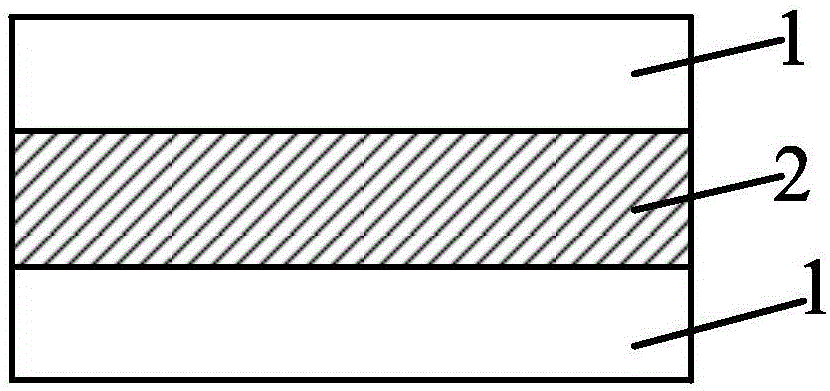

Layered magnetoelectric composite material with high Curie temperature and high magnetoelectric coupling performance and preparation method of layered magnetoelectric composite material

A magnetoelectric composite material and electric coupling technology, applied in the field of material science, can solve the problems of low magnetoelectric voltage coefficient and uneven dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

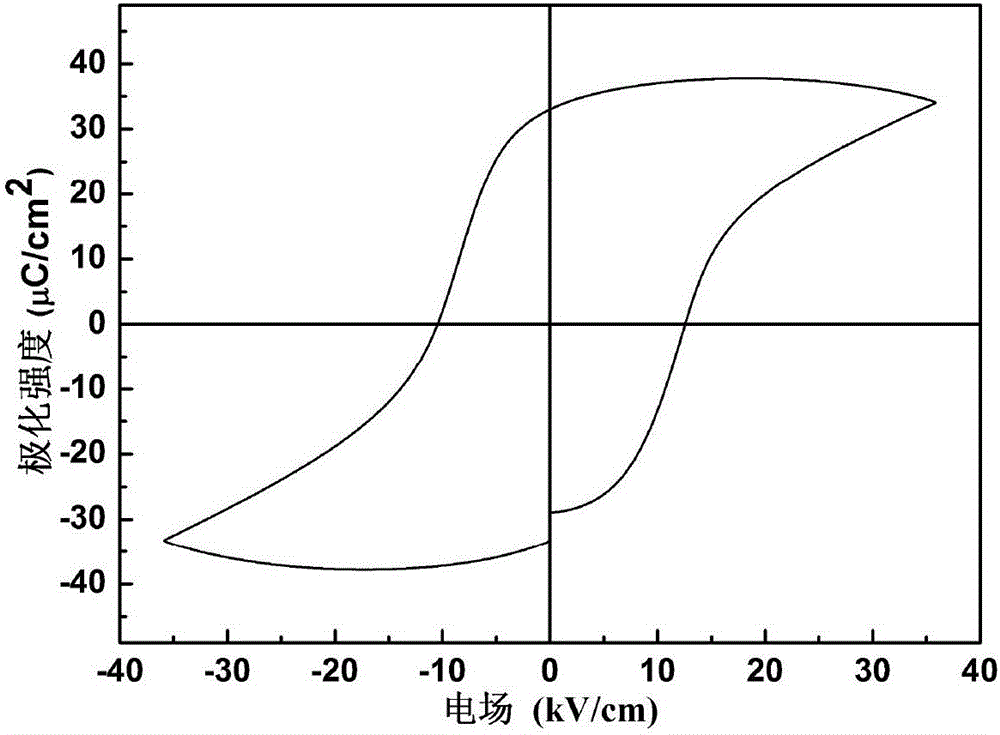

Embodiment 1

[0050] The chemical formula of layered magnetoelectric composites is: (1-x)Li 0.058 (Na 0.535 K 0.48 ) 0.942 NbO 3 / xCo 0.6 Zn 0.4 Fe 1.7 mn 0.3 o 4 , where x is Co 0.6 Zn 0.4 Fe 1.7 mn 0.3 o 4 The mass percentage of , and x = 0.1.

[0051] The preparation method of the above-mentioned layered magnetoelectric composite material comprises the following steps:

[0052] (1) According to the chemical formula Li 0.058 (Na 0.535 K 0.48 ) 0.942 NbO 3 Analytical pure K 2 CO 3 、Na 2 CO 3 , Li 2 CO 3 and Nb 2 o 5 After the preparation, it was mixed uniformly by ball milling for 20 hours, then dried, sieved, and briquetted, and then pre-fired at 840°C for 3 hours to obtain a block product, and then the block product was crushed and passed through a 120-mesh sieve to obtain Li 0.058 (Na 0.535 K 0.48 ) 0.942 NbO 3 Powder;

[0053] (2) According to the chemical formula Co 0.6 Zn0.4 Fe 1.7 mn 0.3 o 4 will analyze pure Co 3 o 4 , ZnO, MnO 2 and Fe 2 o ...

