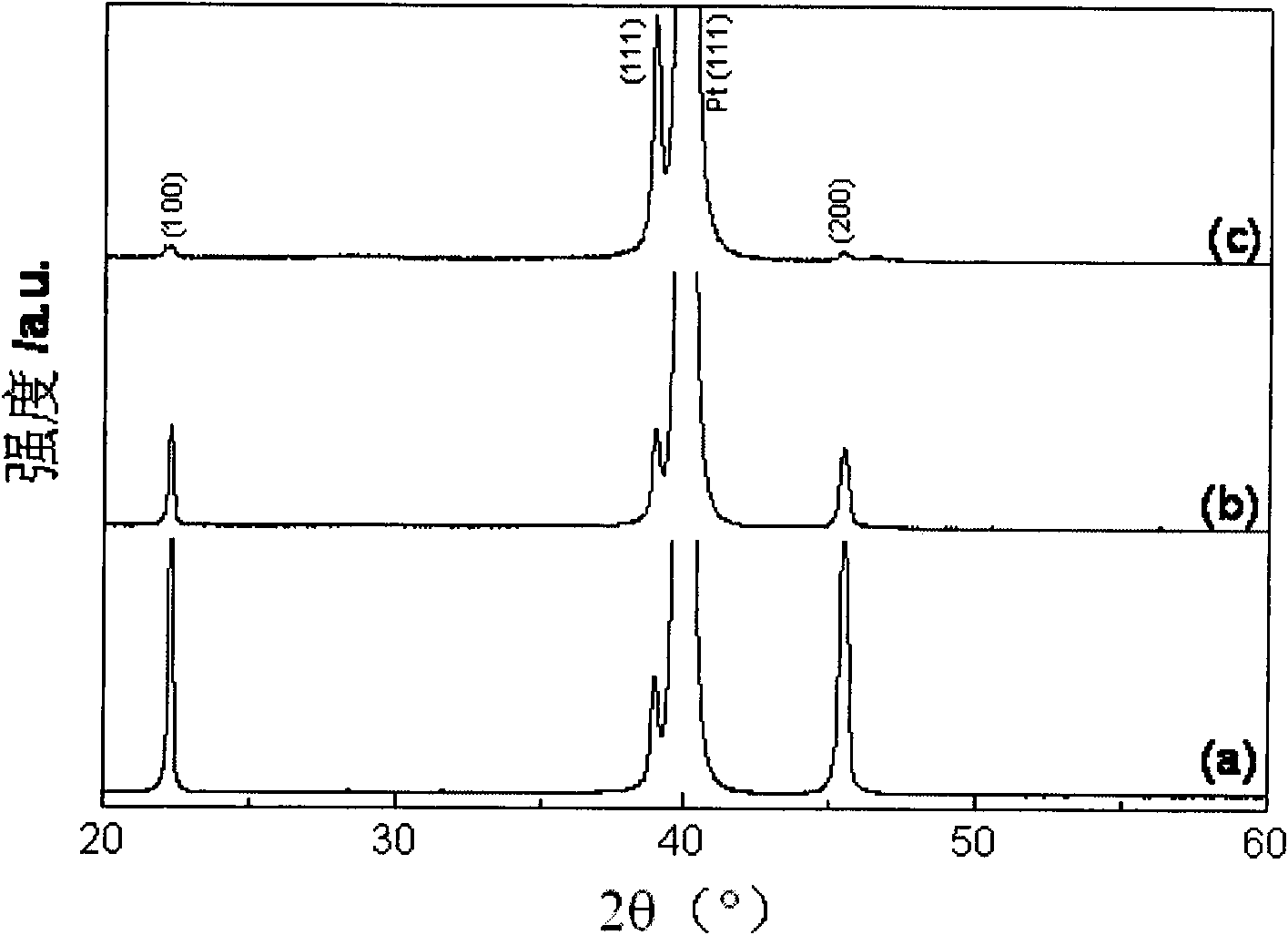

[0010] Specific embodiment one: the method steps of the present embodiment preparation texture controllable lead magnesium niobate-lead titanate ferroelectric thin film are as follows: a, according to chemical formula (1-x)Pb(Mg 1 / 3 Nb 2 / 3 )-xPbTiO 3 Weigh lead acetate, magnesium acetate, niobium ethoxide and tetrabutyl titanate respectively according to the molar ratio of 1:1 / 3(1-x):2 / 3(1-x):x, wherein 01 / 3 Nb 2 / 3 )-xPbTiO 3 sol; e, the substrate was ultrasonically treated in acetone and absolute ethanol for 4 to 6 minutes, and then placed in the air to dry naturally; f, the (1-x)Pb(Mg 1 / 3 Nb 2 / 3 )-xPbTiO 3 The sol is added dropwise on the substrate treated in step e, spin-coated at 1000-2000r / min for 10s, then spin-coated at 3500-4500r / min for 20s, and then dried at 40-80°C to obtain film D; g, Pre-fire film D at 300-500°C to obtain film E; h. Put film E in a rapid heat treatment furnace and bake at 630-670°C for 8-15 minutes, then cool to room temperature to obtain tex...

specific Embodiment approach 2

[0012] Embodiment 2: This embodiment differs from Embodiment 1 in that x=0.2˜0.6 in step a. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0013] Embodiment 3: This embodiment differs from Embodiment 1 in that x=0.32 in step a. Other steps and parameters are the same as those in Embodiment 1.

