Highly doped batio3:fe multiferroic thin film material and preparation method thereof

A multiferroic thin film and high doping technology, applied in the field of material science, can solve the problems of unfavorable large-scale production, complicated preparation process, expensive equipment, etc., and achieve the effect of high unidirectionality, uniform and dense surface, and good crystallization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a method for growing highly doped BaTiO on a suitable substrate 3 The preparation method of the film material of Fe comprises the following steps successively:

[0030] 1. Film preparation:

[0031] 1) Precursor solution. Fe source, Ba source and Ti source are dissolved in solvents such as acetylacetone, alcohol and organic acid and fully stirred to become clear; in addition, in order to enable the solution to be stored for a long time and improve the quality of film formation, add an appropriate amount of ethylene glycol or a suitable concentration of ethylene glycol and For the ethanol solution of polyvinylpyrrolidone (PVP), the content x of Fe in the precursor ranges from 0.01 to 0.4.

[0032] Below, Fe(NO 3 ) 3 9H 2 O is the source of Fe, barium acetate is the source of Ba, tetrabutyl titanate is the source of titanium, acetic acid and acetylacetone are solvents, ethylene glycol and PVP solution are additives, and BaTiO is doped with Fe w...

Embodiment 1

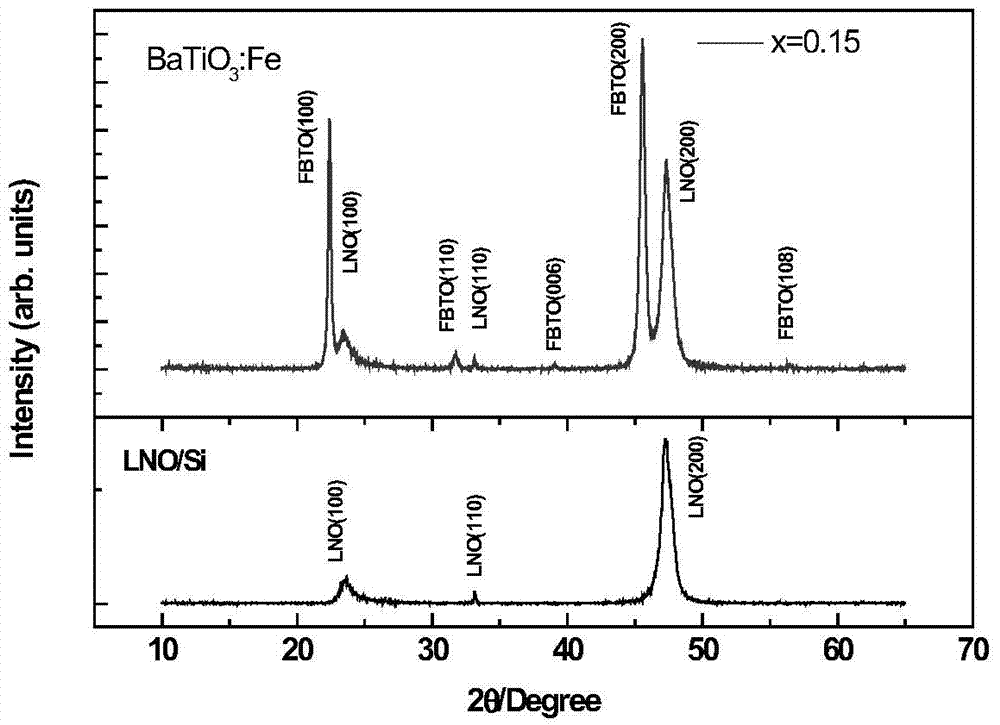

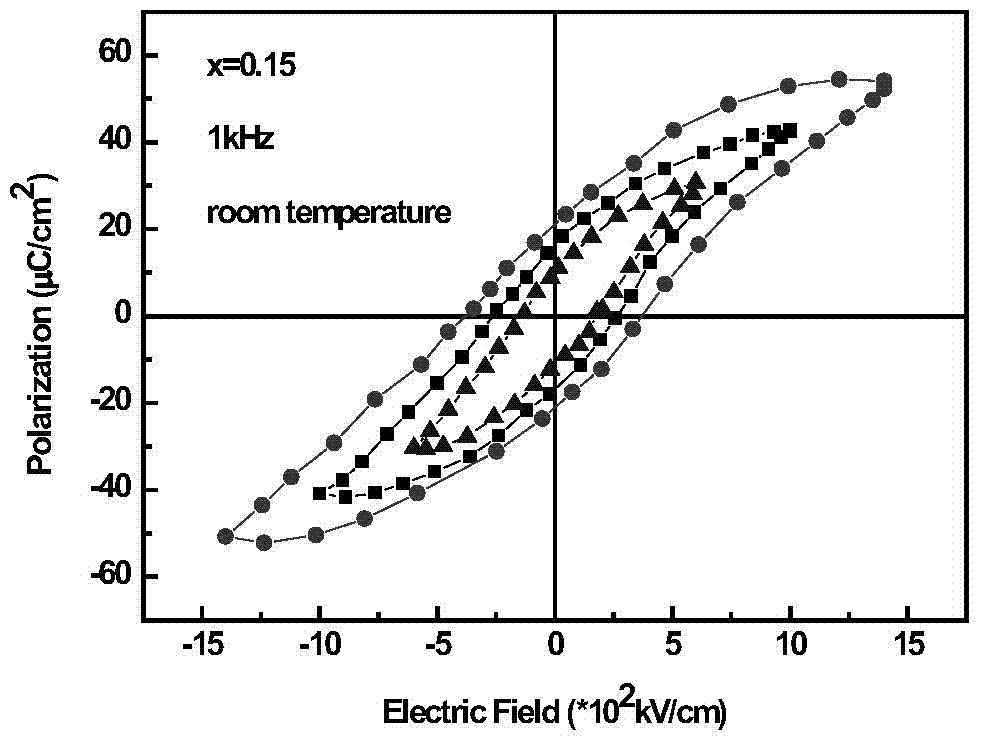

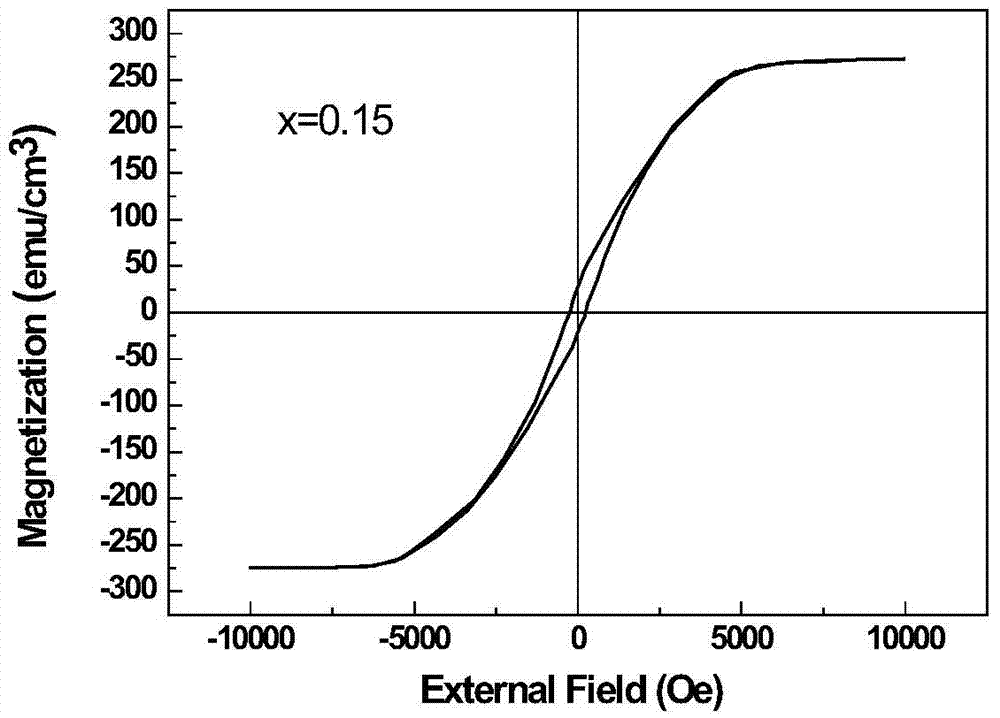

[0041] This example is in LaNiO 3 / Grow x=0.15 highly doped BaTiO on Si substrate 3 : The preparation process of Fe thin film material and its room temperature magnetic and ferroelectricity test.

[0042] 1. Film preparation