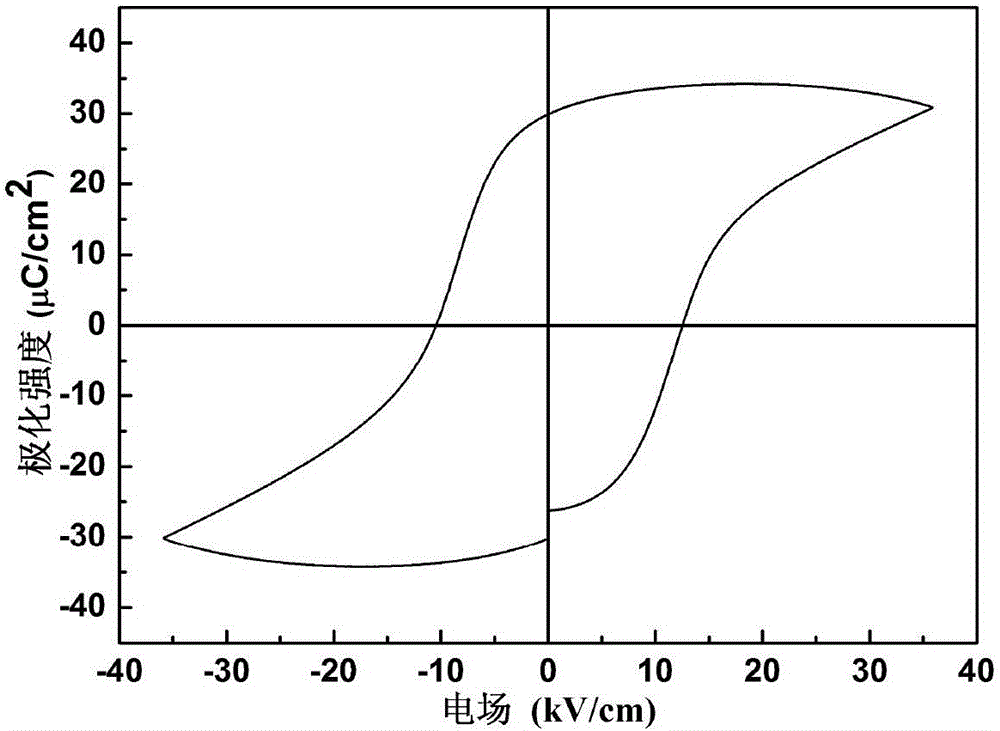

Embodiment 2

[0065] The chemical formula of layered magnetoelectric composites is: (1-x)Li 0.058 (Na 0.535 K 0.48 ) 0.942 NbO 3 / xCo 0.6 Zn 0.4 Fe 1.7 mn 0.3 o 4 , where x is Co 0.6 Zn 0.4 Fe 1.7 mn 0.3 o 4 The mass percentage of , and x = 0.2.

[0066] The preparation method of the above-mentioned layered magnetoelectric composite material comprises the following steps:

[0067] (1) According to the chemical formula Li 0.058 (Na 0.535 K 0.48 ) 0.942 NbO 3 Analytical pure K 2 CO 3 、Na 2 CO 3 , Li 2 CO 3 and Nb 2 o 5 After the preparation, it was mixed evenly by ball milling for 21 hours, then dried, sieved, briquetting, and then pre-fired at 845°C for 3.5 hours to obtain a block product, and then the block product was crushed and passed through a 120-mesh sieve to obtain Li 0.058 (Na 0.535 K 0.48 ) 0.942 NbO 3 Powder;

[0068] (2) According to the chemical formula Co 0.6 Zn 0.4 Fe 1.7 mn 0.3 o 4 will analyze pure Co 3 o 4 , ZnO, MnO 2 and Fe 2 o 3 ...

Embodiment 3

[0080] The chemical formula of layered magnetoelectric composites is: (1-x)Li 0.058 (Na 0.535 K 0.48 ) 0.942 NbO 3 / xCo 0.6 Zn 0.4 Fe 1.7 mn 0.3 o 4 , where x is Co 0.6 Zn 0.4 Fe 1.7 mn 0.3 o 4 The mass percentage of x=0.3.

[0081] The preparation method of the above-mentioned layered magnetoelectric composite material comprises the following steps:

[0082] (1) According to the chemical formula Li 0.058 (Na 0.535 K 0.48 ) 0.942 NbO 3 Analytical pure K 2 CO 3 、Na 2 CO 3 , Li 2 CO 3 and Nb 2 o 5 After preparation, it was mixed uniformly by ball milling for 22 hours, then dried, sieved, briquetting, and then pre-fired at 850°C for 4 hours to obtain a block product, and then the block product was crushed and passed through a 120-mesh sieve to obtain Li 0.058 (Na 0.535 K 0.48 ) 0.942 NbO 3 Powder;

[0083] (2) According to the chemical formula Co 0.6 Zn 0.4 Fe 1.7 mn 0.3 o 4 will analyze pure Co 3 o 4 , ZnO, MnO 2 and Fe 2 o 3 After the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| saturated polarization | aaaaa | aaaaa |

| saturated polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com