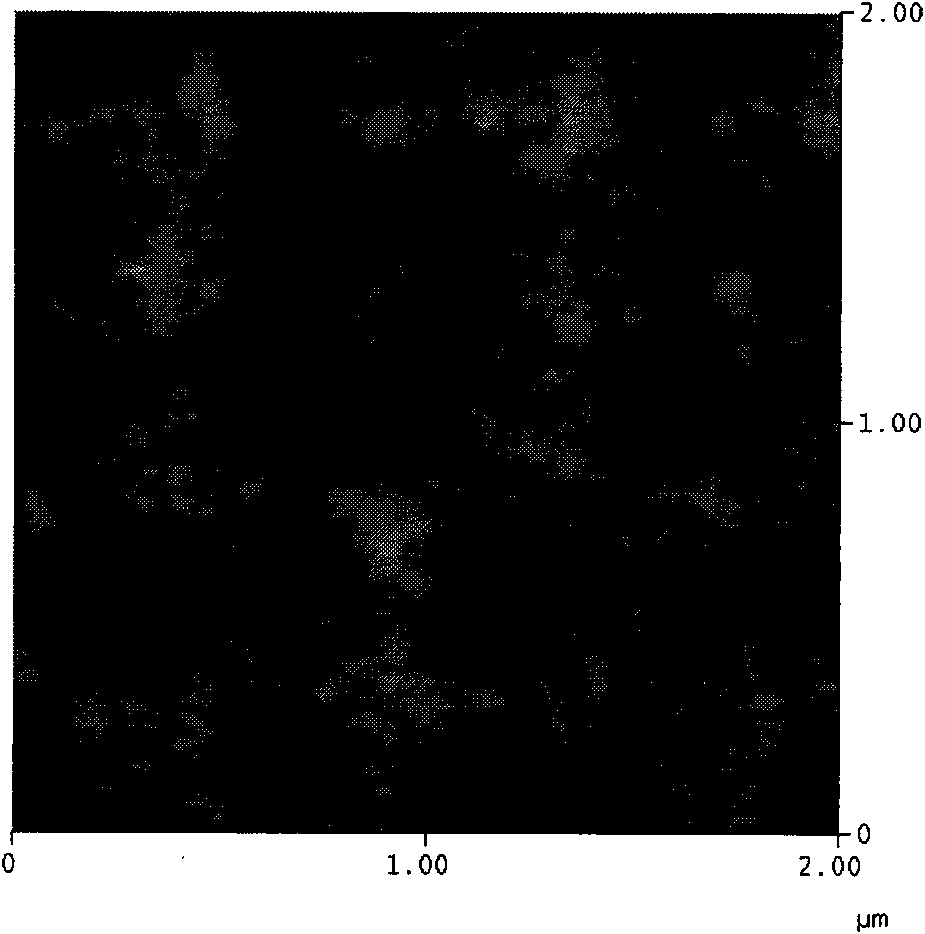

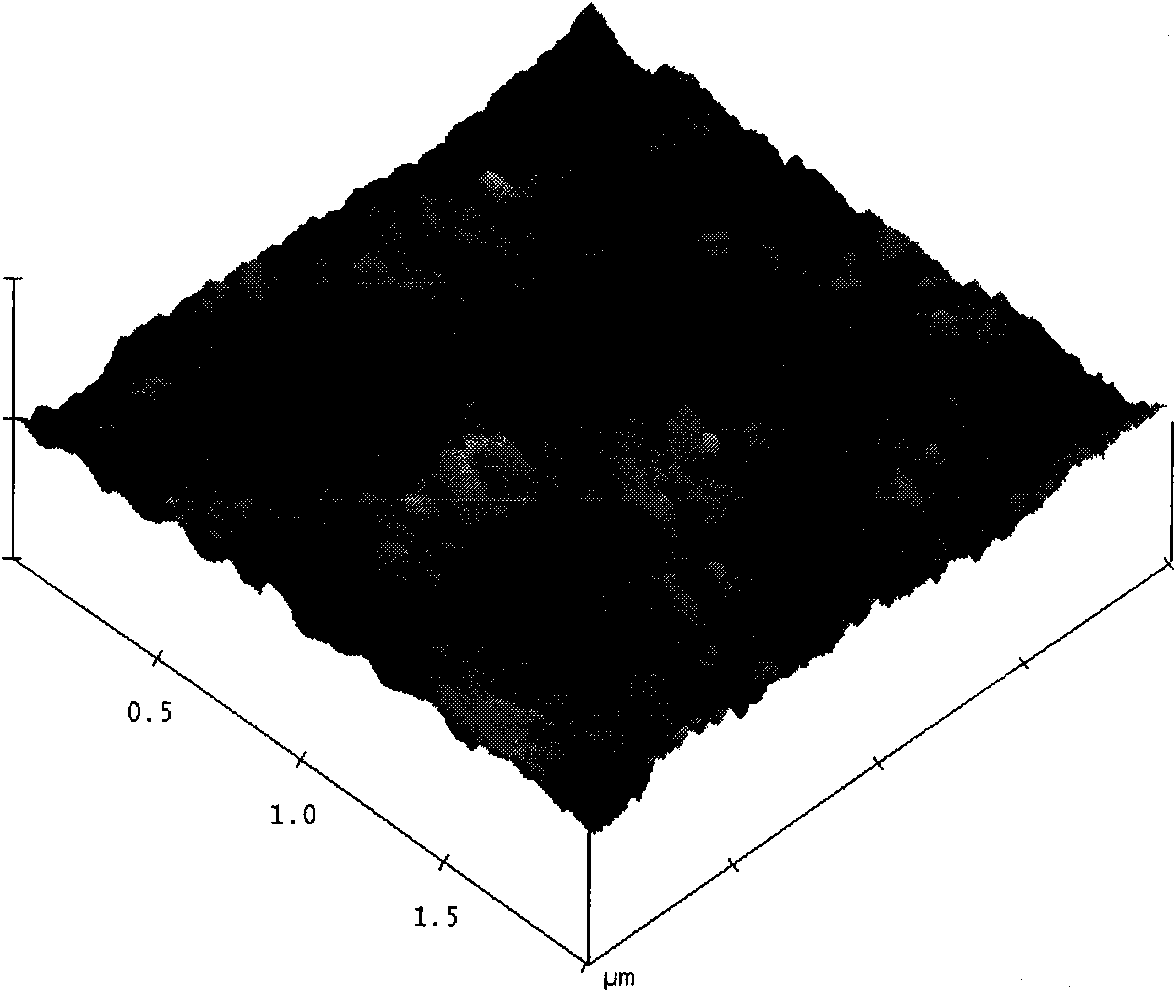

[0014] The texture-controllable lead magnesium niobate-lead titanate ferroelectric film obtained in this embodiment is characterized by AFM surface morphology, and the two-dimensional and three-dimensional AFM spectra of the film are as follows figure 2 with image 3 As shown, it can be seen from the AFM spectrum that the surface roughness of the obtained film is low, only 3.08nm. In this embodiment, the surface morphology of the lead magnesium niobate-lead titanate ferroelectric film with controllable texture is characterized by SEM, as shown in Figure 4 It can be seen from the figure that the film thickness is uniform, and there is no crack on the surface, and the compactness is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com