[0043] 1. Preparation of precursor solution. The Fe(NO 3 ) 3 9H 2 O, dissolving barium acetate powder in glacial acetic acid, stirring at 80°C for 90 minutes at a stirring rate of 500 rpm to completely dissolve ferric nitrate and barium acetate, then cooling to room temperature and adding acetylacetone and ethanol with a volume ratio of 10:1 ~1:1 mixed solution, continue to stir for 30 minutes, slowly add tetrabutyl titanate ethanol solution in the temperature range of room temperature to 80°C, and continue to stir for 2 hours. Then add ethylene glycol to adjust the viscosity of the solution so that the concentration of Ba ions in the solution is 0.3mol / L. Stirring was continued at room temperature for 60 minutes at a stirring rate of 600 rpm. A ...

Embodiment 2

[0057] This embodiment is to grow x=0.10 highly doped BaTiO on the quartz substrate 3 : The preparation process of Fe thin film material and its XRD and transmission spectrum test.

[0058] 1. Preparation of precursor solution. The Fe(NO 3 ) 3 9H 2 O, dissolving barium acetate powder in glacial acetic acid, stirring at 100°C for 60 minutes at a stirring rate of 600 rpm, completely dissolving ferric nitrate and barium acetate, then cooling to room temperature and adding acetylacetone and ethanol with a volume ratio of 10:1 ~1:1 mixed solution, continue to stir for 20 minutes, slowly add tetrabutyl titanate ethanol solution in the temperature range of room temperature to 80°C, and continue to stir for 2 hours. Then add ethylene glycol to adjust the viscosity of the solution so that the concentration of Ba ions in the solution is 0.25mol / L. Stirring was continued at room temperature for 60 minutes at a stirring rate of 600 rpm. A brown-red clear and transparent solution was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com